lock VOLKSWAGEN T-ROC 2021 Owner´s Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 2021, Model line: T-ROC, Model: VOLKSWAGEN T-ROC 2021Pages: 502, PDF Size: 9.42 MB

Page 313 of 502

Turn the key ⑦ clockwise until the part of the lock with the holes is at the top.

Fit the lock cap ⑧ on the lock and place the key ⑦ in the vehicle toolkit.

Step 5: safety check

Before hitching a trailer, check if the ball head is fixed correctly.

The locking lever ⇒ Fig. 155 ⑥ is in the uppermost position.

The green section of the release pin ⑨ is visible.

Shake the ball head ② or pull it down with some force. It must sit firmly in the mounting ⇒ .

The lock must be locked and the key ⑦ removed.

The lock cover ⑧ must cover the lock in the locking lever.

WARNING

Improper use of the towing bracket can cause injuries and accidents.

t diameter of the ball ⇒ Fig. 155 ③ is less than 49 mm, do not use the towing

bracket.

injuries.

been pre-tensioned. When the ball head is

pressed into the mounting, the locking lever will spring back to its original position.

workshop.

wing bracket if the ball head does not engage properly or if you are unable to

pre-tension it.

ball head has been mounted. This means that ball head is not locked properly.

NOTICE

and undamaged. Otherwise you may not be able to lock the ball head securely.

-pressure hose or steam cleaner directly at the ball head mounting. This could

wash the grease required for lubrication out of the mounting.

1) Not always included in the scope of delivery.

Page 314 of 502

Removing the ball head

First read and observe the introductoryinformation and safety warnings⇒Introduction

⇒ Electronic parking brake .

ailer and disconnect the electrical connection between the vehicle and the trailer.

If fitted, remove adapters from the trailer socket.

⇒ Fig. 155 ⑧ from the lock in the locking lever and insert the key ⑦ into

the lock.

e key ⑦ anti-clockwise until the part of the key with the hole is at the top.

② with your hand.

⑨ and at the same time press the locking lever ⑥ down as far as it will go

⇒ . The ball head is pre-tensioned.

⑥ and stow the pre-tensioned ball head safely with the vehicle toolkit.

② with your hand.

damage to the mounting.

WARNING

The removable ball head is heavy. The ball head could fall while it is being removed. This could cause

injuries.

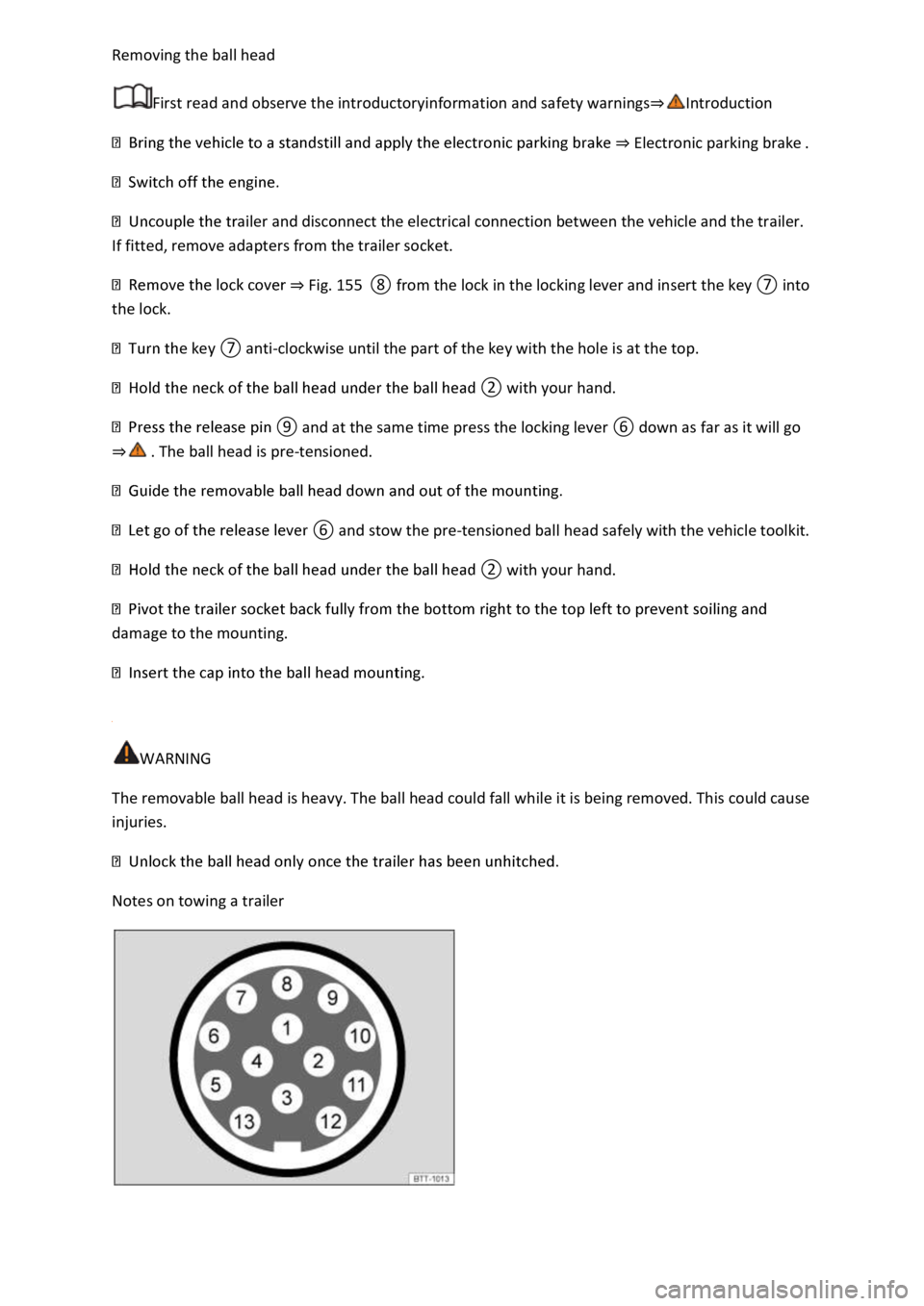

Notes on towing a trailer

Page 316 of 502

If you are uncertain whether the trailer has been properly electrically connected to the towing

vehicle, please contact a qualified workshop. Volkswagen recommends using a Volkswagen

dealership for this purpose.

Connection to the anti-theft alarm

The trailer is integrated in the anti-theft system if the following conditions are fulfilled:

-fitted anti-theft alarm and a factory-fitted towing bracket.

ult-free and undamaged.

-theft alarm is active.

When the vehicle is locked, the alarm will be triggered as soon as the electrical connection to the

trailer is interrupted.

Connection to the anti-theft alarm (trailer with LED tail light clusters)

For technical reasons, trailers with LED tail light clusters cannot be integrated into the anti-theft

alarm system.

When the vehicle is locked, the alarm is not triggered as soon as the electrical connection to the

trailer with LED tail light clusters is interrupted.

WARNING

Any electrical cables which are not connected properly or are connected incorrectly could cause the

trailer to become live. This could lead to malfunctions in the entire vehicle electronics system and

could also cause accidents and serious injuries.

wing

vehicle's tail light clusters or to other power sources.

WARNING

Contact between the pins in the trailer socket can lead to short circuits, overloading of the electrical

system and failure of the lighting system, thereby causing accidents and serious injuries.

NOTICE

Page 318 of 502

possible.

Tyre pressure

Follow the trailer manufacturer's recommendations concerning the tyre pressure for the trailer

tyres.

When towing a trailer, inflate the wheels on the towing vehicle with the maximum permitted tyre

pressure ⇒ Tyre pressure .

WARNING

Accidents and serious injuries can occur if you exceed the vehicle's maximum permitted gross axle

weight rating, drawbar load, gross vehicle weight rating or gross combination weight rating.

exceed the permissible gross vehicle weight for the vehicle with weight at the front and rear of the

vehicle.

WARNING

Loads that may slide can severely impair stability and driving safety, which can cause accidents and

severe injuries.

secure loads using suitable and undamaged lashing, retaining or securing straps.

Driving with a trailer

First read and observe the introductoryinformation and safety warnings⇒Introduction

Headlight adjustment

Towing a trailer can raise the front end of the vehicle enough for the dipped beam to dazzle other

road users. Use the headlight range control to lower the light cone as required. Vehicles with

dynamic headlight range control are adjusted automatically.

Things to note when driving with a trailer

If the trailer has an overrun brake, apply the brakes gently at first and then firmly. This will

prevent the jerking that can be caused by the trailer wheels locking.

Page 342 of 502

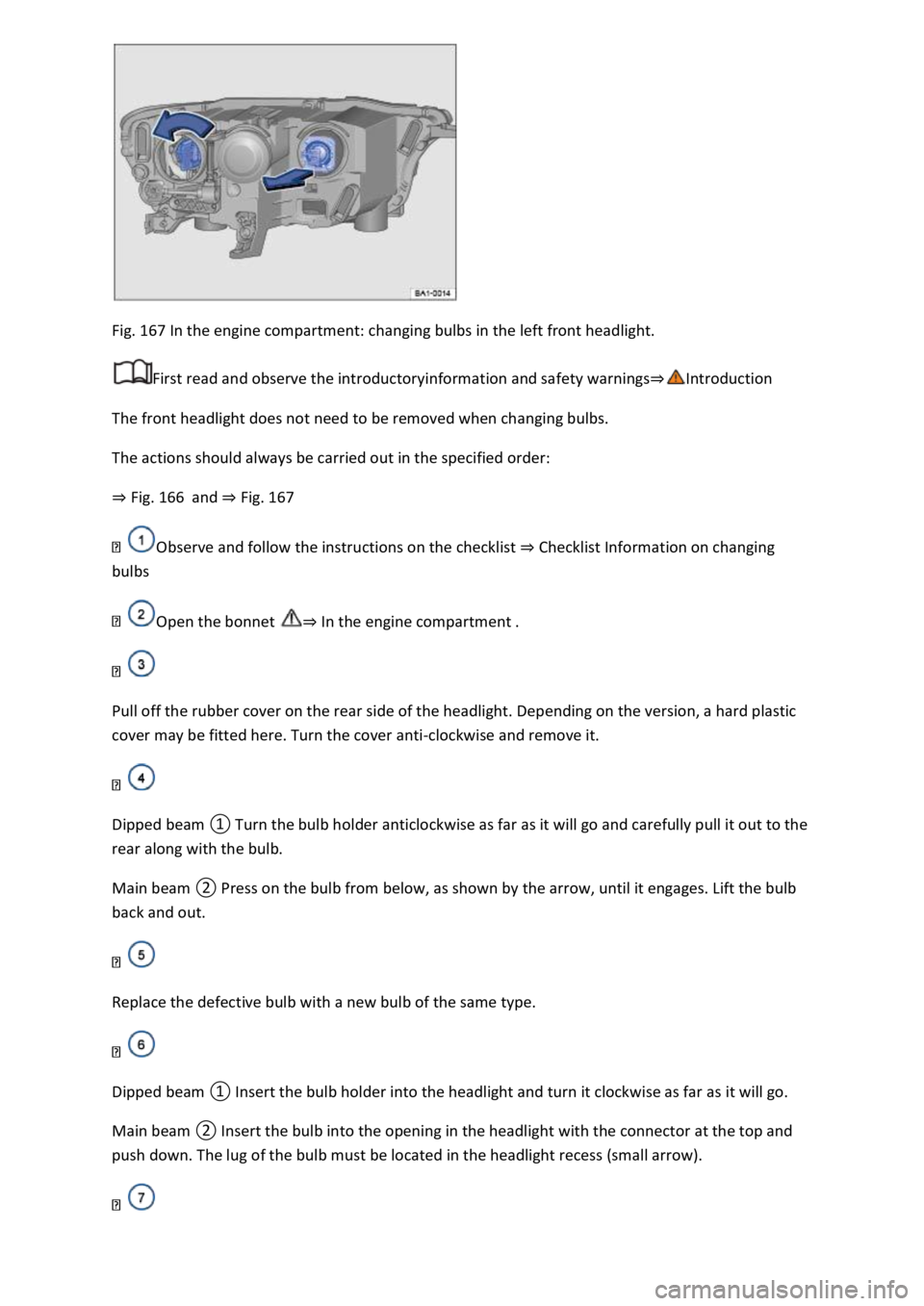

Fig. 167 In the engine compartment: changing bulbs in the left front headlight.

First read and observe the introductoryinformation and safety warnings⇒Introduction

The front headlight does not need to be removed when changing bulbs.

The actions should always be carried out in the specified order:

⇒ Fig. 166 and ⇒ Fig. 167

Observe and follow the instructions on the checklist ⇒ Checklist Information on changing

bulbs

Open the bonnet ⇒ In the engine compartment .

Pull off the rubber cover on the rear side of the headlight. Depending on the version, a hard plastic

cover may be fitted here. Turn the cover anti-clockwise and remove it.

Dipped beam ① Turn the bulb holder anticlockwise as far as it will go and carefully pull it out to the

rear along with the bulb.

Main beam ② Press on the bulb from below, as shown by the arrow, until it engages. Lift the bulb

back and out.

Replace the defective bulb with a new bulb of the same type.

Dipped beam ① Insert the bulb holder into the headlight and turn it clockwise as far as it will go.

Main beam ② Insert the bulb into the opening in the headlight with the connector at the top and

push down. The lug of the bulb must be located in the headlight recess (small arrow).

Page 343 of 502

Attach the rubber cover or hard plastic cover and turn it clockwise as far as it will go.

Close the bonnet ⇒ In the engine compartment .

Changing the bulbs in the headlights (lights with LED technology)

First read and observe the introductoryinformation and safety warnings⇒Introduction

These lamps use LED technology. The LEDs cannot be replaced by customers. If some LEDs fail, this

may be an indication that more elements are on the point of failure. In this case, have the lights

checked and renewed if necessary at a qualified workshop.

Changing the front turn signal bulbs

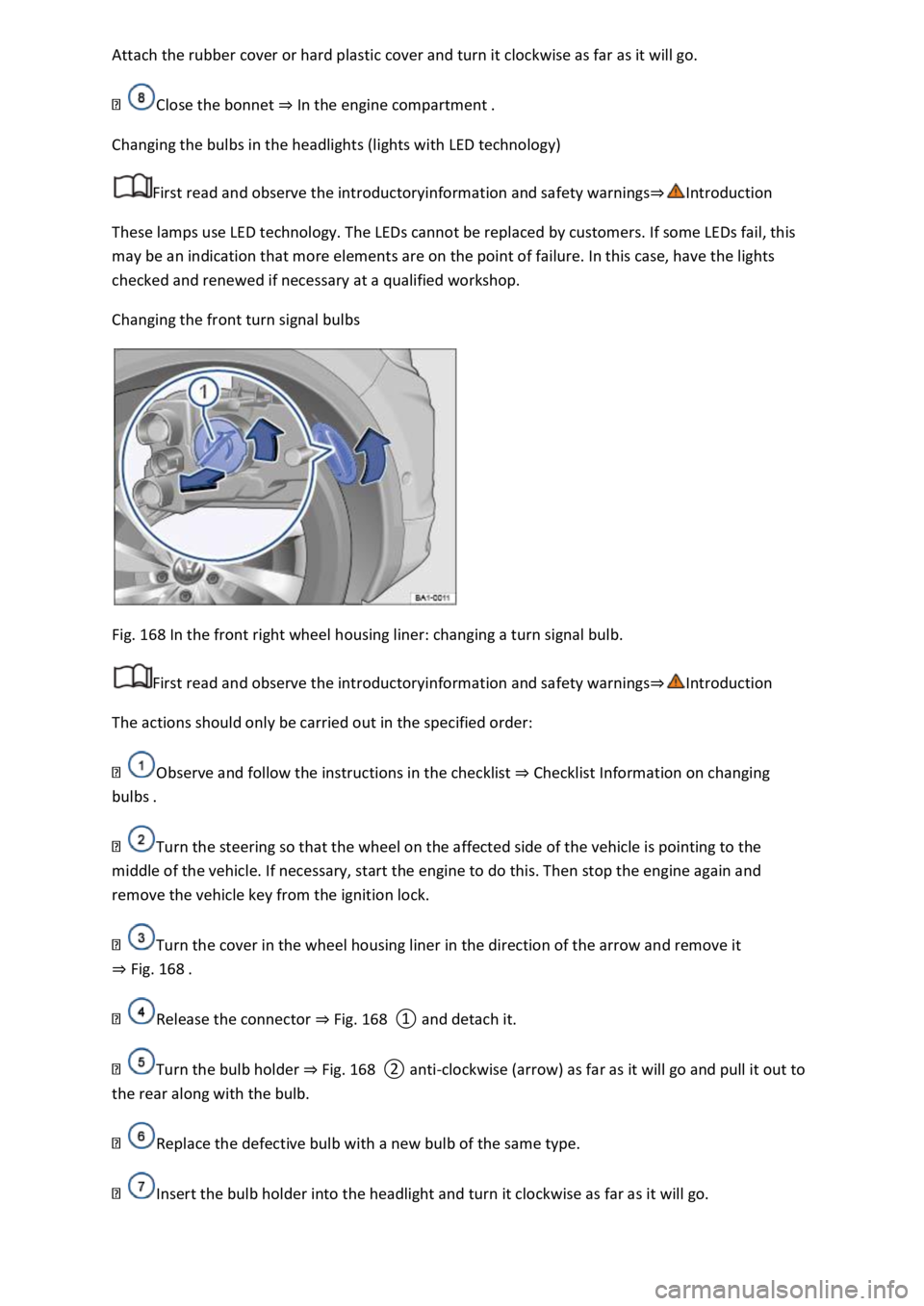

Fig. 168 In the front right wheel housing liner: changing a turn signal bulb.

First read and observe the introductoryinformation and safety warnings⇒Introduction

The actions should only be carried out in the specified order:

Observe and follow the instructions in the checklist ⇒ Checklist Information on changing

bulbs .

Turn the steering so that the wheel on the affected side of the vehicle is pointing to the

middle of the vehicle. If necessary, start the engine to do this. Then stop the engine again and

remove the vehicle key from the ignition lock.

Turn the cover in the wheel housing liner in the direction of the arrow and remove it

⇒ Fig. 168 .

Release the connector ⇒ Fig. 168 ① and detach it.

Turn the bulb holder ⇒ Fig. 168 ② anti-clockwise (arrow) as far as it will go and pull it out to

the rear along with the bulb.

Replace the defective bulb with a new bulb of the same type.

Insert the bulb holder into the headlight and turn it clockwise as far as it will go.

Page 344 of 502

Fit the connector ⇒ Fig. 168 ① on the bulb holder ⇒ Fig. 168 ②. The connector should

click into place.

Fit the cover in the wheel housing liner ⇒ Fig. 168 and lock it in position.

NOTICE

the headlight housing is seated properly in order to

prevent damage to the electrical system caused by water entering the system.

damaged.

Changing bulbs in the front bumper

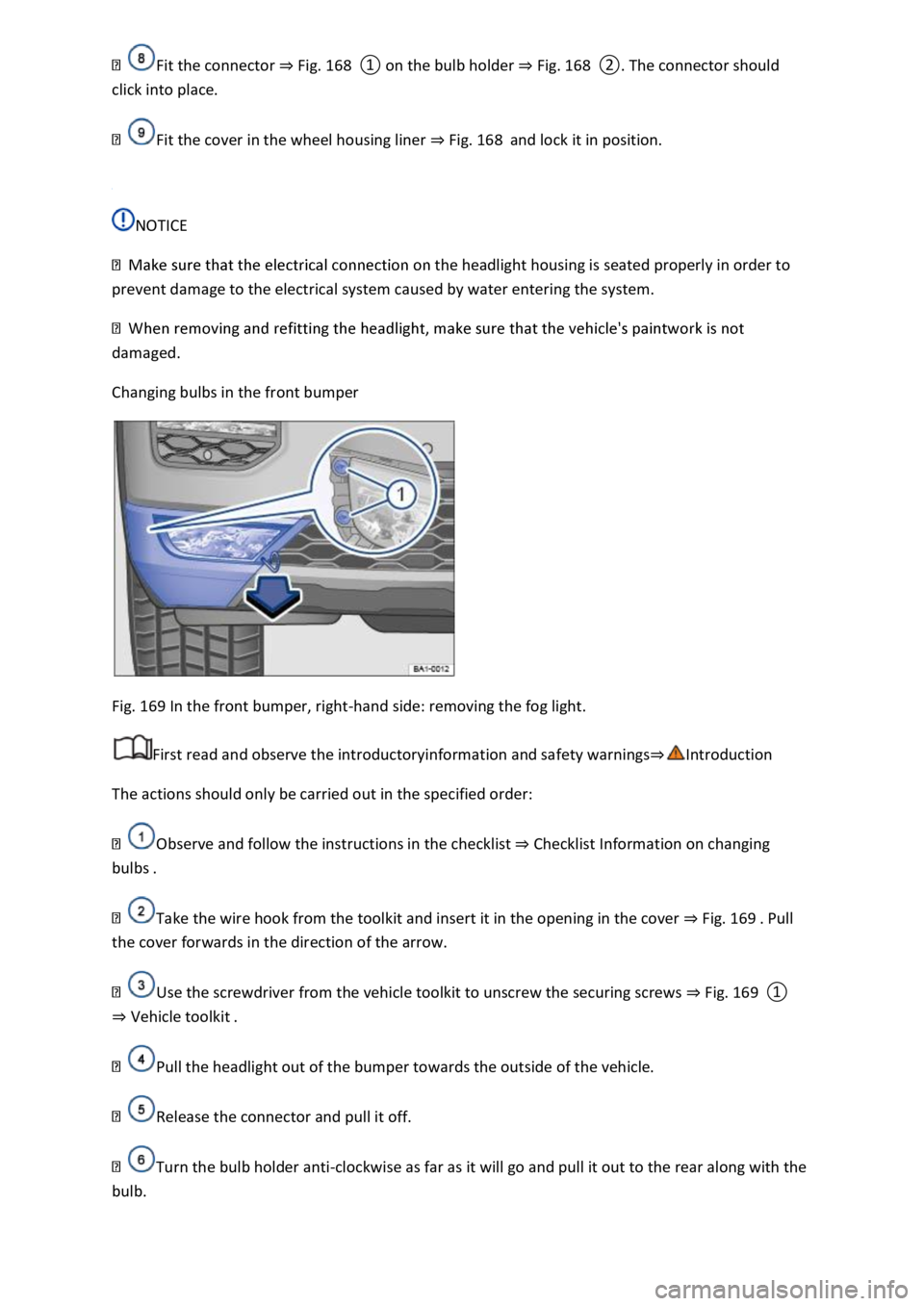

Fig. 169 In the front bumper, right-hand side: removing the fog light.

First read and observe the introductoryinformation and safety warnings⇒Introduction

The actions should only be carried out in the specified order:

Observe and follow the instructions in the checklist ⇒ Checklist Information on changing

bulbs .

Take the wire hook from the toolkit and insert it in the opening in the cover ⇒ Fig. 169 . Pull

the cover forwards in the direction of the arrow.

Use the screwdriver from the vehicle toolkit to unscrew the securing screws ⇒ Fig. 169 ①

⇒ Vehicle toolkit .

Pull the headlight out of the bumper towards the outside of the vehicle.

Release the connector and pull it off.

Turn the bulb holder anti-clockwise as far as it will go and pull it out to the rear along with the

bulb.

Page 345 of 502

Replace the defective bulb with a new bulb of the same type.

Insert the bulb holder into the headlight and turn it clockwise as far as it will go.

Connect the connector to the bulb holder. The connector must audibly click into place.

Push the headlight from the outside into the openings and insert into the bumper.

Use the screwdriver to tighten the securing screws ⇒ Fig. 169 ①.

Fit the cover in the bumper ⇒ Fig. 169 .

Stow the wire hook and screwdriver in the vehicle toolkit.

Changing bulbs in the tail light clusters (LED lights)

First read and observe the introductoryinformation and safety warnings⇒Introduction

These lamps use LED technology. The LEDs cannot be replaced by customers. If some LEDs fail, this

may be an indication that more elements are on the point of failure. In this case, have the lights

checked and renewed if necessary at a qualified workshop. Volkswagen recommends using a

Volkswagen dealership for this purpose.

Changing bulbs in the number plate light (LED lights)

First read and observe the introductoryinformation and safety warnings⇒Introduction

These lamps use LED technology. The LEDs cannot be replaced by customers. If some LEDs fail, this

may be an indication that more elements are on the point of failure. In this case, have the lights

checked and renewed if necessary at a qualified workshop.

Troubleshooting

First read and observe the introductoryinformation and safety warnings⇒Introduction

Fault in vehicle lighting

The indicator lamp lights up yellow.

Fault in vehicle lighting or fault in cornering lights.

Check the vehicle lighting and change the appropriate bulb as required ⇒ Changing bulbs . If all

bulbs are OK or there is a fault in the dynamic cornering light, go to a qualified workshop.

Changing fuses

Introduction

This chapter contains information on the followingsubjects:

⇒ Fuses in the dash panel

Page 349 of 502

boxes can damage the electrical system.

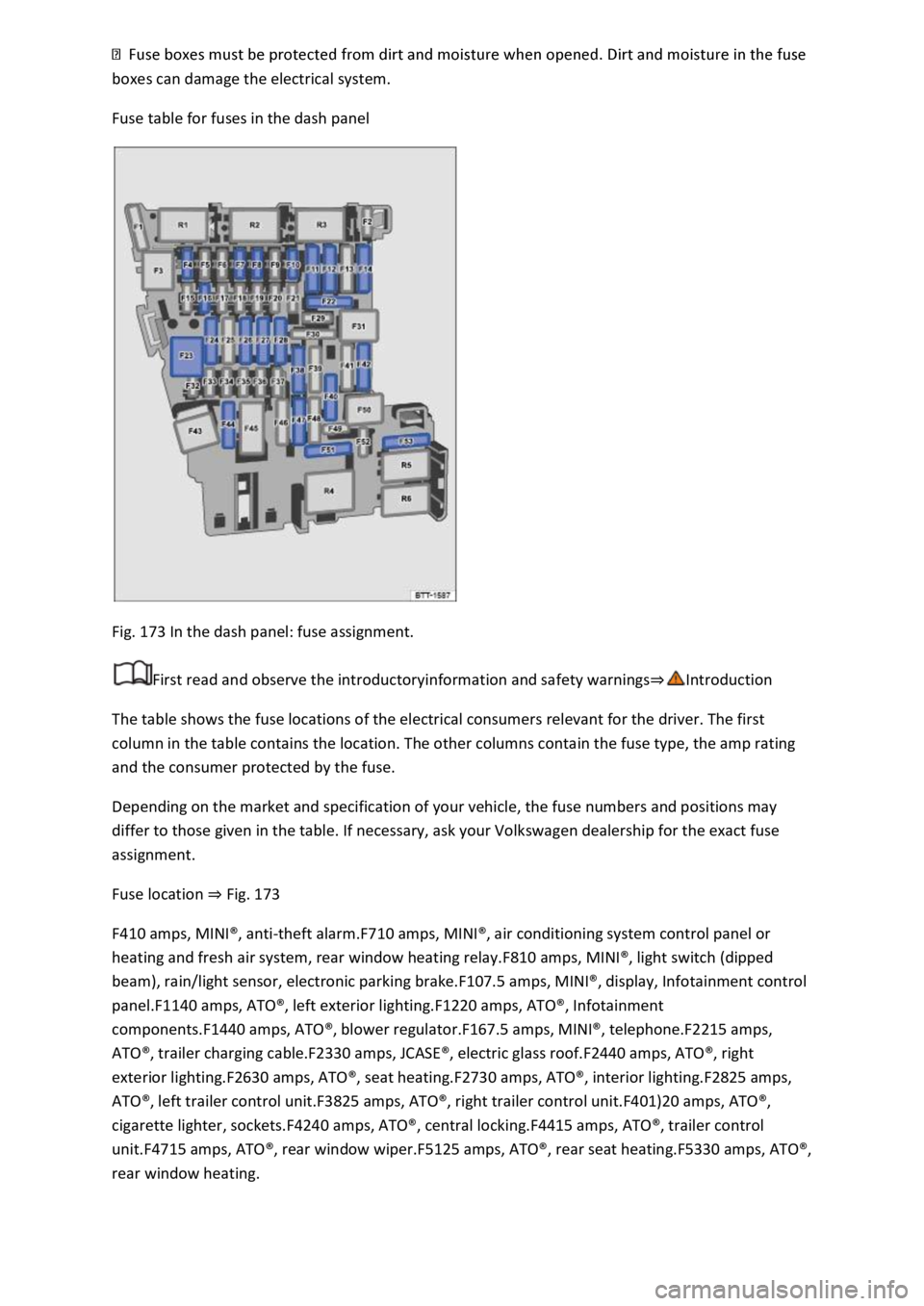

Fuse table for fuses in the dash panel

Fig. 173 In the dash panel: fuse assignment.

First read and observe the introductoryinformation and safety warnings⇒Introduction

The table shows the fuse locations of the electrical consumers relevant for the driver. The first

column in the table contains the location. The other columns contain the fuse type, the amp rating

and the consumer protected by the fuse.

Depending on the market and specification of your vehicle, the fuse numbers and positions may

differ to those given in the table. If necessary, ask your Volkswagen dealership for the exact fuse

assignment.

Fuse location ⇒ Fig. 173

F410 amps, MINI®, anti-theft alarm.F710 amps, MINI®, air conditioning system control panel or

heating and fresh air system, rear window heating relay.F810 amps, MINI®, light switch (dipped

beam), rain/light sensor, electronic parking brake.F107.5 amps, MINI®, display, Infotainment control

panel.F1140 amps, ATO®, left exterior lighting.F1220 amps, ATO®, Infotainment

components.F1440 amps, ATO®, blower regulator.F167.5 amps, MINI®, telephone.F2215 amps,

ATO®, trailer charging cable.F2330 amps, JCASE®, electric glass roof.F2440 amps, ATO®, right

exterior lighting.F2630 amps, ATO®, seat heating.F2730 amps, ATO®, interior lighting.F2825 amps,

ATO®, left trailer control unit.F3825 amps, ATO®, right trailer control unit.F401)20 amps, ATO®,

cigarette lighter, sockets.F4240 amps, ATO®, central locking.F4415 amps, ATO®, trailer control

unit.F4715 amps, ATO®, rear window wiper.F5125 amps, ATO®, rear seat heating.F5330 amps, ATO®,

rear window heating.

Page 354 of 502

Suitable earth connection: preferably the jump lead connection point (earth connection), a

solid metal part which is securely bolted onto the cylinder block, or the cylinder block itself.

The discharged 12-volt vehicle battery must be properly connected to the vehicle's electrical system.

The vehicles must not touch. Otherwise electricity could flow as soon as the positive terminals are

connected.

Ensure that the battery clamps have good metal-to-metal contact with the battery terminals.

If the engine does not start immediately, switch off the starter after about 10 seconds and try again

after about a minute.

If the engine still does not start, seek expert assistance.

Attaching the jump leads

The jump leads should be connected only in the order A – B – C – D⇒ Fig. 177 .

The black jump lead should never be connected to the negative terminal (–) on the 12-volt vehicle

battery. Connecting the lead to the negative terminal can cause incorrect condition evaluation of the

12-volt vehicle battery in the vehicle electronics.

⇒ Starting the engine .

-volt vehicle battery in the engine compartment, if a cover is installed

⇒ 12-volt vehicle battery .

discharged 12-volt vehicle battery ⇒ Fig. 177 ① ⇒ .

providing assistance ⇒ Fig. 177 ②.

⇒ Fig. 177 ③ preferably to a suitable jump start

connection point (earth connection) or otherwise to a solid metal part that is securely bolted onto

the cylinder block, or to the cylinder block itself of the vehicle providing assistance.

-volt battery, connect the other end of the black jump lead

⇒ Fig. 177 ③ preferably to the jump lead connection point (earth connection), or otherwise to a

solid metal part that is securely bolted onto the cylinder block, or to the cylinder block itself ⇒ .

s in such a way that they cannot come into contact with any moving parts in the

engine compartment.

Starting the engine

2-volt vehicle battery and wait two or three

minutes until the engine is running smoothly.

Removing the jump leads