gearbox VOLKSWAGEN TRANSPORTER 2015 Owner´s Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 2015, Model line: TRANSPORTER, Model: VOLKSWAGEN TRANSPORTER 2015Pages: 486, PDF Size: 72.17 MB

Page 398 of 486

Retrofitting two-way radios

.--m First read and observe the introductory L-.lc.U information and safety warnings & on page 394.

You will need an external aerial to use a two-way radio in the vehicle.

Any retrofit installation of electrical or electronic equipment in the vehicle will affect its vehicle type approval. Under certain circumstances, this can negate the type approval for the vehicle.

Volkswagen Commercial Vehicles has approved the vehicle for use with two-way radios providing the following conditions are observed:

• Correct installation of external aerial.

• A maximum transmitting power of 10 watts.

The equipment can only operate at maximum range with an external aerial.

Check first with a qualified workshop if you wish to use a two-way radio with a transmitting power of over 10 watts. Qualified workshops are familiar with the technical options for retrofitting. Volkswa-gen Commercial Vehicles recommends using a Volkswagen Commercial Vehicles dealership for this purpose.

Information stored in the control units

.--m First read and observe the introductory L-.lc.U Information and safety warnings & on page 394.

Your vehicle is factory fitted with electronic control units which are responsible for engine and gearbox management. The control units also monitor the function of the exhaust system and the airbags.

These electronic control units continuously evalu-ate data relevant to the vehicle while the vehicle is being driven. Only these data will be stored if there are any faults recorded or any deviations from the specified values. This is generally displayed by the indicator lamps on the instrument cluster.

Special units are required to read and evaluate da-ta stored in the control units.

These data are stored so that specialist workshops can diagnose and solve problems. The following data may have been stored:

• Engine and gearbox-relevant data.

• Speed.

• Direction of travel.

398 Cleaning and maintenance

Please comply with relevant legislation and the in-structions and information given in the operating manuals for radio equipment.

A WARNING

If radio equipment is not secured or not prop-erly secured in the vehicle, it could be flung though the interior during a sudden driving or braking manoeuvre, or In the event of an accident. This can cause Injuries.

• While the vehicle is in motion, always se-cure radio equipment properly outside the airbag deployment zone or stow them away safely.

A CAUTION

If you use two-way radios in the car without an external aerial, electromagnetic radiation in the vehicle could exceed limit values. This also applies to external aerials which have not been correctly installed.

• Two-way radios should only be used In the vehicle If an external aerial Is properly connected.

• Braking power.

• Seat belt monitor.

The control units never record conversations that take place in the vehicle. it is neither possible nor permitted to use the stored data to create move-ment profiles.

When the vehicle is being used, situations may arise in which the stored data (alone or in conjunc-tion with other information such as accident re-ports, vehicle damage, witness statements etc.) can become assignable to a particular person, whereby consultation of an expert and use of the expert's information may be necessary.

In vehicles with an emergency call function via a mobile telephone or other units, the current loca-tion can be transmitted. In the event of an accident in which the control units register that an airbag has been triggered, the system can automatically send out a signal. This depends on your service provider. Transmission is possible only in areas

Page 401 of 486

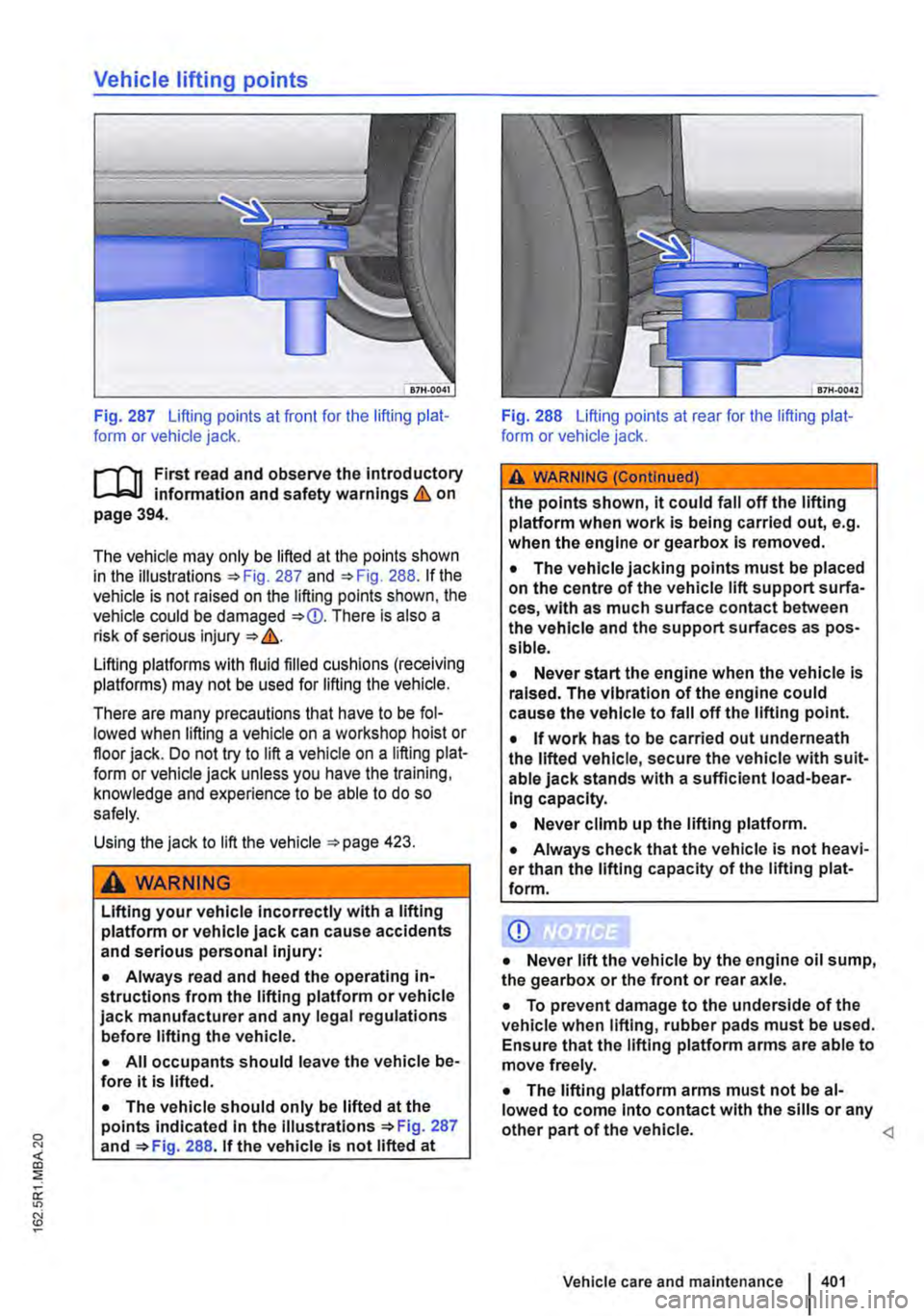

Vehicle lifting points

Fig. 287 Lifting points at front for the lifting plat-form or vehicle jack.

First read and observe the introductory l.-J,::..U information and safety warnings & on page 394.

The vehicle may only be lifted at the points shown in the illustrations =>Fig. 287 and =>Fig. 288. If the vehicle is not raised on the lifting points shown, the vehicle could be damaged =>

Lifting platforms with fluid filled cushions (receiving platforms) may not be used for lifting the vehicle.

There are many precautions that have to be fol-lowed when lifting a vehide on a workshop hoist or floor jack. Do not try to lift a vehicle on a lifting plat-form or vehicle jack unless you have the training, knowledge and experience to be able to do so safely.

Using the jack to lift the vehicle =>page 423.

A WARNING

Lifting your vehicle incorrectly with a lifting platform or vehicle jack can cause accidents and serious personal injury:

• Always read and heed the operating in-structions from the lifting platform or vehicle jack manufacturer and any legal regulations before lifting the vehicle.

• All occupants should leave the vehicle be-fore it is lifted.

• The vehicle should only be lifted at the points indicated In the illustrations =>Fig. 287 and =>Fig. 288. If the vehicle is not lifted at

Fig. 288 Lifting points at rear for lhe lifting plat-form or vehicle jack.

A WARNING_(Contlnued)

the points shown, it could fall off the lifting platform when work is being carried out, e.g. when the engine or gearbox is removed.

• The vehicle jacking points must be placed on the centre of the vehicle lift support surfa-ces, with as much surface contact between the vehicle and the support surfaces as pos-sible.

• Never start the engine when the vehicle is raised. The vibration of the engine could cause the vehicle to fall off the lifting point.

• If work has to be carried out underneath the lifted vehicle, secure the vehicle with suit-able jack stands with a sufficient load-bear-ing capacity.

• Never climb up the lifting platform.

• Always check that the vehicle is not heavi-er than the lifting capacity of the lifting plat-form.

CD

• Never lift the vehicle by the engine oil sump, the gearbox or the front or rear axle.

• To prevent damage to the underside of the vehicle when lifting, rubber pads must be used. Ensure that the lifting platform arms are able to move freely.

• The lifting platform arms must not be al-lowed to come Into contact with the sills or any other part of the vehicle.

Page 408 of 486

Lit up Possible cause Solution

Drive in 4th gear (manual gearbox) or in gear D (DSG® dual clutch gearbox) at a speed of at

Diesel particulate filter has become satura-least 70 km/h (43 mph) for approximately 15 mi-nutes. ted with soot (except for courier vehicles). Observe the valid speed limits &. Go to the nearest qualified workshop if the indi-cator lamp still does not go out 409.

If possible, do not switch off the engine.

Only for specially equipped courier vehi-Please observe the applicable regulations for switching off the engine in special traffic situa-cles: lions (e.g. at level The indicator diesel particulate filter is being regenerated. lamp switches off when the diesel particulate fil-ter has been regenerated.

Flashes Possible cause Solution

Fault in engine management system (diesel The engine should be checked by a qualified } engine).

Misfiring, which damages the catalytic con-vert er.

Several warning and indicator lamps will light up briefly as a functional check when the ignition is switched on. They will go out after a few seconds.

A WARNING

Please observe legal requirements If cleaning the diesel particulate filter when in traffic.

• Follow driving recommendation only if visibility, weather, road and traffic conditions are suitable.

• Do not endanger other vehicles on the road.

A WARNING

The exhaust fumes contain carbon monoxide, an odourless and colourless toxic gas. Car-bon monoxide can cause people to lose con-sclousness. lt can also cause death.

• Never start or run the engine In unventlla-ted or closed spaces.

• Never leave the engine running If you leave the vehicle unattended.

Catalytic converter

,..-('n First read and observe the introductory L-J,:.U Information and safety warnings & on page 407.

408 I Cleaning and maintenance

workshop as soon as possible.

Decrease speed. Drive carefully to the next qualified workshop. The engine should be checked.

CD

To avoid damage to your vehicle, always ob-serve the Indicator lamps and associated warn-Ing texts.

m If the indicator lamps -.. c or EPC are lit up, L!J fuel consumption may be higher and engine performance reduced.

Page 409 of 486

• Use unleaded petrol only.

• Do not allow the fuel tank to run empty.

• Do not overfill engine oil 353.

• Do not tow-start the vehicle. Use jump leads 443.

If you notice misfiring, uneven running or loss of power when the vehicle is moving, reduce speed Immediately. The vehicle should be inspected at

Diesel particulate filter

r-f'n First read and observe the Introductory L-J,:,.IJ Information and safety warnings & on page 407.

The diesel particulate filter filters out soot particles in the exhaust gas. The soot particles gather in the filter and are burnt under high temperatures peri-odically (regeneration). Heat produced can warm the engine.

Regeneration can cause noises, light smells and delay in radiator fan irrespective of the outside temperature, even after the engine is switched off.

To assist the regeneration of diesel particle filter, Volkswagen recommends that you avoid making only short journeys. In vehicles with a DSG® dual clutch gearbox the engine speed can increase while the vehicle is being driven. However, the indi-cator lamp • will not light up.

Observe the following points to ensure that the ex-haust system and the diesel particulate filter will work properly for a long time:

the nearest qualified workshop. If this happens, un-bumt fuel can enter the exhaust system and es-cape into the atmosphere. The catalytic converter can also be damaged by overheating.

Even when the exhaust purification system is W working perfectly, there may be a smell of sulphur from the exhaust in some conditions. This depends on the sulphur content of the fuel being used. <1

• Only use diesel with low sulphur levels 343.

• Never use biodiesel, petrol or heating oil.

• Do not allow the fuel tank to run empty.

• Do not overfill engine oil 353.

• Do not tow-start the vehicle. Use jump leads =page 443.

Even when the exhaust purification system is W working perfectly, there may be a smell of sulphur from the exhaust in some conditions. This depends on the sulphur content of the fuel being used.

m Note for courier vehicles: vehicles with diesel l!J particulate filter are identified accordingly with

Vehicle care and maintenance 409

Page 410 of 486

If and when

Practical tips

Frequently asked questions

If you suspect that a vehicle fault has arisen or your vehicle has been damaged, read and observe the following information before contacting a Volkswagen Commercial Vehicles dealership or

qualified workshop. You may also find useful infor-mation in the index under the headings "Things to note" or "Checklist".

To note Some possible causes Possible solution

Vehicle battery is discharged. -How to jump start =>page 443. -Recharge vehicle battery 362.

Engine does not start. The incorrect vehicle key is be-Use a valid vehicle key 36. ing used.

Fuel level is too low. Fill the tank 340.

Supplementary heating system Switch off the supplementary heating

Smoke is coming from the is running. system 332. wing. Supplementary heater is run-No solution 345. ning.

-Battery in the remote control -Replace the battery 36. Vehicle cannot be locked or key is flat. -Move closer to the vehicle. unlocked with the remote -Located too far away from the -Synchronise the vehicle key =>page 36. vehicle. control key. -Buttons were pressed outside -Lock or unlock the vehicle manually

the range. 413.

Cold engine. brake assist sys-Refer to the index under entries for Unusual noises. tems, supplementary heating "Noises". system.

Assist systems are active. Refer to the index under entries for "As-sist systems". Unusual handling. DSG® dual clutch gearbox is too Stop the vehicle immediately hot. 266.

Front seats cannot be ad-Vehicle battery is discharged. Recharge vehicle battery 362.

justed electrically. Fuse blown. Check fuse and replace as necessary 429.

The vehicle has no vehicle No direct solutions possible as it depends

jack, spare wheel or break-Equipment depends on type of on the equipment level. Contact a Volks-vehicle. wagen Commercial Vehicles dealership if down set. necessary 416.

-Windows or sliding roof are open. The interior monitoring sys--Item attached to the interior Remove any objects that could trigger a tem triggers a false alarm. mirror is moving. false alarm 44. -A mobile telephone is vibrating inside the vehicle.

Functions are not working Settings have been made in the Check and if necessary reset back to fac-as described in the owner's manual. Volkswagen information system. tory settings 24.

410 I If and when

Page 415 of 486

Closing the sliding/tilting roof manually

r-111 First read and observe the introductory L-J,.:.U information and safety warnings & on page 413.

• Take the screwdriver from the vehicle tool kit.

• Remove cover with the sliding/tilting roof rotary button. Use the flat blade of the screwdriver side-ways between the cover and the roof console and pull it downwards.

• Fit a commercially available hexagon key1) of the right size in the hexagon socket head bolt and push the hexagon key approximately 2 mm up-wards.

• Turn the hexagon key to close the sliding/tilting roof.

• Remove the hexagon key and fit the cover again. The cover should lie flush with the surround-ing parts.

• The sliding/tilting roof should be checked by a qualified workshop. The functioning and roll-back function of the sliding/tilting roof could malfunction if it is closed manually.

BSG-

r-111 First read and observe the introductory L-J,.:.lJ information and safety warnings & on page 413.

If the power fails in the vehicle (for example if the battery is discharged) and the vehicle has to be pushed or towed, the manual release mechanism must be used to put the selector lever in the N po-sition.

The manual release mechanism is located under the cover of the gearshift gate.

Preparation

• Apply the handbrake.

• Switch off the ignition.

< CD

;;;: "' 1) Not included in the vehicle toolkit.

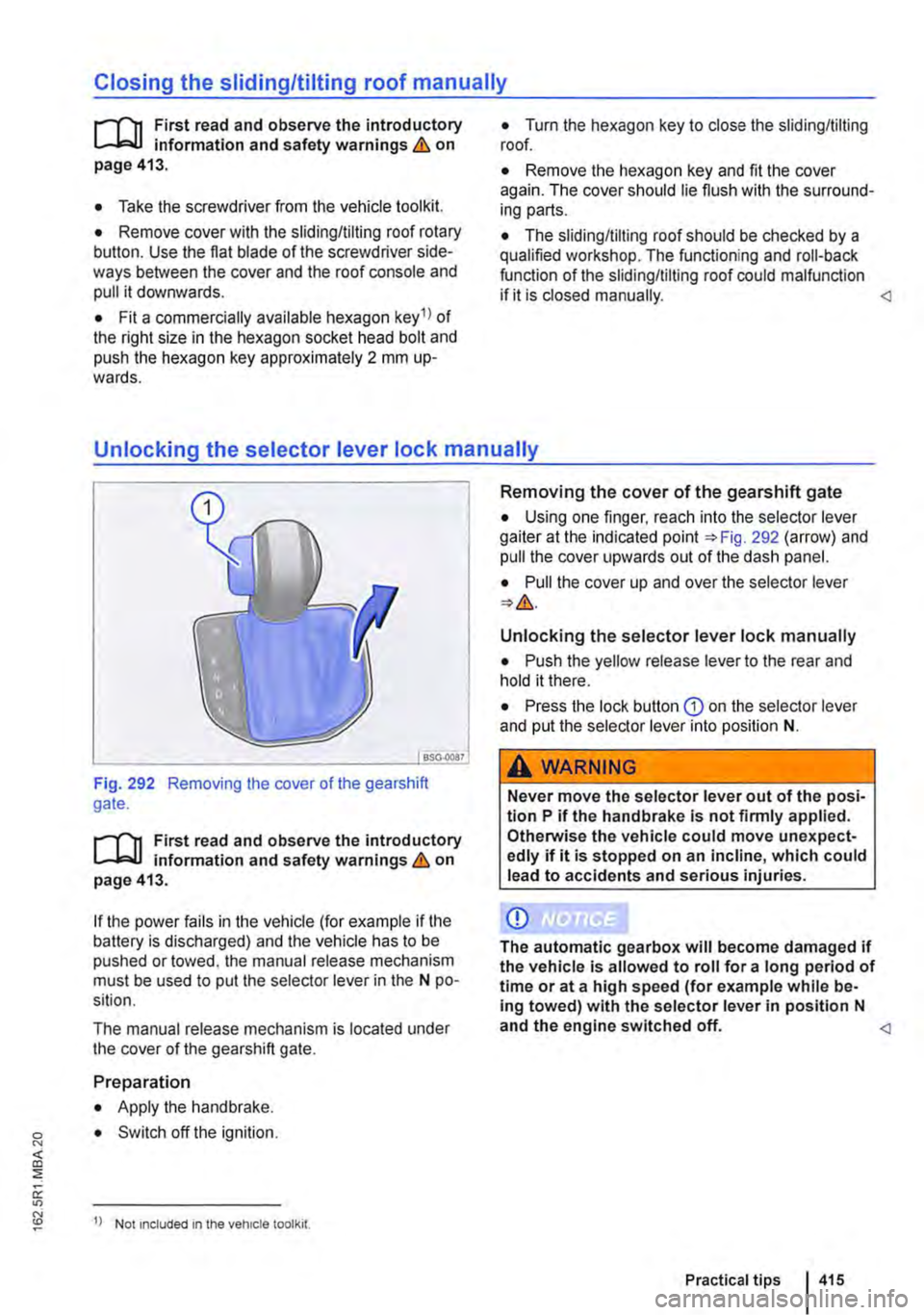

Removing the cover of the gearshift gate

• Using one finger, reach into the selector lever gaiter at the indicated Fig. 292 (arrow) and pull the cover upwards out of the dash panel.

• Pull the cover up and over the selector lever

Unlocking the selector lever lock manually

• Push the yellow release lever to the rear and hold it there.

• Press the lock button G) on the selector lever and put the selector lever into position N.

A WARNING

Never move the selector lever out of the posi-tion P if the handbrake is not finnly applied. Otherwise the vehicle could move unexpect-edly if it is stopped on an incline, which could lead to accidents and serious injuries.

CD

The automatic gearbox will become damaged if the vehicle is allowed to roll for a long period of time or at a high speed (for example while be-ing towed) with the selector lever in position N and the engine switched off.

Page 420 of 486

Changing a wheel

CllJ Introduction

This chapter contains information on the following subjects:

Preparations for changing a wheel . . . . . . . . . 420

Wheel bolts . . . . . . . . . . . . . . . . . . . 421

Lifting the vehicle with the jack . . . . . . . . . . . . 423

Changing a wheel . . . . . . . . . . . . . . . . . . . . . . . 424

After changing a wheel . . . . . . . . . . . . . 425

Some models are delivered without a factory-fitted jack or box spanner. If this is the case, the wheel should be changed by a qualified workshop.

The vehicle jack supplied with the vehicle is only designed for changing a wheel when one vehicle tyre is damaged and has to be replaced. Seek ex-pert assistance if both tyres on one side of the ve-hicle, both tyres on one axle, or all tyres are dam-aged.

Only change the wheel yourself when the car is parked in a safe place, you are familiar with the necessary steps and safety procedures and you have access to all the correct tools. Seek expert assistance if this is not the case.

Additional information and warnings:

• Exterior views =>page 5

• Vehicle key set =>page 36

• Tyre monitoring system =>page 318

• Wheels and tyres =>page 367

• In an emergency =>page 411

• Vehicle tool kit =>page 416

• Hubcaps =>page 417

Preparations for changing a wheel

1"1'11 First read and observe the introductory L-1o:.U information and safety warnings & on page 420.

Checklist

The following actions must always be carried out in the given order in preparation for changing the wheel=>&:

1. In the event of a flat tyre, park your vehicle on a firm and level surface at a safe dis-tance from the flow of traffic.

2. Apply the handbrake =>page 269.

420 I If and when

A wARNING

Changing a wheel can be dangerous, espe-cially when carried out at the side of a road. Please note the following steps in order to re-duce the risk of serious injuries:

• Stop the vehicle as soon as possible and when safe to do so. Park the vehicle at a safe distance from moving traffic in order to carry out the wheel change.

• All passengers and children in particular must be at a safe distance and away from your area of work during the wheel change.

• Switch on the hazard warning lights to warn other road users.

• Check that the surface the vehicle Is parked on Is level and firm. If necessary use a large, strong board or similar support for the vehicle jack.

• Only change the wheel yourself if you feel confident carrying out the procedure. If not, seek expert assistance.

• Always use suitable and undamaged tools to change the wheel.

• Always switch off the engine, apply the handbrake and move the selector lever to the position P or select a gear on a manual gear-box in order to reduce the risk of unintended vehicle movement.

• The wheel bolt tightening torque should be checked with a torque wrench immediately after changing a wheel.

4. Stop the engine and remove the key from the ignition =>page 257.

5. Manual gearbox: select a gear =>page 260.

6. Make sure all vehicle occupants exit the ve-hicle and move to safety, for instance be-hind the safety barrier.

7. Chock the wheel diagonally opposite the wheel being worked on with a stone or a similar object. ""

Page 423 of 486

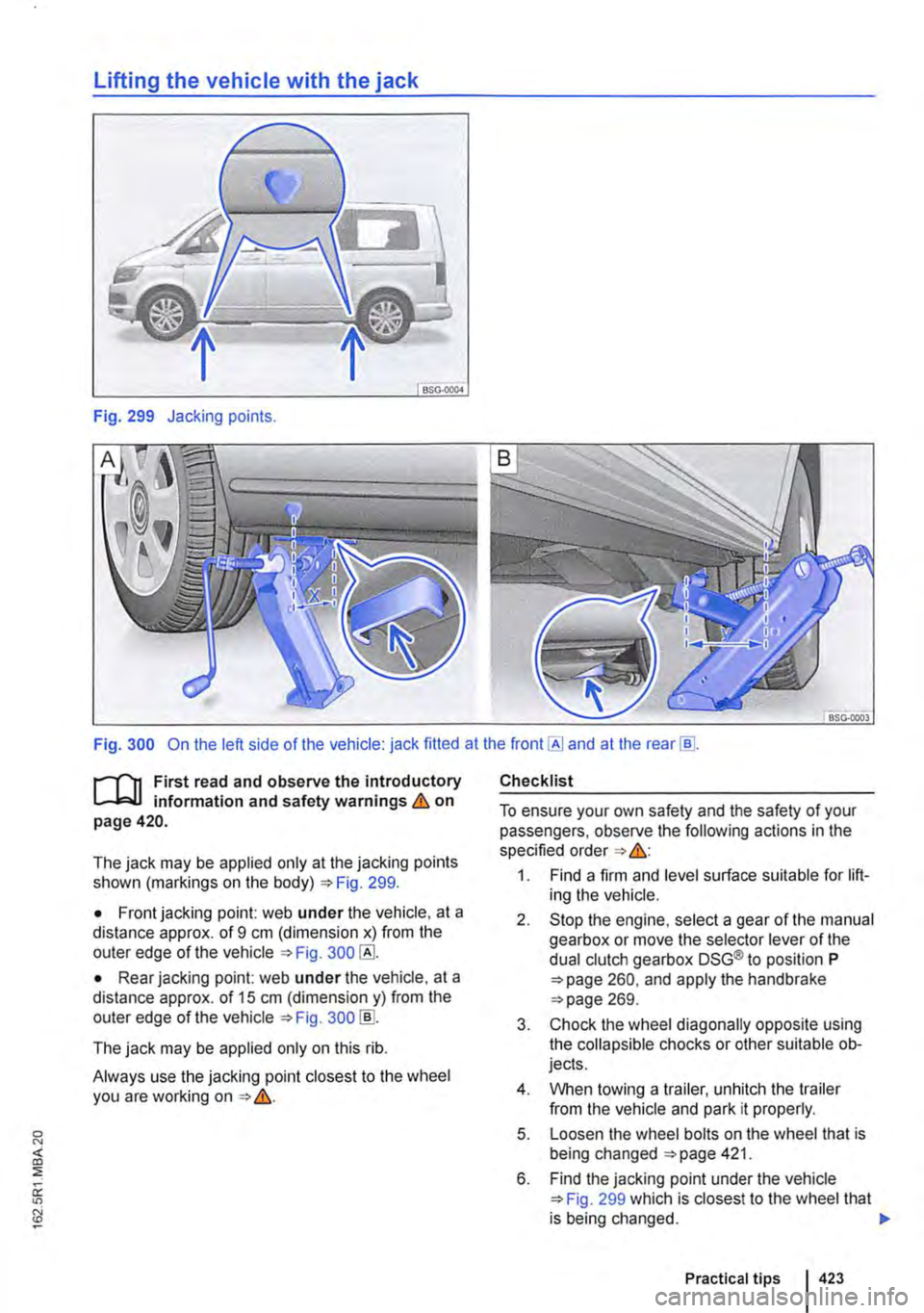

Lifting the vehicle with the jack

Fig. 299 Jacking points.

Fig. 300 On the left side of the vehicle: jack fitted at the front [AI and at the rear [ID.

r-('n First read and observe the introductory l.,...Jc.ll information and safety warnings & on page 420.

The jack may be applied only at the jacking points shown (markings on the body) '*Fig. 299.

• Front jacking point: web under the vehicle, at a distance approx. of 9 cm (dimension x) from the outer edge of the vehicle 300

• Rear jacking point: web under the vehicle, at a distance approx. of 15 cm (dimension y) from the outer edge of the vehicle 300 [ID.

The jack may be applied only on this rib.

Always use the jacking point closest to the wheel you are working on &.

Checklist

To ensure your own safety and the safety of your passengers, observe the following actions in the specified order &:

1. Find a firm and level surface suitable for lift-ing the vehicle.

2. Stop the engine, select a gear of the manual gearbox or move the selector lever of the dual clutch gearbox DSG® to position P '*page 260, and apply the handbrake 269.

3. Chock the wheel diagonally opposite using the collapsible chocks or other suitable ob-jects.

4. When towing a trailer, unhitch the trailer from the vehicle and park it properly.

5. Loosen the wheel bolts on the wheel that is being changed 421.

6. Find the jacking point under the vehicle '*Fig. 299 which is closest to the wheel that is being changed. .,.

Practical tips I 423

Page 427 of 486

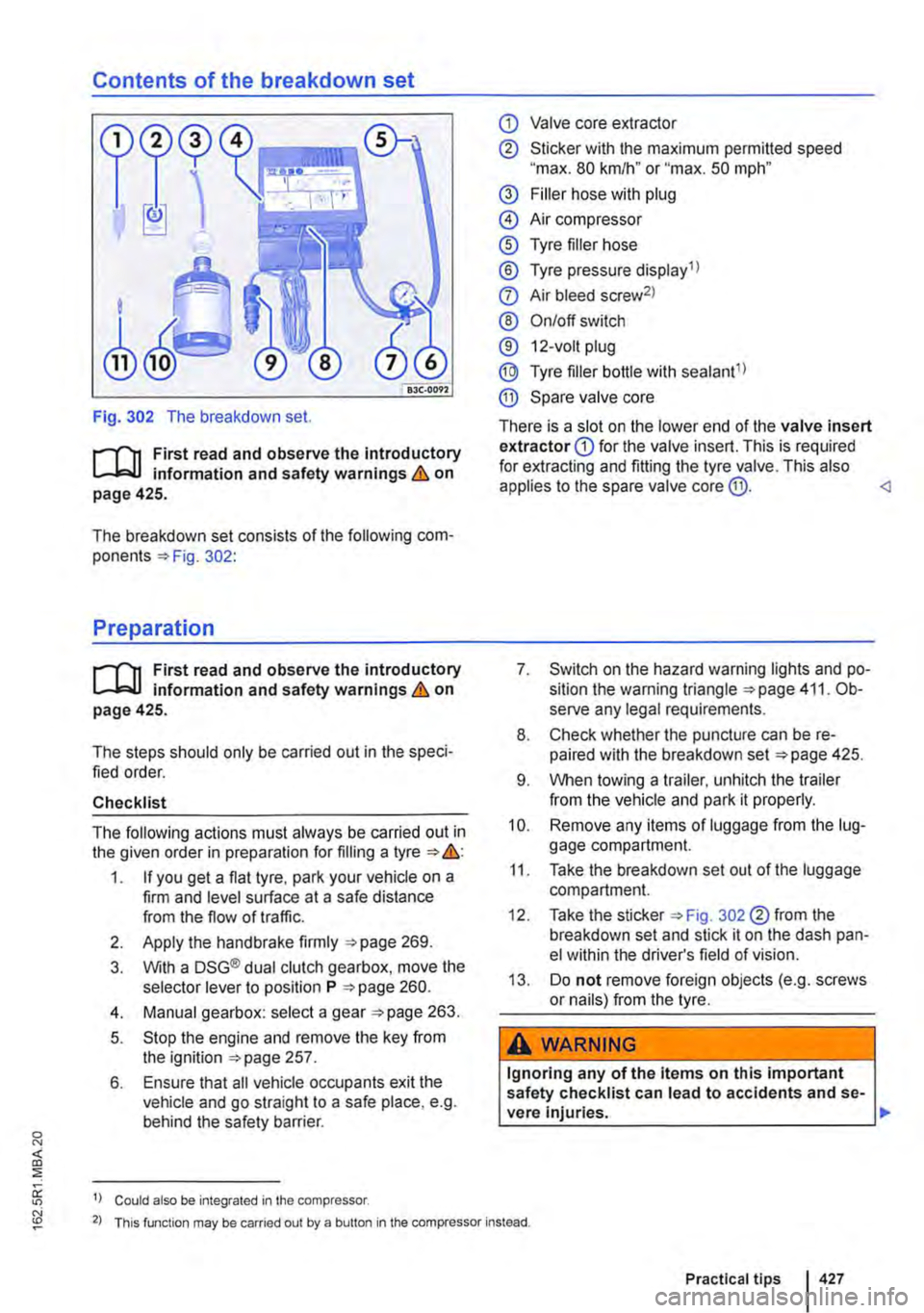

Contents of the breakdown set

Fig. 302 The breakdown set.

r--T'n First read and observe the introductory L-L::.U information and safety warnings & on page 425.

The breakdown set consists of the following com-ponents 302:

Preparation

r--T'n First read and observe the introductory L-L::.U information and safety warnings & on page 425.

The steps should only be carried out in the speci-fied order.

Checklist

The following actions must always be carried out in the given order in preparation for filling a tyre &:

1. If you get a flat tyre, park your vehicle on a firm and level surface at a safe distance from the flow of traffic.

2. Apply the handbrake firmly 269.

3. With a DSG® dual clutch gearbox, move the selector lever to position P 260.

4. Manual gearbox: select a gear 263.

5. Stop the engine and remove the key from the ignition 257.

6. Ensure that all vehicle occupants exit the vehicle and go straight to a safe place, e.g. behind the safety barrier.

1) Could also be integrated in the compressor.

CD Valve core extractor

® Sticker with the maximum permitted speed "max. 80 km/h" or "max. 50 mph"

@ Filler hose with plug

@ Air compressor

® Tyre filler hose

® Tyre pressure display 1 l

0 Air bleed screw2l

® On/off switch

® 12-volt plug

@ Tyre filler bottle with sealant1l

® Spare valve core

There is a slot on the lower end of the valve insert extractor CD for the valve insert. This is required for extracting and fitting the tyre valve. This also applies to the spare valve core @.

8. Check whether the puncture can be re-paired with the breakdown set 425.

9. When towing a trailer, unhitch the trailer from the vehicle and park it properly.

10. Remove any items of luggage from the lug-gage compartment.

11. Take the breakdown set out of the luggage compartment.

12. Take the sticker 302 ®from the breakdown set and stick it on the dash pan-el within the driver's field of vision.

13. Do not remove foreign objects (e.g. screws or nails) from the tyre.

A WARNING

Ignoring any of the items on this important safety checklist can lead to accidents and se-vere Injuries. ,..

2) This function may be carried out by a button in the compressor instead.

Practical tips 427

Page 434 of 486

Checklist (Continued)

3. Turn the light switch to position o 106.

4. Shift the tu m signal lever to neutral 106.

5. With a DSG® dual clutch gearbox, move the selector lever to position P 260.

6. Manual gearbox: select a gear 263.

7. Stop the engine and remove the key from the ignition 257.

8. Switch off the orientation lighting 106.

9. Leave the defective bulbs to cool down.

10. Check to see if a fuse has blown 429.

11. Follow the instructions to change the affec-ted bulb Always use identical bulbs of the same type. The designation is inscribed on the bulb, either on the glass part or on the base.

12. Do not touch the glass part of the bulb with unprotected fingers. The heat of the bulb would cause the fingerprint to evaporate and condense on the renector. This will im-pair the brightness of the headlight.

LED lights on the vehicle

r--f'n First read and observe the introductory L-I=J.I information and safety warnings & on page 432.

Depending on the vehicle equipment, the following lights may be LED lights:

• Dipped beam, main beam, daytime running lights and side lights on vehicles with LED head-lights.

• Tail light, brake light and fog light on vehicles with LED tail lights.

• Number plate lights.

434 If and when

13. After changing the bulb, check to ensure that the bulb is working properly. If the bulb is not working properly, the bulb may not have been inserted properly or may have failed again, or the connector may have been inserted incorrectly.

14. Any time you change a bulb in the front of the vehicle, the headlight settings should be checked by a qualified workshop.

A WARNING

Ignoring any of the items on this important safety checklist can lead to accidents and se-vere Injuries.

• Always follow the instructions in the checklist and observe the general safety pro-cedures.

CD

Always take care when removing or fitting lights in order to prevent damage to the paint-work or to other vehicle parts. <1

Owners cannot replace the LEDs themselves. If some LEDs fail, this may be an indication that more elements are on the point of failure. If this happens, have the lights checked and replaced if necessary at a qualified workshop.