rims VOLKSWAGEN UP! 2021 Owner´s Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 2021, Model line: UP!, Model: VOLKSWAGEN UP! 2021Pages: 211, PDF Size: 5.98 MB

Page 160 of 211

Rims

First read and observe the introductoryinformation and safety warnings⇒

Introduction

The design of the wheel bolts is matched to the rims. If different rims are fitted, the correct wheel

bolts with the right length and correctly shaped bolt heads must be used. This ensures that the

wheels are fitted securely and that the brake system works properly ⇒ Changing a wheel.

For technical reasons, it is not generally possible to use the wheels from other vehicles. This can

also apply to wheels of the same vehicle type.

The tyres and rims approved by Volkswagen are specifically matched to the characteristics of the

vehicle and make a major contribution to good road holding and safe handling.

Wheel bolts

Wheel bolts must always be tightened with the correct tightening torque ⇒ Changing a wheel.

Rims with bolted-on rings

Rims with bolted-on rings consist of several components. These components are fastened using

special bolts and special fastening technology. This ensures that the wheel functions properly, does

not leak, remains safe and runs true. For this reason, damaged rims should be replaced. They may

only be repaired by a qualified workshop. Volkswagen recommends using a Volkswagen dealership

for this purpose ⇒.

Rims with bolted-on trims

Rims may have removable trims that are attached to the rim with self-locking bolts. Damaged trims

may only be repaired by a qualified workshop. Volkswagen recommends using a Volkswagen

dealership for this purpose ⇒.

Rims identification

In some countries, new rims are legally required to contain certain specifications on them.

Depending on the country the following specifications can appear on the rims:

•Seal of conformity

•Rim size

•Name of manufacturer or brand name

•Date manufactured (month / year)

•Country of origin

•Production number

•Raw materials batch number

•Product code

New wheels and tyres

First read and observe the introductoryinformation and safety warnings⇒

Introduction

New tyres

•Drive particularly carefully for the first 600 km with new tyres as the tyres have to be run in.

Tyres that have not been run in have reduced grip ⇒ and braking effect ⇒.

•All four wheels must be fitted with radial tyres of the same type, size (rolling circumference) and

the same tread.

The use of unsuitable or damaged rims can impair vehicle safety and cause accidents and

serious injury.

•Only use rims that have been approved for the vehicle.

•Check the rims regularly for damage and replace as necessary.

WARNING

Incorrect loosening and tightening of the bolts on rims with bolted-on rings can cause

accidents and serious injury.

•Never remove the bolts on rims with bolted-on rings.

•All work on rims with bolted-on rings must be carried out by a qualified workshop.

Volkswagen recommends using a Volkswagen dealership for this purpose.

WARNING

Page 163 of 211

Tyre damage

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Damage to tyres and rims is often not readily visible. Any unusual vibrations or signs that the car is

pulling to one side may indicate that one of the tyres is damaged ⇒.

•Reduce your speed immediately if you suspect that a wheel is damaged.

•Check the tyres and rims for damage.

•If the tyre is damaged, do not drive on. Seek expert assistance.

•If there is no visible damage, drive slowly and cautiously to the next qualified workshop in order

to have the vehicle checked.

Foreign bodies in the tyre

•Leave the foreign body in the tyre if it has entered the inner tyre. However, foreign bodies that

are stuck between the tyre tread blocks can be removed.

•For vehicles with a spare wheel or temporary spare wheel: where appropriate, change the

damaged wheel ⇒ Changing a wheel If required, seek expert assistance when changing the

damaged wheel. Volkswagen recommends using a Volkswagen dealership for this purpose.

•For vehicles with a breakdown set: if required, seal the tyre and pump it up using the

breakdown set ⇒ Breakdown set. Proceed to a qualified workshop. Volkswagen recommends

using a Volkswagen dealership for this purpose.

•Check the pressure and adjust it as required.

Tyre wear

Tyre wear is affected by several factors. These include:

•Driving style.

•Unbalanced wheels.

•Running gear setting.

Driving style – fast cornering, heavy acceleration and hard braking all increase tyre wear. The

running gear should be checked by a qualified workshop if the tyres show excessive wear despite a

normal driving style.

Unbalanced wheels – the wheels on new vehicles are balanced. However, various factors

encountered in normal driving can cause them to become unbalanced, which results in steering

vibration. Unbalanced wheels will affect levels of wear on the steering system and the suspension.

In this case the wheels should be balanced again. A new tyre will have to be balanced after fitting.

Running gear setting – incorrect wheel alignment causes excessive tyre wear, impairing the safety

of the vehicle. The wheel alignment should be checked by a qualified workshop if tyres show

excessive wear.

Spare wheel or temporary spare wheel

Worn tyres are a safety risk and can lead to a loss of control of the vehicle and cause serious

injury.

•Tyres must be replaced at the latest when the tread is worn down to the tread wear

indicators.

•Worn tyres have considerably less tread, particularly on wet roads, which can cause the

vehicle to glide along the road surface (aquaplaning).

•Worn tyres reduce the possibility of controlling the vehicle well in normal and difficult

driving situations and increase braking distance and the risk of sliding.

WARNING

If you notice unusual vibration or the car pulling to one side while the vehicle is in motion, this

may indicate that one of the tyres is damaged.

•Reduce speed immediately and park the vehicle without obstructing traffic.

•Check the tyres and rims for damage.

•Never drive on if wheels or tyres are damaged. Seek expert assistance instead.

•If there is no visible damage, drive slowly and cautiously to the next qualified workshop in

order to have the vehicle checked.

WARNING

Page 181 of 211

Practical tips

Frequently asked questions

If you suspect that there is a fault in the vehicle or if your vehicle has been damaged, read and

observe the following information before contacting a Volkswagen dealership or qualified

workshop. You may also find useful information in the index under the headings Things to note or

Checklist.

IrregularitySome possible causesPossible solution

Engine does not start.

Vehicle battery is discharged.

– Jump start the engine ⇒ Starting the

engine with jump leads.

– Recharge the vehicle battery

⇒ Vehicle battery.

An incorrect vehicle key is

being used.

Use a valid vehicle key ⇒ Vehicle key

set.

The fuel level is too low.Fill the tank ⇒ Filling the tank.

Vehicle cannot be locked

or unlocked with the

vehicle key.

– The battery in the vehicle

key is discharged.

– The vehicle key is too far

away from the vehicle.

– Replace battery ⇒ Vehicle key set.

– Move closer to the vehicle.

– Synchronise vehicle key ⇒ Vehicle

key set.

– Unlock or lock vehicle manually

⇒ Manual opening and closing.

Unusual noises.

Cold engine, brake assist

systems, electronic steering

column lock, auxiliary heater,

filling up with natural gas.

Refer to the index under entries for

Noises.

Unusual handling.

Assist systems are active.Refer to the index under entries for

Assist systems.

An incorrect tyre pressure is

being used.

Check tyre pressure ⇒ Wheels and

tyres.

Damage to the tyre or wheel.

Check the rims and tyres regularly for

damage ⇒ Wheels and tyres and

replace as necessary ⇒ Changing a

wheel.

The vehicle has no

vehicle jack, spare wheel

or breakdown set.

Equipment depends on type

of vehicle.

No direct solutions possible as it

depends on the equipment level.

Contact a Volkswagen dealership if

necessary ⇒ Vehicle toolkit.

The road ahead is not lit

up properly.

– Headlight has been masked

for driving on the left or on the

right.

– Headlight not adjusted

correctly.

– Bulbs have failed.

– Dipped beam headlight not

switched on.

– Mask the headlights accordingly for

driving on the left or right ⇒ Lights.

– Adjust headlight range ⇒ Lights.

– Change bulbs ⇒ Changing bulbs.

– Switch dipped headlights on

⇒ Lights.

Electrical consumers not

working.

Low vehicle battery charge.Recharge vehicle battery ⇒ Vehicle

battery.

Low fuel level.Fill the tank ⇒ Filling the tank.

Fuse blown.Check fuse and replace as necessary

⇒ Fuses.

Fuel consumption is

higher than indicated.

– Short distances driven.

– Uneven acceleration.

– Avoid driving short distances.

– Think ahead when driving.

– Accelerate evenly.

An electrical consumer is

switched on.

Switch off all consumers that are not

needed.

Fault in engine management

system.

Have the fault rectified ⇒ Engine

management system and exhaust

purification system.

Tyre pressure too low.Adjust the tyre pressure ⇒ Wheels

and tyres.

Driving in hilly regions.No direct solutions possible.

Driving with a heavy load.No direct solutions possible.

Driving at high engine speed.Select a high gear.

In an emergency

Introduction

This chapter contains information on the followingsubjects:

⇒ Making you and your vehicle safe

⇒ First aid kit, warning triangle and fire extinguisher

Additional information and warnings:

Page 188 of 211

The centre cover has to be pulled off to gain access to the wheel bolts.

Removing and installing the centre cover

•To remove: take the wire hook from the toolkit and insert it in a hole (alloy wheel) or into an

edge on the cover (steel wheel) ⇒ Fig. 148 or ⇒ Fig. 149.

•Remove the cover in the direction of the arrow.

•To replace: press the centre cover against the rim until you feel it engage.

The centre cover protects the wheel bolts and must be replaced after changing the tyre.

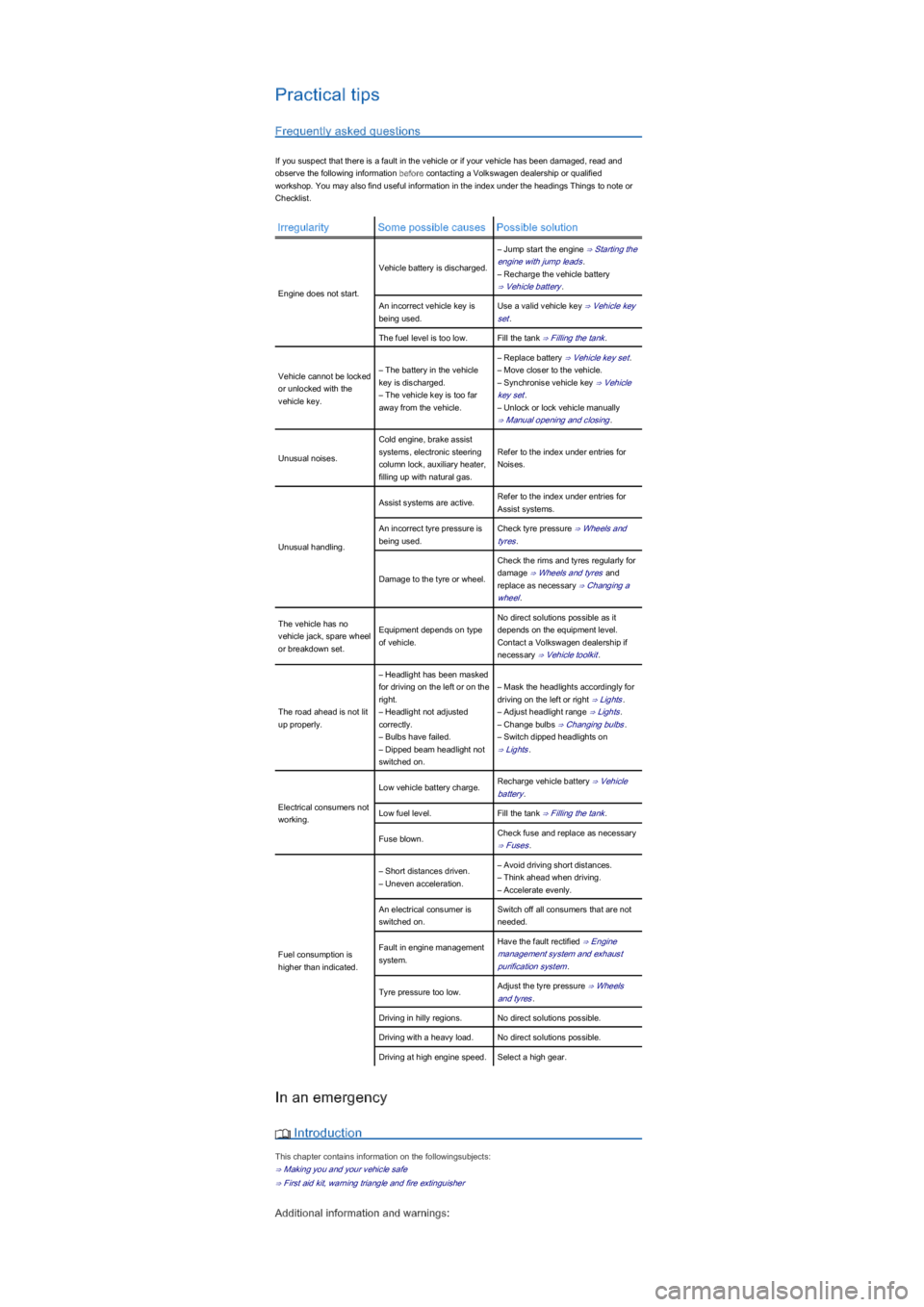

Wheel cover

Fig. 150 Removing the wheel covers

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Removing the wheel covers

•Take the box spanner and wire hook from the vehicle toolkit ⇒ Vehicle toolkit.

•Insert the wire hook into one of the holes in the wheel cover.

•Push the box spanner through the wire hook ⇒ Fig. 150 and remove the wheel cover in the

direction of the arrow.

Fitting the wheel covers

The wheel covers must be pushed on to the rims with the hole for the valve aligned with the valve.

When fitting the wheel cover, ensure that it engages securely on the entire circumference. If using

an anti-theft wheel bolt, insert the bolt in the position opposite the valve.

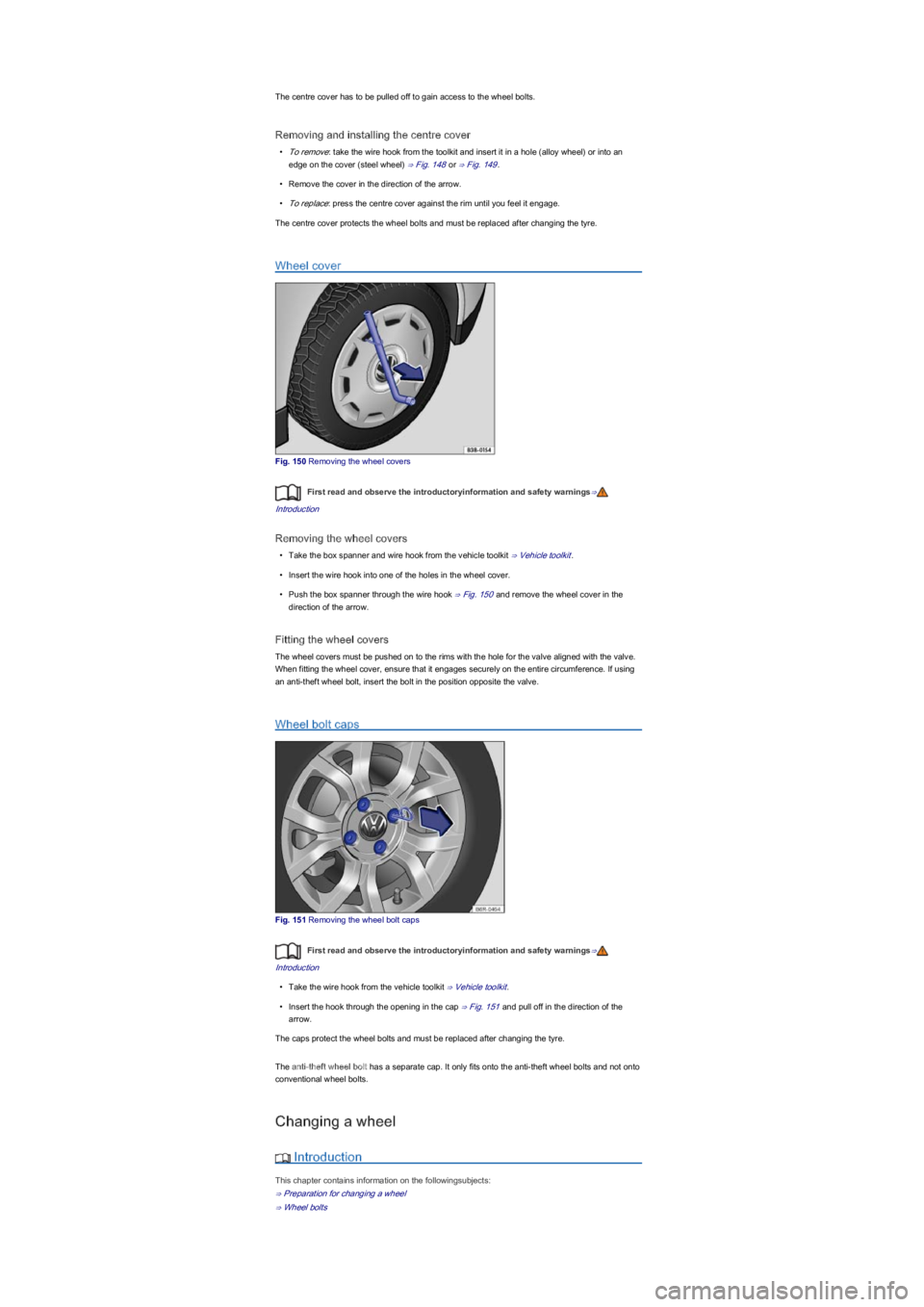

Wheel bolt caps

Fig. 151 Removing the wheel bolt caps

First read and observe the introductoryinformation and safety warnings⇒

Introduction

•Take the wire hook from the vehicle toolkit ⇒ Vehicle toolkit.

•Insert the hook through the opening in the cap ⇒ Fig. 151 and pull off in the direction of the

arrow.

The caps protect the wheel bolts and must be replaced after changing the tyre.

The anti-theft wheel bolt has a separate cap. It only fits onto the anti-theft wheel bolts and not onto

conventional wheel bolts.

Changing a wheel

Introduction

This chapter contains information on the followingsubjects:

⇒ Preparation for changing a wheel

⇒ Wheel bolts

Page 190 of 211

Wheel bolts

Fig. 152 Changing a wheel: loosening the wheel bolts

Fig. 153 Changing wheel: tyre valve ① and location of the anti-theft wheel bolt ②

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Only the spanner delivered with the vehicle should be used to loosen the wheel bolts.

Only loosen the wheel bolts by approximately one turn before raising the vehicle with the vehicle

jack.

If the wheel bolt is very tight, you may be able to loosen it by pushing down the end of the spanner

carefully with your foot. Hold on to the car for support and take care not to slip.

Loosening the wheel bolts

•Fit the box spanner over the wheel bolt as far as it will go ⇒ Fig. 152.

•Hold the end of the box spanner and turn the wheel bolt one turn anticlockwise ⇒.

Loosening the anti-theft wheel bolt

The anti-theft wheel bolt must be bolted into position ⇒ Fig. 153② on wheels with a wheel cover.

Otherwise, it will not be possible to fit the wheel cover.

•Take the adapter for anti-theft wheel bolts out of the vehicle toolkit.

•Insert the adapter into the anti-theft wheel bolt ⇒ Fig. 153. Push it in as far as it will go.

•Insert the box spanner into the adapter as far as it will go.

•Hold the end of the box spanner and turn the wheel bolt one turn anticlockwise ⇒.

Important information about the wheel bolts

The design of the wheel rims and wheel bolts is matched to the factory-fitted wheels. If different

rims are fitted, the correct wheel bolts with the right length and correctly shaped bolt heads must be

used. This ensures that wheels are fitted securely and that the brake system works properly.

In certain circumstances, wheel bolts from a vehicle of the same model series may not be used.

Tightening torque for the wheel bolts

The tightening torque for wheel bolts for steel and alloy wheels is 110 Nm. The tightening torque

should be checked with a torque wrench immediately after changing a wheel.

If the wheel bolts are corroded and difficult to turn, they must be replaced and the wheel hub

threads cleaned before the tightening torque is checked.

Never grease or lubricate the wheel bolts or the threads of the wheel hub. This could cause them to

loosen while the vehicle is in motion, even if the required torque setting is used.

Ignoring any of the items on this important safety checklist can lead to accidents and severe

injuries.

•Always follow the instructions in the checklist and observe the general safety procedures.

WARNING

Page 191 of 211

Find a firm and level surface suitable for lifting the vehicle.

Stop the engine, select a gear on a manual gearbox or with an automated manual

gearbox, move the selector lever to D or R with the ignition switched onChanging gear

then apply the handbrake firmly Braking, stopping and parking.

Chock the wheel diagonally opposite using the collapsible chocks or other suitable objects.

Loosen the wheel bolts on the wheel that is being changed Wheel bolts.

Find the jacking point under the vehicle which is closest to the wheel that is being

changed.

Raise the vehicle jack until it just fits under the jacking point of the vehicle.

Ensure that the foot of the jack is resting securely on the ground with its whole surface and

that the foot of the jack is positioned precisely, i.e. vertically beneath the point of

application .

Position the vehicle jack. At the same time, continue to crank the claw up until it is in

position around the vertical rib underneath the vehicle .

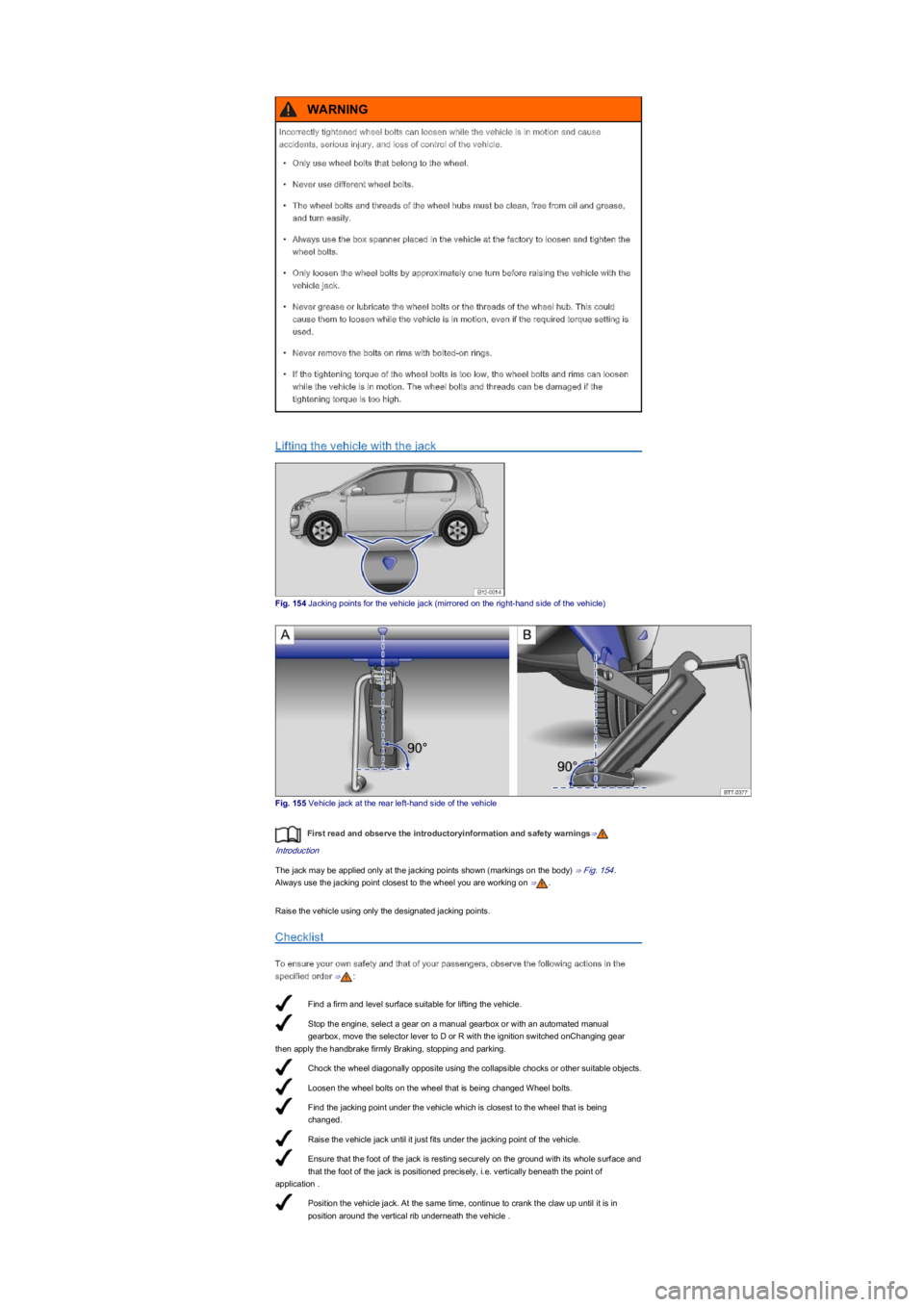

Lifting the vehicle with the jack

Fig. 154 Jacking points for the vehicle jack (mirrored on the right-hand side of the vehicle)

Fig. 155 Vehicle jack at the rear left-hand side of the vehicle

First read and observe the introductoryinformation and safety warnings⇒

Introduction

The jack may be applied only at the jacking points shown (markings on the body) ⇒ Fig. 154.

Always use the jacking point closest to the wheel you are working on ⇒.

Raise the vehicle using only the designated jacking points.

Checklist

To ensure your own safety and that of your passengers, observe the following actions in the

specified order ⇒:

Incorrectly tightened wheel bolts can loosen while the vehicle is in motion and cause

accidents, serious injury, and loss of control of the vehicle.

•Only use wheel bolts that belong to the wheel.

•Never use different wheel bolts.

•The wheel bolts and threads of the wheel hubs must be clean, free from oil and grease,

and turn easily.

•Always use the box spanner placed in the vehicle at the factory to loosen and tighten the

wheel bolts.

•Only loosen the wheel bolts by approximately one turn before raising the vehicle with the

vehicle jack.

•Never grease or lubricate the wheel bolts or the threads of the wheel hub. This could

cause them to loosen while the vehicle is in motion, even if the required torque setting is

used.

•Never remove the bolts on rims with bolted-on rings.

•If the tightening torque of the wheel bolts is too low, the wheel bolts and rims can loosen

while the vehicle is in motion. The wheel bolts and threads can be damaged if the

tightening torque is too high.

WARNING