warning light VOLKSWAGEN UP! 2021 Owner´s Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 2021, Model line: UP!, Model: VOLKSWAGEN UP! 2021Pages: 211, PDF Size: 5.98 MB

Page 194 of 211

Dispose of used or out-of-date sealant in accordance with legal requirements.

You can get a new tyre filler bottle from a Volkswagen dealership.

Observe the separate instructions from the manufacturer of the breakdown set.

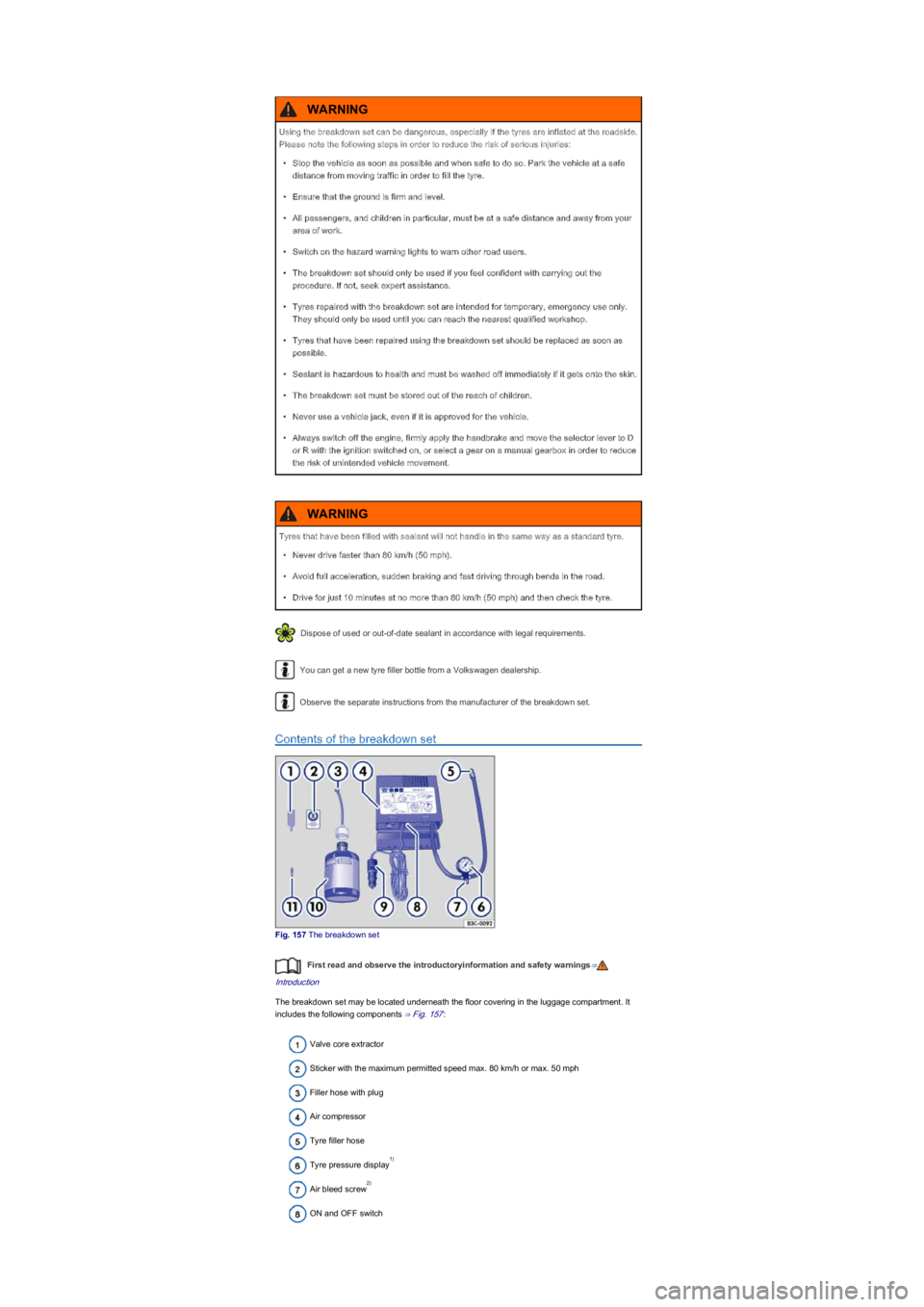

Contents of the breakdown set

Fig. 157 The breakdown set

First read and observe the introductoryinformation and safety warnings⇒

Introduction

The breakdown set may be located underneath the floor covering in the luggage compartment. It

includes the following components ⇒ Fig. 157:

Valve core extractor

Sticker with the maximum permitted speed max. 80 km/h or max. 50 mph

Filler hose with plug

Air compressor

Tyre filler hose

Tyre pressure display

Air bleed screw

ON and OFF switch

Using the breakdown set can be dangerous, especially if the tyres are inflated at the roadside.

Please note the following steps in order to reduce the risk of serious injuries:

•Stop the vehicle as soon as possible and when safe to do so. Park the vehicle at a safe

distance from moving traffic in order to fill the tyre.

•Ensure that the ground is firm and level.

•All passengers, and children in particular, must be at a safe distance and away from your

area of work.

•Switch on the hazard warning lights to warn other road users.

•The breakdown set should only be used if you feel confident with carrying out the

procedure. If not, seek expert assistance.

•Tyres repaired with the breakdown set are intended for temporary, emergency use only.

They should only be used until you can reach the nearest qualified workshop.

•Tyres that have been repaired using the breakdown set should be replaced as soon as

possible.

•Sealant is hazardous to health and must be washed off immediately if it gets onto the skin.

•The breakdown set must be stored out of the reach of children.

•Never use a vehicle jack, even if it is approved for the vehicle.

•Always switch off the engine, firmly apply the handbrake and move the selector lever to D

or R with the ignition switched on, or select a gear on a manual gearbox in order to reduce

the risk of unintended vehicle movement.

WARNING

Tyres that have been filled with sealant will not handle in the same way as a standard tyre.

•Never drive faster than 80 km/h (50 mph).

•Avoid full acceleration, sudden braking and fast driving through bends in the road.

•Drive for just 10 minutes at no more than 80 km/h (50 mph) and then check the tyre.

WARNING

1)

2)

Page 195 of 211

If you get a flat tyre, park your vehicle on a firm and level surface at a safe distance from

the flow of traffic.

Apply the handbrake firmly Braking, stopping and parking.

With an automated manual gearbox, move the selector lever to D or R with the ignition on

Changing gear.

Stop the engine and remove the vehicle key from the ignition Starting and stopping the

engine.

Manual gearbox: select a gear Changing gear.

Ensure that all vehicle occupants exit the vehicle and proceed to a safe position, e.g.

behind the safety barrier.

Switch on the hazard warning lights and position the warning triangle In an emergency.

Observe any legal requirements.

Check whether the puncture can be repaired with the breakdown set The tyre sealant must

not be used:.

Remove any items of luggage in the luggage compartment.

Take the breakdown set out of the luggage compartment.

Take the sticker ② from the breakdown set and stick it on the dash panel within the

driver's field of vision.

Do not remove foreign objects (e.g. screws or nails) from the tyre.

12-volt plug

Tyre filler bottle with sealant

Spare valve core

There is a slot on the lower end of the valve core extractor ① for the valve core. This is required

for extracting and fitting the tyre valve. This also applies to the spare valve core ⑪.

Could also be integrated in the compressor.

This function may be carried out by a button in the compressor instead.

Preparation

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Checklist

The following actions must always be carried out in the given order in preparation for filling a

tyre ⇒:

Sealing and inflating tyres

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Sealing a tyre

•Unscrew the cap from the tyre valve.

•Use the valve core extractor ⇒ Fig. 157① to screw the valve core out of the tyre valve. Place

the core on a clean surface.

•Shake the tyre filler bottle ⇒ Fig. 157⑩ vigorously up and down several times.

•Screw the filler hose ⇒ Fig. 157③ tightly onto the tyre filler bottle in a clockwise direction. The

plastic foil on the plug is pierced automatically.

•Remove the plug from the filler hose ⇒ Fig. 157③ and place the open end fully on the tyre

valve.

•Hold the bottle upside down and inject the entire contents of the tyre filler bottle into the tyre.

•Remove the empty tyre filler bottle from the valve.

•Use the valve core extractor ⇒ Fig. 157① to screw the valve core back onto the tyre valve.

Inflating the tyre

•Screw the tyre filler hose ⇒ Fig. 157⑤ of the air compressor tightly onto the tyre valve.

•Check that the bleed screw ⇒ Fig. 157⑦ is closed.

•Start the engine and let it run.

1)

1)

2)

Ignoring any of the items on this important safety checklist can lead to accidents and severe

injuries.

•Always follow the instructions in the checklist and observe the general safety procedures.

WARNING

Page 197 of 211

Several electrical consumers could share a single fuse. Conversely, a single consumer could have

more than one fuse.

Therefore fuses should only be replaced when the cause of the fault has been rectified. If a new

fuse blows shortly after insertion, have the electrical system checked by a qualified workshop as

soon as possible.

Additional information and warnings:

•Preparation for working in the engine compartment ⇒ Preparation for working in the engine

compartment

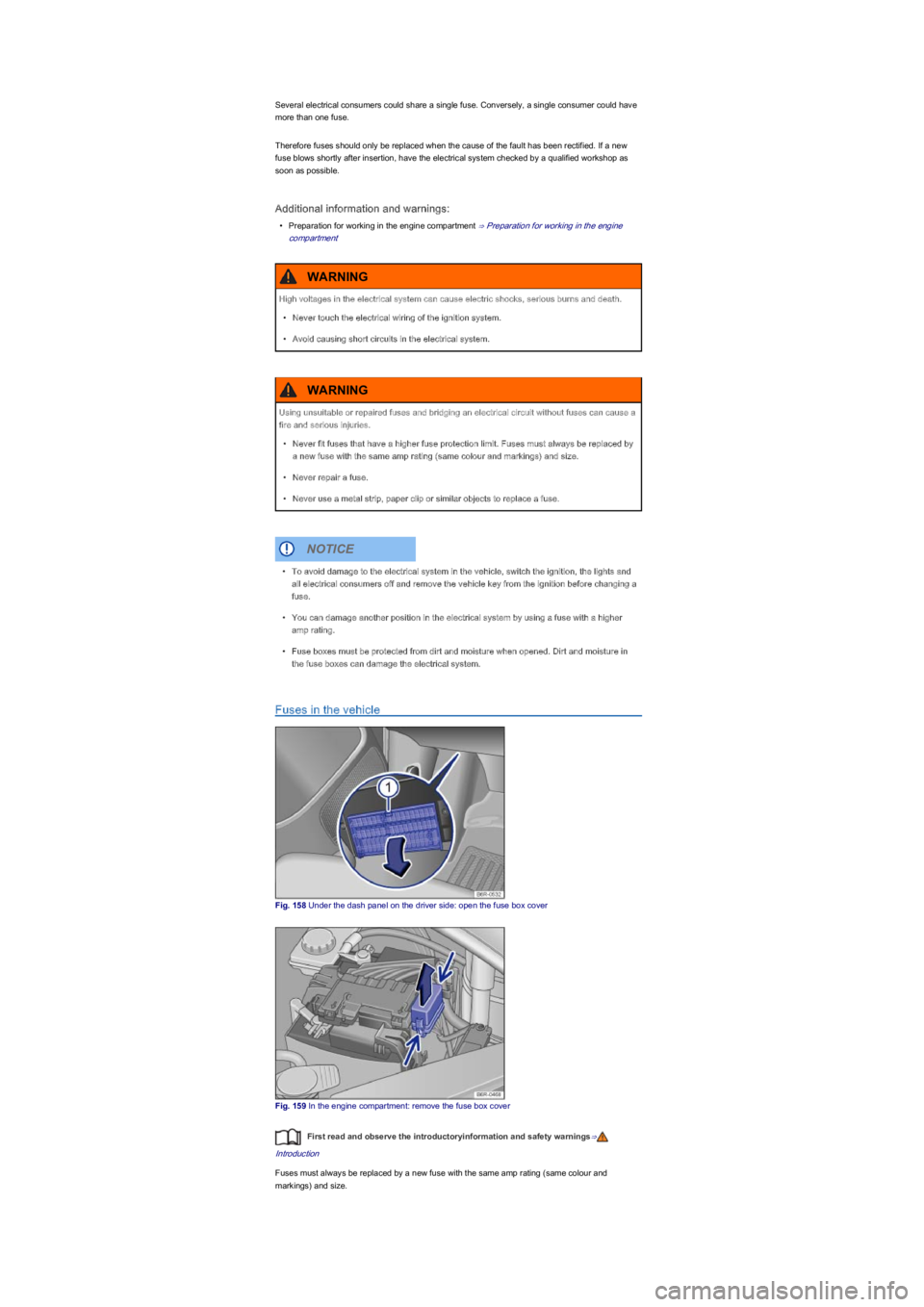

Fuses in the vehicle

Fig. 158 Under the dash panel on the driver side: open the fuse box cover

Fig. 159 In the engine compartment: remove the fuse box cover

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Fuses must always be replaced by a new fuse with the same amp rating (same colour and

markings) and size.

High voltages in the electrical system can cause electric shocks, serious burns and death.

•Never touch the electrical wiring of the ignition system.

•Avoid causing short circuits in the electrical system.

WARNING

Using unsuitable or repaired fuses and bridging an electrical circuit without fuses can cause a

fire and serious injuries.

•Never fit fuses that have a higher fuse protection limit. Fuses must always be replaced by

a new fuse with the same amp rating (same colour and markings) and size.

•Never repair a fuse.

•Never use a metal strip, paper clip or similar objects to replace a fuse.

WARNING

•To avoid damage to the electrical system in the vehicle, switch the ignition, the lights and

all electrical consumers off and remove the vehicle key from the ignition before changing a

fuse.

•You can damage another position in the electrical system by using a fuse with a higher

amp rating.

•Fuse boxes must be protected from dirt and moisture when opened. Dirt and moisture in

the fuse boxes can damage the electrical system.

NOTICE

Page 198 of 211

Colour coding of fuses under the dash panel

ColourAmp rating

Purple3

Light brown5

Brown7.5

Red10

Blue15

Yellow20

White or clear25

Green30

Orange40

Opening and closing the fuse box under the dash panel

•Opening: push the locking lever ⇒ Fig. 158① until the cover can be opened.

•Fold the cover down.

•Closing: push the cover up in the opposite direction to the arrow until it perceptibly engages in

the locking lever ①.

Opening the fuse box in the engine compartment

•Open the bonnet ⇒ Preparation for working in the engine compartment.

•Press the release buttons in the direction of the arrow (thin arrow) ⇒ Fig. 159 to release the

fuse box cover.

•Lift off the cover.

•To fit, place the cover over the fuse box. Press the release buttons down in the opposite

direction to the arrow until the release buttons click into place.

This chapter does not refer to all the fuses located in the vehicle. These should be changed

only by a qualified workshop.

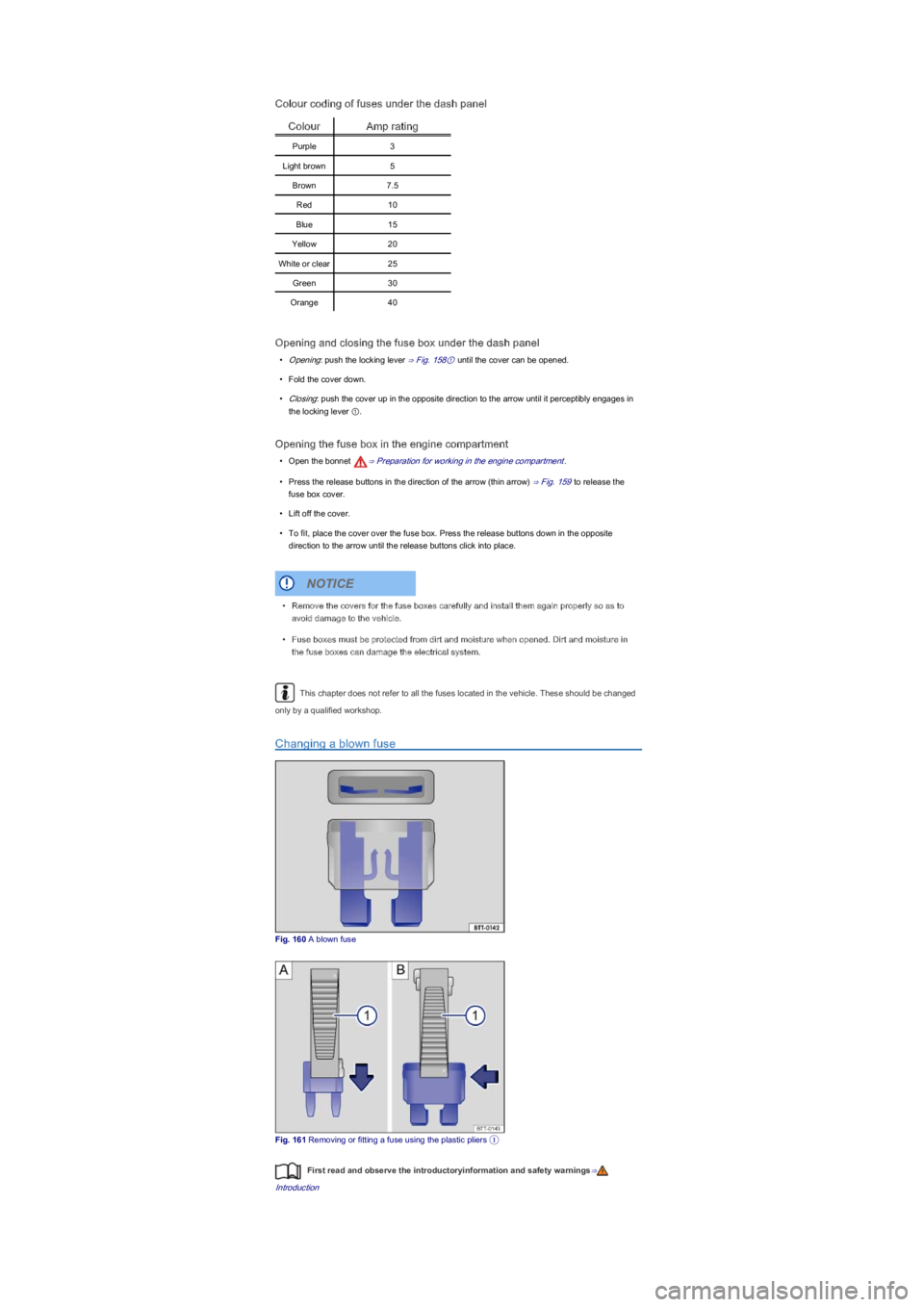

Changing a blown fuse

Fig. 160 A blown fuse

Fig. 161 Removing or fitting a fuse using the plastic pliers ①

First read and observe the introductoryinformation and safety warnings⇒

Introduction

•Remove the covers for the fuse boxes carefully and install them again properly so as to

avoid damage to the vehicle.

•Fuse boxes must be protected from dirt and moisture when opened. Dirt and moisture in

the fuse boxes can damage the electrical system.

NOTICE

Page 199 of 211

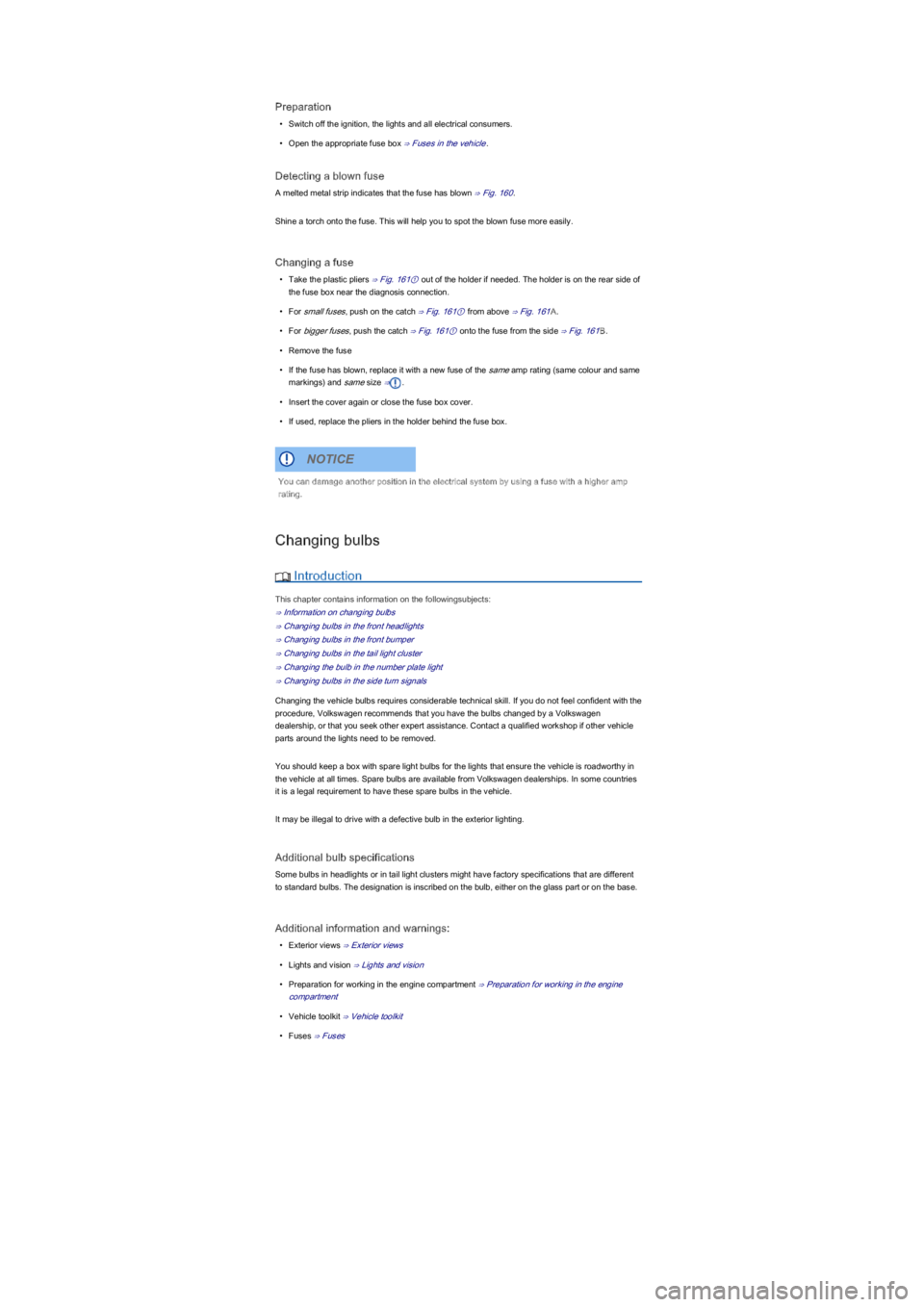

Preparation

•Switch off the ignition, the lights and all electrical consumers.

•Open the appropriate fuse box ⇒ Fuses in the vehicle.

Detecting a blown fuse

A melted metal strip indicates that the fuse has blown ⇒ Fig. 160.

Shine a torch onto the fuse. This will help you to spot the blown fuse more easily.

Changing a fuse

•Take the plastic pliers ⇒ Fig. 161① out of the holder if needed. The holder is on the rear side of

the fuse box near the diagnosis connection.

•For small fuses, push on the catch ⇒ Fig. 161① from above ⇒ Fig. 161A.

•For bigger fuses, push the catch ⇒ Fig. 161① onto the fuse from the side ⇒ Fig. 161B.

•Remove the fuse

•If the fuse has blown, replace it with a new fuse of the same amp rating (same colour and same

markings) and same size ⇒.

•Insert the cover again or close the fuse box cover.

•If used, replace the pliers in the holder behind the fuse box.

Changing bulbs

Introduction

This chapter contains information on the followingsubjects:

⇒ Information on changing bulbs

⇒ Changing bulbs in the front headlights

⇒ Changing bulbs in the front bumper

⇒ Changing bulbs in the tail light cluster

⇒ Changing the bulb in the number plate light

⇒ Changing bulbs in the side turn signals

Changing the vehicle bulbs requires considerable technical skill. If you do not feel confident with the

procedure, Volkswagen recommends that you have the bulbs changed by a Volkswagen

dealership, or that you seek other expert assistance. Contact a qualified workshop if other vehicle

parts around the lights need to be removed.

You should keep a box with spare light bulbs for the lights that ensure the vehicle is roadworthy in

the vehicle at all times. Spare bulbs are available from Volkswagen dealerships. In some countries

it is a legal requirement to have these spare bulbs in the vehicle.

It may be illegal to drive with a defective bulb in the exterior lighting.

Additional bulb specifications

Some bulbs in headlights or in tail light clusters might have factory specifications that are different

to standard bulbs. The designation is inscribed on the bulb, either on the glass part or on the base.

Additional information and warnings:

•Exterior views ⇒ Exterior views

•Lights and vision ⇒ Lights and vision

•Preparation for working in the engine compartment ⇒ Preparation for working in the engine

compartment

•Vehicle toolkit ⇒ Vehicle toolkit

•Fuses ⇒ Fuses

You can damage another position in the electrical system by using a fuse with a higher amp

rating.

NOTICE

Page 200 of 211

Park the vehicle on a firm and level surface at a safe distance from the flow of traffic.

Apply the handbrake firmly Braking, stopping and parking.

Turn the light switch to position 0 Lights.

Shift the turn signal lever to neutral Lights.

Automated manual gearbox: move the selector lever to D or R Changing gear.

Stop the engine and remove the vehicle key from the ignition Starting and stopping the

engine.

Manual gearbox: select a gear Changing gear.

Leave the defective bulbs to cool down.

Check to see if a fuse has blown Fuses.

Follow the instructions to change the affected bulb . Always use identical bulbs with the

same designation. The designation is inscribed on the bulb, either on the glass part or on

the base.

Do not touch the glass part of the bulb with unprotected fingers. The heat of the bulb would

cause the fingerprint to evaporate and condense on the reflector. This will impair the

brightness of the headlight.

After changing the bulb, check to ensure that the bulb is working properly. If the bulb is not

working properly, the bulb may not have been inserted properly or may have failed again,

or the connector may have been inserted incorrectly.

Any time you change a bulb in the front of the vehicle, the headlight settings should be

checked by a qualified workshop.

Information on changing bulbs

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Checklist

Always carry out the following actions for changing a bulb in the given order ⇒:

Accidents can occur if roads are not sufficiently illuminated and other road users have

difficulty seeing the vehicle, or cannot see it at all.

WARNING

Changing the bulb incorrectly can cause accidents and serious injuries.

•When working in the engine compartment, always read and observe the safety warnings

⇒ Preparation for working in the engine compartment. The engine compartment of any

motor vehicle is a dangerous area. Serious injuries can be sustained here.

•H4, HB4 and H7 bulbs are pressurised and could explode when they are being changed.

•Only change the defective bulb once it has had time to cool down completely.

•Never change a bulb unless you are familiar with the procedure. If you are uncertain of

what to do, the work should be carried out by a qualified workshop.

•Do not touch the glass part of the bulb with unprotected fingers. When the light is switched

on, heat will cause fingerprints to evaporate on the bulb, which in turn will cause the

reflector to dim.

•There are sharp-edged parts in the headlight housing in the engine compartment and on

the tail light cluster housing. Protect your hands when changing bulbs.

WARNING

Damage to the electrical system could be caused by water entering the system if the rubber

cover on the headlight housing is not properly mounted.

NOTICE

Ignoring any of the items on this important safety checklist can lead to accidents and severe

injuries.

•Always follow the instructions in the checklist and observe the general safety procedures.

WARNING

Always take care when removing or fitting lights to prevent damage to the paintwork or to

other vehicle parts.

NOTICE

Page 201 of 211

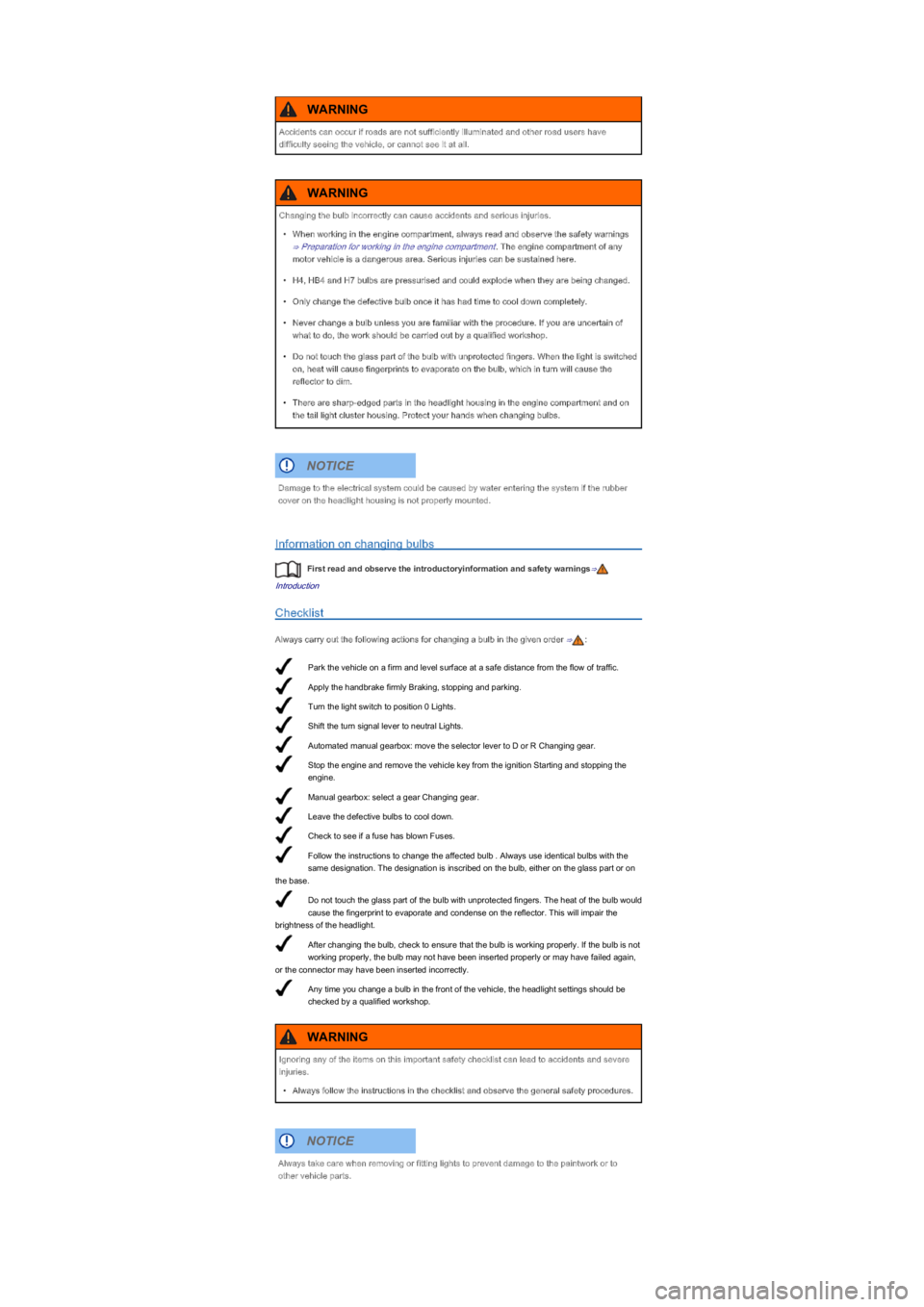

Changing bulbs in the front headlights

Fig. 162 In the engine compartment: rear view of the left-hand front headlight with rubber cover: ①

dipped beam and main beam, ② side lights and daytime running lights, ③ turn signal and

retaining clip ④

First read and observe the introductoryinformation and safety warnings⇒

Introduction

The front headlight does not need to be removed when changing bulbs.

The actions should only be carried out in the specified order:

⇒ Fig. 162①②③

Dipped beam and

main beam

headlights

Side lights and

daytime running

lights

Front turn signal

1.Observe and follow the instructions on the checklist ⇒ Information on changing

bulbs.

2.Open the bonnet ⇒ Preparation for working in the engine compartment.

3.

Remove the connector

from the H4 bulb. Pull off

rubber cover using the

tabs.Turn the bulb holder anticlockwise as far as it will go

and pull it out to the rear along with the bulb.Push retaining clip ④ in

the direction of the arrow

to the front, unhook at

side and fold away.

4.Remove bulb from bulb holder. If necessary, press the catch on the bulb holder.

5.Replace the defective bulb with a new bulb of the same type.

6.

Fit the new bulb, fold back

the retaining clips ④ and

hook in.

Insert the bulb holder into

the headlight and turn it

clockwise as far as it will

go.

Insert the bulb holder into

the headlight and turn it

clockwise as far as it will

go.

7.

Put the rubber cover on

and check if it is fitted

securely. Attach

connector to the H4 bulb.

The illustrations show the left-hand headlight from the rear. The right-hand headlight is a

mirror image of the one shown.

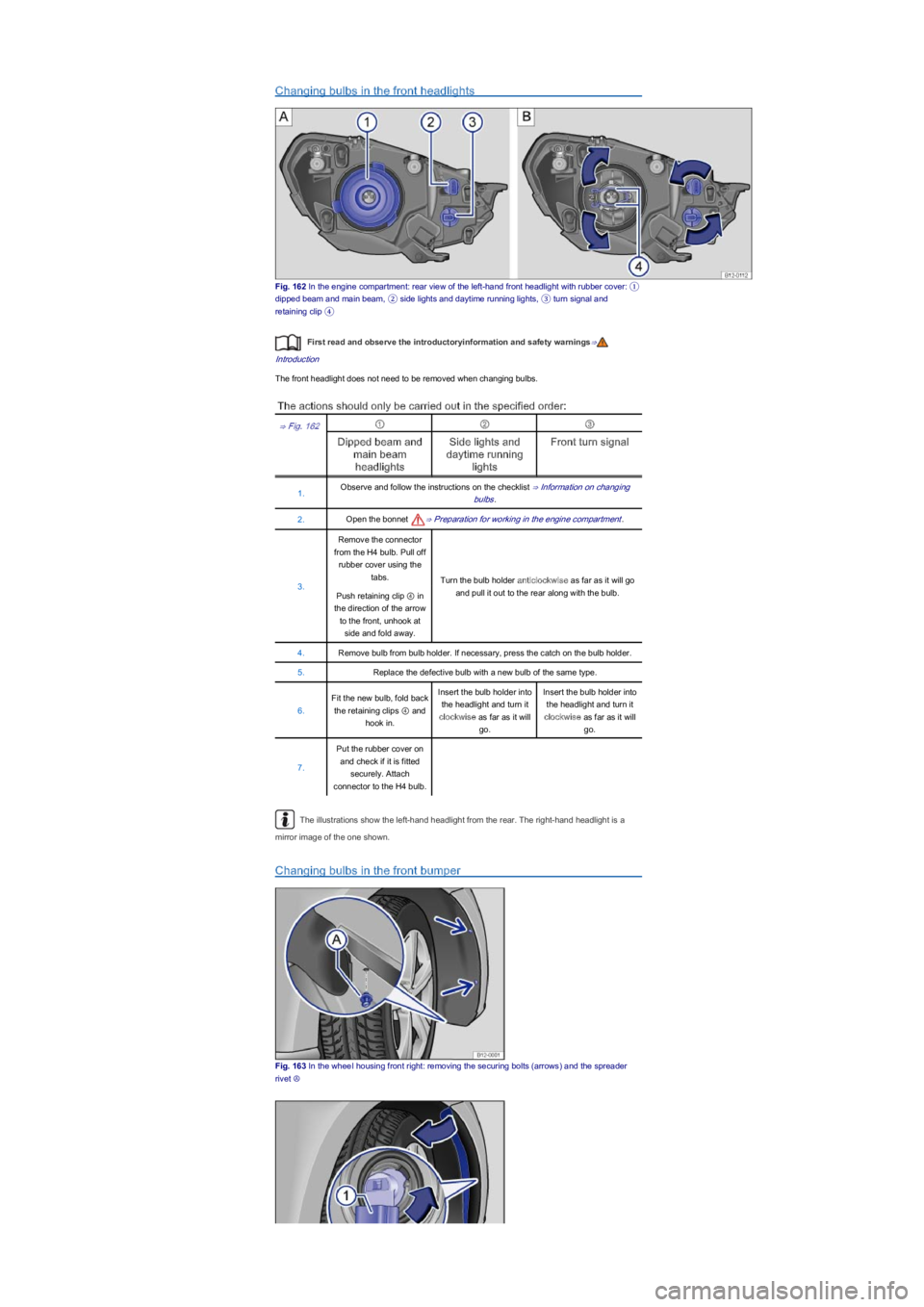

Changing bulbs in the front bumper

Fig. 163 In the wheeI housing front right: removing the securing bolts (arrows) and the spreader

rivet Ⓐ

Page 202 of 211

Fig. 164 Changing the bulbs in the headlights

First read and observe the introductoryinformation and safety warnings⇒

Introduction

The actions should only be carried out in the specified order:

1.Observe and follow the instructions on the checklist ⇒ Information on changing bulbs.

2.Use the screwdriver from the toolkit to unscrew the two securing bolts in the wheel

housing trim ⇒ Fig. 163 (arrows) ⇒ Vehicle toolkit.

3.Unscrew the front spreader rivet at the bottom of the wheel housing trim ⇒ Fig. 163Ⓐ

and remove it completely.

4.Grip the edge of the wheel housing trim in between the holes for the securing bolts and

push it gently towards the vehicle interior to release the clip located behind the trim.

5.Carefully push the wheel housing trim to one side.

6.Release the connector ⇒ Fig. 164① and pull it off.

7.Turn the bulb holder ⇒ Fig. 164anticlockwise in the direction of the arrow as far as it will

go and pull it out to the rear along with the bulb.

8.Replace the defective bulb with a new bulb of the same type.

9.Insert the bulb holder into the headlight and turn it clockwise as far as it will go.

10.Connect the connector ⇒ Fig. 164① to the bulb holder. The connector should click into

place.

11.Return the wheel housing trim to its original position, ensuring that the clip engages.

12.Insert the spreader river in the wheel housing trim and the bumper and push in fully

⇒ Fig. 163Ⓐ.

13.Use the screwdriver to screw in the two securing bolts ⇒ Fig. 163 (arrows).

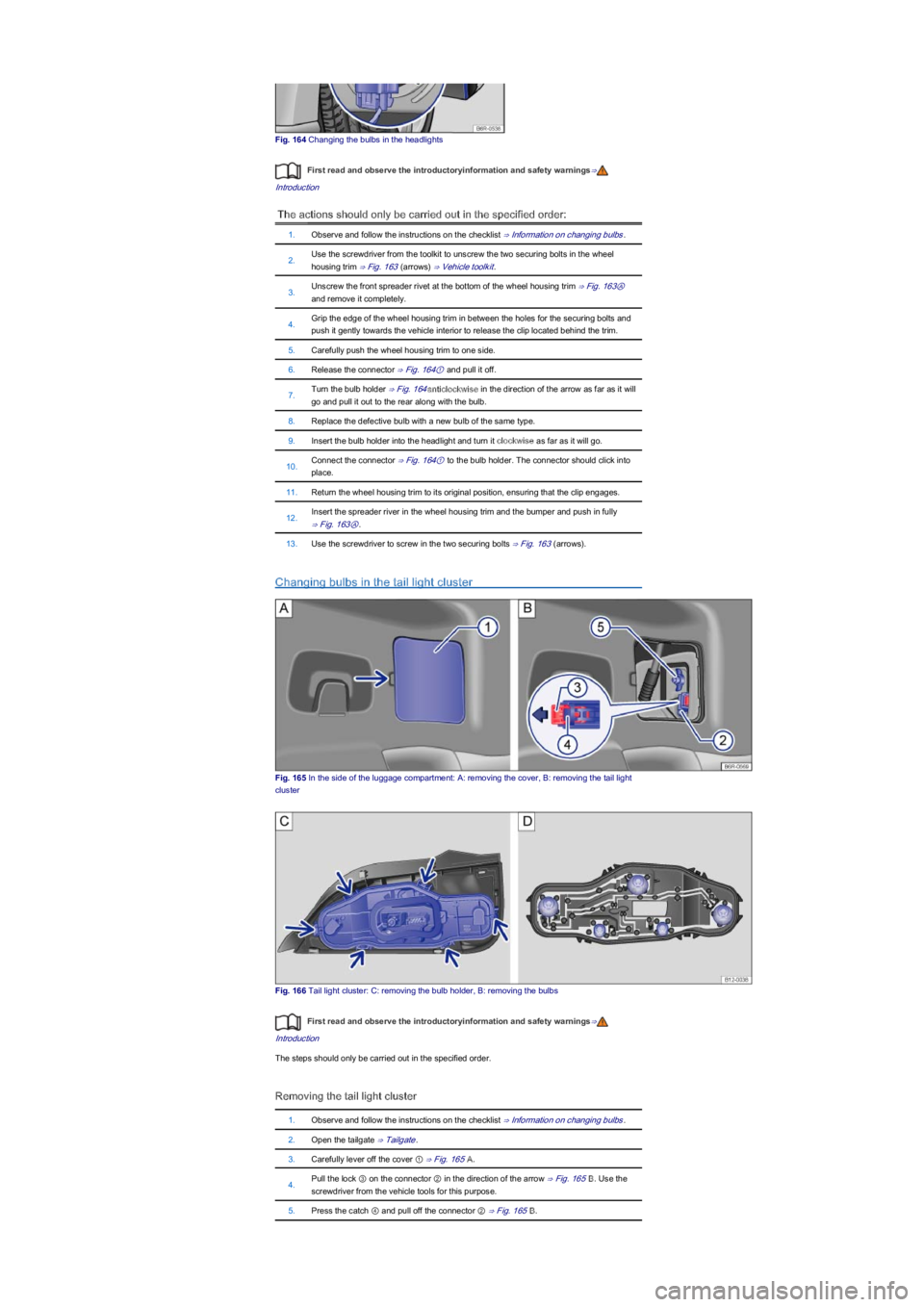

Changing bulbs in the tail light cluster

Fig. 165 In the side of the luggage compartment: A: removing the cover, B: removing the tail light

cluster

Fig. 166 Tail light cluster: C: removing the bulb holder, B: removing the bulbs

First read and observe the introductoryinformation and safety warnings⇒

Introduction

The steps should only be carried out in the specified order.

Removing the tail light cluster

1.Observe and follow the instructions on the checklist ⇒ Information on changing bulbs.

2.Open the tailgate ⇒ Tailgate.

3.Carefully lever off the cover ① ⇒ Fig. 165A.

4.Pull the lock ③ on the connector ② in the direction of the arrow ⇒ Fig. 165B. Use the

screwdriver from the vehicle tools for this purpose.

5.Press the catch ④ and pull off the connector ② ⇒ Fig. 165B.

Page 203 of 211

6.Remove the wing nut ⑤ ⇒ Fig. 165B.

7.Carefully pull the tail light cluster out and remove it from the body.

8.Remove the tail light cluster and place it on a clean, flat surface.

Changing the bulb

9.Release the bulb holder at the tabs (arrows) ⇒ Fig. 166C and remove the bulb holder

from the rear light cluster.

10.Replace the defective bulb with a new bulb of the same type ⇒ Fig. 166D.

11.Insert the bulb holder into the tail light cluster. The release tabs (arrows) ⇒ Fig. 166C

must click into place.

Fitting the tail light cluster

12.Carefully put the tail light cluster into the opening in the body.

13.Use one hand to hold the tail light cluster in the fitting position while using the other hand

to tighten the wing nut ⑤ ⇒ Fig. 165B.

14.Check that the tail light cluster is positioned correctly and securely.

15.Fit the connector ② to the bulb holder and push in the catch ③ against the direction

shown by the arrow ⇒ Fig. 165B.

16.Replace the cover. The cover must engage fully and securely.

17.Close the tailgate ⇒ Tailgate.

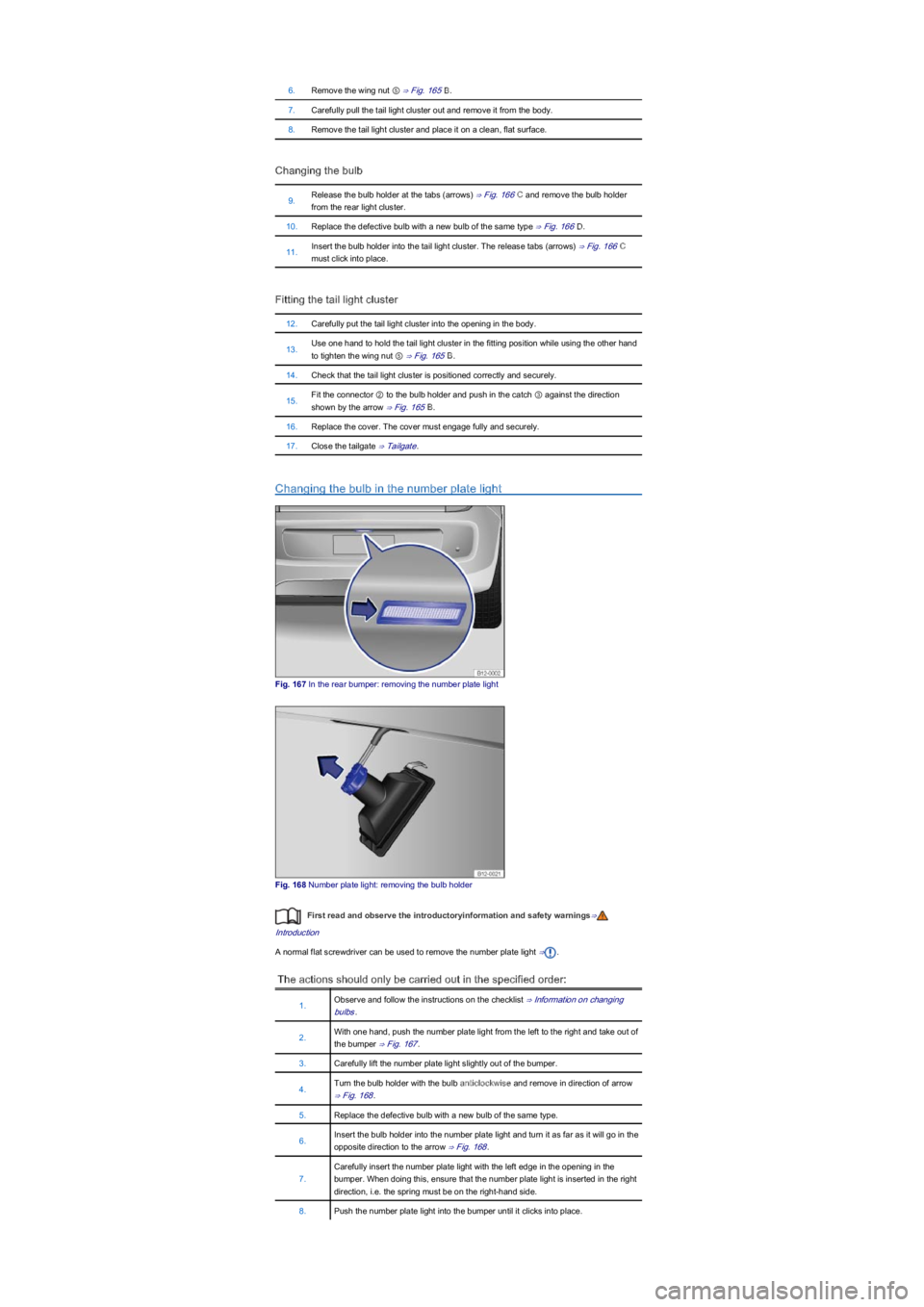

Changing the bulb in the number plate light

Fig. 167 In the rear bumper: removing the number plate light

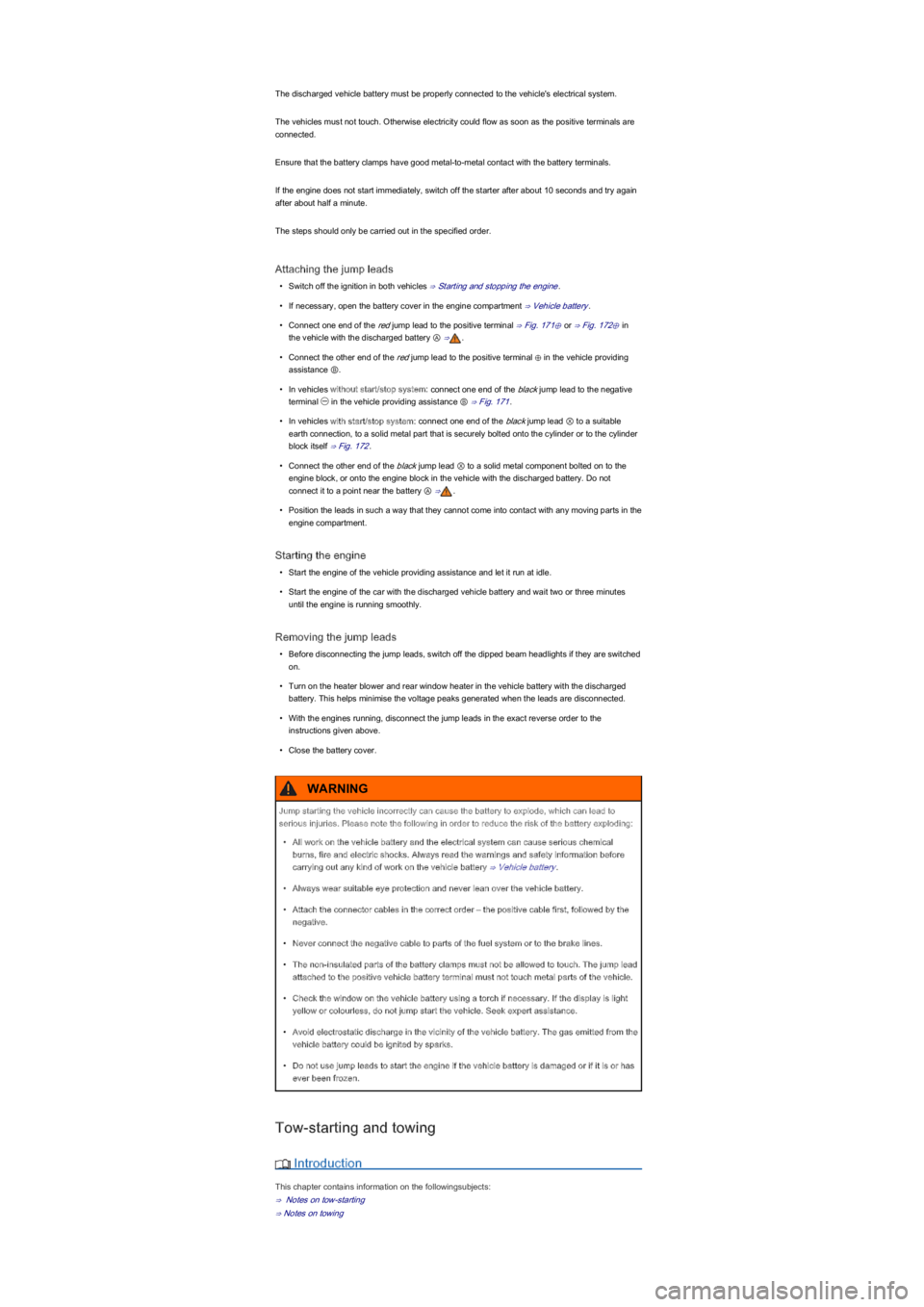

Fig. 168 Number plate light: removing the bulb holder

First read and observe the introductoryinformation and safety warnings⇒

Introduction

A normal flat screwdriver can be used to remove the number plate light ⇒.

The actions should only be carried out in the specified order:

1.Observe and follow the instructions on the checklist ⇒ Information on changing

bulbs.

2.With one hand, push the number plate light from the left to the right and take out of

the bumper ⇒ Fig. 167.

3.Carefully lift the number plate light slightly out of the bumper.

4.Turn the bulb holder with the bulb anticlockwise and remove in direction of arrow

⇒ Fig. 168.

5.Replace the defective bulb with a new bulb of the same type.

6.Insert the bulb holder into the number plate light and turn it as far as it will go in the

opposite direction to the arrow ⇒ Fig. 168.

7.

Carefully insert the number plate light with the left edge in the opening in the

bumper. When doing this, ensure that the number plate light is inserted in the right

direction, i.e. the spring must be on the right-hand side.

8.Push the number plate light into the bumper until it clicks into place.

Page 206 of 211

The discharged vehicle battery must be properly connected to the vehicle's electrical system.

The vehicles must not touch. Otherwise electricity could flow as soon as the positive terminals are

connected.

Ensure that the battery clamps have good metal-to-metal contact with the battery terminals.

If the engine does not start immediately, switch off the starter after about 10 seconds and try again

after about half a minute.

The steps should only be carried out in the specified order.

Attaching the jump leads

•Switch off the ignition in both vehicles ⇒ Starting and stopping the engine.

•If necessary, open the battery cover in the engine compartment ⇒ Vehicle battery.

•Connect one end of the red jump lead to the positive terminal ⇒ Fig. 171⊕ or ⇒ Fig. 172⊕ in

the vehicle with the discharged battery Ⓐ ⇒.

•Connect the other end of the red jump lead to the positive terminal ⊕ in the vehicle providing

assistance Ⓑ.

•In vehicles without start/stop system: connect one end of the black jump lead to the negative

terminal ㊀ in the vehicle providing assistance Ⓑ ⇒ Fig. 171.

•In vehicles with start/stop system: connect one end of the black jump lead Ⓧ to a suitable

earth connection, to a solid metal part that is securely bolted onto the cylinder or to the cylinder

block itself ⇒ Fig. 172.

•Connect the other end of the black jump lead Ⓧ to a solid metal component bolted on to the

engine block, or onto the engine block in the vehicle with the discharged battery. Do not

connect it to a point near the battery Ⓐ ⇒.

•Position the leads in such a way that they cannot come into contact with any moving parts in the

engine compartment.

Starting the engine

•Start the engine of the vehicle providing assistance and let it run at idle.

•Start the engine of the car with the discharged vehicle battery and wait two or three minutes

until the engine is running smoothly.

Removing the jump leads

•Before disconnecting the jump leads, switch off the dipped beam headlights if they are switched

on.

•Turn on the heater blower and rear window heater in the vehicle battery with the discharged

battery. This helps minimise the voltage peaks generated when the leads are disconnected.

•With the engines running, disconnect the jump leads in the exact reverse order to the

instructions given above.

•Close the battery cover.

Tow-starting and towing

Introduction

This chapter contains information on the followingsubjects:

⇒ Notes on tow-starting

⇒ Notes on towing

Jump starting the vehicle incorrectly can cause the battery to explode, which can lead to

serious injuries. Please note the following in order to reduce the risk of the battery exploding:

•All work on the vehicle battery and the electrical system can cause serious chemical

burns, fire and electric shocks. Always read the warnings and safety information before

carrying out any kind of work on the vehicle battery ⇒ Vehicle battery.

•Always wear suitable eye protection and never lean over the vehicle battery.

•Attach the connector cables in the correct order – the positive cable first, followed by the

negative.

•Never connect the negative cable to parts of the fuel system or to the brake lines.

•The non-insulated parts of the battery clamps must not be allowed to touch. The jump lead

attached to the positive vehicle battery terminal must not touch metal parts of the vehicle.

•Check the window on the vehicle battery using a torch if necessary. If the display is light

yellow or colourless, do not jump start the vehicle. Seek expert assistance.

•Avoid electrostatic discharge in the vicinity of the vehicle battery. The gas emitted from the

vehicle battery could be ignited by sparks.

•Do not use jump leads to start the engine if the vehicle battery is damaged or if it is or has

ever been frozen.

WARNING