clock VOLKSWAGEN TRANSPORTER 2015 Owner´s Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 2015, Model line: TRANSPORTER, Model: VOLKSWAGEN TRANSPORTER 2015Pages: 486, PDF Size: 72.17 MB

Page 337 of 486

Action Indicator lamp Fig. 267

Attempt to switch on: lights up orange for approximately Attempt to switch on or off using button @ or@ when the battery in the remote con-trol is low. The auxiliary coolant heater is blocked bl.

2 seconds, then flashes green in very short intervals for an-other 2 seconds. The switch-on signal is not processed. Attempt to switch off: lights up orange for approximately 2 seconds, then turns red for another 2 seconds. The switch-off signal is not processed.

Attempt to switch on or off using button @ or@ when the battery in the remote con-trol is empty.

Flashes orange in very short intervals for approximately 5 seconds. The switch-on or switch-off signal is not pro-cessed.

•> If you are at the edge of the receiving range, the remote control may not be able to receive the confirmation signal from the sen-sor in the vehicle. If this is the case, the remote control will show a fault even though the supplementary heating system has ac-tually been switched on or off. Move closer to the vehicle and try pressing the corresponding button on the remote control again.

b) If the automatic switch-off for electrical consumers page 365 is activated or if the reserve level in lhe fuel tank page 340 has been reached, the auxiliary coolant heater may be blocked automatically.

Settings for remote control

The supplementary heating system is activated or deactivated by means of the remote control. The Start Time menu can be used to program the oper-ating duration and the heating level (auxiliary air heater) or the operating mode (auxiliary coolant heater).

• Press any button on the roof display to activate the roof display.

• Press and hold down the (ill) button for several seconds.

• Press the function button ...... or ,... as often as necessary until "REMOTE CONT." is displayed.

• Press the (ill) button to confirm.

• Press the function button ...... or ,... until the re-quired temperature or mode is displayed.

• Press the (ill) button to confirm the selected heating level or operating mode. The operating du-ration menu is displayed.

• Press the function button ...... or ,... until the re-quired operating duration is displayed.

• Press button @)to confirm the operating dura-tion. A summary of the settings is displayed.

Replacing the battery for the remote control

Auxiliary air heater: the battery is located on the back of the remote control underneath a cover 266 [ID. Pull off the cover® towards the rear.

Auxiliary coolant heater: the battery is located on the back of the remote control underneath a cover 267 [ID. Use a flat object, e.g. a coin, to turn the slot anti-clockwise in order to open the cover

®-

When changing the batteries, ensure you insert them the right way (poles) and that they are the same type

Range

The receiver is located in the vehicle interior. The remote control key has a range of several hundred metres when the battery is fully charged. The range of the remote control key can be considera-bly reduced by obstacles between the remote con-trol key and the vehicle, bad weather conditions, and a flat battery.

To achieve optimal range, hold the remote control vertically with the aerial 266 or 267 at the top. Do not hold the aer-ial with your fingers or the palm of your hand.

The distance between the remote control and the vehicle must be at least 2 metres.

CD

• The remote control contains electronic com-ponents. Protect the remote control from mois-ture, excessive vibration and direct sunlight.

• Unsuitable batteries can damage the remote control. Only replace discharged batteries with a new battery of the same voltage rating, size and specification.

Discharged batteries must be disposed of in W accordance with regulations governing the protection of the environment.

The battery in the remote control may contain W perchlorate. Please comply with legislation regarding disposal.

m Protect the remote control against inadver-L!.J tent operation in order to prevent the supple-mentary heater from being switched on uninten-

Air conditioning system I 337

Page 342 of 486

A WARNING_tContlnued)

• The power steering, all driver assist sys-tems and brake assist systems will not func-tion if the engine "sputters" or stops com-pletely due to a lack of fuel or Irregular fuel supply.

• Always fill the tank when it is stlll1/4 full. This reduces the risk of running out of fuel and breaking down.

Filling the tank with petrol or diesel

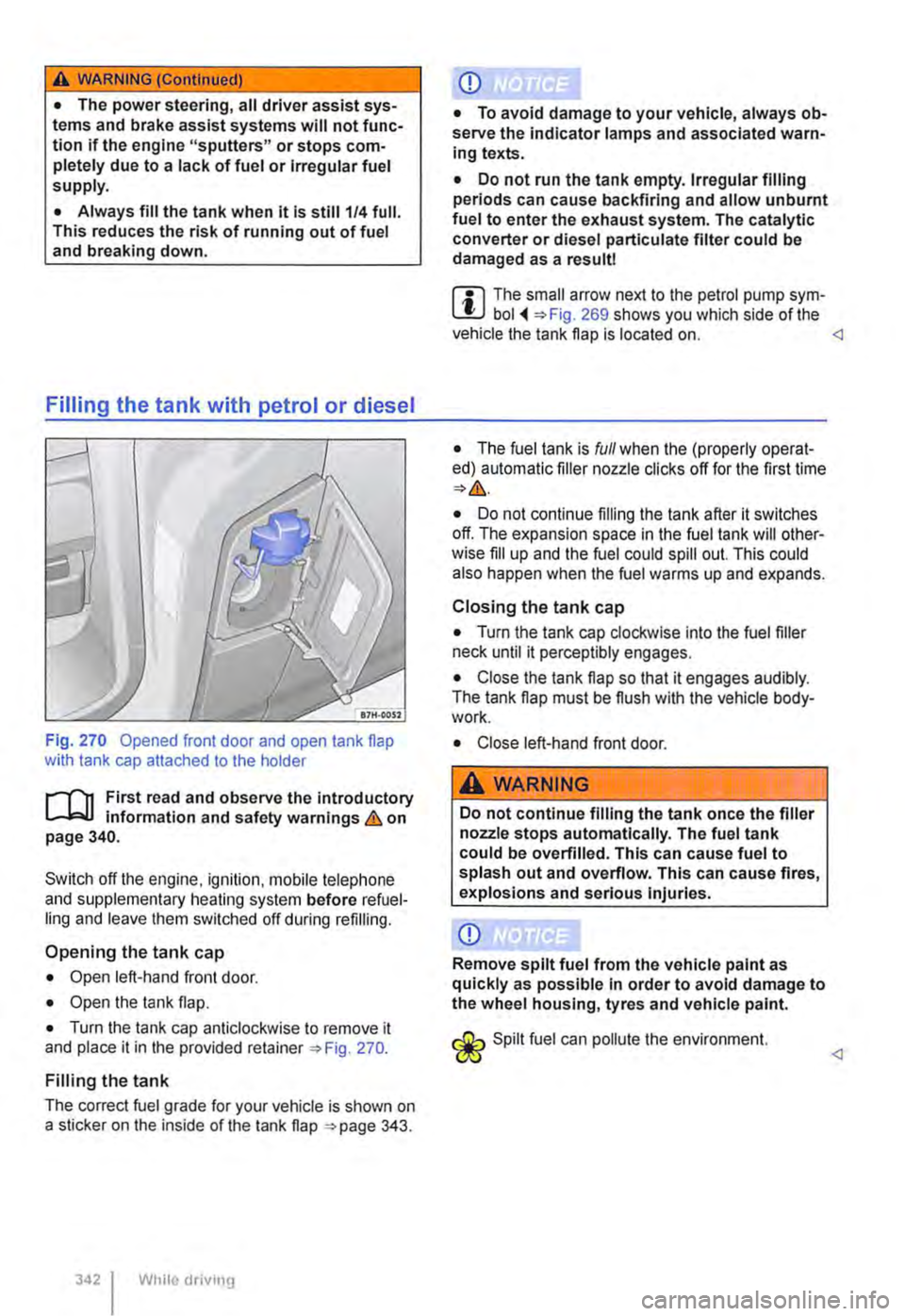

Fig. 270 Opened front door and open tank flap with tank cap attached to the holder

r--f"'n First read and observe the introductory L-.1=.1.1 information and safety warnings & on page 340.

Switch off the engine, ignilion. mobile lelephone and supplementary heating system before refuel-ling and leave them switched off during refilling.

Opening the tank cap

• Open left-hand front door.

• Open the lank flap.

• Turn the tank cap anticlockwise to remove it and place it in the provided retainer 270.

Filling the tank

The correct fuel grade for your vehicle is shown on a sticker on the inside of the tank flap 343.

While driv111g

Q)

• To avoid damage to your vehicle, always ob-serve the indicator lamps and associated warn-ing texts.

• Do not run the tank empty. Irregular filling periods can cause backfiring and allow unburnt fuel to enter the exhaust system. The catalytic converter or diesel partlculate filter could be damaged as a result!

m The small arrow next to the petrol pump sym-L!J bol 269 shows you which side of the vehicle the tank flap is located on.

• The fuel tank is full when the (properly operat-ed) automatic filler nozzle clicks off for the first time

• Do not continue filling the tank after it switches off. The expansion space in the fuel tank will other-wise fill up and the fuel could spill out. This could also happen when the fuel warms up and expands.

Closing the tank cap

• Turn the tank cap clockwise into the fuel filler neck until it perceptibly engages.

• Close the tank flap so that it engages audibly. The tank flap must be flush with the vehicle body-work.

• Close left-hand front door.

A WARNING

Do not continue filling the tank once the filler nozzle stops automatically. The fuel tank could be overfilled. This can cause fuel to splash out and overflow. This can cause fires, explosions and serious Injuries.

Q)

Remove spilt fuel from the vehicle paint as quickly as possible in order to avoid damage to the wheel housing, tyres and vehicle paint.

Spilt fuel can pollute lhe environment.

Page 348 of 486

![VOLKSWAGEN TRANSPORTER 2015 Owner´s Manual Refilling AdBiue®

Fig. 271 Behind the tank flap: filler cap of the Ad Blue tank unscrewed [A CD and attached in holder [[ ®. Fill the Ad Blue tank using a filler bottle [B@ or a filler nozzle C] @. VOLKSWAGEN TRANSPORTER 2015 Owner´s Manual Refilling AdBiue®

Fig. 271 Behind the tank flap: filler cap of the Ad Blue tank unscrewed [A CD and attached in holder [[ ®. Fill the Ad Blue tank using a filler bottle [B@ or a filler nozzle C] @.](/img/18/40253/w960_40253-347.png)

Refilling AdBiue®

Fig. 271 Behind the tank flap: filler cap of the Ad Blue tank unscrewed [A CD and attached in holder [[ ®. Fill the Ad Blue tank using a filler bottle [B@ or a filler nozzle C] @.

,....-.('n First read and observe the Introductory 1.-J=,U Information and safety warnings & on page 346.

To refill with Ad Blue®, park the vehicle on a level surface and not on any kind of incline. The tank level gauge may not detect the refill quantity cor-rectly if the vehicle is not parked on a level surface.

Do not fill fuel and AdBiue® at the same lime.

If a message about the Ad Blue® level appears on the instrument cluster display, refill with at least 7 litres of Ad Blue®. A smaller amount of refill is insufficient. if no message about the AdBiue® level appears on the instrument cluster display, use any quantity to refill the tank to the maximum level.

Opening the tank filler neck

• Opening the tank flap.

• Unscrew the cap of the tank filler neck =>Fig. 271 anticlockwise.

• Fit the cap of the filler neck into the holder]) @.

Use only Ad Blue® that complies with the stand-ard ISO 22241-1.

Refilling using a refill bottle

• Please read the manufacturer's notes and infor-mation on the refill bottle.

• Observe the expiry date.

• Remove the screw top of the refill bottle.

• Place the neck of the refill bottle =>Fig. 271 [ID @ vertically onto the tank filler neck and turn it clockwise hand-tight.

• Push the refill bottle towards the filler neck, press and hold down.

348 While driving

• Wait until the contents of the refill bottle have entered the Ad Blue® tank. Do not crumple up or damage the refill bottle!

• Unscrew the refill bottle anticlockwise and lift it carefully up and out =>CD.

• When the Ad Blue® tank is full, Ad Blue® will no longer flow out of the bottle and into the tank.

Refilling using a filler bottle

• Please read the manufacturer's notes and infor-mation on the container.

• Observe the expiry date.

• Use the integrated spout.

• Refill at least 7 litres of AdBiue®. A smaller amount of refill is insufficient.

• Do overfill the tank. The Ad Blue® tank is com-pletely filled when Ad Blue® reaches the top level of tank filler neck.

Refilling using a filler nozzle

• The procedure for refilling with an Ad Blue® filler nozzle =>Fig. 271 @]@) is the same as for refilling the fuel tank with fuel =>CD.

• The Ad Blue® tank is full as soon as the (proper-ly operated) filler nozzle clicks off for the first time =>CD.

Closing the tank filler neck

• Screw the cap onto the tank filler neck =>Fig. 271 clockwise until it clicks into place.

• Close the tank flap.

Page 351 of 486

A WARNING (Continued)

-Remove the vehicle key from the igni-tion lock.

-Always keep children away from the en-gine compartment and never leave the ve-hicle unattended.

• The engine cooling system Is under pres-sure when the engine Is hot. Never open the cap of the coolant expansion tank when the engine Is hot. Coolant may spray out and cause serious burns and other Injuries.

-Turn the cap slowly and very carefully anti-clockwise while exerting gentle down-ward pressure on the cap.

-Always protect the face, hands and arms from hot coolant or steam with a large, thick cloth.

• When refilling, do not spill any service flu-ids on engine components or on the exhaust system. The spilt service fluids can start a fire.

A WARNING

High voltages in the electrical system can cause electric shocks, burns, serious injuries and death!

• Never short circuit the electric system. The vehicle battery could explode.

• Please note the following guidelines to help reduce the risk of an electric shock and serious Injuries while the engine is running or being started:

-Never touch the electrical wiring of the Ignition system.

A WARNING

There are rotating components in the engine compartment that can cause serious injury.

• Never place your hand near these compo-nents or In the radiator fan. Touching the ro-tary blades can result in serious injuries. The fan Is temperature-controlled and can start automatically, even if the engine has been switched off and the vehicle key has been re-moved from the ignition lock.

• If any work has to be performed when the engine Is started or with the engine running, there is an additional, potentially fatal, safety risk from the rotating parts, such as the drive belts, alternator, radiator fan, etc., and from the high-voltage ignition system. Always be particularly careful.

A WARNING (Continued)

-Always ensure that no body parts, jew-ellery, ties, loose items of clothing or long hair can be caught up in rotating engine components. Before starting work, re-move any jewellery and ties, tie up long hair and pull clothes In tightly to avoid them getting caught In the engine com-partment.

-Always depress the accelerator careful-ly and never without due consideration. The vehicle can start to move even if the handbrake is applied.

• Always ensure that you have not left any objects, such as cleaning cloths and tools, in the engine compartment. Any forgotten items can cause malfunctions, engine damage and fires.

A WARNING

Additional insulating materials such as cov-ers in the engine compartment could disrupt the operation of the engine, cause damage and lead to severe Injuries.

• Never cover the engine with any Insulating materials.

A WARNING

Service fluids and some materials In the en-glne compartment are highly flammable and can cause fires and serious Injuries!

• Never smoke while working on the vehl-cl e.

• Never work near naked flames or sparks .

• Never spill fluids onto the engine. They could Ignite on hot engine components and hence cause injuries.

• Please note the following when carrying out any work on the fuel system or the elec-trlcal system:

-Always disconnect the vehicle battery. Ensure that the vehicle Is unlocked when the vehicle battery Is disconnected as oth-erwlse the anti-theft alarm will be activa-ted.

-Never work in the direct proximity of heating systems, water heaters or any oth-er open flames.

• Always have a fully functional and tested fire extinguisher to hand.

In the engine compartment I 351

...

Page 362 of 486

A WARNING (Continued)

-Always keep children away from the en-gine compartment and never leave the ve-hicle unattended.

• The engine cooling system is under pres-sure when the engine is hot. Never open the cap of the coolant expansion tank when the engine is hot. Coolant may spray out and cause serious burns and other injuries.

-Turn the cap slowly and very carefully anti-clockwise while exerting gentle down-ward pressure on the cap.

-Always protect the face, hands and arms from hot coolant or steam with a large, thick cloth.

• When refilling, do not spill any service flu-ids on engine components or on the exhaust system. The spilt service fluids can start a fire. In certain circumstances, the ethylene glycol in the engine can catch fire.

CD

• Refill only with distilled water. All other types of water can cause corrosion in the en-gine due to the chemical components con-

Vehicle battery

CQJ Introduction

This chapter conlains information on the following subjects:

Warning lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . 364

Checking the electrolyte level of the vehicle battery ................................. 364 Charging, replacing, disconnecling and connecting the vehicle battery . . . . . . . . . . . . . 365

The vehicle battery is a component of the electrical system in the vehicle.

Never carry out any work on the electrical system if you are not familiar with the necessary procedures and the general safety requirements and only un-suitable tools are available => &. The work should be carried out by a qualified workshop if you are uncertain. Volkswagen Commercial Vehicles rec-ommends using a Volkswagen Commercial Vehi-cles dealership for this purpose. Serious injuries can be caused if work is carried out incorrectly.

3621 Cleaning and maintenance

(j)

tained therein. This can also lead to engine fail-ure. If any other type of water is refilled, the flu-id in the engine cooling system should be com-pletely replaced immediately by a qualified workshop.

• Do not fill coolant above the top of the marked area =>Fig. 277. Otherwise the excess coolant will be pressed out of the cooling sys-tem when the engine is hot and could cause damage.

• If a large amount of coolant has been lost, do not refill the coolant until the engine has cooled completely. Heavy coolant loss is an in-dication of leaks in the engine cooling system. The engine cooling system should be checked by a qualified workshop as soon as possible. Failure to do so can result in engine damage.

• Do not top up with coolant if there is no more coolant in the coolant expansion tank. Air could enter the cooling system. Do not drive on! Seek expert assistance. Failure to do so can result in engine damage.

• When refilling service fluids, please ensure that the correct container is filled. The use of incorrect service fluids can result In serious faults and engine damage.

The vehicle battery is located on the left of the en-gine compartment.

Depending on the vehicle equipment level, the ve-hicle could have two vehicle batteries. Camper vans can have up to three vehicle batteries. The second vehicle battery is located under the left front seat: the third battery in camper vans is loca-ted in the wardrobe on the rear left of the vehicle. •

Page 421 of 486

Checklist (Continued)

8. VI/hen towing a trailer, unhitch the trailer from the vehicle and park it properly.

9. Remove any items of luggage from the lug-gage compartment.

10. Remove the spare wheel and vehicle tools from the vehicle.

11. Remove the hubcaps =>page 417.

Wheel bolts

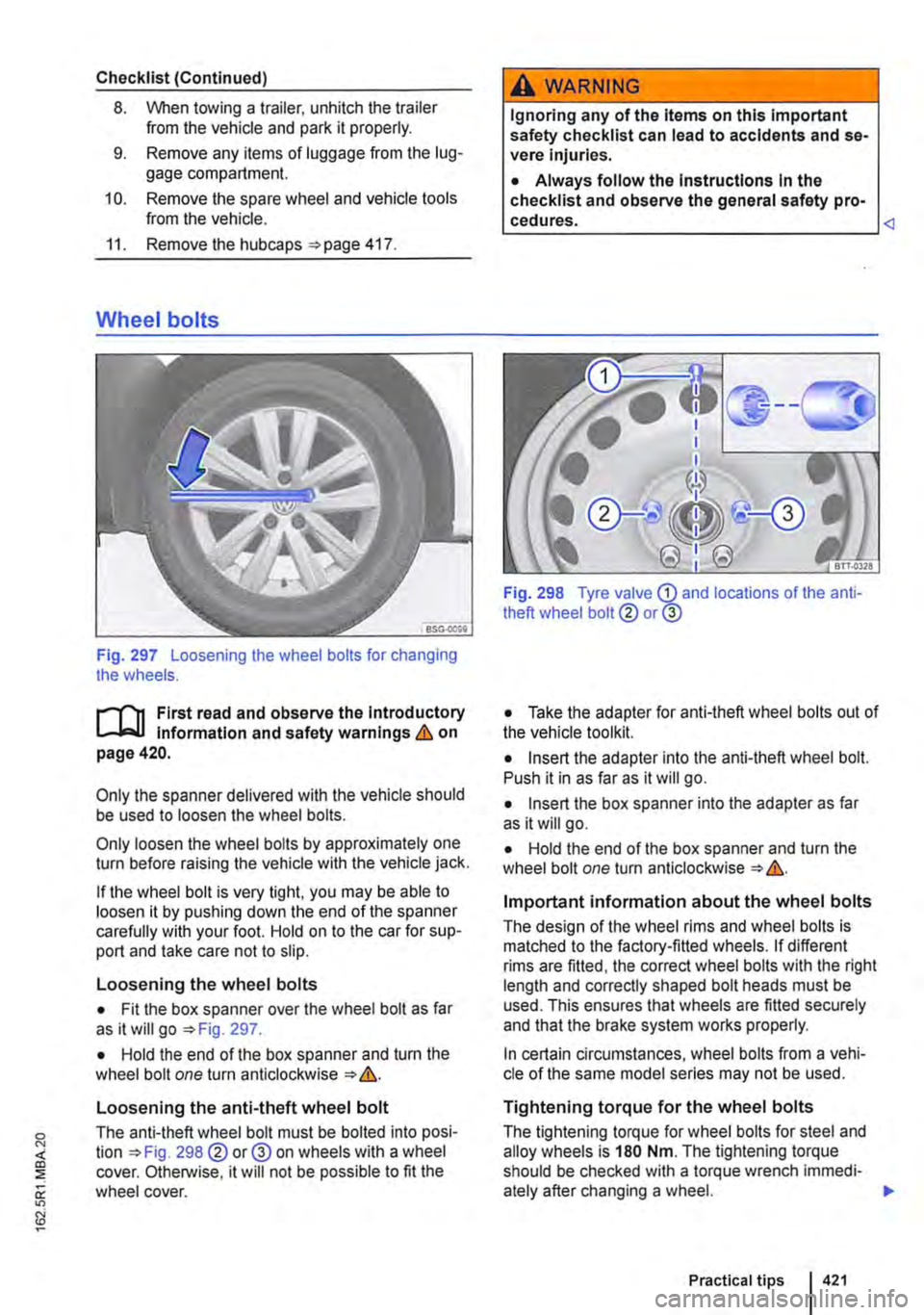

Fig. 297 Loosening the wheel bolts for changing the wheels.

r-"f"'n First read and observe the Introductory l.-J,:..LJ Information and safety warnings & on page420.

Only the spanner delivered with the vehicle should be used to loosen the wheel bolts.

Only loosen the wheel bolts by approximately one turn before raising the vehicle with the vehicle jack.

If the wheel bolt is very tight, you may be able to loosen it by pushing down the end of the spanner carefully with your foot. Hold on to the car for sup-port and take care not to slip.

Loosening the wheel bolts

• Fit the box spanner over the wheel bolt as far as it will go =>Fig. 297.

• Hold the end of the box spanner and turn the wheel bolt one turn anticlockwise => &.

Loosening the anti-theft wheel bolt

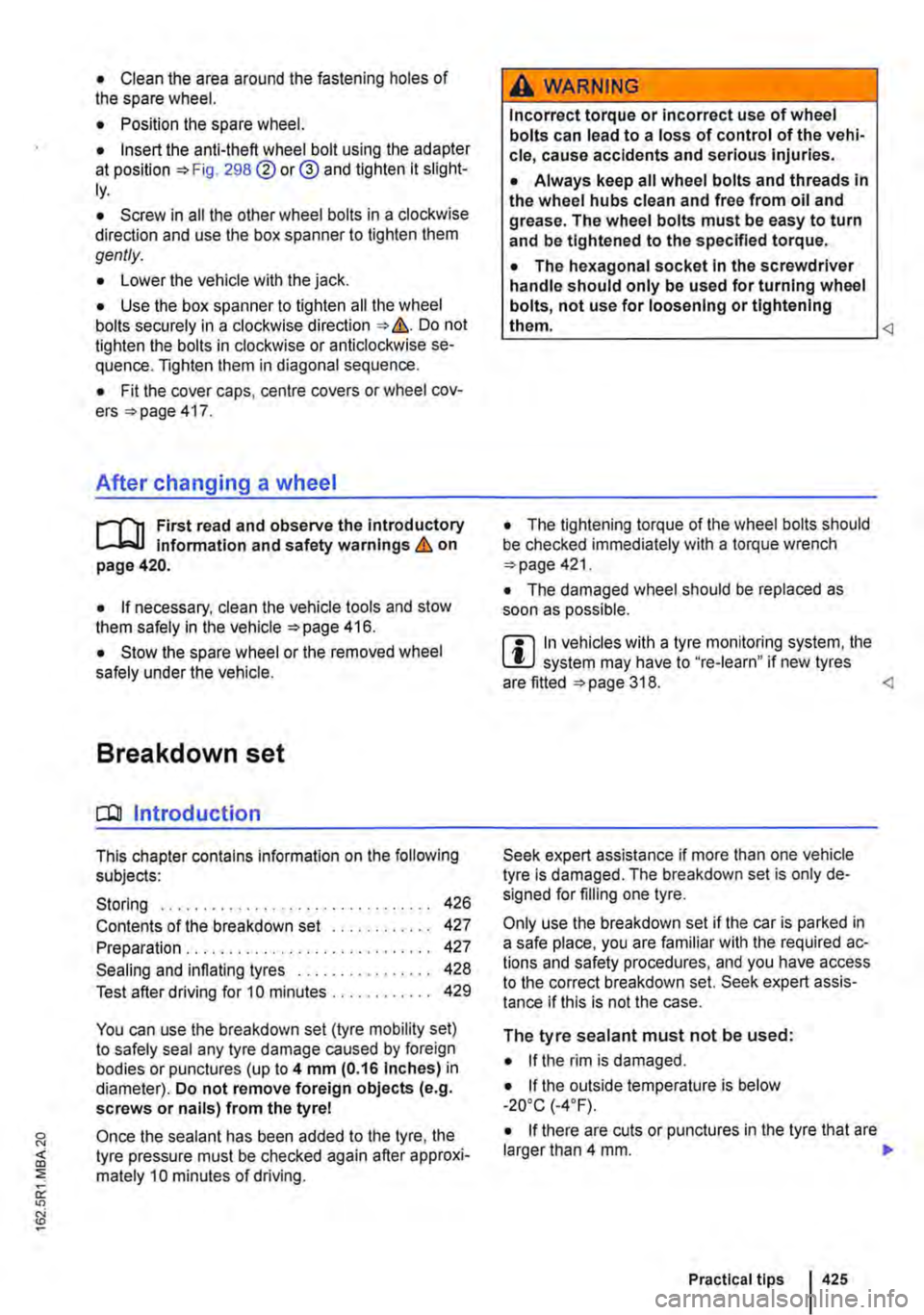

The anti-theft wheel bolt must be bolted into posi-tion =>Fig. 298@ or@ on wheels with a wheel cover. Otherwise, it will not be possible to fit the wheel cover.

A WARNING

Ignoring any of the Items on this Important safety checklist can lead to accidents and se-vere Injuries.

• Always follow the Instructions In the checklist and observe the general safety pro-

Fig. 298 Tyre valve G) and locations of the anti-theft wheel bolt@ or@

• Take the adapter for anti-theft wheel bolts out of the vehicle toolkit.

• Insert the adapter into the anti-theft wheel bolt. Push it in as far as it will go.

• Insert the box spanner into the adapter as far as it will go.

• Hold the end of the box spanner and turn the wheel bolt one turn anticlockwise => &.

Important information about the wheel bolts

The design of the wheel rims and wheel bolts is matched to the factory-fitted wheels. If different rims are fitted, the correct wheel bolts with the right length and correctly shaped bolt heads must be used. This ensures that wheels are fitted securely and that the brake system works properly.

In certain circumstances, wheel bolts from a vehi-cle of the same model series may not be used.

Tightening torque for the wheel bolts

The tightening torque for wheel bolts for steel and alloy wheels is 180 Nm. The tightening torque should be checked with a torque wrench immedi-ately after changing a wheel. .,.

Practical tips 421

Page 425 of 486

• Clean the area around the fastening holes of the spare wheel.

• Position the spare wheel.

• Insert the anti-theft wheel bolt using the adapter at position 298 @or® and tighten it slight-ly.

• Screw in all the other wheel bolts in a clockwise direction and use the box spanner to tighten them gently.

• Lower the vehicle with the jack.

• Use the box spanner to tighten all the wheel bolts securely in a clockwise direction &. Do not tighten the bolts in clockwise or anticlockwise se-quence. Tighten them in diagonal sequence.

• Fit the cover caps, centre covers or wheel cov-ers 417.

After changing a wheel

rl'l1 First read and observe the Introductory L-.lo:.ll Information and safety warnings & on page 420.

• If necessary, clean the vehicle tools and stow them safely in the vehicle 416.

• Stow the spare wheel or the removed wheel safely under the vehicle.

Breakdown set

CQJ Introduction

This chapter contains information on the following subjects:

Storing . . . . . . . . . . . . . . . . . . . . 426

Contents of the breakdown set . . . . . . . . . . . . 427 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . 427

Sealing and inflating tyres . . . . • . . . . . . . 428

Test after driving for 10 minutes . . . . 429

You can use the breakdown set (tyre mobility set) to safely seal any tyre damage caused by foreign bodies or punctures (up to 4 mm (0.16 Inches) in diameter). Do not remove foreign objects (e.g. screws or nails) from the tyrel

Once the sealant has been added to the tyre, the tyre pressure must be checked again after approxi-mately 10 minutes of driving.

,A WARNING

Incorrect torque or incorrect use of wheel bolts can lead to a loss of control of the vehi-cle, cause accidents and serious Injuries.

• Always keep all wheel bolts and threads In the wheel hubs clean and free from oil and grease. The wheel bolts must be easy to turn and be tightened to the specified torque.

• The hexagonal socket In the screwdriver handle should only be used for turning wheel bolts, not use for loosening or tightening them.

• The damaged wheel should be replaced as soon as possible.

m In vehicles with a tyre monitoring system, the L!..J system may have to "re-learn" if new tyres are fitted 318.

Only use the breakdown set if the car is parked in a safe place, you are familiar with the required ac-tions and safety procedures, and you have access to the correct breakdown set. Seek expert assis-tance if this is not the case.

The tyre sealant must not be used:

• If the rim is damaged.

• If the outside temperature is below -2o•c (-4 ·F).

• If there are cuts or punctures in the tyre that are larger than 4 mm. .,.

Practical tips 425

Page 428 of 486

A WARNING (Continued)

• Always follow the instructions In the checklist and observe the general safety pro-

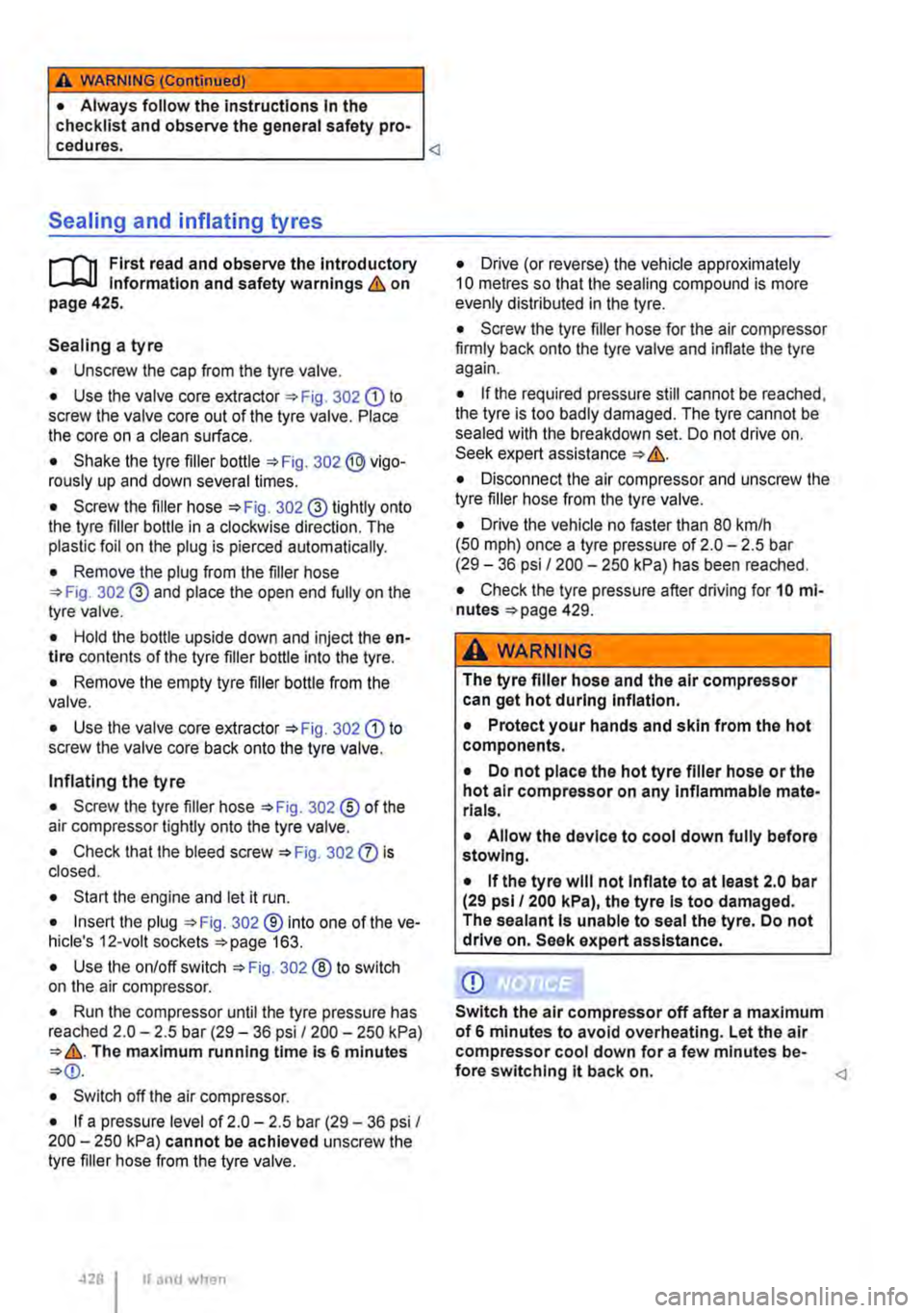

Sealing and inflating tyres

r-"'('n First read and observe the Introductory L-J,.:.U Information and safety warnings & on page 425.

Sealing a tyre

• Unscrew the cap from the tyre valve.

• Use the valve core extractor 302 CD to screw the valve core out of the tyre valve. Place the core on a clean surface.

• Shake the tyre filler bottle 302 ® vigo-rously up and down several times.

• Screw the filler hose 302 @tightly onto the tyre filler bottle in a clockwise direction. The plastic foil on the plug is pierced automatically.

• Remove the plug from the filler hose 302@ and place the open end fully on the tyre valve.

• Hold the bottle upside down and inject the en-tire contents of the tyre filler bottle into the tyre.

• Remove the empty tyre filler bottle from the valve.

• Use the valve core extractor 302 CD to screw the valve core back onto the tyre valve.

Inflating the tyre

• Screw the tyre filler hose 302 ® of the air compressor tightly onto the tyre valve.

• Check that the bleed screw 302 (?) is closed.

• Start the engine and let it run.

• Insert the plug 302 ®into one of the ve-hicle's 12-volt sockets 163.

• Use the on/off switch 302 ®to switch on the air compressor.

• Run the compressor until the tyre pressure has reached 2.0-2.5 bar (29-36 psi I 200-250 kPa) maximum running time is 6 minutes

• Switch off the air compressor.

• If a pressure level of 2.0-2.5 bar (29-36 psi I 200 -250 kPa) cannot be achieved unscrew the tyre filler hose from the tyre valve.

428 I If and when

• Drive (or reverse) the vehicle approximately 1 0 metres so that the sealing compound is more evenly distributed in the tyre.

• Screw the tyre filler hose for the air compressor firmly back onto the tyre valve and inflate the tyre again.

• If the required pressure still cannot be reached, the tyre is too badly damaged. The tyre cannot be sealed with the breakdown set. Do not drive on. Seek expert assistance &.

• Disconnect the air compressor and unscrew the tyre filler hose from the tyre valve.

• Drive the vehicle no faster than 80 km/h (50 mph) once a tyre pressure of 2.0-2.5 bar (29-36 psi I 200-250 kPa) has been reached.

• Check the tyre pressure after driving for 10 mi-nutes 429.

A WARNING

The tyre filler hose and the air compressor can get hot during Inflation.

• Protect your hands and skin from the hot components.

• Do not place the hot tyre filler hose or the hot air compressor on any Inflammable mate-rials.

• Allow the device to cool down fully before stowing.

• If the tyre will not Inflate to at least 2.0 bar (29 psi/ 200 kPa), the tyre Is too damaged. The sealant Is unable to seal the tyre. Do not drive on. Seek expert assistance.

CD

Switch the air compressor off after a maximum of 6 minutes to avoid overheating. Let the air compressor cool down for a few minutes be-fore switching it back on.

Page 436 of 486

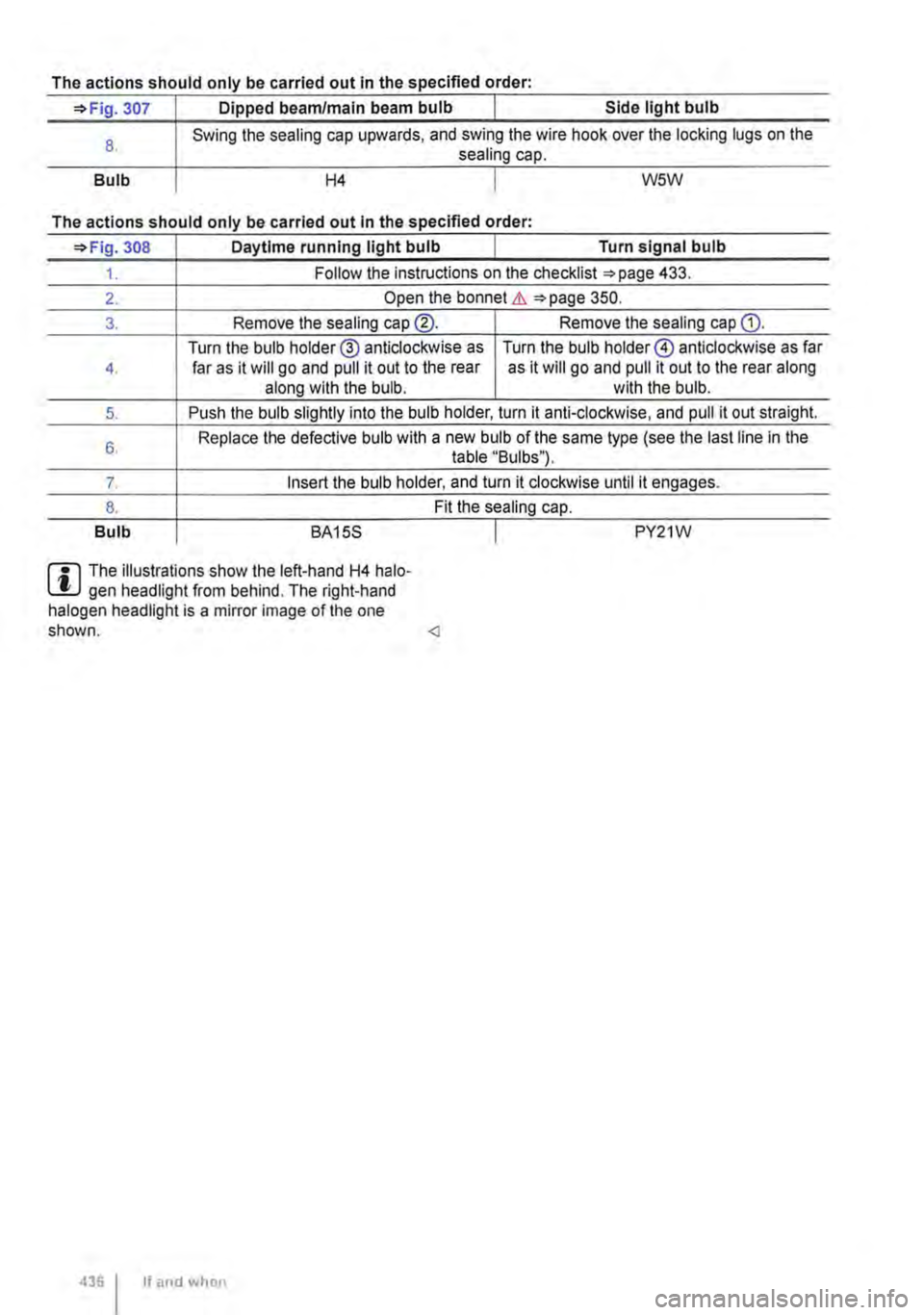

The actions should only be carried out in the specified order:

=>Fig. 307 Dipped beam/main beam bulb Side light bulb

8.

Bulb

Swing the sealing cap upwards, and swing the wire hook over the locking lugs on the sealing cap.

H4 W5W

The actions should only be carried out In the specified order·

=>Fig. 308 Daytime running light bulb Turn signal bulb

1. Follow the instructions on the checklist =>page 433.

2. Open the bonnet &. =>page 350.

3. Remove the sealing cap@. Remove the sealing cap Q).

Turn the bulb holder® anticlockwise as Turn the bulb holder@ anticlockwise as far 4. far as it will go and pull it out to the rear as it will go and pull it out to the rear along along with the bulb. with the bulb.

5. Push the bulb slightly into the bulb holder, turn it anti-clockwise, and pull it out straight.

6. Replace the defective bulb with a new bulb of the same type (see the last line in the table "Bulbs").

7. Insert the bulb holder, and turn it clockwise until it engages.

8. Fit the sealing cap.

Bulb BA15S I PY21W

m The illustrations show the left-hand H4 halo-L.!J gen headlight from behind. The right-hand halogen headlight is a mirror image of the one shown.

Page 439 of 486

The actions should only be carried out in the specified order·

311 Turn signal bulb

1. Observe and follow the instructions on the checklist ""page 433.

2. Open the bonnet.&. 350.

3. Remove the seating cap Q).

4. Release the connector@, and pull it off the bulb holder.

5. Turn the bulb holder@ anticlockwise as far as it will go and pull it out to the rear along with the bulb.

6. Push the bulb slightly into the bulb holder, turn it anti-clockwise, and pull it out straight.

7. Replace the defective bulb with a new bulb of the same type (see the last line in the table "Bulbs").

8. Insert the bulb holder into the headlight and turn it clockwise as far as it will go.

9. Fit the sealing cap.

Bulb H21W

m The illustrations show the left-hand LED W headlight from behind. The right-hand LED headlight is a mirror image of the one shown.

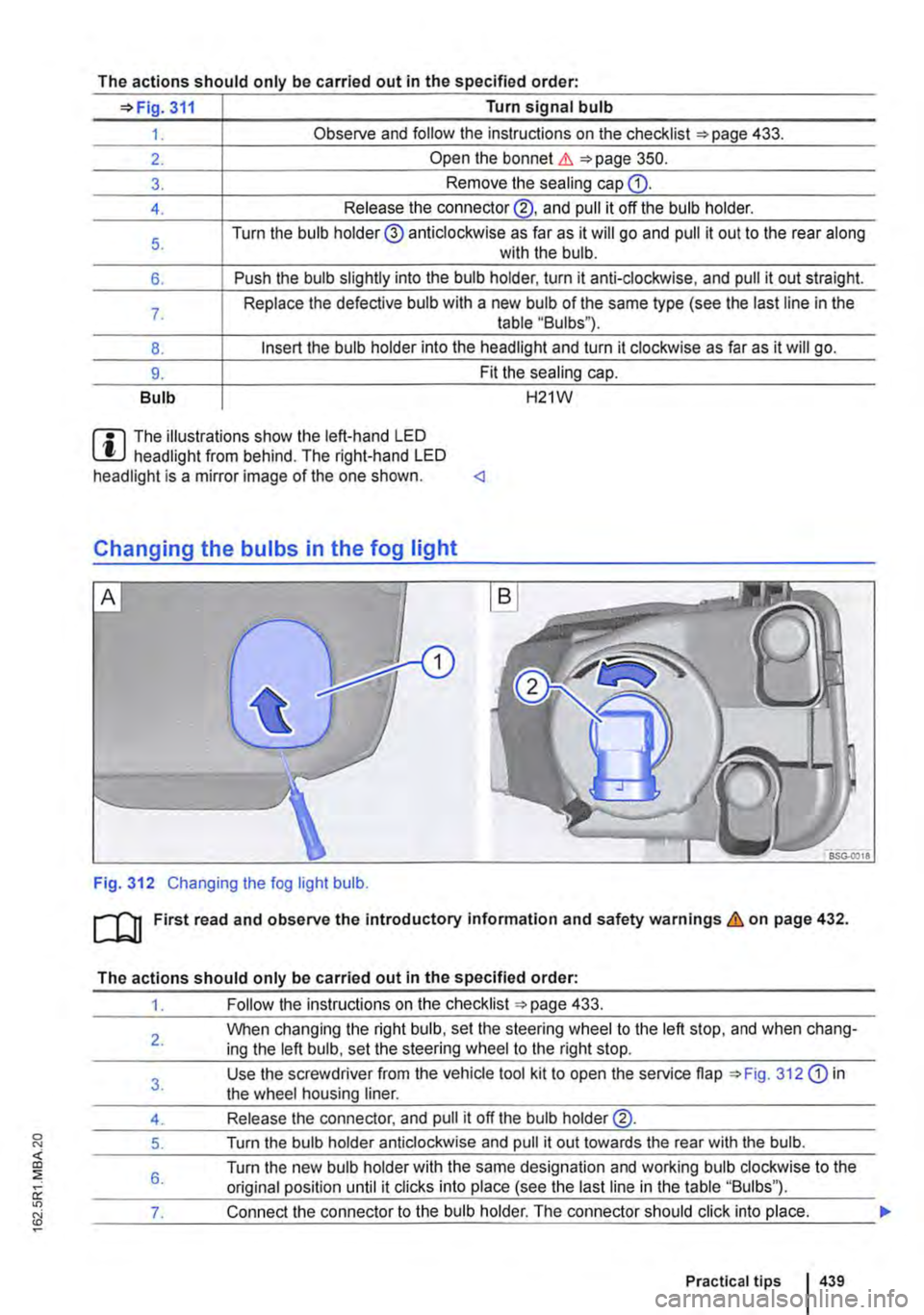

Fig. 312 Changing the fog light bulb.

m First read and observe the introductory information and safety warnings & on page 432.

The actions should only be carried out in the specified order:

1. Follow the instructions on the checklist 433.

2.

3.

4.

5.

6.

When changing the right bulb, set the steering wheel to the left stop, and when chang-ing the left bulb, set the steering wheel to the right stop.

Use the screwdriver from the vehicle tool kit to open the service flap 312 Q) in the wheel housing liner.

Release the connector, and pull it off the bulb holder@.

Turn the bulb holder anticlockwise and pull it out towards the rear with the bulb.

Turn the new bulb holder with the same designation and working bulb clockwise to the original position until it clicks into place (see the last line in the table "Bulbs").

__ ___:7...:.. ___ ..::.sh...:.o:...:u:....ld::.....:.c:...:lic.::.k:....i:....nt.:..:.o-"p-'-la:....c:..:e...:.. ___

Practical tips 439