Auto start stop VOLKSWAGEN TIGUAN 2017 Owner´s Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 2017, Model line: TIGUAN, Model: VOLKSWAGEN TIGUAN 2017Pages: 341, PDF Size: 9.14 MB

Page 240 of 341

Trailer towing

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Headlight adjustment

Towing a trailer can raise the front end of the vehicle enough for the dipped beam to blind other

road users. Use the headlight range control to lower the light cone as required. Vehicles with

automatic headlight range adjustment are adjusted automatically.

Things to note when driving with a trailer

•If the trailer has an overrun brake, apply the brakes gently at first and then firmly. This will

prevent the jerking that can be caused by the trailer wheels locking.

•The combination weight causes the braking distance to increase.

•Engage a lower gear prior to inclines (manual gearbox or Tiptronic mode of the automatic

gearbox) to additionally make use of engine braking. The brake system could otherwise

overheat and fail.

•The vehicle's centre of gravity and, in turn, the vehicle's handling, will change because of the

trailer load and the increased combined towing weight of the vehicle and trailer.

•The weight distribution of a loaded trailer with an unladen towing vehicle is very unfavourable.

When driving in this situation, drive particularly carefully and slowly.

Pulling off on slopes when towing a trailer

A vehicle towing a trailer is liable to roll back a short distance when moving off on a slope,

depending on the angle of the slope and the total weight of the trailer and vehicle.

When towing a trailer, pull off on slopes as follows:

•Depress and hold the brake pedal.

•Press button once to switch off the electronic parking brake ⇒ Electronic parking

brake.

•Manual gearbox: depress the clutch fully.

•Select first gear ⇒ Manual gearbox: selecting a gear or selector lever position D/S⇒ DSG dual

clutch gearbox.

•Pull on the button and hold it in this position to hold the vehicle and trailer with the

electronic parking brake.

•Release the brake pedal.

•Pull away slowly. To do this, slowly release the clutch pedal for a manual gearbox.

•Only let go of the button when the engine has sufficient power to move off.

Trailer stabilisation

First read and observe the introductoryinformation and safety warnings⇒

Introduction

The trailer stabilisation function can detect if an attached trailer is starting to lurch from side to side

and can provide countersteer.

Trailer stabilisation is a subsidiary function of the Electronic Stability Control (ESC).

®

Incorrect trailer towing can cause loss of vehicle control and serious personal injury.

•Towing a trailer and transporting heavy or bulky items can change the way the vehicle

handles and increase the braking distance.

•Always drive carefully and think ahead. Brake earlier than in normal driving.

•Always adapt your speed and driving style to suit visibility, weather, road and traffic

conditions. Reduce your speed, particularly when going downhill.

•Accelerate carefully and gently. Avoid abrupt and sudden driving and braking

manoeuvres.

•Take special care when overtaking. Reduce your speed immediately if the trailer shows

even the slightest sign of snaking.

•Never try to stop a trailer from snaking by increasing your speed.

•Keep to speed limits which may be lower for vehicles with trailers than for vehicles

without trailers.

WARNING

Page 254 of 341

Park the vehicle on a firm and level surface at a safe distance from the flow of traffic.

Switch on the electronic parking brake Electronic parking brake.

Turn the light switch to position 0 Lights.

Move the turn signal lever to neutral position Lights.

Move the automatic gearbox selector lever to position P DSG® dual clutch gearbox.

Switch off the ignition and remove the vehicle key from the ignition lock Starting and

stopping the engine.

Manual gearbox: select a gear Manual gearbox: selecting a gear.

Switch off the orientation lighting Lights.

Leave the defective bulbs to cool down.

You can change the following bulbs yourself:

•Bulbs in the halogen headlight: dipped beam, main beam, daytime running light, side light, turn

signal.

•Bulbs in front bumper: fog lights, static cornering light.

•Bulbs in the tail light clusters: rear turn signal, if it does not feature LED technology (depending

on vehicle equipment level).

All other bulbs and lamps in the vehicle should always be changed by an expert.

Additional bulb specifications

Some bulbs in headlights or in tail light clusters might have factory specifications that are different

to standard bulbs. The designation is inscribed on the bulb, either on the glass part or on the base.

LED bulbs on the vehicle

•Brake light, rear fog light, tail light, turn signal and reversing light in the tail light clusters.

•Dipped beam, main beam, daytime running lights, static cornering light, side lights and turn

signal.

•Number plate light.

Owners cannot replace the LEDs themselves. If some LEDs fail, this may be an indication that

more elements are on the point of failure. If this happens, have the bulbs checked and replaced if

necessary at a qualified workshop.

Checklist Information on changing bulbs

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Checklist

Always carry out the following actions for changing a bulb in the given order ⇒:

Accidents can occur if roads are not sufficiently illuminated and other road users have

difficulty seeing the vehicle, or cannot see it at all.

WARNING

Changing the bulb incorrectly can cause accidents and serious injuries.

•When working in the engine compartment, always read and observe the safety

warnings ⇒ In the engine compartment. The engine compartment of any motor vehicle

is a dangerous area. Serious injuries can be sustained here.

•H7/H15 bulbs are pressurised and could explode when they are being changed.

•Only change the defective bulb once it has had time to cool down completely.

•Never change a bulb unless you are familiar with the procedure. If you are uncertain of

what to do, the work should be carried out by a qualified workshop.

•Do not touch the glass part of the bulb with unprotected fingers. When the light is

switched on, heat will cause fingerprints to evaporate on the bulb, which in turn will

cause the reflector to dim.

•There are sharp-edged parts in the headlight housing in the engine compartment and

on the tail light cluster housing. Protect your hands when changing bulbs.

WARNING

Damage to the electrical system can be caused by water entering the system if the rubber

covers or plastic caps on the headlight housing are not properly mounted after a bulb has

been changed.

NOTICE

Page 273 of 341

Park the vehicle on a level and stable surface.

Depress and hold the brake pedal until you have switched off the ignition.

Switch on the electronic parking brake Electronic parking brake.

Select the neutral position Manual gearbox: selecting a gear or move the selector lever to

position P DSG® dual clutch gearbox.

Switch off the ignition and remove the vehicle key from the ignition lock Starting and

stopping the engine.

Service fluids leaks are harmful to the environment. So you should regularly check the

ground underneath your vehicle. If there are spots of oil or other service fluids on the ground, the

vehicle should be inspected by a qualified workshop. Any spilt service fluids must be disposed of

properly.

Preparing the vehicle for working in the engine compartment

Checklist

The following steps should always be carried out in the specified order before working in

the engine compartment ⇒:

There are rotating components in the engine compartment that can cause serious injury.

•Never place your hand near these components or in the radiator fan. Touching the

rotary blades can result in serious injuries. The fan is temperature-controlled and can

start automatically, even if the ignition has been switched off and the vehicle key has

been removed from the ignition lock.

•If any work has to be performed when the engine is started or with the engine running,

there is an additional, potentially fatal, safety risk from the rotating parts, such as the

poly V-belts, alternator, radiator fan etc., and from the high-voltage ignition system.

Always be particularly careful.

- Always ensure that no body parts, jewellery, ties, loose items of clothing or long

hair can be caught up in rotating engine components. Before starting work,

remove any jewellery and ties, tie up long hair and pull clothes in tightly to avoid

them getting caught in the engine compartment.

- Always take due care and attention when depressing the accelerator. The vehicle

could move, even if the electronic parking brake is applied.

•Always ensure you have not left any objects, such as cleaning cloths and tools, in the

engine compartment. Any forgotten items can cause malfunctions, engine damage and

fires.

WARNING

Additional insulating materials such as covers in the engine compartment could disrupt

the operation of the engine, start fires and lead to severe injuries.

•Never cover the engine with any insulating materials.

WARNING

Service fluids and some materials in the engine compartment are highly flammable and

can cause fires and serious injuries!

•Never smoke in the vicinity of the engine compartment.

•Never work near naked flames or sparks.

•Never spill fluids onto the engine. They could ignite on hot engine components and

hence cause injuries.

•Please note the following when carrying out any work on the fuel system or the

electrical system:

- Always disconnect the 12-volt vehicle battery. Ensure that the vehicle is

unlocked when the 12-volt vehicle battery is disconnected as otherwise the anti-

theft alarm will be activated.

- Never work in the direct proximity of heating systems, water heaters or any other

open flames.

•Always have a fully functional and tested fire extinguisher to hand.

WARNING

When topping up or changing service fluids, ensure that you pour the correct service

fluids into the correct openings. The use of incorrect service fluids could result in serious

malfunctions and engine damage.

NOTICE

Page 291 of 341

•Open the Vehicle settings menu in the Infotainment system.

•Touch the Tyres function button.

•Touch the SET function button.

•When all four tyre pressures correspond to the required values, touch the Confirm function

button.

After an extended driving time with driving at different speeds, the system will automatically learn

the new values and monitor them.

•If the tyre pressures have been changed.

•If one or more wheels have been changed.

•If the wheels have been swapped round, e.g. from front to rear ⇒ Rotating wheels front to rear.

The Tyre Pressure Loss Indicator stops working if there is a fault in the ESC or ABS ⇒ Brake

support systems.

After a warning about the tyre pressure being too low, switch the ignition off and then back

on again. The Tyre Pressure Loss Indicator can only then be re-synchronised.

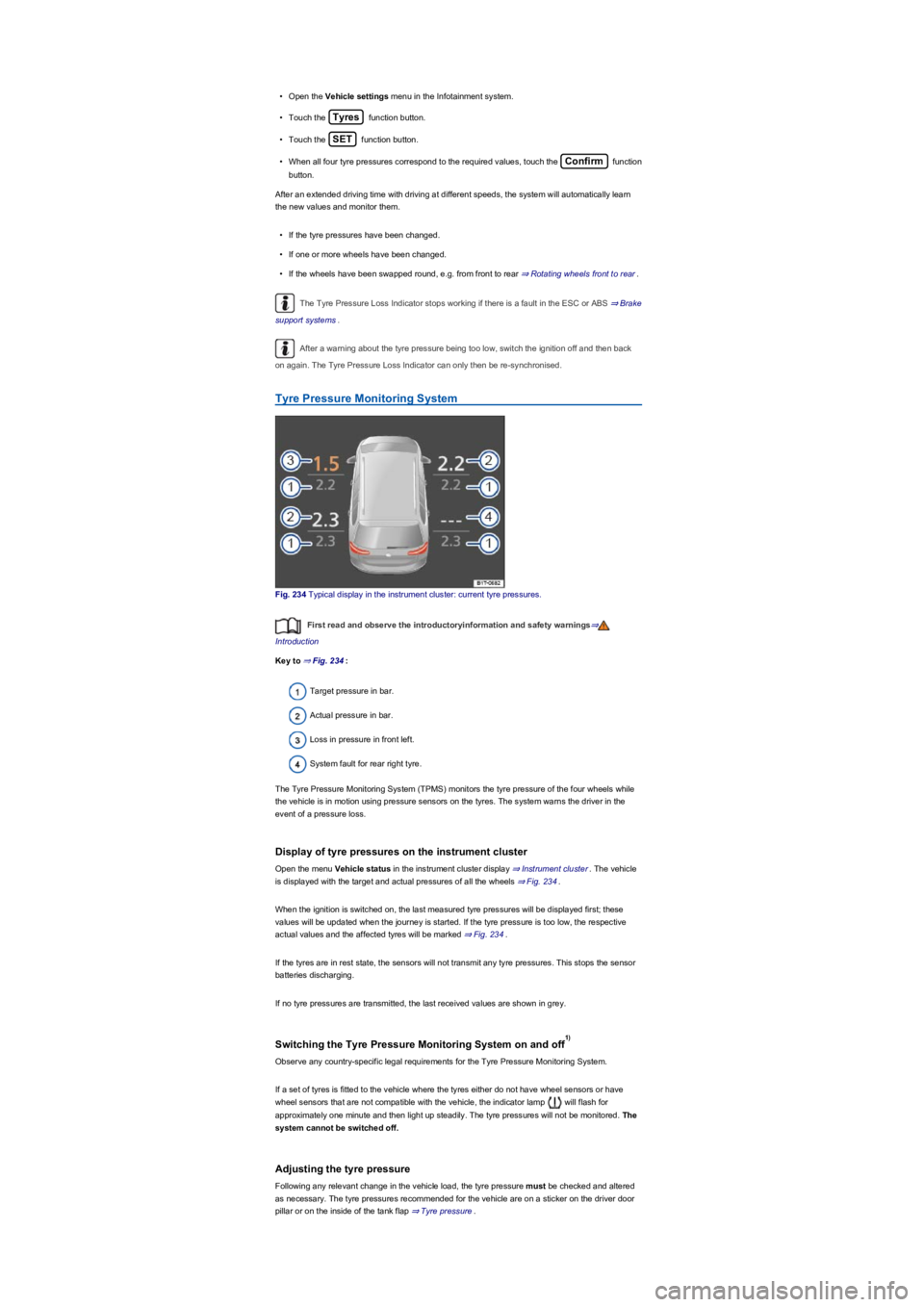

Tyre Pressure Monitoring System

Fig. 234 Typical display in the instrument cluster: current tyre pressures.

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Key to ⇒ Fig. 234:

Target pressure in bar.

Actual pressure in bar.

Loss in pressure in front left.

System fault for rear right tyre.

The Tyre Pressure Monitoring System (TPMS) monitors the tyre pressure of the four wheels while

the vehicle is in motion using pressure sensors on the tyres. The system warns the driver in the

event of a pressure loss.

Display of tyre pressures on the instrument cluster

Open the menu Vehicle status in the instrument cluster display ⇒ Instrument cluster. The vehicle

is displayed with the target and actual pressures of all the wheels ⇒ Fig. 234.

When the ignition is switched on, the last measured tyre pressures will be displayed first; these

values will be updated when the journey is started. If the tyre pressure is too low, the respective

actual values and the affected tyres will be marked ⇒ Fig. 234.

If the tyres are in rest state, the sensors will not transmit any tyre pressures. This stops the sensor

batteries discharging.

If no tyre pressures are transmitted, the last received values are shown in grey.

Switching the Tyre Pressure Monitoring System on and off

Observe any country-specific legal requirements for the Tyre Pressure Monitoring System.

If a set of tyres is fitted to the vehicle where the tyres either do not have wheel sensors or have

wheel sensors that are not compatible with the vehicle, the indicator lamp will flash for

approximately one minute and then light up steadily. The tyre pressures will not be monitored. The

system cannot be switched off.

Adjusting the tyre pressure

Following any relevant change in the vehicle load, the tyre pressure must be checked and altered

as necessary. The tyre pressures recommended for the vehicle are on a sticker on the driver door

pillar or on the inside of the tank flap ⇒ Tyre pressure.

1)

Page 313 of 341

If you get a flat tyre, park your vehicle on a firm and level surface at a safe distance from

the flow of traffic.

Switch on the electronic parking brake Parking and manoeuvring.

With a DSG® dual clutch gearbox, move the selector lever to position P DSG® dual clutch

gearbox.

Stop the engine and remove the key from the ignition Starting and stopping the engine.

Manual gearbox: select a gear Manual gearbox: selecting a gear.

Ask all vehicle occupants to leave the vehicle and stand at a safe distance away from

moving traffic.

Switch on the hazard warning lights and position the warning triangle In an emergency.

Observe any legal requirements.

Check whether the puncture can be repaired with the breakdown set The tyre sealant must

not be used:.

When towing a trailer: unhitch the trailer from the vehicle and park it properly .

Remove any items of luggage from the luggage compartment.

Take the breakdown set out of the luggage compartment.

Take the sticker ② from the breakdown set and stick it on the dash panel within the

driver's field of vision.

Do not remove foreign objects (e.g. screws or nails) from the tyre.

Tyre filler hose.

12-volt plug.

Tyre filler bottle with sealant.

Spare valve core.

There is a slot on the lower end of the valve insert extractor① for the valve insert. This is

required for extracting and fitting the tyre valve. This also applies to the spare valve core ⑪.

Could also be integrated in the tyre filler hose.

Preparation

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Checklist

Always carry out the following actions in the given order ⇒:

Sealing and inflating tyres

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Sealing a tyre

•Unscrew the cap from the tyre valve.

•Use the valve core extractor ⇒ Fig. 249① to screw the valve core out of the tyre valve. Place

the core on a clean surface.

•Shake the tyre filler bottle ⇒ Fig. 249⑩ vigorously up and down several times.

•Screw the filler hose ⇒ Fig. 249③ tightly onto the tyre filler bottle in a clockwise direction. The

plastic foil on the plug is pierced automatically.

•Remove the plug from the filler hose ⇒ Fig. 249③ and place the open end fully on the tyre

valve.

•Hold the bottle upside down and inject the entire contents of the tyre filler bottle into the tyre.

•Remove the empty tyre filler bottle from the valve.

•Use the valve core extractor ⇒ Fig. 249① to screw the valve core back onto the tyre valve.

Inflating the tyre

•Screw the tyre filler hose ⇒ Fig. 249⑧ of the air compressor tightly onto the tyre valve.

•Check that the bleed screw ⇒ Fig. 249⑥ is closed.

•Start the engine and let it run.

1)

Ignoring any of the items on this important safety checklist can lead to accidents and

severe injuries.

•Always follow the instructions in the checklist and observe the general safety

procedures.

WARNING