clock VOLKSWAGEN TRANSPORTER 2015 Owner´s Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 2015, Model line: TRANSPORTER, Model: VOLKSWAGEN TRANSPORTER 2015Pages: 486, PDF Size: 72.17 MB

Page 144 of 486

A WARNING (Continued)

• If the ball coupling will not fit properly, the towing bracket should be checked by a quali-fied workshop.

• Do not use the towing bracket If the ball coupling does not engage properly or if you are unable to set it to the "ready" position.

• Do not use the towing bracket if you are unable to remove the key from the handwheel once the ball coupling has been mounted. This means that ball coupling Is not locked properly.

Removing the ball coupling

r--T'n First read and observe the Introductory L-J.:.IJ information and safety warnings & on page 139.

• Unhitch the trailer => &.

• Remove the cover =>Fig. 113 ®from the lock on the handwheel.

• Insert the key® into the lock and turn it clock-wise.

• Hold the ball coupling tightly in your left hand =>&.

• Use your right hand to pull out the handwheel 0 in the direction of arrow 1 and keep it in this po-sition.

• Turn the handwheel 0 in the direction of arrow 2 until it engages.

Hitching and connecting the trailer

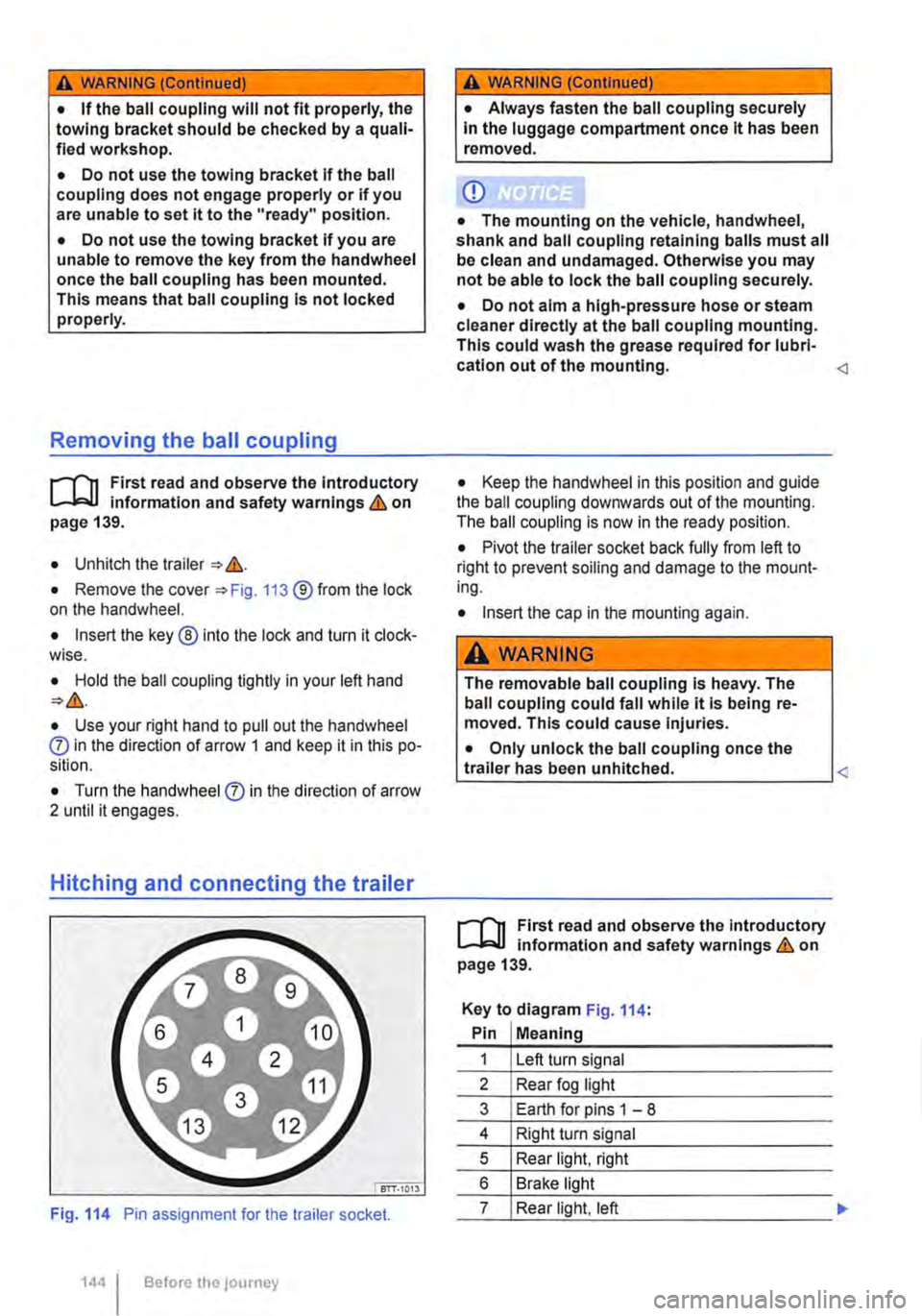

Fig. 114 Pin assignment for the trailer socket.

1441 Before the journey

A WARNING (Continued)

• Always fasten the ball coupling securely In the luggage compartment once it has been removed.

CD

• The mounting on the vehicle, handwheel, shank and ball coupling retaining balls must all be clean and undamaged. Otherwise you may not be able to lock the ball coupling securely.

• Do not aim a high-pressure hose or steam cleaner directly at the ball coupling mounting. This could wash the grease required for lubri-cation out of the mounting.

• Pivot the trailer socket back fully from left to right to prevent soiling and damage to the mount-ing.

• Insert the cap in the mounting again.

A WARNING

The removable ball coupling Is heavy. The ball coupling could fall while it Is being re-moved. This could cause Injuries.

• Only unlock the ball coupling once the L-tr_a_ile_r_h_a_s __ be_e_n __ u_n_hi_tc_h_e_d_. ____________

r--T'n First read and observe the Introductory L-J.:.IJ information and safety warnings & on page 139.

Key to diagram Fig. 114:

Pin Meaning

1 Left turn signal

2 Rear fog light

3 Earth for pins 1 -8

4 Right turn signal

5 Rear light, right

6 Brake light

7 Rear light, left

Page 204 of 486

Central control panel, California

COl Introduction

This chapter contains information on the following subjects:

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Display . . . . . . . . . . . . . . . . . . . . • . . . . 205

Menu structure . . . . . . . . . . . . . . . . . . . . . . . . . . 206 Programming the wake up time . . . . . . . • . . . . 207

Programming the countdown timer . . . . . . . . . 207

The central control panel is the "control and infor-mation centre" for the camping equipment. The central control panel can be used to open and con-trol the following displays and functions:

• Opening and closing the electric pop-up roof 221

• Displays showing the ambient temperature, clock and charging status of the additional batter-ies 205

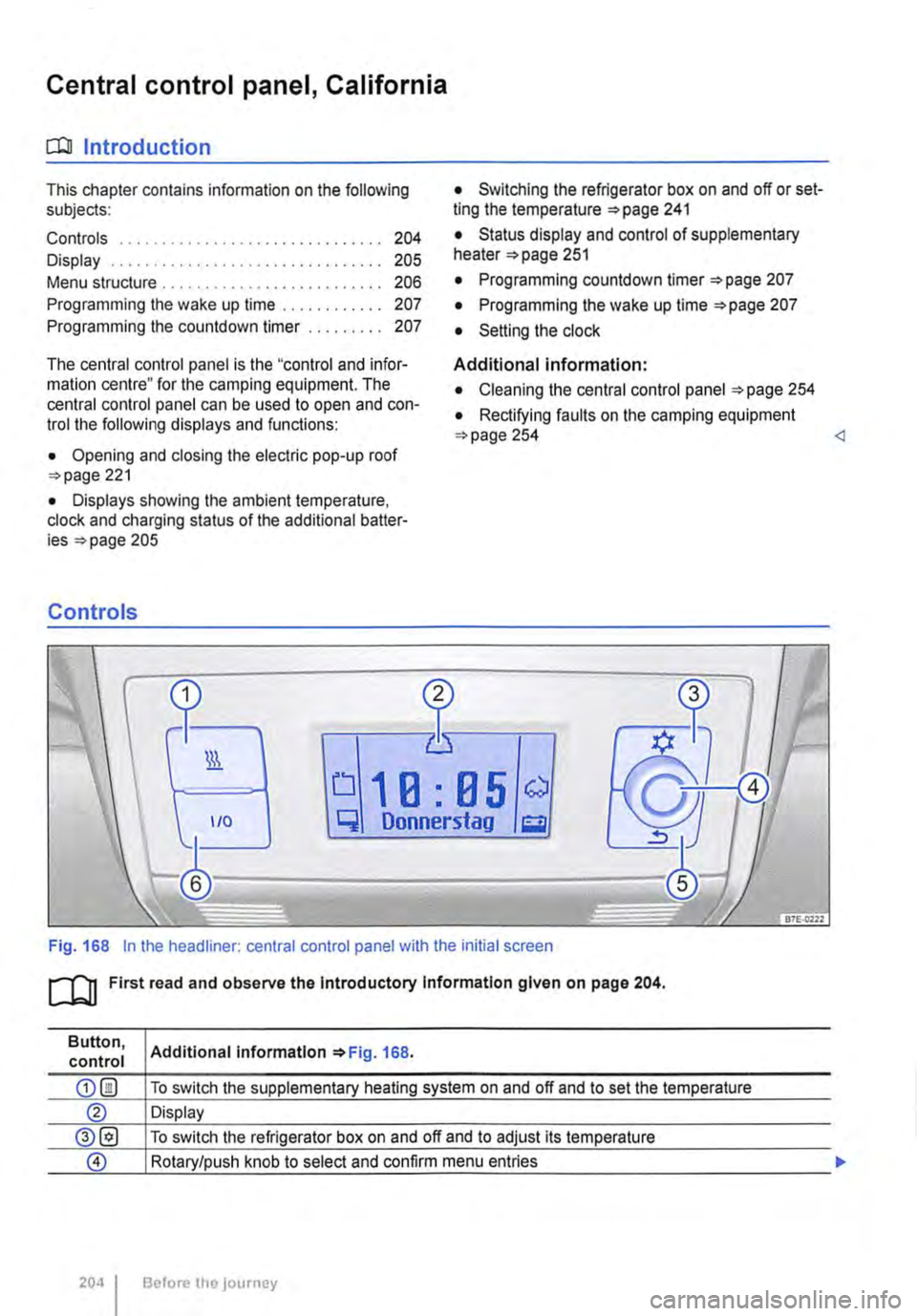

Controls

• Switching the refrigerator box on and off or set-ting the temperature =>page 241

• Status display and control of supplementary heater 251

• Programming countdown timer 207

• Programming the wake up time 207

• Setting the clock

Additional information:

• Cleaning the central control panel 254

• Rectifying faults on the camping equipment 254

q Donnerstag g

Fig. 168 In the headliner: central control panel with the initial screen

ro First read and observe the Introductory Information given on page 204.

Button, control

204 I

Additional Information 168.

To switch the supplementary heating system on and off and to set the temperature

Display

To switch the refrigerator box on and off and to adjust its temperature

Rotary/push knob to select and confirm menu entries

Before the journey

Page 207 of 486

Main menu Possible functions

Battery status

Clock

Refrigerator box Switching on

Switching off

Temperature selection

Supplementary Switching on heating system

Switching off

Temperature selection

Status

Program

Clock Date I time

Countdown timer

Wake-up time

Settings

Back

Programming the wake up time

r--f"'n First read and observe the introductory L-lo::.U information given on page 204.

Setting a wake-up time

• Select the Clock menu.

• Select the Wake up time submenu.

• Select New.

• Change the flashing figures by turning the knob 168@ and press the knob to confirm. The display will show this symbol 0.

Setting different wake-up times

Select New to set an additional wake up time. When you have entered seven wake-up times, the display shows the text 7 entries made.

Programming the countdown timer

r--f"'n First read and observe the introductory L-lo::.U information given on page 204.

Description of the submenu with examples

Battery voltage and battery capacity (12.8V, 100%)

Time

Refrigerator box switched on .t

Refrigerator box switched off ./

Cooling temperature settings 1 to "Max." maxi-mum cooling level

Switched on manually .;

Switched off manually .;

Temperature setting (01-10)

Supplementary heating system status (on I man-ual)

Program the supplementary heating system

Day of week and time (10:09. Friday)

Program the countdown time (New)

Program the wake up time: a maximum of 7 wake up times can be stored.

Change flashing figures by turning the knob. Press knob to confirm.

Return to previous menu or initial screen without saving changes.

Deleting or changing a wake-up time

• Use the rotary/push knob to select the desired wake up time.

• Select Change or Del et e. To delete a wake up time, select it and confirm with Yes.

Turning off the wake up alarm

• Press button.

r::l All stored wake-up times are deleted if the L!J central control panel is switched off.

Setting the countdown timer

• Select the Clock menu.

• Select the Countdown timer submenu.

Equipment, California I 207

Page 225 of 486

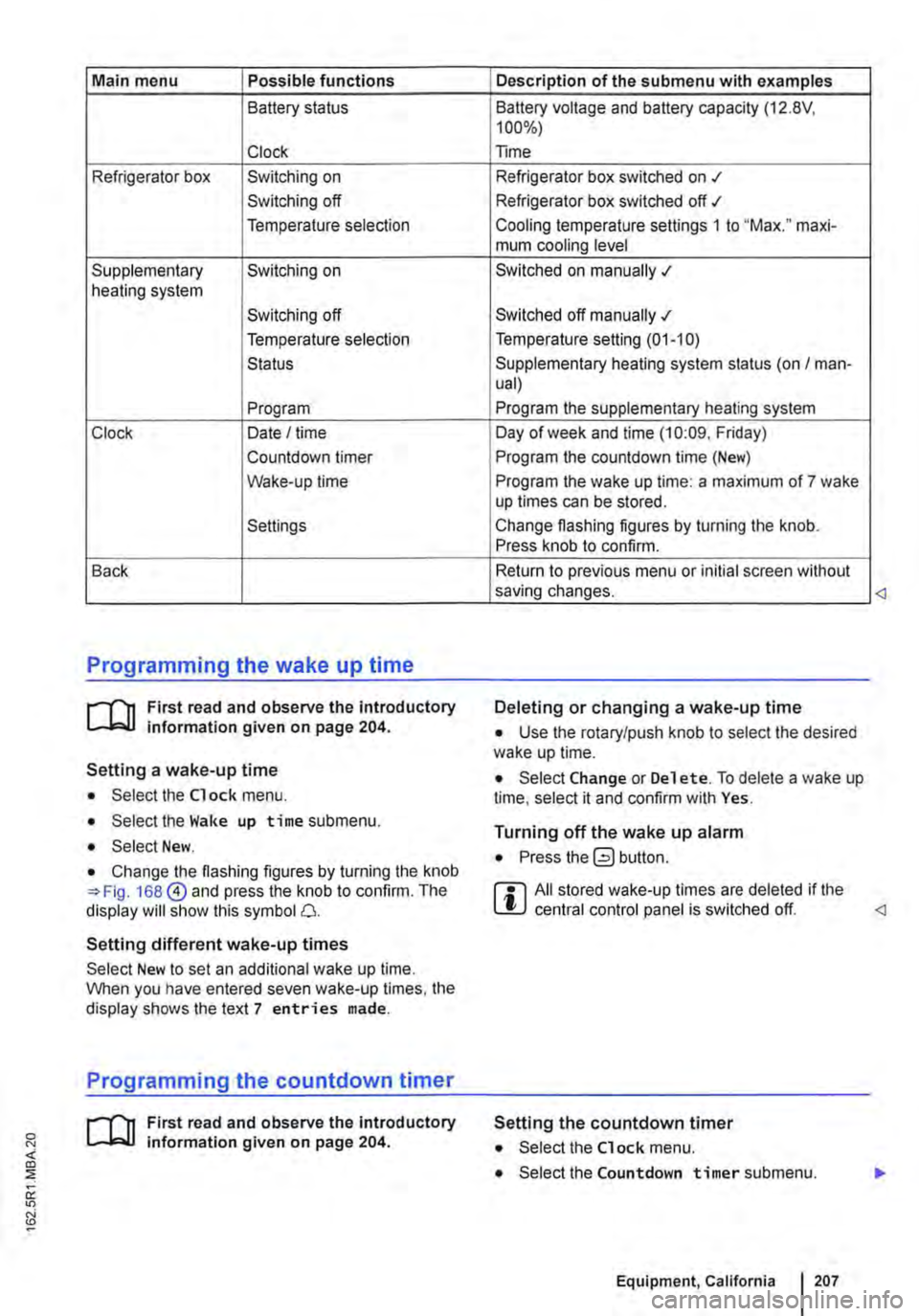

Closing the electric pop-up roof manually

Fig. 186 Manual closing of the pop-up roof with the central control panel removed

t'""('n First read and observe the introductory Information and safety warnings & on page 221.

• Follow the preparatory steps 224.

• Cut through the sealing material using the screwdriver at the marking shown 186 G).

• Insert the flat edge of the screwdriver into the slotted screw behind the marking.

• Carefully, and little by little, partially unscrew the slotted screw in an anticlockwise direction. The pop-up roof starts to close. The closing speed de-pends on the roof load and the degree to which the slotted screw has been unscrewed.

• Make sure that the canvas is not pinched at the front or on the side between the vehicle and the roof or the rods.

• Continue closing the pop-up roof until it rests fully on the vehicle body.

• Screw the slotted screw completely back in us-ing a clockwise movement.

• Place the central control panel back into its opening and allow it to snap securely into place. lt should lie flush with the surrounding parts.

• Secure the pop-up roof manually from the out-side 225.

• Drive carefully and slowly to the nearest quali-fied workshop and have the pop-up roof checked Introduction on page 221.

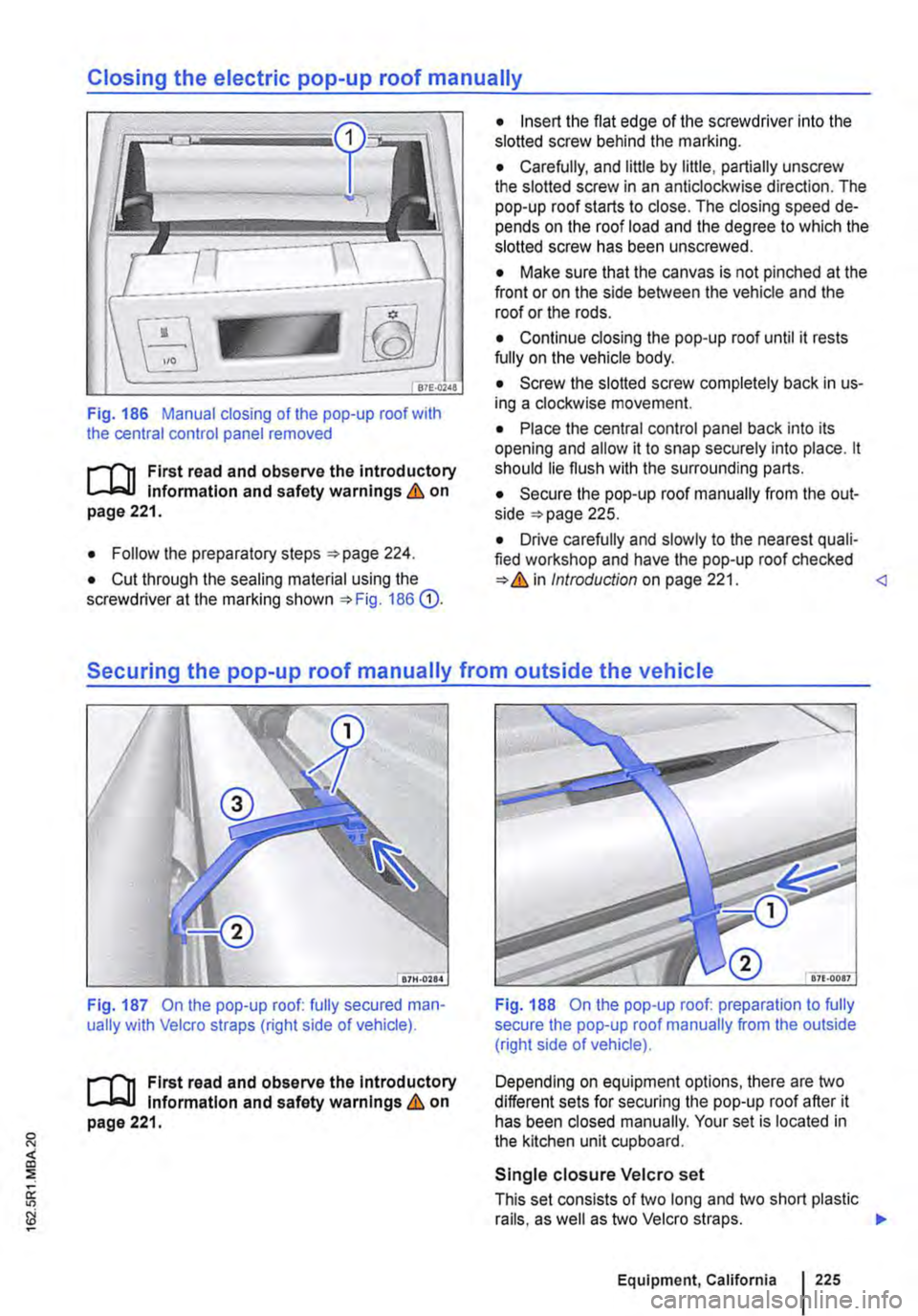

Fig. 187 On the pop-up roof: fully secured man-ually with Velcro straps (right side of vehicle).

t'""('n First read and observe the Introductory Information and safety warnings & on page 221.

Fig. 188 On the pop-up roof: preparation to fully secure the pop-up roof manually from the outside (right side of vehicle).

Depending on equipment options, there are two different sets for securing the pop-up roof after it has been closed manually. Your set is located in the kitchen unit cupboard.

Single closure Velcro set

This set consists of two long and two short plastic rails, as well as two Velcro straps. .,.

Equipment, California 225

Page 235 of 486

Connecting the gas bottle

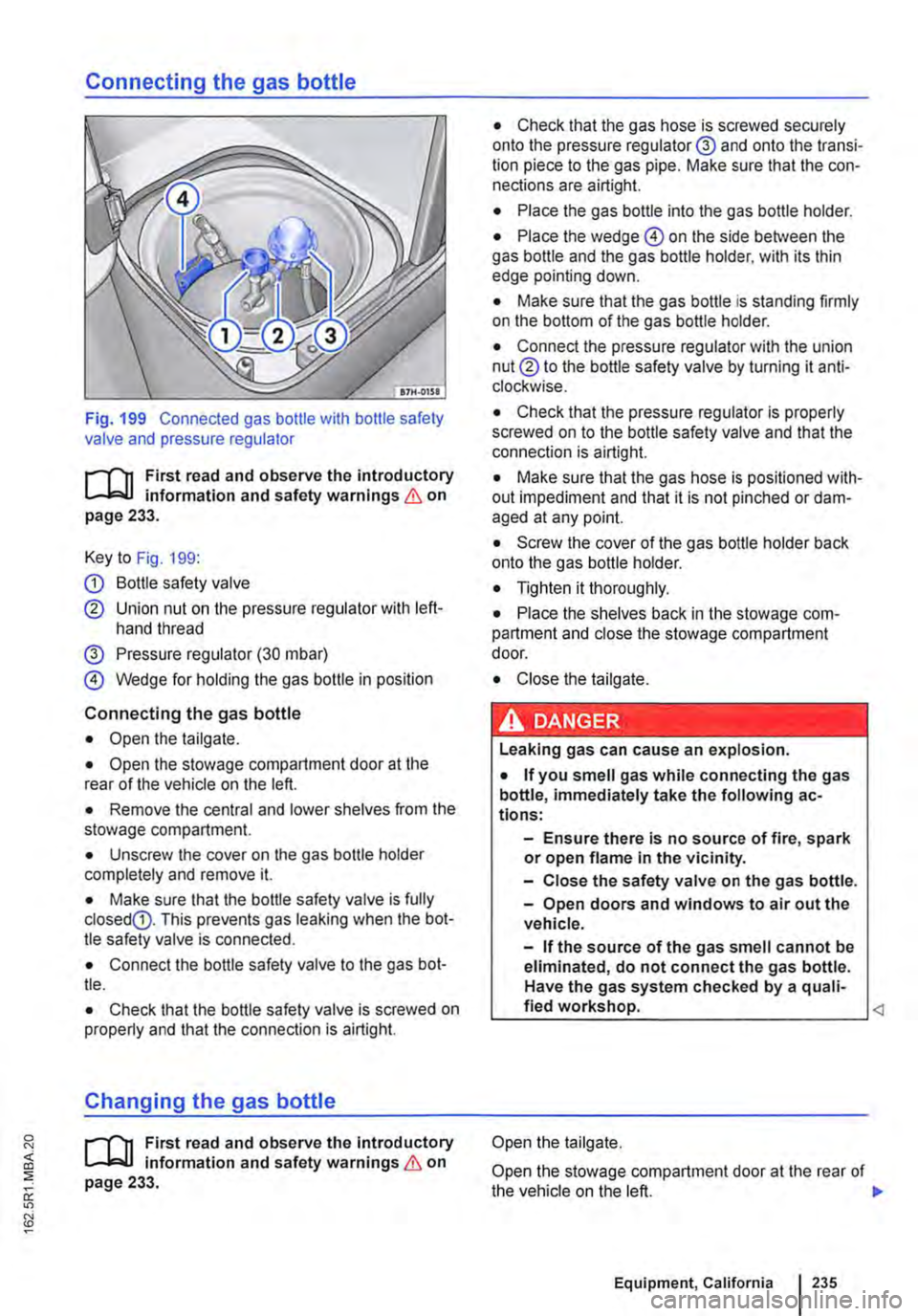

Fig. 199 Connected gas bottle with bottle safety valve and pressure regulator

r-l'n First read and observe the introductory L-J.:.IJ information and safety warnings & on page 233.

Key to Fig. 199:

G) Bottle safety valve

® Union nut on the pressure regulator with left-hand thread

@ Pressure regulator (30 mbar)

@ Wedge for holding the gas bottle in position

Connecting the gas bottle

• Open the tailgate.

• Open the stowage compartment door at the rear of the vehicle on the left.

• Remove the central and lower shelves from the stowage compartment.

• Unscrew the cover on the gas bottle holder completely and remove it.

• Make sure that the bottle safety valve is fully closedG). This prevents gas leaking when the bot-tle safety valve is connected.

• Connect the bottle safety valve to the gas bot-tle.

• Check that the bottle safety valve is screwed on properly and that the connection is airtight.

Changing the gas bottle

r-l'n First read and observe the Introductory L-J.:.IJ information and safety warnings & on page 233.

• Check that the gas hose is screwed securely onto the pressure regulator@ and onto the transi-tion piece to the gas pipe. Make sure that the con-nections are airtight.

• Place the gas bottle into the gas bottle holder.

• Place the wedge @ on the side between the gas bottle and the gas bottle holder. with its thin edge pointing down.

• Make sure that the gas bottle is standing firmly on the bottom of the gas bottle holder.

• Connect the pressure regulator with the union nut® to the bottle safety valve by turning it anti-clockwise.

• Check that the pressure regulator is properly screwed on to the bottle safety valve and that the connection is airtight.

• Make sure that the gas hose is positioned with-out impediment and that it is not pinched or dam-aged at any point.

• Screw the cover of the gas bottle holder back onto the gas bottle holder.

• Tighten it thoroughly.

• Place the shelves back in the stowage com-partment and close the stowage compartment door.

• Close the tailgate.

· &' DANGER .. --' • ,.,_.._.. '·-• I Leaking gas can cause an explosion.

• If you smell gas while connecting the gas bottle, immediately take the following ac-tions:

-Ensure there is no source of fire, spark or open flame in the vicinity.

-Close the safety valve on the gas bottle.

-Open doors and windows to air out the vehicle.

-If the source of the gas smell cannot be eliminated, do not connect the gas bottle. Have the gas system checked by a quali-fied workshop.

Open the stowage compartment door at the rear of the vehicle on the left. 11>

Equipment, California I 235

Page 236 of 486

Remove the central and lower shelves from the stowage compartment.

Unscrew the cover on the gas bottle holder com-pletely and remove it.

Make sure that the bottle safety valve 199 G) is completely closed. This prevents gas from leaking when the union nut® is slack-ened.

Completely unscrew the union nut of the pressure regulator from the bottle safety valve by turning it clockwise.

Lift out the gas bottle together with the wedge.

Connecting a new gas bottle 235

Turning the gas cooker on and off

B7H·0274

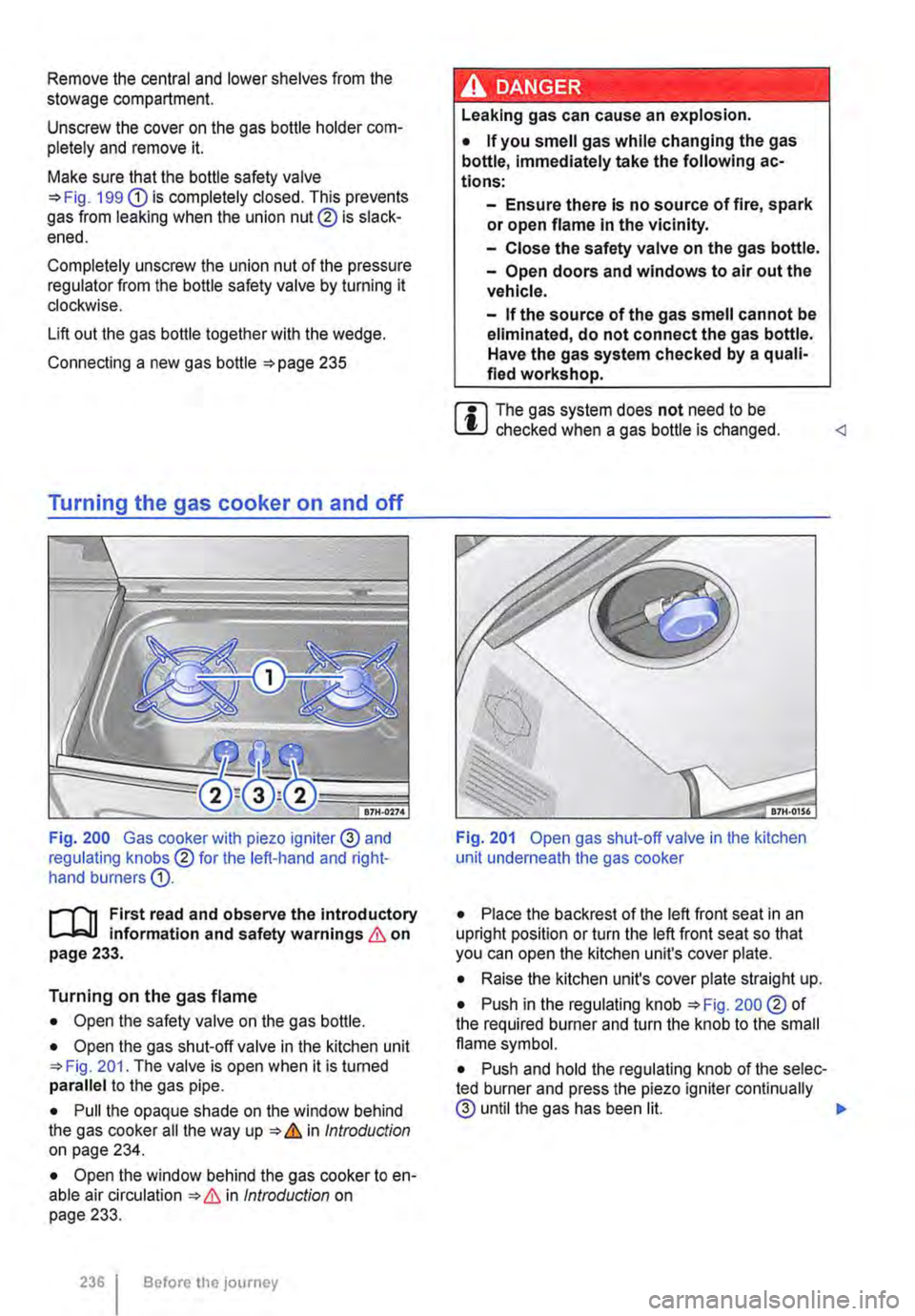

Fig. 200 Gas cooker with piezo igniter 0 and regulating knobs® for the left-hand and right-hand burners G).

i""""('n First read and observe the introductory information and safety warnings & on page 233.

Turning on the gas flame

• Open the safety valve on the gas bottle.

• Open the gas shut-off valve in the kitchen unit 201. The valve is open when it is turned parallel to the gas pipe.

• Pull the opaque shade on the window behind the gas cooker all the way up & in Introduction on page 234.

• Open the window behind the gas cooker to en-able air circulation & in Introduction on page 233.

236 Before the journey

Leaking gas can cause an explosion.

• If you smell gas while changing the gas bottle, immediately take the following ac-tions:

-Ensure there is no source of fire, spark or open flame In the vicinity.

-Close the safety valve on the gas bottle.

-Open doors and windows to air out the vehicle.

-If the source of the gas smell cannot be eliminated, do not connect the gas bottle. Have the gas system checked by a quali-fied workshop.

m The gas system does not need to be L!J checked when a gas bottle is changed.

• Place the backrest of the left front seat in an upright position or turn the left front seat so that you can open the kitchen unit's cover plate.

• Raise the kitchen unit's cover plate straight up.

• Push in the regulating knob 200 ®of the required burner and turn the knob to the small flame symbol.

• Push and hold the regulating knob of the selec-ted burner and press the piezo igniter continually 0 until the gas has been lit. .,.

Page 237 of 486

• Keep the knob pressed in for approx. 15 sec-onds to temporarily bridge the igniter safety device. If you let go of the knob too quickly, the gas flame goes out. If this occurs, re-light the burner as de-scribed above.

• Release the regulating knob and adjust the gas flame as required.

Turning off the gas flame

• Turn the appropriate knob@ fully clockwise to turn off the gas flame.

• Close the gas shut-off valve in the kitchen unit.

• Close the safety valve on the gas bottle.

• Remove all objects from the gas cooker and al-low the cooker to cool fully.

• Place the backrest of the left front seat in an upright position or turn the left front seat so that you can close the kitchen unit's cover plate.

• Lower the kitchen unit cover plate and latch it securely. <1

Water supply and disposal, California

n::n Introduction

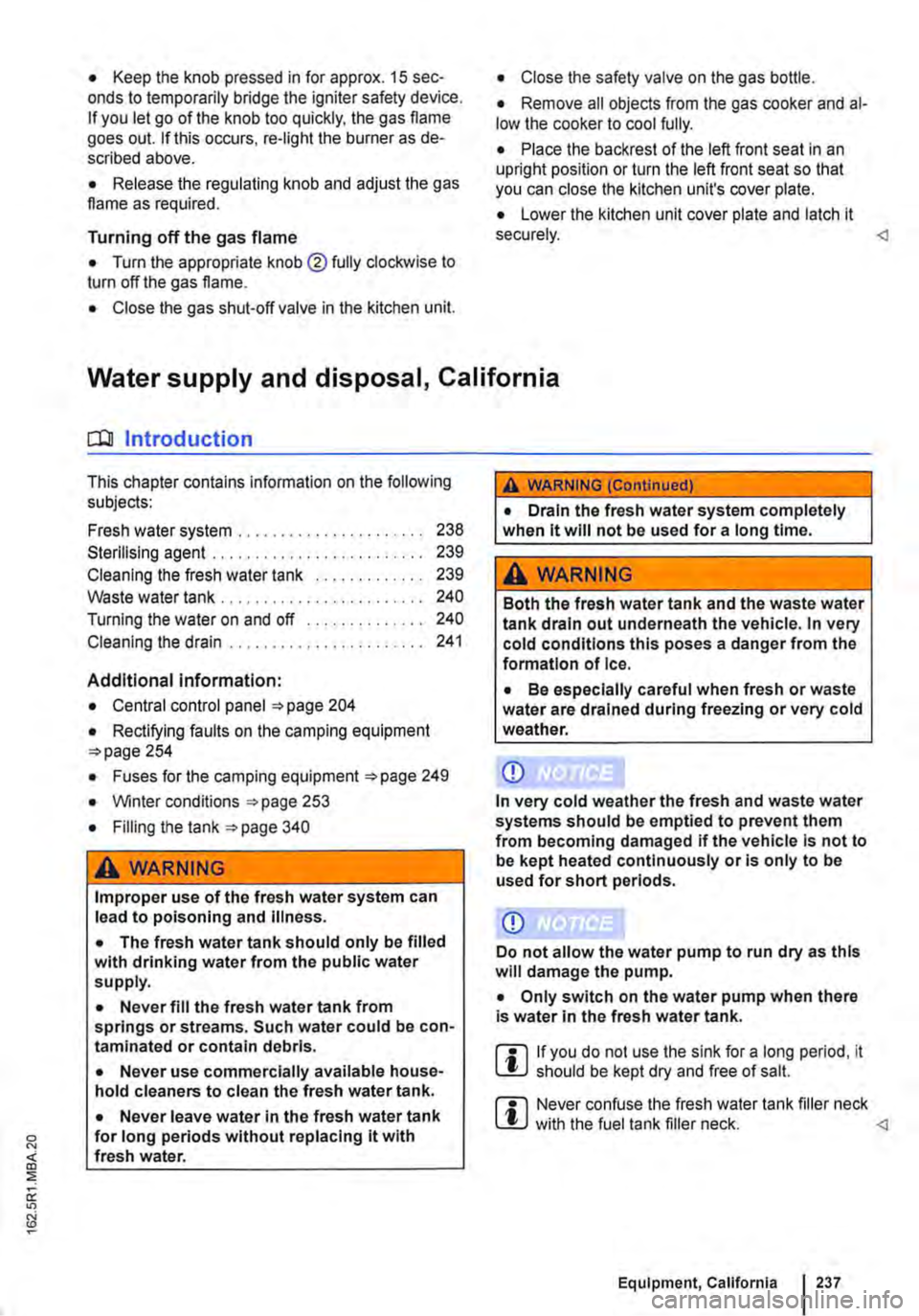

This chapter contains information on the following subjects:

Fresh water system . . . . . . . . . . . . . . . . . . . . . . 238

Sterilising agent . . . . . . . . . . . . . . . . • . . . . . . . . 239

Cleaning the fresh water tank . . . . . . . . . . . . . 239 Waste water tank . . . . . . . . . . . . . . . . . . . . . . . . 240

Turning the water on and off . . . . . . . . . . . . . . 240

Cleaning the drain . . . . . . . . . . . . . . . . . . . . . . . 241

Additional information:

• Central control panel 204

• Rectifying faults on the camping equipment 254

• Fuses for the camping equipment 249

• Winter conditions 253

• Filling the tank 340

A WARNING

Improper use of the fresh water system can lead to poisoning and illness.

• The fresh water tank should only be filled with drinking water from the public water supply.

• Never fill the fresh water tank from springs or streams. Such water could be con-taminated or contain debris.

• Never use commercially available house-hold cleaners to clean the fresh water tank.

• Never leave water in the fresh water tank for long periods without replacing it with fresh water.

,A WARNING (Continued)

• Drain the fresh water system completely when it will not be used for a long time.

A WARNING

Both the fresh water tank and the waste water tank drain out underneath the vehicle. In very cold conditions this poses a danger from the formation of ice.

• Be especially careful when fresh or waste water are drained during freezing or very cold weather.

CD

In very cold weather the fresh and waste water systems should be emptied to prevent them from becoming damaged if the vehicle is not to be kept heated continuously or Is only to be used for short periods.

CD

Do not allow the water pump to run dry as this will damage the pump.

• Only switch on the water pump when there Is water in the fresh water tank.

m if you do not use the sink for a long period' it L.:!J should be kept dry and free of salt.

m Never confuse the fresh water tank filler neck L.:!J with the fuel tank filler neck. <1

Equipment, California 237

Page 239 of 486

Sterilising agent

f"""('n First read and observe the Introductory L-J,:,U information and safety warnings & on page 237.

Volkswagen Commercial Vehicles recommends adding a sterilising agent to the fresh water through the fresh water filler neck =>&.After add-ing sterilising agent, turn on the tap and allow ap-proximately one litre of water to run out and down the drain. This will distribute the sterilising agent through the fresh water system.

You may also pour sterilising agent down the sink, followed by a little water, to sterilize the waste wa-ter tank.

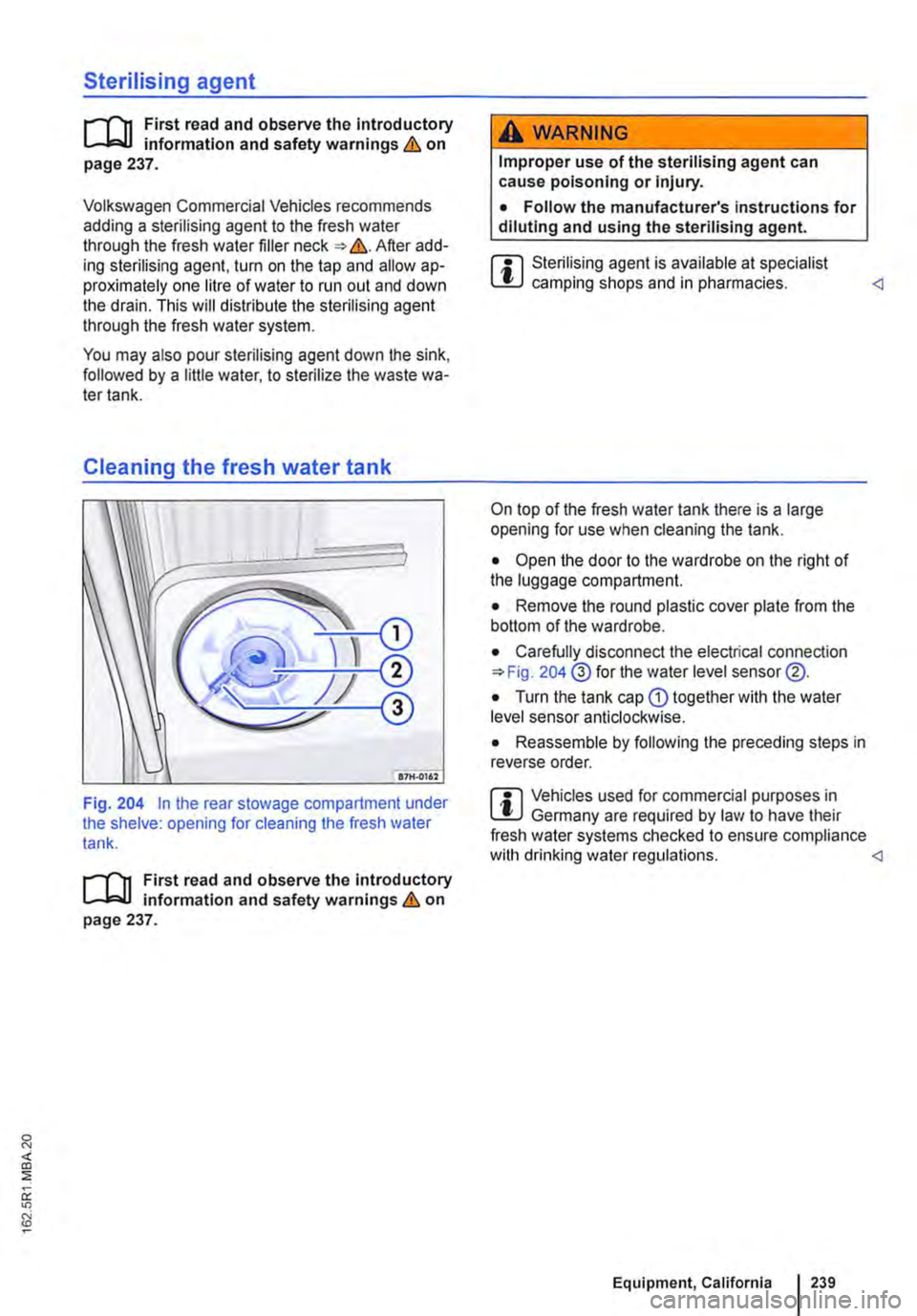

Cleaning the fresh water tank

Fig. 204 In the rear stowage compartment under the shelve: opening for cleaning the fresh water tank.

f"""('n First read and observe the introductory l-J,:,,J information and safety warnings & on page 237.

A WARNING

Improper use of the sterilising agent can cause poisoning or Injury.

• Follow the manufacturer's instructions for diluting and using the sterilising agent.

m Sterilising agent is available at specialist L!J camping shops and in pharmacies.

• Open the door to the wardrobe on the right of the luggage compartment.

• Remove the round plastic cover plate from the bottom of the wardrobe.

• Carefully disconnect the electrical connection =>Fig. 204@ for the water level sensor@.

• Turn the tank cap Q) together with the water level sensor anticlockwise.

• Reassemble by following the preceding steps in reverse order.

m Vehicles used for commercial purposes in L!J Germany are required by law to have their fresh water systems checked to ensure compliance with drinking water regulations.

Page 250 of 486

A WARNING (Continued)

• Never fit fuses that have a higher fuse pro-tection limit. Fuses must always be replaced by a new fuse with the same amp rating (same colour and markings) and size.

• Never repair a fuse.

• Never use a metal strip, paper clip or simi-lar objects to replace a fuse.

CD

• To avoid damage to the electrical system in the vehicle, switch the ignition, the lights and all electrical consumers off and remove the ve-hicle key from the ignition before changing a fuse.

• You can damage another position in the electrical system by using a fuse with a higher amp rating.

• Fuse boxes must be protected from dirt and moisture when opened. Dirt and moisture in the fuse boxes can damage the electrical system.

o::n Introduction

This chapter contains information on the following subjects:

Controls for the living area 250

Controls for the living area

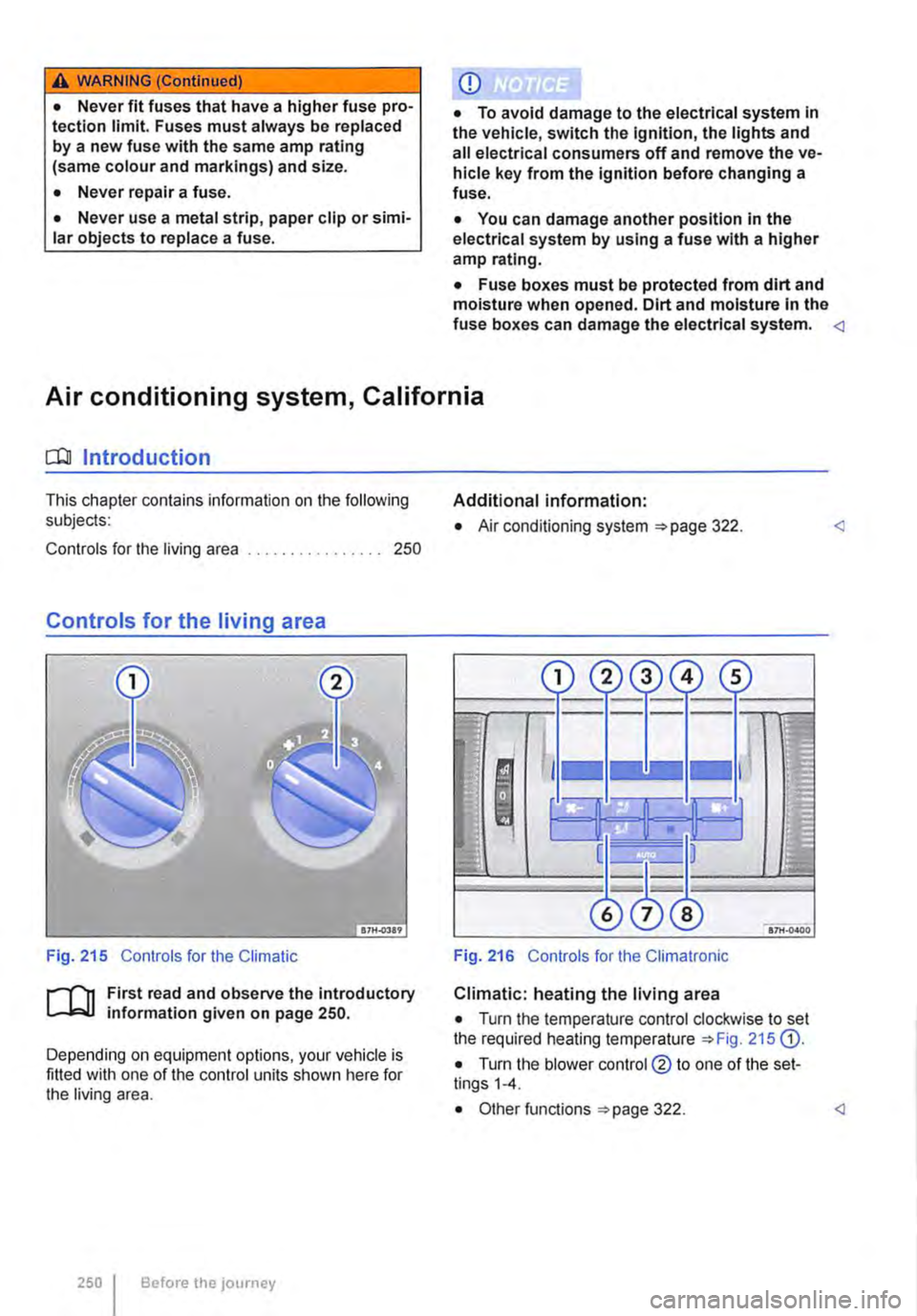

Fig. 215 Controls for the Climatic

ifl1 First read and observe the introductory L-.J.=.IJ information given on page 250.

Depending on equipment options, your vehicle is fitted with one of the control units shown here for the living area.

250 I Before the journey

Additional information:

• Air conditioning system 322.

Fig. 216 Controls for the Climatronic

Climatic: heating the living area

• Turn the temperature control clockwise to set the required heating temperature 215 G).

• Turn the blower control @ to one of the set-tings 1-4.

Page 281 of 486

Steering

CJ:n Introduction

This chapter contains information on the following subjects:

Information on steering . . . . . . . . . . . . . . . . . . . 281

Additional information and warnings:

• Starting and stopping the engine 257

• Battery 362

• Tow-starting and towing 446

Information on steering

r--f"n First read and observe the introductory L-la.LI infonmation and safety warnings & on page 281.

Locking the steering wheel

• When the vehicle key has been removed, turn the steering wheel slightly until you hear the lock-ing pin engage.

The steering should be locked every time you leave the vehicle to make il more difficult for the vehicle to be stolen.

Unlocking the steering wheel

• Turn the steering wheel slightly to lake the load off the steering lock mechanism. Hold the steering wheel in this position and tu m the vehicle key clockwise out of position 217 @.

A WARNING

If the power steering is not working, the steering wheel is difficult to turn, which makes it difficult to steer the vehicle.

• The power steering only functions when the engine Is running.

• Never allow the vehicle to roll if the engine is switched off.

• Never remove the vehicle key from the ig-nition lock when the vehicle is in motion. The steering lock may be activated and you will no longer be able to steer the vehicle.

With power steering, the steering assistance is au-tomatically matched to vehicle speed, the steering wheel torque and the steering wheel angle. The power steering will only function when the engine is running.

You will need considerably more strength than nor-mal to steer the vehicle if lhe power steering is re-duced or has failed completely.