Oil VOLKSWAGEN TRANSPORTER 2018 Repair Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 2018, Model line: TRANSPORTER, Model: VOLKSWAGEN TRANSPORTER 2018Pages: 486, PDF Size: 69.28 MB

Page 396 of 486

should be replaced at a qualified workshop. Volks-wagen Commercial Vehicles dealers are kept up to date with regard to any changes.

A WARNING

Unsuitable service fluids and consumables, and the Incorrect use of these fluids and con-sumables, can cause accidents, serious inju-ries, burns or poisoning.

• Service fluids must be kept In their origi-nal sealed container.

• Never store service fluids In empty food containers, bottles or any other non-original containers as people finding these containers could drink them.

• Keep children away from all service fluids and consumables.

• Always read and follow the Information and warnings on the service fluid packaging.

Repairs and technical modifications

.....-T'n First read and observe the Introductory l-J,::JJ Information and safety warnings & on page 394.

Repairs and modifications must always be car-ried out according to Volkswagen Commercial Vehicles specifications =:ob:,!

Unauthorised modifications to the electronic com-ponents or software in the vehicle may cause faults. As the electronic components are linked to-gether in networks. other systems may be affected by the faults. This can seriously impair safety, lead to excessive wear of components, and also invalid-ate the type approval for the vehicle.

The Volkswagen Commercial Vehicles dealer can-not be held liable for any damage caused by tech-nical modifications and/or work performed incor-rectly.

The Volkswagen Commercial Vehicles dealer can-not be held liable for any damage caused by tech-nical modifications and/or work performed incor-rectly. This is also not covered by the Volkswagen guarantee.

3961 Clt!aning and maintenance

A WARNING (Continued)

• When using products that give off harmful fumes, always work outdoors or In a well-ventilated area.

• Never use fuel, turpentine, engine oil, nail varnish remover or other volatile fluids for vehicle care. They are toxic and highly flam-mable. They could cause fires and explo-sions.

CD

• Only use suitable service fluids for refilling. Never use the wrong service fluid. Failure to observe this warning can result In serious mal-functions and engine damage.

• Optional equipment and other accessories In front of the air Inlet reduce the cooling effect of the coolant. The engine may overheat at high ambient temperatures and high engine loads.

Leaking service fluids can pollute the envi-C!IS ronment. Spilt service fluids must be collec-ted in suitable containers and disposed of properly and with respect for the environment.

Vehicles with special auxiliary equipment or body parts

The manufacturer of these components must en-sure that these parts (fittings) adhere to the stipula-ted environmental laws and regulations, particular-ly the EU directive 2000/53/EC concerning end-of-life vehicles and EU directive 2003/11/EC concern-ing the restriction on the marketing and use of cer-tain dangerous substances and preparations.

The vehicle owner should keep all assembly docu-mentation for these auxiliary fittings, and pass it on to any scrapping company later engaged. This is to facilitate environmentally responsible disposal for all vehicles, Including refitted vehicles.

Windscreen repairs

To function properly, some items of equipment re-quire a camera or sensor, which Is located on the inside of the windscreen near the interior mirror. If the windscreen in the viewing field of the camera ,..

Page 401 of 486

Vehicle lifting points

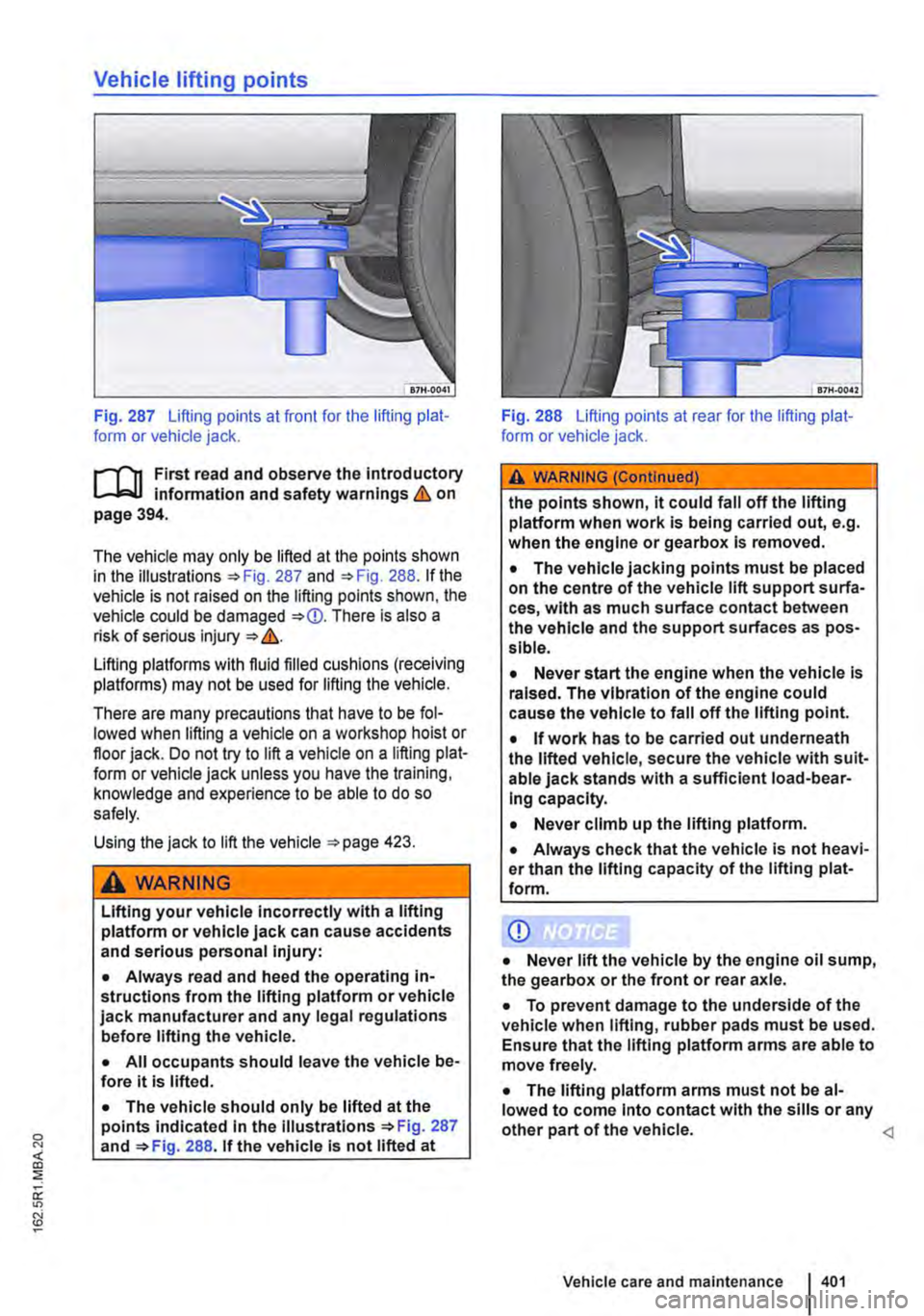

Fig. 287 Lifting points at front for the lifting plat-form or vehicle jack.

First read and observe the introductory l.-J,::..U information and safety warnings & on page 394.

The vehicle may only be lifted at the points shown in the illustrations =>Fig. 287 and =>Fig. 288. If the vehicle is not raised on the lifting points shown, the vehicle could be damaged =>

Lifting platforms with fluid filled cushions (receiving platforms) may not be used for lifting the vehicle.

There are many precautions that have to be fol-lowed when lifting a vehide on a workshop hoist or floor jack. Do not try to lift a vehicle on a lifting plat-form or vehicle jack unless you have the training, knowledge and experience to be able to do so safely.

Using the jack to lift the vehicle =>page 423.

A WARNING

Lifting your vehicle incorrectly with a lifting platform or vehicle jack can cause accidents and serious personal injury:

• Always read and heed the operating in-structions from the lifting platform or vehicle jack manufacturer and any legal regulations before lifting the vehicle.

• All occupants should leave the vehicle be-fore it is lifted.

• The vehicle should only be lifted at the points indicated In the illustrations =>Fig. 287 and =>Fig. 288. If the vehicle is not lifted at

Fig. 288 Lifting points at rear for lhe lifting plat-form or vehicle jack.

A WARNING_(Contlnued)

the points shown, it could fall off the lifting platform when work is being carried out, e.g. when the engine or gearbox is removed.

• The vehicle jacking points must be placed on the centre of the vehicle lift support surfa-ces, with as much surface contact between the vehicle and the support surfaces as pos-sible.

• Never start the engine when the vehicle is raised. The vibration of the engine could cause the vehicle to fall off the lifting point.

• If work has to be carried out underneath the lifted vehicle, secure the vehicle with suit-able jack stands with a sufficient load-bear-ing capacity.

• Never climb up the lifting platform.

• Always check that the vehicle is not heavi-er than the lifting capacity of the lifting plat-form.

CD

• Never lift the vehicle by the engine oil sump, the gearbox or the front or rear axle.

• To prevent damage to the underside of the vehicle when lifting, rubber pads must be used. Ensure that the lifting platform arms are able to move freely.

• The lifting platform arms must not be al-lowed to come Into contact with the sills or any other part of the vehicle.

Page 407 of 486

Recycling and scrapping end-of-life vehicles

rl'l1 First read and observe the Introductory L-J,:,JJ information and safety warnings & on page 404.

Recycling end-of-life vehicles

Volkswagen Commercial Vehicles has already made provision for the time when you choose to have your vehicle recycled in an environmentally-friendly manner. The recycling system operating in many European countries will take back your vehi-cle at the end of its useful life. Once the vehicle has been recycled, a certificate of destruction will be issued to show that the vehicle has been dis-posed of correctly.

End-of-life vehicles are recycled free of charge, provided that national legislation is complied with.

Further information on the recycling of end-of-life vehicles can be found at a Volkswagen Commer-cial Vehicles dealership.

Scrapping

The relevant safety requirements must be ob-served when the vehicle or components of the air-bag and the belt tensioners are scrapped. Quali-fied workshops are familiar with these require-ments.

o:JJ Introduction

This chapter contains information on the following subjects:

Indicator lamps . . . . . . . . . . . . . . . . 407

Catalytic converter . . . . . . . . . . . . . . . . . . . . . . 408 Diesel particulate filter . . . . . . . . . . 409

Additional information and warnings:

• Changing gear =>page 260

• Filling the tank =>page 340

• Fuel =>page 343

• Engine oil =>page 353

• Battery =>page 362

• Information stored in the control units =>page 394

• Tow-starting and towing =>page 446

Indicator lamps

A WARNING

The components of the exhaust system be-come very hot. This can cause fires.

• Park the vehicle so that no part of the ex-haust system can come into contact with any inflammable material underneath the vehicle, e.g. dry grass.

• Never apply undersea! or anti-corrosion coatings to the exhaust pipes, catalytic con-verter, diesel particulate fitter or the heat shields on the exhaust system.

lit up Possible cause Solution

Engine management system fault {Electron-The engine should be checked by a qualified

J ic Power Control). workshop as soon as possible.

R Diesel engine is preheating before starting. =>page 257

Decrease speed. Drive carefully to the next Fault in catalytic converter . qualified workshop. The engine should be ..... checked.

Vehicle care and maintenance 407

Page 409 of 486

• Use unleaded petrol only.

• Do not allow the fuel tank to run empty.

• Do not overfill engine oil 353.

• Do not tow-start the vehicle. Use jump leads 443.

If you notice misfiring, uneven running or loss of power when the vehicle is moving, reduce speed Immediately. The vehicle should be inspected at

Diesel particulate filter

r-f'n First read and observe the Introductory L-J,:,.IJ Information and safety warnings & on page 407.

The diesel particulate filter filters out soot particles in the exhaust gas. The soot particles gather in the filter and are burnt under high temperatures peri-odically (regeneration). Heat produced can warm the engine.

Regeneration can cause noises, light smells and delay in radiator fan irrespective of the outside temperature, even after the engine is switched off.

To assist the regeneration of diesel particle filter, Volkswagen recommends that you avoid making only short journeys. In vehicles with a DSG® dual clutch gearbox the engine speed can increase while the vehicle is being driven. However, the indi-cator lamp • will not light up.

Observe the following points to ensure that the ex-haust system and the diesel particulate filter will work properly for a long time:

the nearest qualified workshop. If this happens, un-bumt fuel can enter the exhaust system and es-cape into the atmosphere. The catalytic converter can also be damaged by overheating.

Even when the exhaust purification system is W working perfectly, there may be a smell of sulphur from the exhaust in some conditions. This depends on the sulphur content of the fuel being used. <1

• Only use diesel with low sulphur levels 343.

• Never use biodiesel, petrol or heating oil.

• Do not allow the fuel tank to run empty.

• Do not overfill engine oil 353.

• Do not tow-start the vehicle. Use jump leads =page 443.

Even when the exhaust purification system is W working perfectly, there may be a smell of sulphur from the exhaust in some conditions. This depends on the sulphur content of the fuel being used.

m Note for courier vehicles: vehicles with diesel l!J particulate filter are identified accordingly with

Vehicle care and maintenance 409

Page 422 of 486

If the wheel boils are corroded and difficult to turn, they must be replaced and the wheel hub threads cleaned before the tightening torque is checked.

Never grease or lubricate the wheel bolts or the threads of the wheel hub. This could cause them to loosen while the vehicle is in motion, even if the re-quired torque setting is used.

A WARNING

Incorrectly tightened wheel bolts can loosen while the vehicle is in motion and cause acci-dents, serious injury, and loss of control of the vehicle.

• Only use wheel bolts that belong to the wheel.

• Never use different wheel bolts.

• The wheel bolts and threads of the wheel hubs must be clean, free from oil and grease, and turn easily.

4221 If and when

A WARNING (Continued)

• Always use the box spanner placed In the vehicle at the factory to loosen and tighten the wheel bolts.

• Only loosen the wheel bolts by approxi-mately one turn before raising the vehicle with the vehicle jack.

• Never grease or lubricate the wheel bolts or the threads of the wheel hub. This could cause them to loosen while the vehicle is in motion, even if the required torque setting is used.

• Never remove the bolts on rims with bol-ted-on rings.

• If the tightening torque of the wheel bolts Is too low, the wheel bolts and rims can loos-en while the vehicle is In motion. The wheel bolts and threads can be damaged if the tightening torque is too high.

Page 425 of 486

• Clean the area around the fastening holes of the spare wheel.

• Position the spare wheel.

• Insert the anti-theft wheel bolt using the adapter at position 298 @or® and tighten it slight-ly.

• Screw in all the other wheel bolts in a clockwise direction and use the box spanner to tighten them gently.

• Lower the vehicle with the jack.

• Use the box spanner to tighten all the wheel bolts securely in a clockwise direction &. Do not tighten the bolts in clockwise or anticlockwise se-quence. Tighten them in diagonal sequence.

• Fit the cover caps, centre covers or wheel cov-ers 417.

After changing a wheel

rl'l1 First read and observe the Introductory L-.lo:.ll Information and safety warnings & on page 420.

• If necessary, clean the vehicle tools and stow them safely in the vehicle 416.

• Stow the spare wheel or the removed wheel safely under the vehicle.

Breakdown set

CQJ Introduction

This chapter contains information on the following subjects:

Storing . . . . . . . . . . . . . . . . . . . . 426

Contents of the breakdown set . . . . . . . . . . . . 427 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . 427

Sealing and inflating tyres . . . . • . . . . . . . 428

Test after driving for 10 minutes . . . . 429

You can use the breakdown set (tyre mobility set) to safely seal any tyre damage caused by foreign bodies or punctures (up to 4 mm (0.16 Inches) in diameter). Do not remove foreign objects (e.g. screws or nails) from the tyrel

Once the sealant has been added to the tyre, the tyre pressure must be checked again after approxi-mately 10 minutes of driving.

,A WARNING

Incorrect torque or incorrect use of wheel bolts can lead to a loss of control of the vehi-cle, cause accidents and serious Injuries.

• Always keep all wheel bolts and threads In the wheel hubs clean and free from oil and grease. The wheel bolts must be easy to turn and be tightened to the specified torque.

• The hexagonal socket In the screwdriver handle should only be used for turning wheel bolts, not use for loosening or tightening them.

• The damaged wheel should be replaced as soon as possible.

m In vehicles with a tyre monitoring system, the L!..J system may have to "re-learn" if new tyres are fitted 318.

Only use the breakdown set if the car is parked in a safe place, you are familiar with the required ac-tions and safety procedures, and you have access to the correct breakdown set. Seek expert assis-tance if this is not the case.

The tyre sealant must not be used:

• If the rim is damaged.

• If the outside temperature is below -2o•c (-4 ·F).

• If there are cuts or punctures in the tyre that are larger than 4 mm. .,.

Practical tips 425

Page 428 of 486

A WARNING (Continued)

• Always follow the instructions In the checklist and observe the general safety pro-

Sealing and inflating tyres

r-"'('n First read and observe the Introductory L-J,.:.U Information and safety warnings & on page 425.

Sealing a tyre

• Unscrew the cap from the tyre valve.

• Use the valve core extractor 302 CD to screw the valve core out of the tyre valve. Place the core on a clean surface.

• Shake the tyre filler bottle 302 ® vigo-rously up and down several times.

• Screw the filler hose 302 @tightly onto the tyre filler bottle in a clockwise direction. The plastic foil on the plug is pierced automatically.

• Remove the plug from the filler hose 302@ and place the open end fully on the tyre valve.

• Hold the bottle upside down and inject the en-tire contents of the tyre filler bottle into the tyre.

• Remove the empty tyre filler bottle from the valve.

• Use the valve core extractor 302 CD to screw the valve core back onto the tyre valve.

Inflating the tyre

• Screw the tyre filler hose 302 ® of the air compressor tightly onto the tyre valve.

• Check that the bleed screw 302 (?) is closed.

• Start the engine and let it run.

• Insert the plug 302 ®into one of the ve-hicle's 12-volt sockets 163.

• Use the on/off switch 302 ®to switch on the air compressor.

• Run the compressor until the tyre pressure has reached 2.0-2.5 bar (29-36 psi I 200-250 kPa) maximum running time is 6 minutes

• Switch off the air compressor.

• If a pressure level of 2.0-2.5 bar (29-36 psi I 200 -250 kPa) cannot be achieved unscrew the tyre filler hose from the tyre valve.

428 I If and when

• Drive (or reverse) the vehicle approximately 1 0 metres so that the sealing compound is more evenly distributed in the tyre.

• Screw the tyre filler hose for the air compressor firmly back onto the tyre valve and inflate the tyre again.

• If the required pressure still cannot be reached, the tyre is too badly damaged. The tyre cannot be sealed with the breakdown set. Do not drive on. Seek expert assistance &.

• Disconnect the air compressor and unscrew the tyre filler hose from the tyre valve.

• Drive the vehicle no faster than 80 km/h (50 mph) once a tyre pressure of 2.0-2.5 bar (29-36 psi I 200-250 kPa) has been reached.

• Check the tyre pressure after driving for 10 mi-nutes 429.

A WARNING

The tyre filler hose and the air compressor can get hot during Inflation.

• Protect your hands and skin from the hot components.

• Do not place the hot tyre filler hose or the hot air compressor on any Inflammable mate-rials.

• Allow the device to cool down fully before stowing.

• If the tyre will not Inflate to at least 2.0 bar (29 psi/ 200 kPa), the tyre Is too damaged. The sealant Is unable to seal the tyre. Do not drive on. Seek expert assistance.

CD

Switch the air compressor off after a maximum of 6 minutes to avoid overheating. Let the air compressor cool down for a few minutes be-fore switching it back on.

Page 450 of 486

Technical data

Technical data

Vehicle data

COJ Introduction

This chapter contains information on the following subjects:

Vehicle identification data . . . . . . . . . . . . . . . . . 451

Dimensions ........................... . 452

Unless otherwise specified, the technical data of the basic model apply. The values quoted here may differ if additional equipment is fitted, for differ-ent models, for special vehicles or if country-specif-ic equipment is fitted. All data in the official vehicle documents take precedence over these data.

Engine

The vehicle data sticker and the official vehicle documents show which engine is installed in your vehicle.

Weight

The values for the kerb weight in the following ta-bles apply for the road-ready vehicle with driver (75 kg), service fluids including fuel tank carrying 90% of its capacity and, if applicable, toolkit and spare tyre =>&.Additional equipment and retrofit-ted accessories increase the stated kerb weight and reduce the maximum permitted load accord-ingly.

The load comprises the weights of the following:

• Passengers

• Allluggage

• Roof load including the mounts or roof bars and the load carrier system

• Drawbar load when towing a trailer

Performance figures

The performance figures were measured without equipment which may influence performance, such as a roof carrier or mud flaps.

Gross combination weight rating

The gross combination weight ratings listed are on-ly applicable for altitudes up to 1 ,000 m above sea level. The maximum weight of the car and trailer must be reduced by approximately 10% for every further 1 ,000 m in altitude.

450 I Tcchn1cal data

Descriptions of the tables

Gearbox abbreviations: MG = manual gearbox, DSG® = dual clutch gearbox DSG®.

Additional information and warnings:

• Transporting =:o page 125

• Driving with respect for the environment =:.page 278

• Fuel =:.page 343

• Engine oil =:o page 353

• Engine coolant =:o page 358

• Wheels and tyres =>page 367

• Consumer information =>page 404

,A WARNING

Exceeding the maximum permissible weights, payload, dimensions, vehicle speed and axle weight rating could cause damage to the vehicle, accidents and serious Injuries.

• Do not exceed the permitted weights, loads, dimensions and maximum speeds.

• The actual axle loads must never exceed the maximum permissible axle loads.

• The payload and the distribution of the load In the vehicle have an effect on the driv-ing response and braking distance of the ve-hicle. Adjust your speed accordingly.

,A WARNING

Accidents and severe injuries can occur if the maximum permitted gross combination weight Is exceeded.

• Never exceed the specified gross combi-nation weight rating.

Page 453 of 486

CD

• Take care when driving In car parks with protruding kerbstones or bollards. Objects that protrude from the ground can damage the bumper and other components when parking the vehicle.

Petrol engines

CD

• Drive carefully through dips in the road, over driveways, ramps, kerbstones and other objects. Low-lying vehicle components such as the bumper, spoiler and parts of the running gear, engine or exhaust system could be dam-aged.

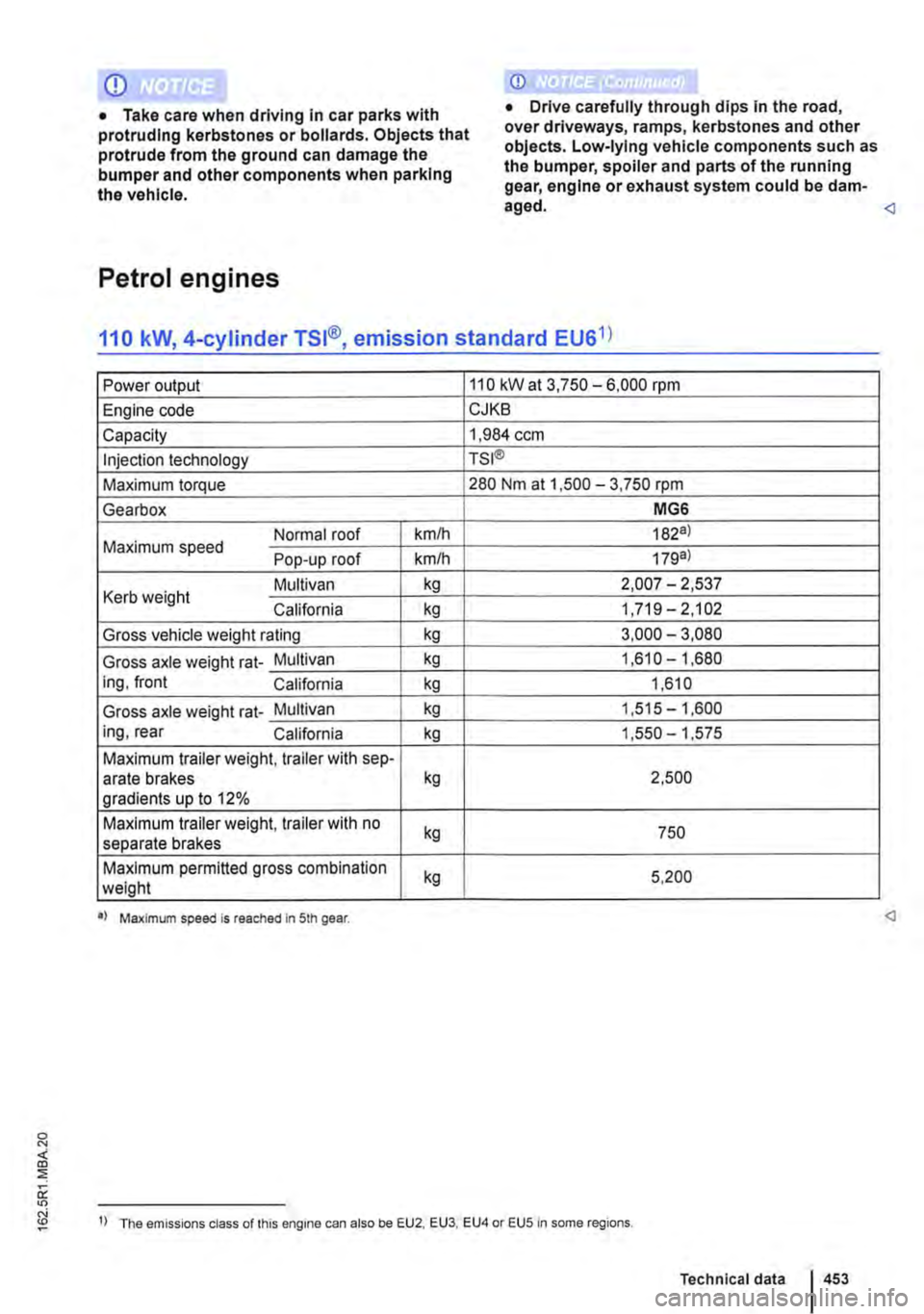

110 kW, 4-cylinder TSI®, emission standard EUG1)

Power output 110 kW at 3,750-6,000 rpm

Engine code CJKB

Capacity 1,984 ccm

Injection technology rs1®

Maximum torque 280 Nm at 1,500-3,750 rpm

Gearbox MGS

Maximum speed Normal roof km/h 1828)

Pop-up roof km/h 1798)

Kerb weight Multivan kg 2,007-2,537

California kg 1,719-2,102

Gross vehicle weight rating kg 3,000-3,080

Gross axle weight rat-Multivan kg 1,610-1,680

ing, front California kg 1,610

Gross axle weight rat-Multivan kg 1,515 -1,600

ing, rear California kg 1,550 1,575

Maximum trailer weight, trailer with sep-arate brakes kg 2,500 gradients up to 12%

Maximum trailer weight, trailer with no kg 750 separate brakes

Maximum permitted gross combination kg 5,200 weight

•> Maximum speed IS reached in 5th gear.

I) The emissions class of this engine can also be EU2, EU3, EU4 or EUS in some regions.

Technical data 453

Page 468 of 486

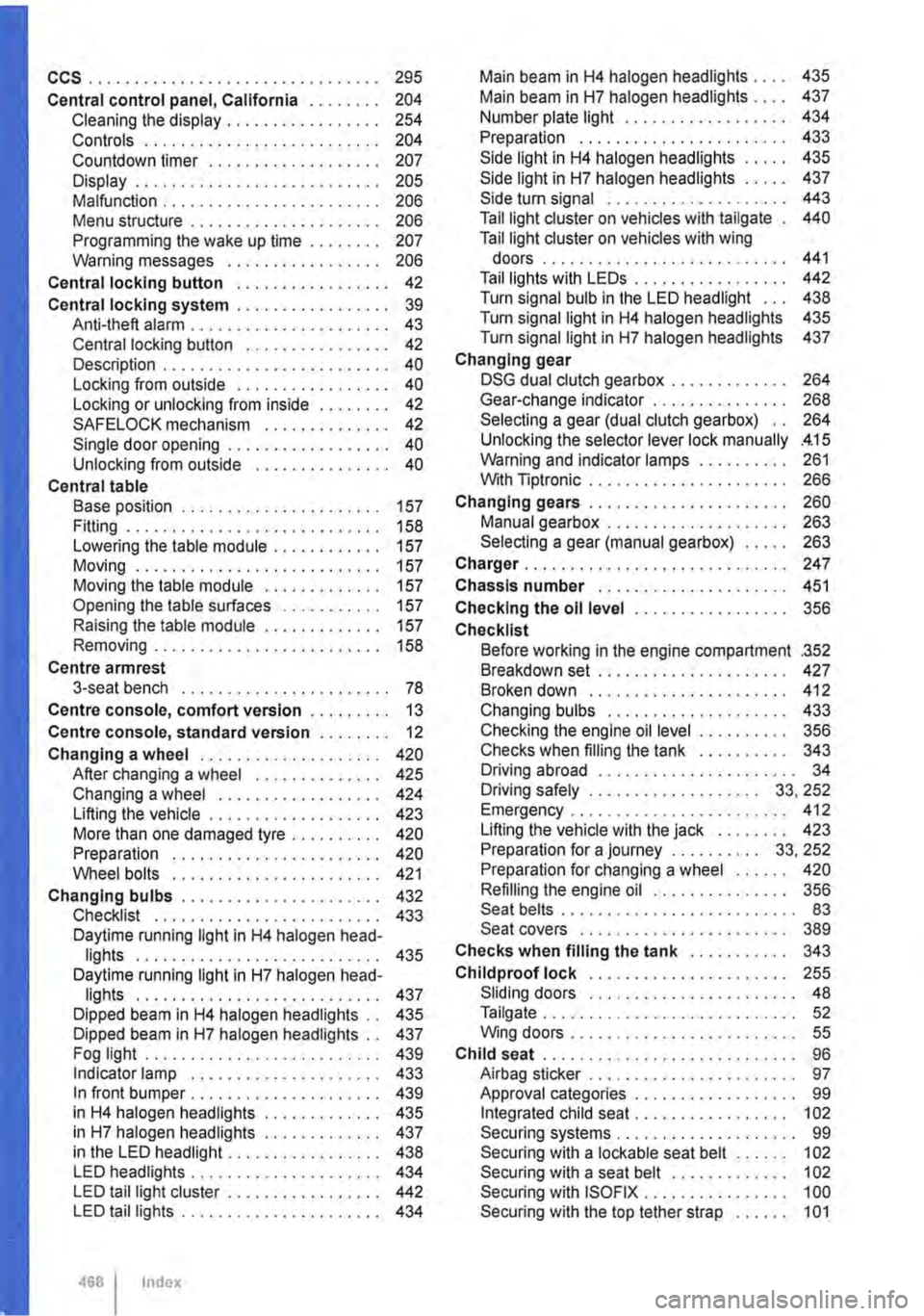

ccs ................................ 295

Central control panel, California . . . . . . . . 204 Cleaning the display . . . . . . . . . . . . . . . . . 254 Controls . . . . . . . . . . . . . . . . . . . . . . . . . . 204 Countdown timer . . . . . . . . . . . . . . . . . . . 207 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . 205 Malfunction . . . . . . . . . . . . . . . . . . . • . . . . 206 Menu structure . . . . . . . . . . . . . . . . . . . . . 206 Programming the wake up time . . . • . . . . 207 Warning messages . . . . . . . . . . . . . . . . . 206

Central locking button . . . . . . . . . . . . . . . . . 42

Central locking system . . . . . . . . . . . . . . . . . 39 Anti-theft alarm . . . . . . . . • . . . . . . . . . . • . . 43 Central locking button . . . . . . . . . . . . . • . . 42 Description . . . . . . . . . . . . . . . . . . . . . . . . . 40 Locking from outside . . . . . . . . . . . . . . . . . 40 Locking or unlocking from inside . . . . . . . . 42 SAFELOCK mechanism . . . . . . . . . . . . . . 42 Single door opening . . . . . . . . . . . . . . . . . . 40 Unlocking from outside . . . . . . . . . . . . . . . 40

Central table Base position . . . . . . . . . . . . . . . • . . . . . . 157 Filling . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158 Lowering the table module . . . . . • . . . . . . 157 Moving . . . . . . . . . . . . . . . . . . . . . . . . . . . 157 Moving the table module . . . . . . • . . . . . . 157 Opening the table surfaces . . . . . . . • . . . 157 Raising the table module . . . . . . . . . . . . . 157 Removing . . . . . . . . . . . . . . . . . . . . . . . . . 158

Centre armrest 3-seat bench . . . . . . . . . . . . . . . . . . • . . . . 78

Centre console, comfort version . . . . . . . . . 13

Centre console, standard version . . . . . . . . 12

Changing a wheel . . . . . . . . . . . . . . . . • . . . 420 After changing a wheel . . . . . . . . • . . . . . 425 Changing a wheel . . . . . . . . . . . . . . . . . . 424 Lifting the vehicle . . . . . . . . . . . . . . . . . . . 423 More than one damaged tyre . . . . . . . . . . 420 Preparation . . . . . . . . . . . . . . . . . . . . . . . 420 Wheel bolts . . . . . • . . . . . . . . . . . . . . . . . 421

Changing bulbs . . . . . . . . . . . . . . . . . . . . . . 432 Checklist . . . . . . . . . . . . . . . . . . . . . . . . . 433 Daytime running light in H4 halogen head-lights . . . . . . . . . . . . . . . . . . . . . . . . . . . 435 Daytime running light in H7 halogen head-lights . . . . . . . . . . . . . . . . . . . . . . . . . . . 437 Dipped beam in H4 halogen headlights . . 435 Dipped beam In H7 halogen headlights . . 437 Fog light . . . . . . . . . . . . . . . . . . . . . . . . . . 439 Indicator lamp . . . . . . . . . . . . . . . . . . . . . 433 In front bumper . . . . . . . . . . . . . . . . . . . . . 439 in H4 halogen headlights . . . . . . . . . . • . . 435 in H7 halogen headlights . . . . . . . . . . . . . 437 in the LED headlight . . . . . . . . . . . . . . . . . 438 LED headlights . . . . . . . . . . • . . . . . . . . . . 434 LED tail light cluster . . . . . . • . . . . . . . . . . 442 LED tail lights . . . . . . . . • . . . . . . . . . . . . . 434

468 I Index

Main beam in H4 halogen headlights . . . . 435 Main beam in H7 halogen headlights . . . . 437 Number plate light . . . . . . . . . . . . . . . . . . 434 Preparation . . . . . . . . . . . . . . . . . . . . . . . 433 Side light in H4 halogen headlights . . . . . 435 Side light in H7 halogen headlights . . . . . 437 Side turn signal . . . . . . . . . . . . . . . . . . . . 443 Tail light cluster on vehicles with tailgate . 440 Tail light cluster on vehicles with wing doors . . . . . . . . . . . . . . . . . . . . . . . . . . . 441 Tail lights with LEDs . . . . . . . . . . . . . . . . . 442 Turn signal bulb in the LED headlight . . . 438 Turn signal light in H4 halogen headlights 435 Turn signal light in H7 halogen headlights 437

Changing gear DSG dual clutch gearbox . . . . . . . . . . . . . 264 Gear-change indicator . . . . . . . . . . . . . . . 268 Selecting a gear (dual clutch gearbox) . . 264 Unlocking the selector lever lock manually .4.15 Warning and indicator lamps . . . . . . . . . . 261 With Tiptronic . . . . . . . . . . . . . . . . . . • . . . 266

Changing gears . . . . . . . . . . . . . . . . . . . . . . 260 Manual gearbox . . . . . . . . . . . . . . . . . . . . 263 Selecting a gear (manual gearbox) . . . . . 263

Charger.. . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Chassis number . . . . . . . . . . . . . . • . . . . . . 451

Checking the oil level . . . . . . . . . . . . . . . . . 356

Checklist Before working in the engine compartment .352 Breakdown set . . . . . . . . . . . . . . . . . . . . . 427 Broken down . . . . . . . . . . . . . . . . • . . . . . 412 Changing bulbs . . . . . . . . . . . . . . . . . . . . 433 Checking the engine oil level . . . . . . . . . . 356 Checks when filling the tank . . . . . . . . . . 343 Driving abroad . . . . . . . . . . . . . . . • . . . . . . 34 Driving safely . . . . . . . . . . . . . . . . . . . 33, 252 Emergency . . . . . . . . . . . . . . . . . . . . . . . . 412 Lifting the vehicle with the jack . . . . . . . . 423 Preparation for a journey . . . . . . . . . . 33, 252 Preparation for changing a wheel . . . . . . 420 Refilling the engine oil . . . . . . . . . . . . . . . 356 Seat belts . . . . . . . . . . . . . . . . . . . . . . . . . . 83 Seat covers . . . . . . . . . . . . . . . . . . . . . . . 389

Checks when filling the tank . . . . . . . . . . . 343

Childproof lock . . . . . . . . . . . . . . . . . . . . . . 255 Sliding doors . . . . . . . . . . . . . . . . . . . . . . . 48 Tailgate . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52 Wing doors . . . . . . . . . . . . . . . . . . . . . . • . . 55

Child seat . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96 Airbag sticker . . . . . . . . . . . . . . . . . • . . . . . 97 Approval categories . . . . . . . . . . . . . . . . . . 99 Integrated child seat . . . . . . . . . . . . . . . . . 102 Securing systems . . . . . . . . . . . . . . . . . . . . 99 Securing with a lockable seat bell . . . . . . 102 Securing with a seat belt . . . . . . . . . . . . . 102 Securing with ISO FIX . . . . . . . . . . . . . . . . 100 Securing with the top tether strap . . . . . . 101