bonnet VOLKSWAGEN TIGUAN 2017 Owner´s Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 2017, Model line: TIGUAN, Model: VOLKSWAGEN TIGUAN 2017Pages: 341, PDF Size: 9.14 MB

Page 252 of 341

Wiper blades

Service position

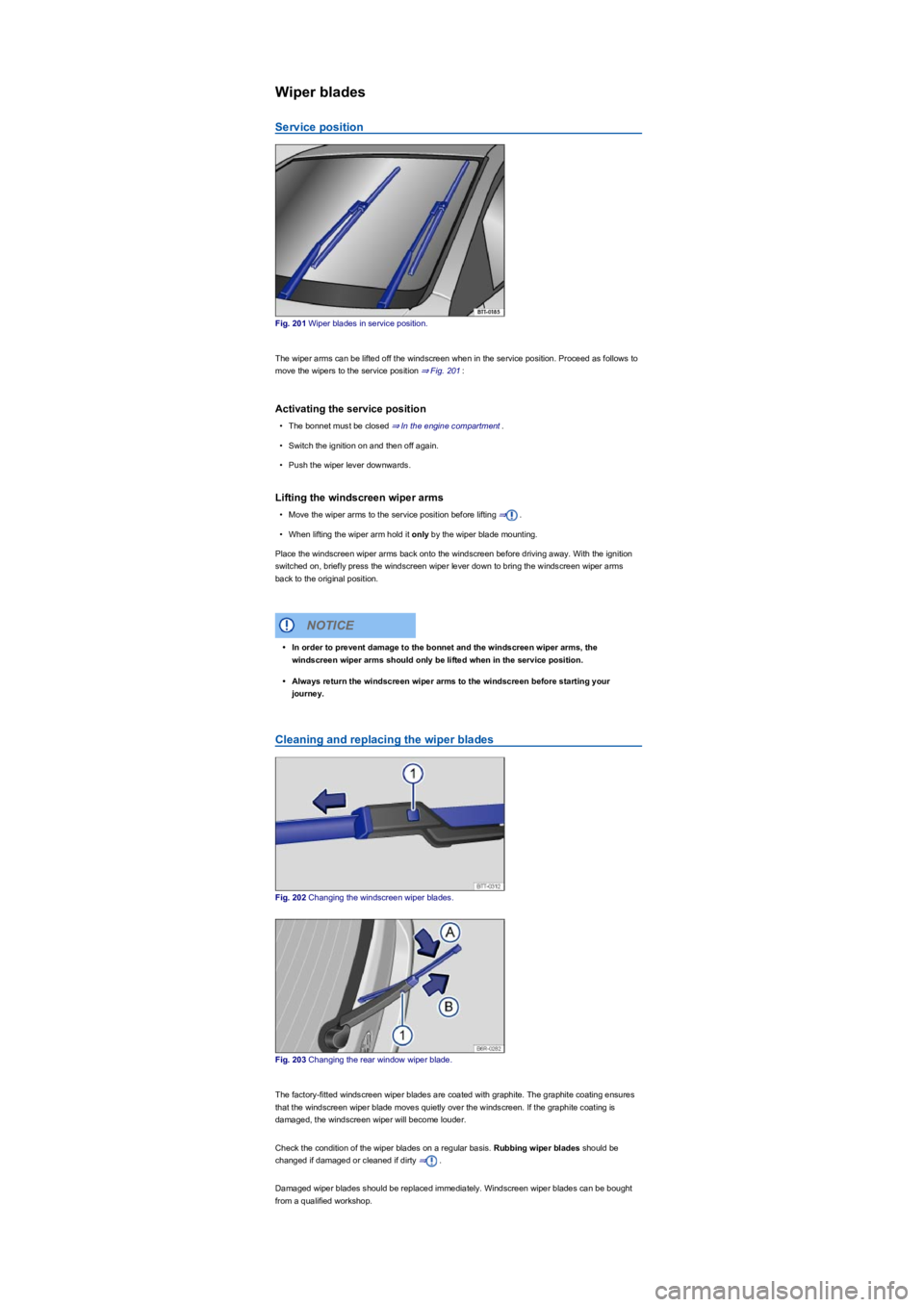

Fig. 201 Wiper blades in service position.

The wiper arms can be lifted off the windscreen when in the service position. Proceed as follows to

move the wipers to the service position ⇒ Fig. 201:

Activating the service position

•The bonnet must be closed ⇒ In the engine compartment.

•Switch the ignition on and then off again.

•Push the wiper lever downwards.

Lifting the windscreen wiper arms

•Move the wiper arms to the service position before lifting ⇒.

•When lifting the wiper arm hold it only by the wiper blade mounting.

Place the windscreen wiper arms back onto the windscreen before driving away. With the ignition

switched on, briefly press the windscreen wiper lever down to bring the windscreen wiper arms

back to the original position.

Cleaning and replacing the wiper blades

Fig. 202 Changing the windscreen wiper blades.

Fig. 203 Changing the rear window wiper blade.

The factory-fitted windscreen wiper blades are coated with graphite. The graphite coating ensures

that the windscreen wiper blade moves quietly over the windscreen. If the graphite coating is

damaged, the windscreen wiper will become louder.

Check the condition of the wiper blades on a regular basis. Rubbing wiper blades should be

changed if damaged or cleaned if dirty ⇒.

Damaged wiper blades should be replaced immediately. Windscreen wiper blades can be bought

from a qualified workshop.

•In order to prevent damage to the bonnet and the windscreen wiper arms, the

windscreen wiper arms should only be lifted when in the service position.

•Always return the windscreen wiper arms to the windscreen before starting your

journey.

NOTICE

Page 255 of 341

Check to see if a fuse has blown Changing fuses.

Follow the instructions to change the affected bulb . Always use identical bulbs with the

same designation. The designation is inscribed on the bulb, either on the glass part or on

the base.

Do not touch the glass part of the bulb with unprotected fingers. The heat of the bulb would

cause the fingerprint to evaporate and condense on the reflector. This will impair the

brightness of the headlight.

After changing the bulb, check to ensure that the bulb is working properly. If the bulb is not

working properly, the bulb may not have been inserted properly or may have failed again,

or the connector may have been inserted incorrectly.

Any time you change a bulb in the front of the vehicle, the headlight settings should be

checked by a qualified workshop.

Changing bulbs in the headlights (halogen bulbs)

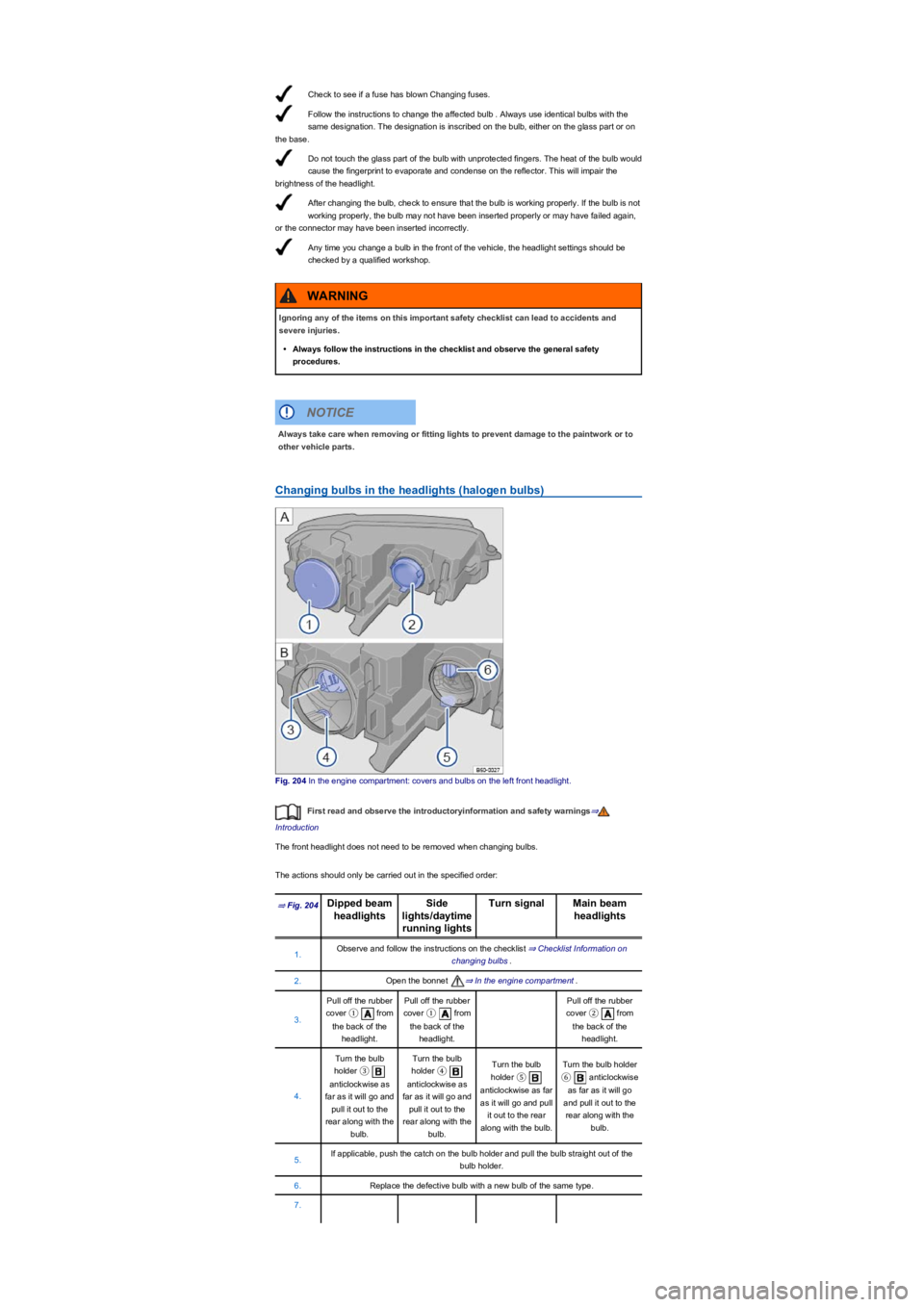

Fig. 204 In the engine compartment: covers and bulbs on the left front headlight.

First read and observe the introductoryinformation and safety warnings⇒

Introduction

The front headlight does not need to be removed when changing bulbs.

The actions should only be carried out in the specified order:

⇒ Fig. 204Dipped beam

headlights

Side

lights/daytime

running lights

Turn signalMain beam

headlights

1.Observe and follow the instructions on the checklist ⇒ Checklist Information on

changing bulbs.

2.Open the bonnet ⇒ In the engine compartment.

3.

Pull off the rubber

cover ① from

the back of the

headlight.

Pull off the rubber

cover ① from

the back of the

headlight.

Pull off the rubber

cover ② from

the back of the

headlight.

4.

Turn the bulb

holder ③

anticlockwise as

far as it will go and

pull it out to the

rear along with the

bulb.

Turn the bulb

holder ④

anticlockwise as

far as it will go and

pull it out to the

rear along with the

bulb.

Turn the bulb

holder ⑤

anticlockwise as far

as it will go and pull

it out to the rear

along with the bulb.

Turn the bulb holder

⑥ anticlockwise

as far as it will go

and pull it out to the

rear along with the

bulb.

5.If applicable, push the catch on the bulb holder and pull the bulb straight out of the

bulb holder.

6.Replace the defective bulb with a new bulb of the same type.

7.

Ignoring any of the items on this important safety checklist can lead to accidents and

severe injuries.

•Always follow the instructions in the checklist and observe the general safety

procedures.

WARNING

Always take care when removing or fitting lights to prevent damage to the paintwork or to

other vehicle parts.

NOTICE

Page 256 of 341

⇒ Fig. 204Dipped beam

headlights

Side

lights/daytime

running lights

Turn signalMain beam

headlights

Insert the bulb

holder ③ into

the headlight and

turn it clockwise as

far as it will go.

Insert the bulb

holder ④ into

the headlight and

turn it clockwise as

far as it will go.

Insert the bulb

holder ⑤ into

the headlight and

turn it clockwise as

far as it will go.

Insert the bulb holder

⑥ into the

headlight and turn it

clockwise as far as it

will go.

8.Fit the rubber

cover ①.

Fit the rubber

cover ①.

Fit the rubber cover

②.

9.Close the bonnet ⇒ In the engine compartment.

The illustrations show the left-hand headlight from the rear. The right-hand headlight is a

mirror image of the one shown.

There are various types of headlight, so the position and design of covers, bulbs and bulb

holders may vary from those shown in the illustrations.

It is not possible for customers to change the LEDs in daytime running lights with LED

technology. Go to a qualified workshop.

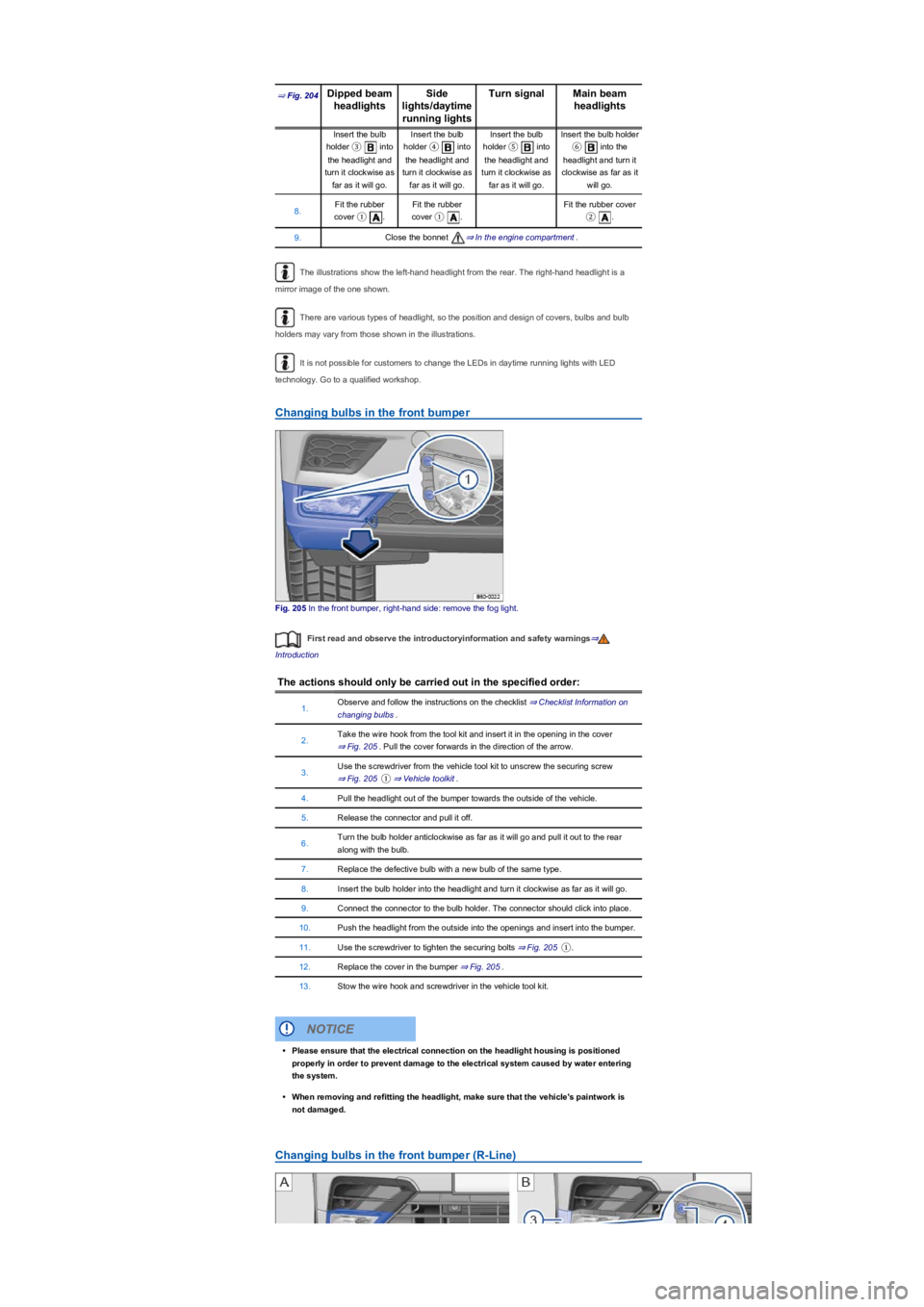

Changing bulbs in the front bumper

Fig. 205 In the front bumper, right-hand side: remove the fog light.

First read and observe the introductoryinformation and safety warnings⇒

Introduction

The actions should only be carried out in the specified order:

1.Observe and follow the instructions on the checklist ⇒ Checklist Information on

changing bulbs.

2.Take the wire hook from the tool kit and insert it in the opening in the cover

⇒ Fig. 205. Pull the cover forwards in the direction of the arrow.

3.Use the screwdriver from the vehicle tool kit to unscrew the securing screw

⇒ Fig. 205①⇒ Vehicle toolkit.

4.Pull the headlight out of the bumper towards the outside of the vehicle.

5.Release the connector and pull it off.

6.Turn the bulb holder anticlockwise as far as it will go and pull it out to the rear

along with the bulb.

7.Replace the defective bulb with a new bulb of the same type.

8.Insert the bulb holder into the headlight and turn it clockwise as far as it will go.

9.Connect the connector to the bulb holder. The connector should click into place.

10.Push the headlight from the outside into the openings and insert into the bumper.

11.Use the screwdriver to tighten the securing bolts ⇒ Fig. 205①.

12.Replace the cover in the bumper ⇒ Fig. 205.

13.Stow the wire hook and screwdriver in the vehicle tool kit.

Changing bulbs in the front bumper (R-Line)

•Please ensure that the electrical connection on the headlight housing is positioned

properly in order to prevent damage to the electrical system caused by water entering

the system.

•When removing and refitting the headlight, make sure that the vehicle's paintwork is

not damaged.

NOTICE

Page 260 of 341

•Push the retaining lugs ⇒ Fig. 208① upwards in the direction of the arrow whilst opening the

stowage compartment until the fuse carrier can be accessed.

•To install, press the stowage compartment into the mounts on the dash panel until it audibly

clicks into place on both sides and then close the compartment.

Right-hand drive: opening the fuse box in the dash panel

•Open the stowage compartment on the front passenger side and remove the contents if

necessary ⇒ Fig. 209.

•Slide the braking element ⇒ Fig. 209① downwards into the opening in the holder and pull it

out sideways.

•Push catches ⇒ Fig. 209② upwards in the direction of the arrow whilst opening the stowage

compartment further.

•To install: bring storage compartment into position. Insert the brake element in the holder

opening and push upwards until it audibly engages. Carefully push the stowage compartment

forwards beyond the resistance of the catches ⇒ Fig. 209②.

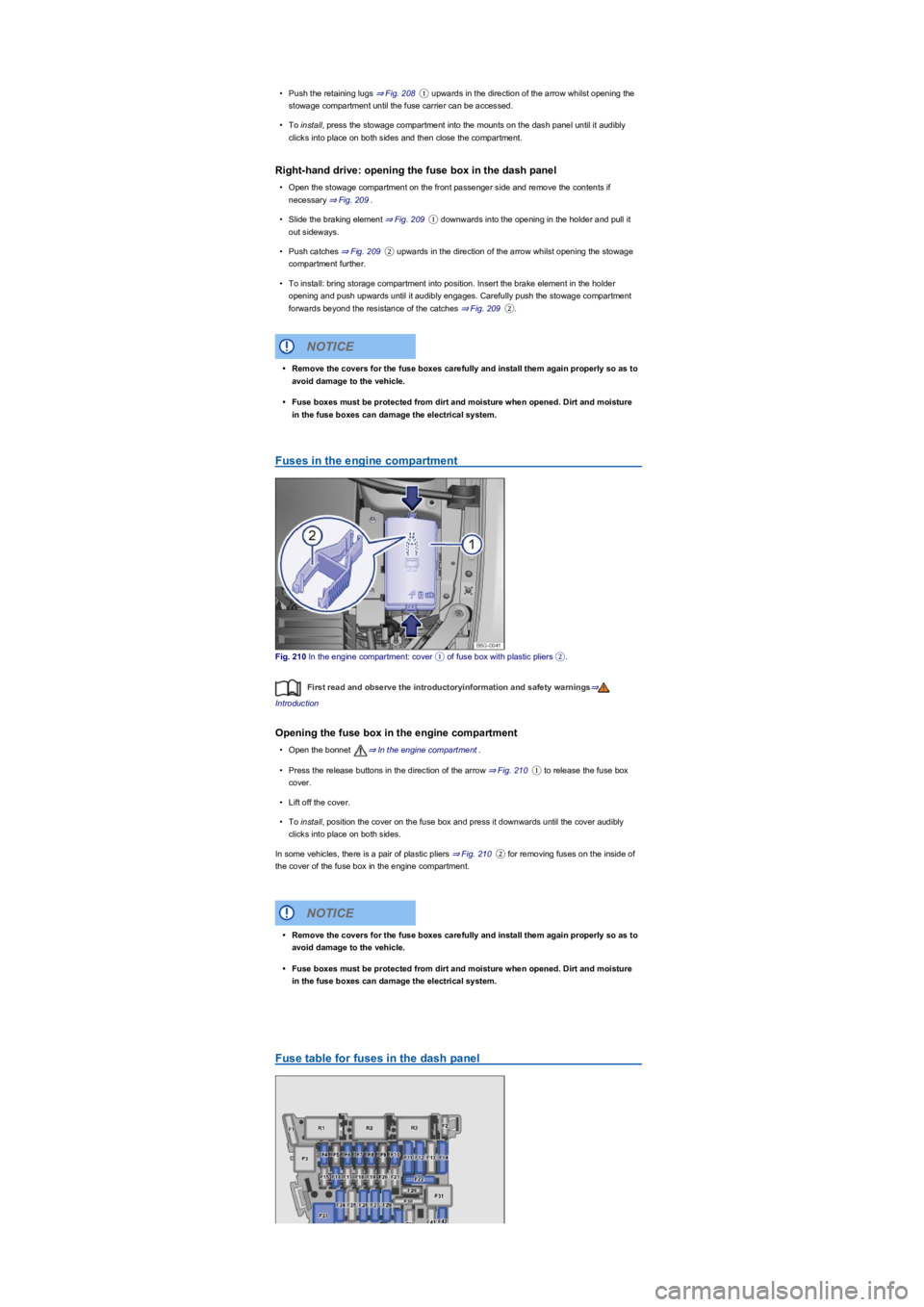

Fuses in the engine compartment

Fig. 210 In the engine compartment: cover ① of fuse box with plastic pliers ②.

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Opening the fuse box in the engine compartment

•Open the bonnet ⇒ In the engine compartment.

•Press the release buttons in the direction of the arrow ⇒ Fig. 210① to release the fuse box

cover.

•Lift off the cover.

•To install, position the cover on the fuse box and press it downwards until the cover audibly

clicks into place on both sides.

In some vehicles, there is a pair of plastic pliers ⇒ Fig. 210② for removing fuses on the inside of

the cover of the fuse box in the engine compartment.

Fuse table for fuses in the dash panel

•Remove the covers for the fuse boxes carefully and install them again properly so as to

avoid damage to the vehicle.

•Fuse boxes must be protected from dirt and moisture when opened. Dirt and moisture

in the fuse boxes can damage the electrical system.

NOTICE

•Remove the covers for the fuse boxes carefully and install them again properly so as to

avoid damage to the vehicle.

•Fuse boxes must be protected from dirt and moisture when opened. Dirt and moisture

in the fuse boxes can damage the electrical system.

NOTICE

Page 272 of 341

Safety notes for working in the engine compartment

Always park the vehicle on a level and stable surface before carrying out any work in the engine

compartment.

The engine compartment of a motor vehicle is a hazardous area. You should only carry out work on

the engine, and in the engine compartment, if you know exactly how to perform the required tasks,

are aware of the general safety procedures and have access to the correct equipment, service

fluids and suitable tools. Failing to carry out work correctly can cause serious injuries ⇒. The

work should be carried out by a qualified workshop if you are uncertain. Volkswagen recommends

using a Volkswagen dealership for this purpose.

Unintentional vehicle movements during service work can cause serious injury.

•Never work underneath a vehicle if it is not secured against rolling away. If you are

working underneath the vehicle while the wheels are on the ground, the vehicle must

be on a level, the wheels chocked, and the vehicle key removed from the ignition lock

as required.

•If you have to work underneath the vehicle, use suitable stands to provide extra

support for the vehicle. The vehicle jack is not sufficient for this task and can fail,

which can lead to serious injuries.

•The start/stop system must have been deactivated.

WARNING

The engine compartment of any motor vehicle is a dangerous area. Serious injuries can be

sustained here.

•The utmost care and attention must be paid when carrying out any work and you must

follow the general safety rules. Never take any risks.

•Never do any work on the engine or in the engine compartment unless you know

exactly how to carry it out. If you are uncertain of what to do, the work should be

carried out by a qualified workshop. Serious injuries can result from work that has not

been carried out properly.

•Never open the bonnet if you see steam or coolant escaping from the engine

compartment. Hot steam or hot coolant can cause serious burns. Always wait until you

can no longer see or hear steam or coolant coming from the engine compartment.

•Always allow the engine to cool down before opening the bonnet.

•Hot parts of the engine or exhaust system can burn the skin.

•Observe the following points before opening the bonnet once the engine has cooled

down:

- Switch on the electronic parking brake and move the selector lever to position P

or move the gear lever to the neutral position.

- Switch off the ignition and remove the vehicle key from the ignition lock.

- Always keep children away from the engine compartment and never leave the

vehicle unattended.

•The cooling system is under pressure when the engine is hot. Never open the cap of

the coolant expansion tank when the engine is hot. Coolant may spray out and cause

serious burns and other injuries.

- Slowly and carefully turn the cap on the coolant expansion tank anticlockwise

while exerting gentle downward pressure on the cap.

- Always protect the face, hands and arms from hot coolant or steam with a large,

thick cloth.

•When refilling, do not spill any service fluids on engine components or on the exhaust

system. The spilt service fluids can start a fire.

WARNING

High voltages in the electrical system can cause electric shocks, burns, serious injuries

and death!

•Never short circuit the electric system. The 12-volt battery could explode.

•Please note the following guidelines to help reduce the risk of an electric shock and

serious injuries while the engine is running or being started:

- Never touch the electrical wiring of the ignition system.

- Never touch the electrical wiring and connections of gas discharge bulbs.

WARNING

Page 274 of 341

Allow the engine to cool sufficiently.

Children and other people should be kept well away from the engine compartment.

Ensure that the vehicle cannot roll away unexpectedly.

Opening and closing the bonnet

Fig. 223 In the footwell on the driver's side: release lever for the bonnet.

Fig. 224 Above the radiator grille: bonnet control lever.

Opening the bonnet

•Ensure that the wiper arms are positioned on the windscreen before opening the bonnet ⇒.

•Open the driver door and pull the release lever in the direction of the arrow ⇒ Fig. 223. The

bonnet is released from its lock by a spring mechanism ⇒.

•Lift the bonnet at the opening lever ⇒ Fig. 224 (arrow) and open fully. The bonnet is held in the

open position by the gas strut.

Closing the bonnet

•To close the bonnet, pull it down to overcome the gas strut pressure ⇒.

•Let the bonnet drop into the catches from a height of about 30 cm – do not press it down!

If the bonnet has not closed properly, lift it and then close it again.

The bonnet sits flush with the body parts around it when it is closed properly. The bonnet is no

longer highlighted in the instrument cluster display ⇒ Display or the display goes out.

Ignoring any of the items on this important safety checklist can lead to severe injuries.

•Always follow the instructions in the checklist and observe the general safety

procedures.

WARNING

Page 275 of 341

Display

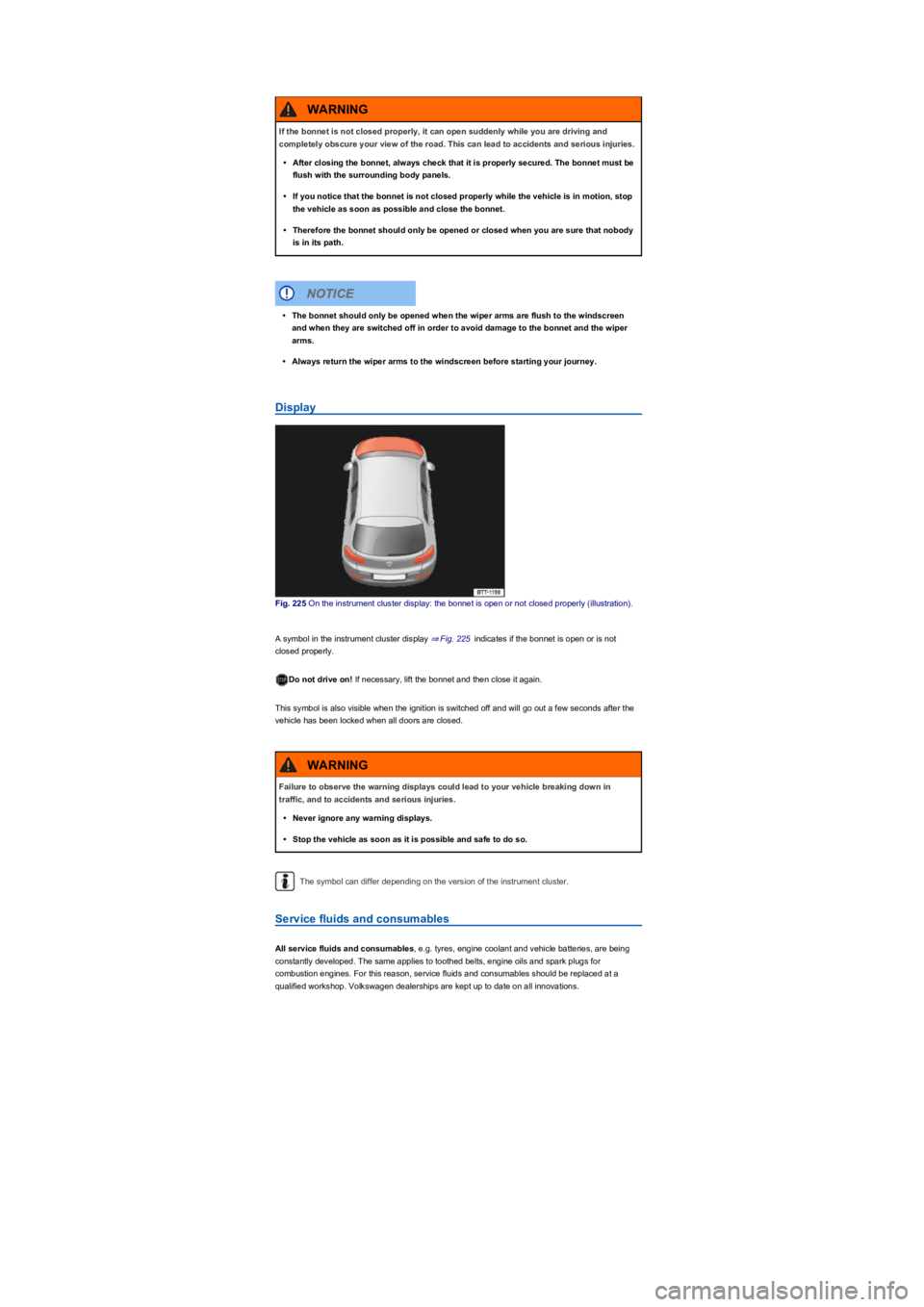

Fig. 225 On the instrument cluster display: the bonnet is open or not closed properly (illustration).

A symbol in the instrument cluster display ⇒ Fig. 225 indicates if the bonnet is open or is not

closed properly.

Do not drive on! If necessary, lift the bonnet and then close it again.

This symbol is also visible when the ignition is switched off and will go out a few seconds after the

vehicle has been locked when all doors are closed.

The symbol can differ depending on the version of the instrument cluster.

Service fluids and consumables

All service fluids and consumables, e.g. tyres, engine coolant and vehicle batteries, are being

constantly developed. The same applies to toothed belts, engine oils and spark plugs for

combustion engines. For this reason, service fluids and consumables should be replaced at a

qualified workshop. Volkswagen dealerships are kept up to date on all innovations.

If the bonnet is not closed properly, it can open suddenly while you are driving and

completely obscure your view of the road. This can lead to accidents and serious injuries.

•After closing the bonnet, always check that it is properly secured. The bonnet must be

flush with the surrounding body panels.

•If you notice that the bonnet is not closed properly while the vehicle is in motion, stop

the vehicle as soon as possible and close the bonnet.

•Therefore the bonnet should only be opened or closed when you are sure that nobody

is in its path.

WARNING

•The bonnet should only be opened when the wiper arms are flush to the windscreen

and when they are switched off in order to avoid damage to the bonnet and the wiper

arms.

•Always return the wiper arms to the windscreen before starting your journey.

NOTICE

Failure to observe the warning displays could lead to your vehicle breaking down in

traffic, and to accidents and serious injuries.

•Never ignore any warning displays.

•Stop the vehicle as soon as it is possible and safe to do so.

WARNING

Page 276 of 341

Leaking service fluids can pollute the environment. Spilt service fluids must be collected in

suitable containers and disposed of properly and with respect for the environment.

Washer fluid

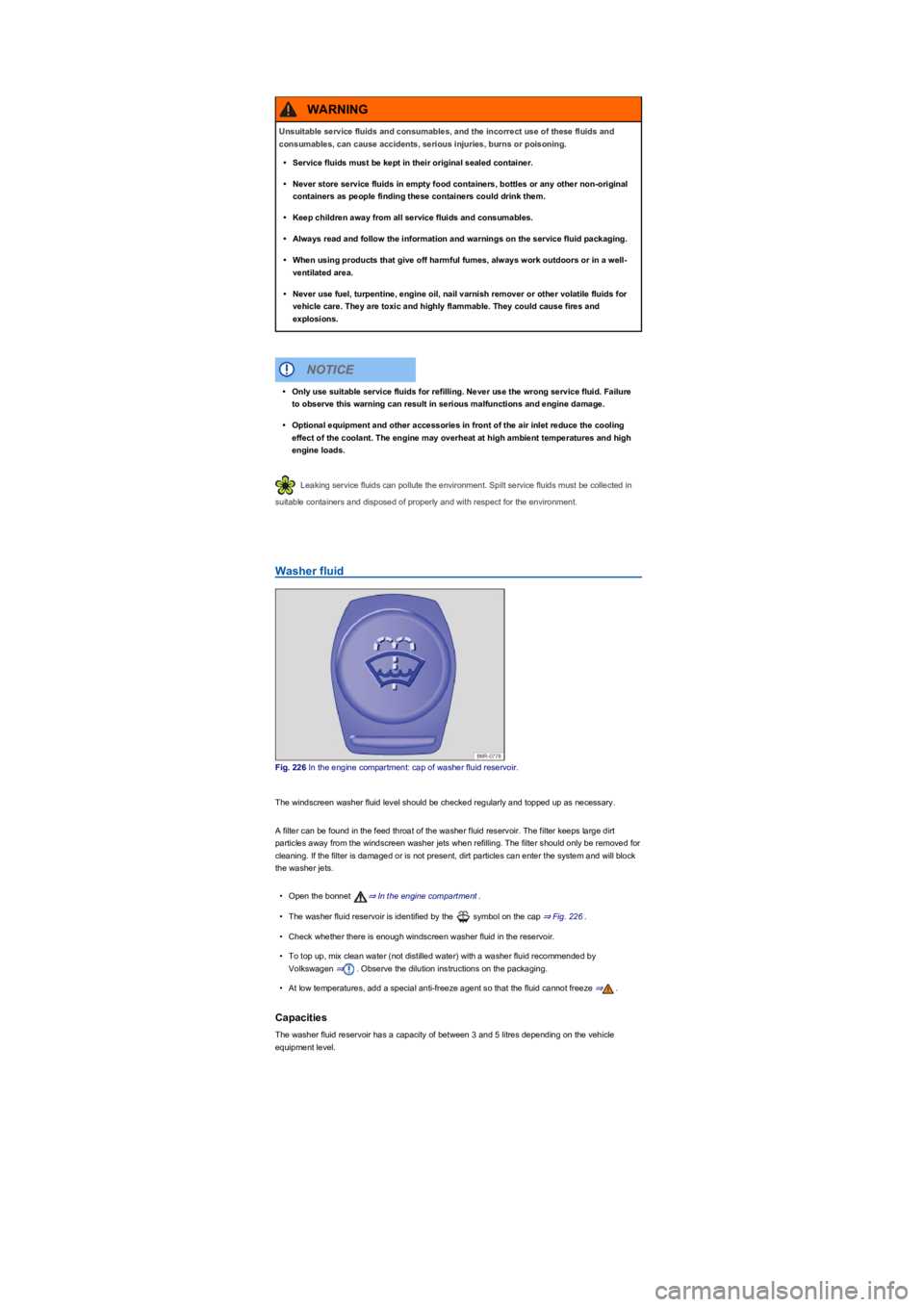

Fig. 226 In the engine compartment: cap of washer fluid reservoir.

The windscreen washer fluid level should be checked regularly and topped up as necessary.

A filter can be found in the feed throat of the washer fluid reservoir. The filter keeps large dirt

particles away from the windscreen washer jets when refilling. The filter should only be removed for

cleaning. If the filter is damaged or is not present, dirt particles can enter the system and will block

the washer jets.

•Open the bonnet ⇒ In the engine compartment.

•The washer fluid reservoir is identified by the symbol on the cap ⇒ Fig. 226.

•Check whether there is enough windscreen washer fluid in the reservoir.

•To top up, mix clean water (not distilled water) with a washer fluid recommended by

Volkswagen ⇒. Observe the dilution instructions on the packaging.

•At low temperatures, add a special anti-freeze agent so that the fluid cannot freeze ⇒.

Capacities

The washer fluid reservoir has a capacity of between 3 and 5 litres depending on the vehicle

equipment level.

Unsuitable service fluids and consumables, and the incorrect use of these fluids and

consumables, can cause accidents, serious injuries, burns or poisoning.

•Service fluids must be kept in their original sealed container.

•Never store service fluids in empty food containers, bottles or any other non-original

containers as people finding these containers could drink them.

•Keep children away from all service fluids and consumables.

•Always read and follow the information and warnings on the service fluid packaging.

•When using products that give off harmful fumes, always work outdoors or in a well-

ventilated area.

•Never use fuel, turpentine, engine oil, nail varnish remover or other volatile fluids for

vehicle care. They are toxic and highly flammable. They could cause fires and

explosions.

WARNING

•Only use suitable service fluids for refilling. Never use the wrong service fluid. Failure

to observe this warning can result in serious malfunctions and engine damage.

•Optional equipment and other accessories in front of the air inlet reduce the cooling

effect of the coolant. The engine may overheat at high ambient temperatures and high

engine loads.

NOTICE

Page 280 of 341

With the engine at operating temperature, park the vehicle on a level surface to ensure

that the engine oil reading is correct.

Switch off the engine and wait a few minutes for the engine oil to flow back into the sump.

Open the bonnet In the engine compartment.

Identify the engine oil filler cap and oil dipstick. The engine oil filler opening bears the

symbol on the cap and the oil dipstick has a coloured handle. If you cannot find the cap

and dipstick please contact a qualified workshop.

Pull the dipstick out of the guide tube and wipe it off with a clean cloth.

Insert the oil dipstick into the guide tube again as far as it will go. If there is a marking on

the upper end of the oil dipstick, this marking must fit in the corresponding groove at the

top end of the guide tube when inserting.

After reading off the oil level, push the oil dipstick back into the guide tube as far as it will

go.

Unscrew the engine oil filler opening cap .

Only the engine oil expressly approved by Volkswagen for this engine should be gradually

refilled in small quantities (no more than 0.5 l).

In order to avoid overfilling, wait for approximately one minute after each refill step to allow

the engine oil to flow into the oil sump up to the marking on the engine oil dipstick.

Read the engine oil level from the dipstick again before refilling with a further small

quantity of engine oil. Never overfill with engine oil .

After refilling, the engine oil level should be in the middle of area Ⓒ. It should not be above

Ⓒ, in area Ⓑ, and must not reach area Ⓐ .

If too much engine oil has been added unintentionally and the engine oil level is in area Ⓐ,

do not start the engine. Inform a qualified workshop and possibly seek expert assistance.

After refilling, close the engine oil filler opening with the cap.

Insert the oil dipstick into the guide tube as far as it will go. If there is a marking on the

upper end of the oil dipstick, this marking must fit in the corresponding groove at the top

end of the guide tube when inserting.

Close the bonnet In the engine compartment.

Do not refill engine oil.

Engine oil level OK.

Engine oil level too low – refill engine oil.

Checklist

Carry out the steps in the specified order ⇒:

Pull the dipstick out again and read the engine oil level on the dipstick as follows: Ⓐ Engine

oil level too high. Follow any messages that are shown on the instrument cluster display and

go to a qualified workshop . Ⓑ Do not fill the engine oil . Continue to step 16. Ⓒ Engine oil

level OK. Engine oil can, e.g. in the case of high engine loads , be filled up to the upper limit

of this range. Continue to step 8 or 16. Ⓓ Engine oil level is too low. The engine oil must be

refilled. Continue to step 8.

The engine oil level must never be above area ⇒ Fig. 227Ⓑ. Otherwise oil can be drawn in

through the crankcase breather and escape into the atmosphere via the exhaust system.

Troubleshooting

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Engine oil can ignite if it comes into contact with hot engine components. It can cause

fires, burns and other serious injuries.

•If engine oil is spilt on cold engine parts it can heat up and ignite when the engine is

running.

•Always ensure that the engine oil filler cap is securely tightened after refilling, and that

the dipstick is properly inserted back into the guide tube. This will prevent the engine

oil from draining out on to hot engine components when the engine is running.

WARNING

•If too much engine oil has been added unintentionally and the engine oil level is in area

⇒ Fig. 227Ⓐ, do not start the engine. Inform a qualified workshop and possibly seek

expert assistance. The catalytic converter and the engine could otherwise be damaged.

•When topping up service fluids, please ensure that you pour the correct service fluids

into the correct openings. The use of incorrect service fluids could result in serious

malfunctions and engine damage.

NOTICE

Page 282 of 341

Coolant and coolant additives can pollute the environment. Spilt service fluids must be

collected then disposed of properly and in an environmentally responsible way.

Checking the coolant level and refilling coolant

Fig. 229 In the engine compartment: markings on the coolant expansion tank.

Fig. 230 In the engine compartment: coolant expansion tank cap (illustration).

First read and observe the introductoryinformation and safety warnings⇒

Introduction

The warning lamp for the engine coolant will light up if the engine coolant level is too low.

Preparation

•Park the vehicle on a firm and level surface.

•Allow the engine to cool down ⇒.

•Open the bonnet ⇒ In the engine compartment.

•The coolant expansion tank is identified by the symbol on the cap ⇒ Fig. 230.

Checking the coolant level

•When the engine is cold, check the coolant level on the side markings of the engine coolant

expansion tank ⇒ Fig. 229. The engine coolant level must be between the marks.

•Refill coolant if the liquid level in the coolant expansion tank is below the minimum marking

(min). When the engine is warm, the engine coolant level may be slightly above the maximum

(MAX) mark.

Refilling coolant

•Always protect your face, hands and arms from hot coolant or steam by placing a suitable cloth

on the cap of the coolant expansion tank.

•Unscrew the cap carefully ⇒.

•Refill only new coolant according to the Volkswagen specification ⇒ Coolant specification⇒

.

Insufficient anti-freeze in the coolant system can cause the engine to break down and

cause serious injuries.

•Please note that the amount of correct coolant additive used must be sufficient for the

lowest ambient temperature that you expect the vehicle to be exposed to.

•Coolant can freeze at extremely cold outside temperatures, causing the vehicle to

break down. Vehicle occupants with inadequate winter clothing could then freeze to

death as the heating will also no longer function.

WARNING

Never mix genuine coolant additives with other coolants that have not been approved by

Volkswagen. Mixing other coolants could cause serious damage to the engine and cooling

system.

•If the liquid in the coolant expansion tank is not pink (colouring results from mixing the

purple coolant additive with distilled water) but for example, brown instead, - G 13 - has

been mixed with an unsuitable coolant. The coolant must be changed as soon as

possible if this is the case. Failure to observe this point can result in serious faults or

engine damage.

NOTICE