lock VOLKSWAGEN T-ROC 2021 Owner´s Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 2021, Model line: T-ROC, Model: VOLKSWAGEN T-ROC 2021Pages: 502, PDF Size: 9.42 MB

Page 278 of 502

Never use the system where visibility is restricted or in unclear traffic situations, e.g. on extremely

busy roads or across several lanes.

Always pay attention to the area around the vehicle, since cyclists and pedestrians are often not

reliably detected, for example.

The Rear Traffic Alert will not always independently bring the vehicle to a complete stop.

Brake support systems

Information on brake support systems

The vehicle is fitted with brake support systems. The systems can support the driver in critical driving

or braking situations. Brake support systems cannot overcome the limits of physics and cannot

always keep the vehicle under control in every single critical driving or braking situation. The driver is

responsible for driving safety ⇒ .

Driving with brake support systems

The brake support systems work when the engine is running. They do not need to be operated

separately.

The brake pedal may pulsate or noises may occur while the brake support systems are regulating.

Continue to apply the necessary amount of brake pressure. Apply the necessary pressure to the

brake pedal consistently. If necessary, steer the vehicle while the brake pedal is depressed.

Electronic Stability Control (ESC)

ESC helps to reduce the risk of skidding and to improve driving stability in certain driving situations

⇒ .

ESC is always switched on.

Traction control system (TCS)

The TCS reduces the drive output if wheelspin occurs and adapts the drive output to suit road

surface conditions ⇒ Troubleshooting . The TCS makes it easier to pull away, accelerate and drive up

hills.

With some equipment levels, the TCS can be switched off in exceptional circumstances ⇒ Switching

the TCS on and off .

Anti-lock brake system (ABS)

The anti-lock brake system can prevent the wheels from locking when the brakes are applied up until

the point where the vehicle is nearly stationary and assists the driver in steering the vehicle and

keeping it under control ⇒ Troubleshooting .

Brake assist system

The brake assist system can help to reduce the stopping distance. The brake assist system reinforces

the braking force when the driver depresses the brake pedal quickly in an emergency situation.

If you reduce the pressure on the brake pedal, the brake assist system will switch off the brake

servo.

Page 279 of 502

Electronic differential lock (EDL and XDS)

EDL brakes a spinning wheel automatically and distributes the drive force to the other drive wheels.

The EDL switches off automatically under unusually heavy loads to prevent the brake from

overheating. The EDL switches back on again automatically as soon as the brake has cooled down.

XDS improves traction in order to keep the vehicle on its intended course.

Automatic Post-Collision Braking System

In the event of a collision, the Automatic Post-Collision Braking System can help the driver to reduce

the risk of skidding, and the danger of secondary collisions, through automatic braking.

The Automatic Post-Collision Braking System functions only for collisions that are detected as a

collision by the airbag control unit.

The vehicle is braked automatically if the required systems have not been damaged in the collision

and have remained functional.

The following actions override automatic braking in the event of a collision:

When the driver depresses the accelerator.

When the brake pressure transmitted through the depressed brake pedal is greater than the brake

pressure provided by the system.

WARNING

The intelligent technology used in brake support systems cannot overcome the laws of physics, and

functions only within the limits of the systems. Driving fast on icy, slippery or wet roads can lead to a

loss of control of the vehicle and could cause serious injury to the driver and passengers.

Always adapt your speed and driving style to suit visibility, weather, road and traffic conditions. Do

not let the extra safety afforded by the brake support systems ABS, BAS, EDL, TCS and ESC tempt you

into taking any risks when driving.

The brake support systems cannot overcome the laws of physics. Slippery and wet roads will remain

dangerous, even when the ESC and other systems are active.

Driving too fast on wet roads can cause the wheels to lose contact with the road surface and

aquaplane. The vehicle cannot be braked, steered or controlled once it has lost contact with the

road surface.

Brake support systems cannot prevent an accident if, for example, you are driving too close to the

vehicle in front or are driving too fast for the individual situation.

Although the brake support systems are very effective and can help to control the vehicle in difficult

driving situations, please always remember that the driving stability of the vehicle depends on the

tyre grip.

Page 281 of 502

Do not drive on! Brake system fault.

Warning lamp lights up red.

Seek expert assistance immediately.

ABS failure or fault.

Warning lamp lights up yellow.

Go to a qualified workshop. The vehicle can be braked without the anti-lock brake system.

TCS regulating to prevent the wheels from spinning.

Indicator lamp flashes yellow.

ESC switched off for system-related reasons.

Indicator lamp lights up yellow.

Switch the ignition on and off.

Drive a short distance at a speed of 15 – 20 km/h (9 – 12 mph) if necessary.

If is still lit up, seek expert assistance.

The brake support systems make noises

Noises may be heard when the brake support systems are performing control interventions.

Unexpected reduction in engine power

Faults can occur in the ESC and TCS systems if the four wheels have different types of tyres.

Any differences in the rolling radius of the tyres can cause the system to reduce engine power

unexpectedly.

WARNING

If the brake system warning lamp lights up together with the ABS indicator lamp , the ABS

control function may have failed. This can cause the rear wheels to lock quickly when you brake.

Locked rear wheels can lead to a loss of control of the vehicle. If possible, reduce your speed and

drive carefully at low speed to the nearest qualified workshop in order to have the brake system

tested. Avoid sudden braking and driving manoeuvres on the way.

If the ABS indicator lamp does not go out or comes on while the vehicle is in motion, ABS is not

working properly. The vehicle can be stopped using the normal brakes only (without the anti-lock

brake system). The protection provided by the anti-lock brake system is no longer available. Go to a

qualified workshop as soon as possible.

Practical equipment

Stowage areas

Page 284 of 502

If necessary, unlock the stowage compartment. The stowage compartment is locked when the key

slot is vertical.

To open: pull the opening lever.

To close: push the stowage compartment upwards.

WARNING

If the stowage compartment on the front passenger side is left open, this can increase the risk of

serious injury in the event of an accident or during sudden braking or driving manoeuvres.

Always keep the stowage compartment closed while the vehicle is in motion.

NOTICE

In some vehicle models, the stowage compartment on the front passenger side contains apertures.

Small items could fall through the apertures and become trapped behind the trim. This could cause

unusual noises and damage to the vehicle.

Stow small objects only in the stowage areas that are intended for such items.

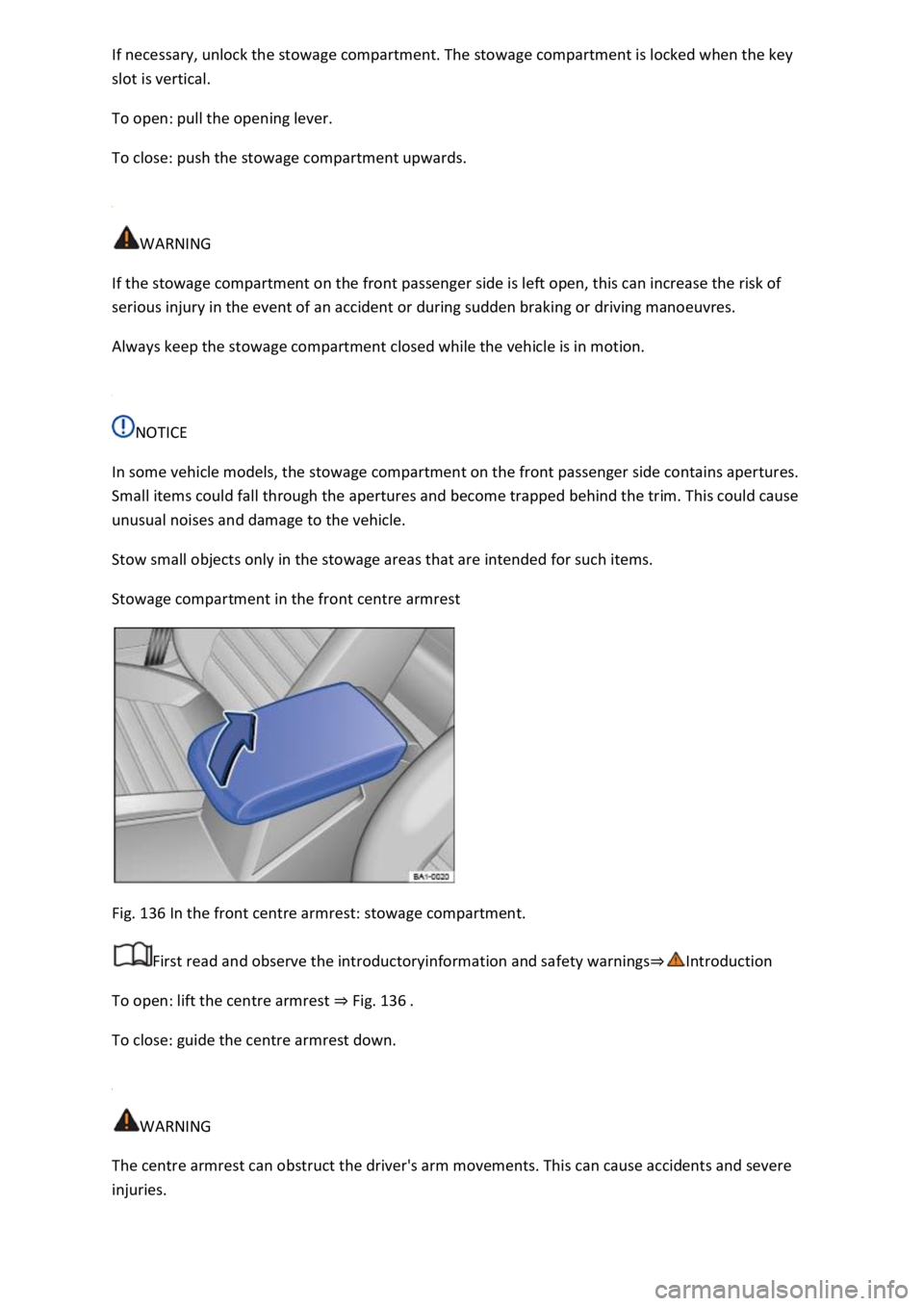

Stowage compartment in the front centre armrest

Fig. 136 In the front centre armrest: stowage compartment.

First read and observe the introductoryinformation and safety warnings⇒Introduction

To open: lift the centre armrest ⇒ Fig. 136 .

To close: guide the centre armrest down.

WARNING

The centre armrest can obstruct the driver's arm movements. This can cause accidents and severe

injuries.

Page 291 of 502

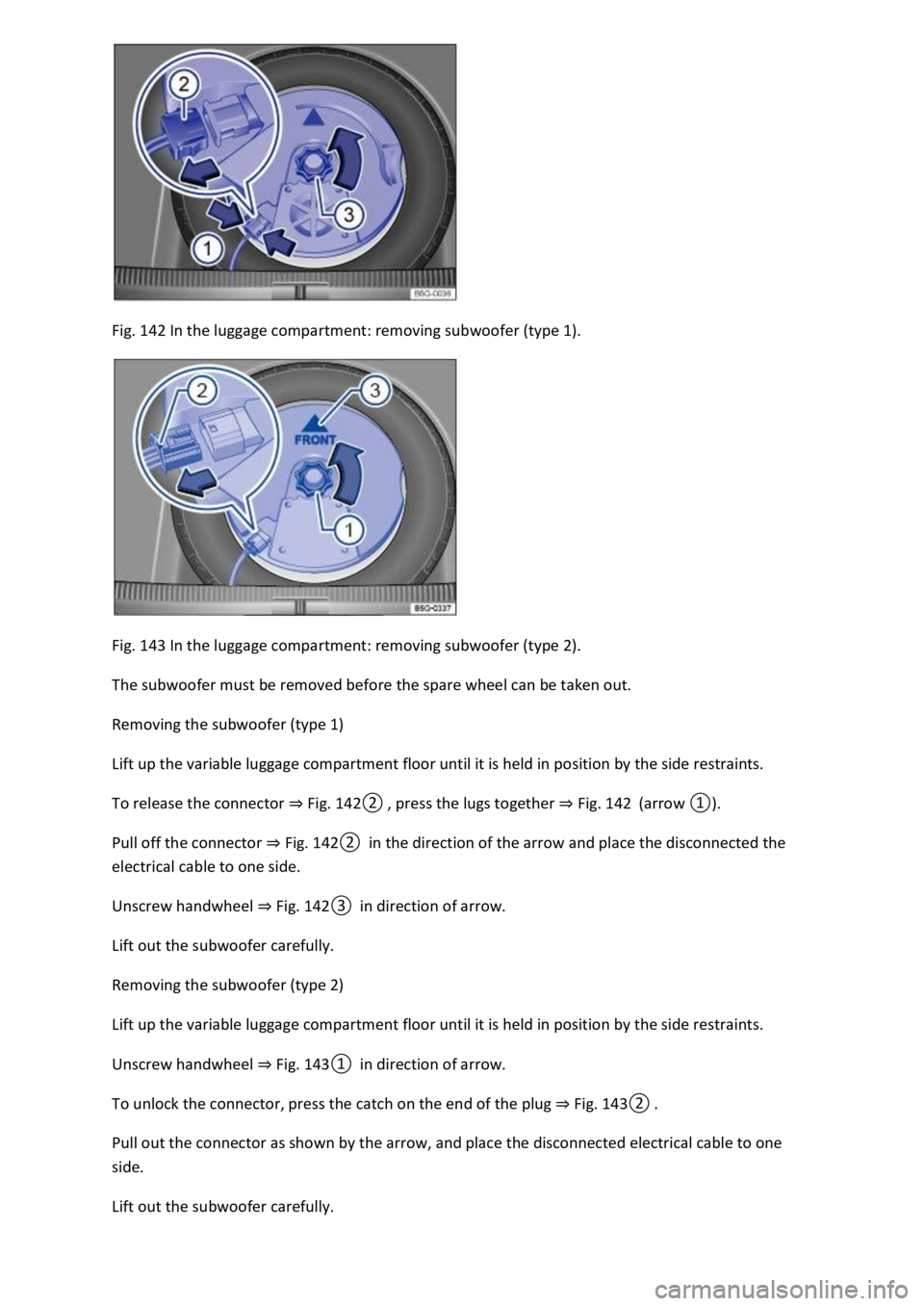

Fig. 142 In the luggage compartment: removing subwoofer (type 1).

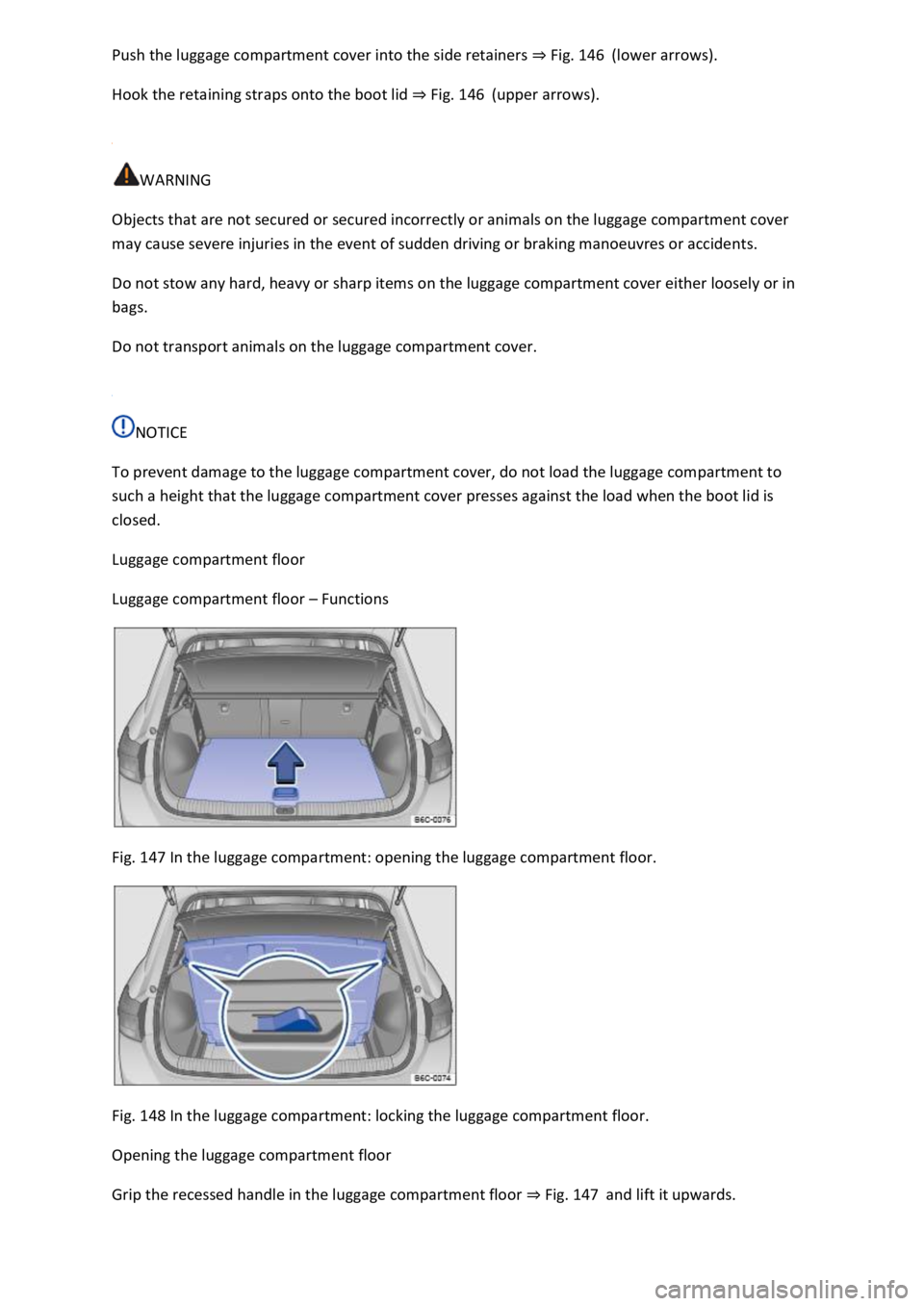

Fig. 143 In the luggage compartment: removing subwoofer (type 2).

The subwoofer must be removed before the spare wheel can be taken out.

Removing the subwoofer (type 1)

Lift up the variable luggage compartment floor until it is held in position by the side restraints.

To release the connector ⇒ Fig. 142② , press the lugs together ⇒ Fig. 142 (arrow ①).

Pull off the connector ⇒ Fig. 142② in the direction of the arrow and place the disconnected the

electrical cable to one side.

Unscrew handwheel ⇒ Fig. 142③ in direction of arrow.

Lift out the subwoofer carefully.

Removing the subwoofer (type 2)

Lift up the variable luggage compartment floor until it is held in position by the side restraints.

Unscrew handwheel ⇒ Fig. 143① in direction of arrow.

To unlock the connector, press the catch on the end of the plug ⇒ Fig. 143② .

Pull out the connector as shown by the arrow, and place the disconnected electrical cable to one

side.

Lift out the subwoofer carefully.

Page 299 of 502

Push the luggage compartment cover into the side retainers ⇒ Fig. 146 (lower arrows).

Hook the retaining straps onto the boot lid ⇒ Fig. 146 (upper arrows).

WARNING

Objects that are not secured or secured incorrectly or animals on the luggage compartment cover

may cause severe injuries in the event of sudden driving or braking manoeuvres or accidents.

Do not stow any hard, heavy or sharp items on the luggage compartment cover either loosely or in

bags.

Do not transport animals on the luggage compartment cover.

NOTICE

To prevent damage to the luggage compartment cover, do not load the luggage compartment to

such a height that the luggage compartment cover presses against the load when the boot lid is

closed.

Luggage compartment floor

Luggage compartment floor – Functions

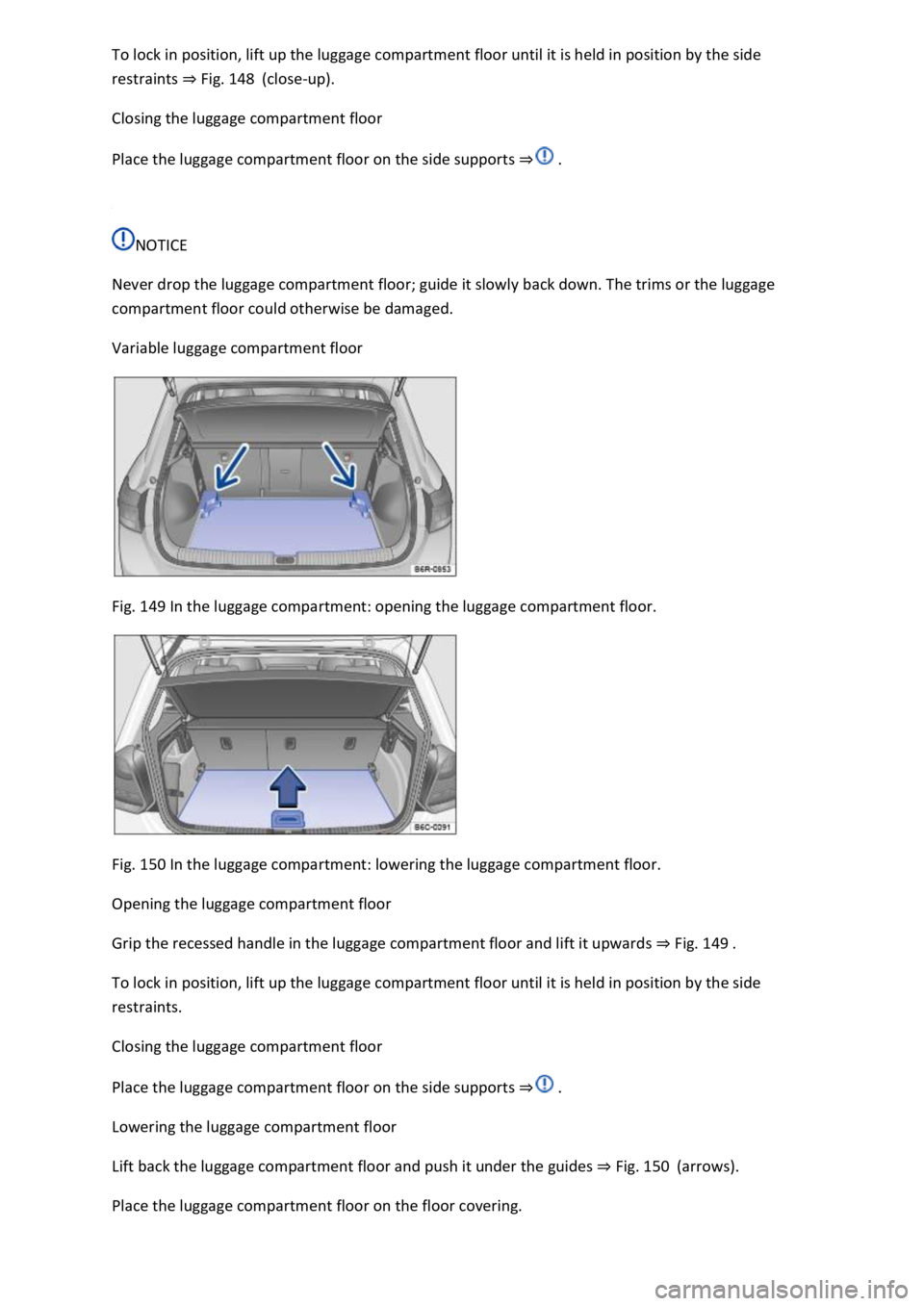

Fig. 147 In the luggage compartment: opening the luggage compartment floor.

Fig. 148 In the luggage compartment: locking the luggage compartment floor.

Opening the luggage compartment floor

Grip the recessed handle in the luggage compartment floor ⇒ Fig. 147 and lift it upwards.

Page 300 of 502

To lock in position, lift up the luggage compartment floor until it is held in position by the side

restraints ⇒ Fig. 148 (close-up).

Closing the luggage compartment floor

Place the luggage compartment floor on the side supports ⇒ .

NOTICE

Never drop the luggage compartment floor; guide it slowly back down. The trims or the luggage

compartment floor could otherwise be damaged.

Variable luggage compartment floor

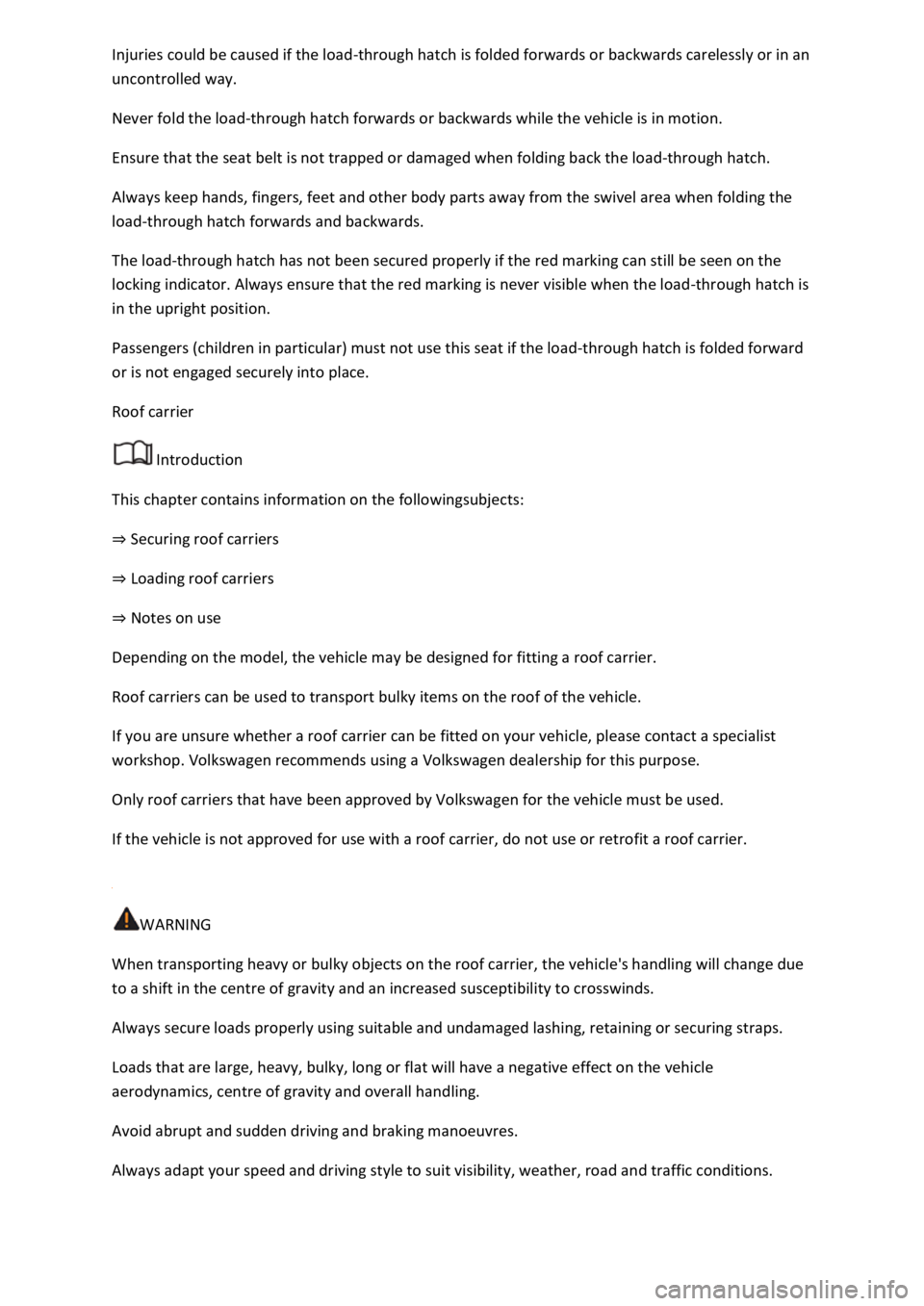

Fig. 149 In the luggage compartment: opening the luggage compartment floor.

Fig. 150 In the luggage compartment: lowering the luggage compartment floor.

Opening the luggage compartment floor

Grip the recessed handle in the luggage compartment floor and lift it upwards ⇒ Fig. 149 .

To lock in position, lift up the luggage compartment floor until it is held in position by the side

restraints.

Closing the luggage compartment floor

Place the luggage compartment floor on the side supports ⇒ .

Lowering the luggage compartment floor

Lift back the luggage compartment floor and push it under the guides ⇒ Fig. 150 (arrows).

Place the luggage compartment floor on the floor covering.

Page 304 of 502

Injuries could be caused if the load-through hatch is folded forwards or backwards carelessly or in an

uncontrolled way.

Never fold the load-through hatch forwards or backwards while the vehicle is in motion.

Ensure that the seat belt is not trapped or damaged when folding back the load-through hatch.

Always keep hands, fingers, feet and other body parts away from the swivel area when folding the

load-through hatch forwards and backwards.

The load-through hatch has not been secured properly if the red marking can still be seen on the

locking indicator. Always ensure that the red marking is never visible when the load-through hatch is

in the upright position.

Passengers (children in particular) must not use this seat if the load-through hatch is folded forward

or is not engaged securely into place.

Roof carrier

Introduction

This chapter contains information on the followingsubjects:

⇒ Securing roof carriers

⇒ Loading roof carriers

⇒ Notes on use

Depending on the model, the vehicle may be designed for fitting a roof carrier.

Roof carriers can be used to transport bulky items on the roof of the vehicle.

If you are unsure whether a roof carrier can be fitted on your vehicle, please contact a specialist

workshop. Volkswagen recommends using a Volkswagen dealership for this purpose.

Only roof carriers that have been approved by Volkswagen for the vehicle must be used.

If the vehicle is not approved for use with a roof carrier, do not use or retrofit a roof carrier.

WARNING

When transporting heavy or bulky objects on the roof carrier, the vehicle's handling will change due

to a shift in the centre of gravity and an increased susceptibility to crosswinds.

Always secure loads properly using suitable and undamaged lashing, retaining or securing straps.

Loads that are large, heavy, bulky, long or flat will have a negative effect on the vehicle

aerodynamics, centre of gravity and overall handling.

Avoid abrupt and sudden driving and braking manoeuvres.

Always adapt your speed and driving style to suit visibility, weather, road and traffic conditions.

Page 311 of 502

The vehicle electronics system may be damaged if the trailer's power consumption is too high.

Never connect the trailer's electrical system directly to the electrical connections of the tail light

clusters or to other power sources. Use only suitable connectors to supply power to the trailer.

Towing a trailer places additional demands on the vehicle. Volkswagen recommends additional

services between the normal inspection intervals if the vehicle is used frequently for towing a trailer.

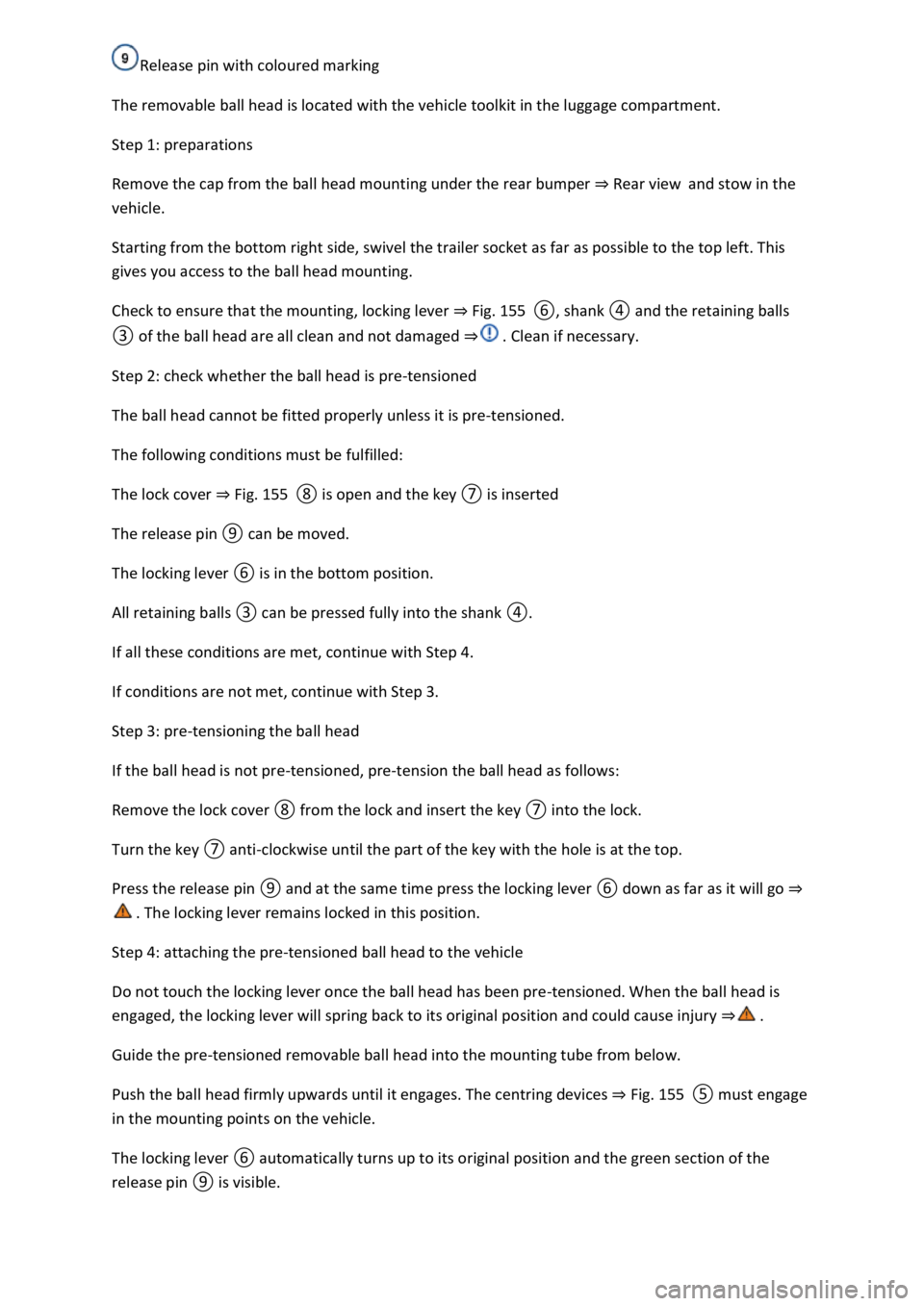

Fitting the removable ball head

Fig. 155 Overview: removable ball head.

First read and observe the introductoryinformation and safety warnings⇒Introduction

Key to⇒ Fig. 155

Protective cap 1)

Ball head

Retaining balls

Shank

Centring device

Release lever

Keys

Lock cap

Page 312 of 502

Release pin with coloured marking

The removable ball head is located with the vehicle toolkit in the luggage compartment.

Step 1: preparations

Remove the cap from the ball head mounting under the rear bumper ⇒ Rear view and stow in the

vehicle.

Starting from the bottom right side, swivel the trailer socket as far as possible to the top left. This

gives you access to the ball head mounting.

Check to ensure that the mounting, locking lever ⇒ Fig. 155 ⑥, shank ④ and the retaining balls

③ of the ball head are all clean and not damaged ⇒ . Clean if necessary.

Step 2: check whether the ball head is pre-tensioned

The ball head cannot be fitted properly unless it is pre-tensioned.

The following conditions must be fulfilled:

The lock cover ⇒ Fig. 155 ⑧ is open and the key ⑦ is inserted

The release pin ⑨ can be moved.

The locking lever ⑥ is in the bottom position.

All retaining balls ③ can be pressed fully into the shank ④.

If all these conditions are met, continue with Step 4.

If conditions are not met, continue with Step 3.

Step 3: pre-tensioning the ball head

If the ball head is not pre-tensioned, pre-tension the ball head as follows:

Remove the lock cover ⑧ from the lock and insert the key ⑦ into the lock.

Turn the key ⑦ anti-clockwise until the part of the key with the hole is at the top.

Press the release pin ⑨ and at the same time press the locking lever ⑥ down as far as it will go ⇒

. The locking lever remains locked in this position.

Step 4: attaching the pre-tensioned ball head to the vehicle

Do not touch the locking lever once the ball head has been pre-tensioned. When the ball head is

engaged, the locking lever will spring back to its original position and could cause injury ⇒ .

Guide the pre-tensioned removable ball head into the mounting tube from below.

Push the ball head firmly upwards until it engages. The centring devices ⇒ Fig. 155 ⑤ must engage

in the mounting points on the vehicle.

The locking lever ⑥ automatically turns up to its original position and the green section of the

release pin ⑨ is visible.