wheel VOLKSWAGEN UP! 2021 Owner´s Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 2021, Model line: UP!, Model: VOLKSWAGEN UP! 2021Pages: 211, PDF Size: 5.98 MB

Page 191 of 211

Find a firm and level surface suitable for lifting the vehicle.

Stop the engine, select a gear on a manual gearbox or with an automated manual

gearbox, move the selector lever to D or R with the ignition switched onChanging gear

then apply the handbrake firmly Braking, stopping and parking.

Chock the wheel diagonally opposite using the collapsible chocks or other suitable objects.

Loosen the wheel bolts on the wheel that is being changed Wheel bolts.

Find the jacking point under the vehicle which is closest to the wheel that is being

changed.

Raise the vehicle jack until it just fits under the jacking point of the vehicle.

Ensure that the foot of the jack is resting securely on the ground with its whole surface and

that the foot of the jack is positioned precisely, i.e. vertically beneath the point of

application .

Position the vehicle jack. At the same time, continue to crank the claw up until it is in

position around the vertical rib underneath the vehicle .

Lifting the vehicle with the jack

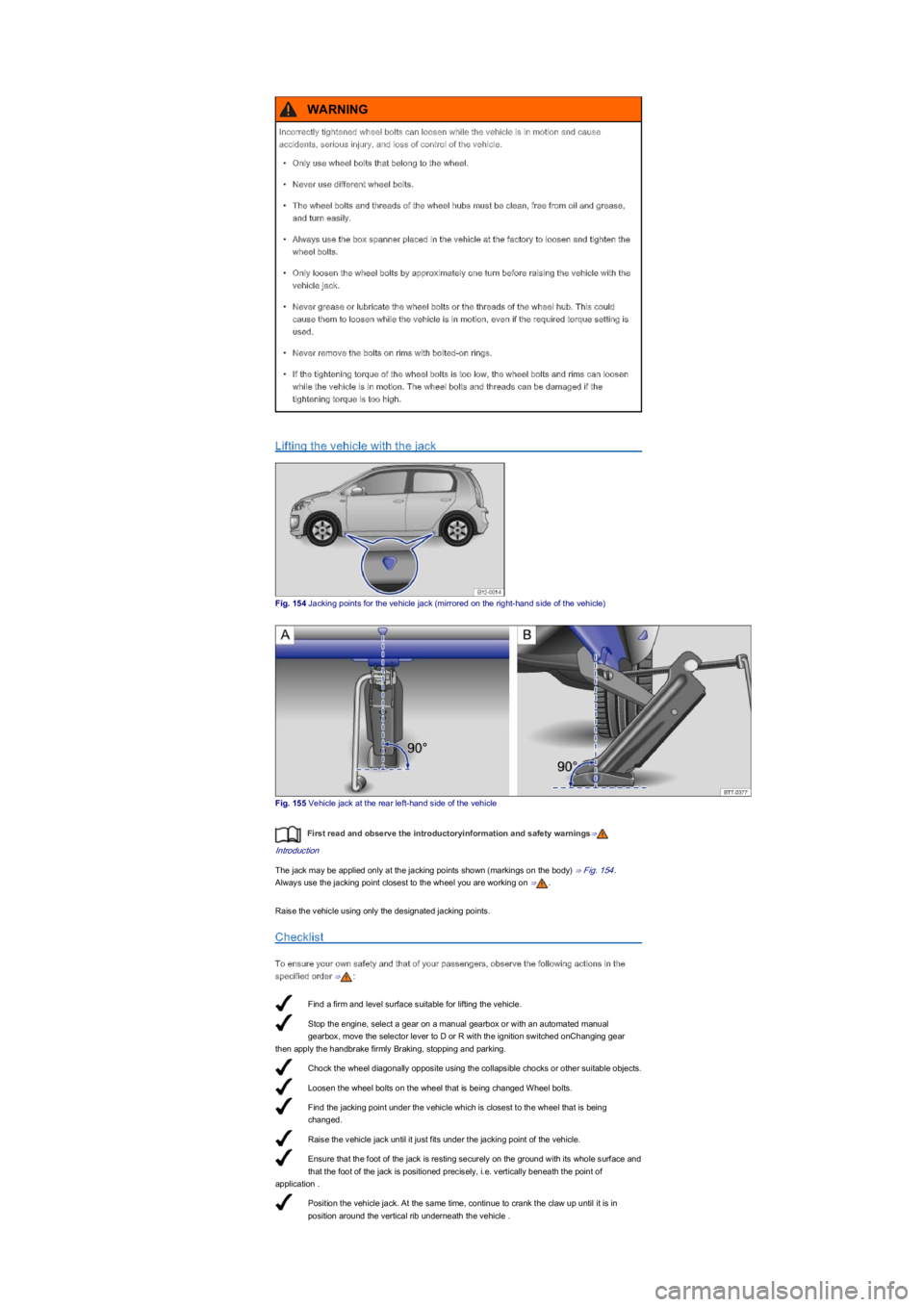

Fig. 154 Jacking points for the vehicle jack (mirrored on the right-hand side of the vehicle)

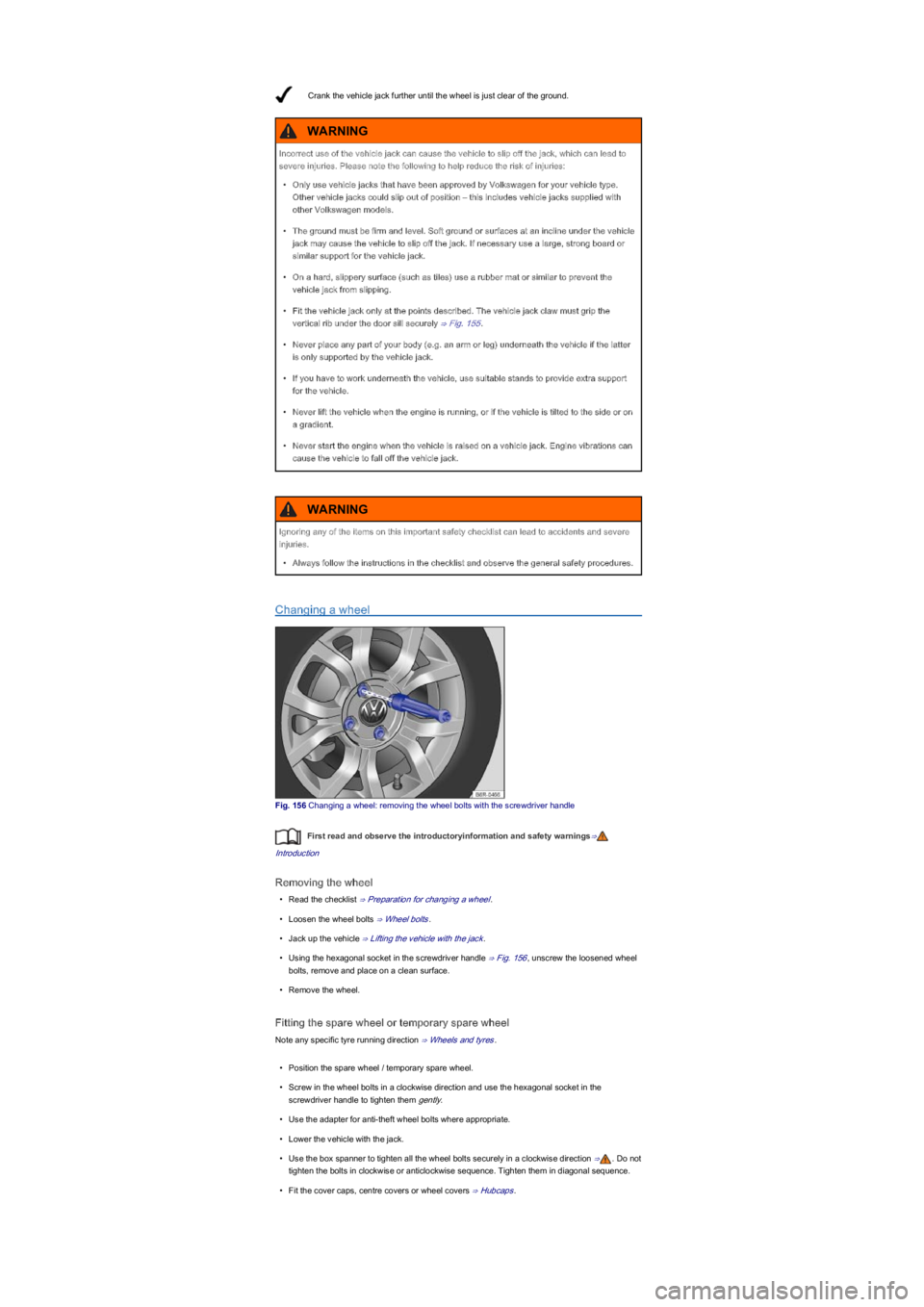

Fig. 155 Vehicle jack at the rear left-hand side of the vehicle

First read and observe the introductoryinformation and safety warnings⇒

Introduction

The jack may be applied only at the jacking points shown (markings on the body) ⇒ Fig. 154.

Always use the jacking point closest to the wheel you are working on ⇒.

Raise the vehicle using only the designated jacking points.

Checklist

To ensure your own safety and that of your passengers, observe the following actions in the

specified order ⇒:

Incorrectly tightened wheel bolts can loosen while the vehicle is in motion and cause

accidents, serious injury, and loss of control of the vehicle.

•Only use wheel bolts that belong to the wheel.

•Never use different wheel bolts.

•The wheel bolts and threads of the wheel hubs must be clean, free from oil and grease,

and turn easily.

•Always use the box spanner placed in the vehicle at the factory to loosen and tighten the

wheel bolts.

•Only loosen the wheel bolts by approximately one turn before raising the vehicle with the

vehicle jack.

•Never grease or lubricate the wheel bolts or the threads of the wheel hub. This could

cause them to loosen while the vehicle is in motion, even if the required torque setting is

used.

•Never remove the bolts on rims with bolted-on rings.

•If the tightening torque of the wheel bolts is too low, the wheel bolts and rims can loosen

while the vehicle is in motion. The wheel bolts and threads can be damaged if the

tightening torque is too high.

WARNING

Page 192 of 211

Crank the vehicle jack further until the wheel is just clear of the ground.

Changing a wheel

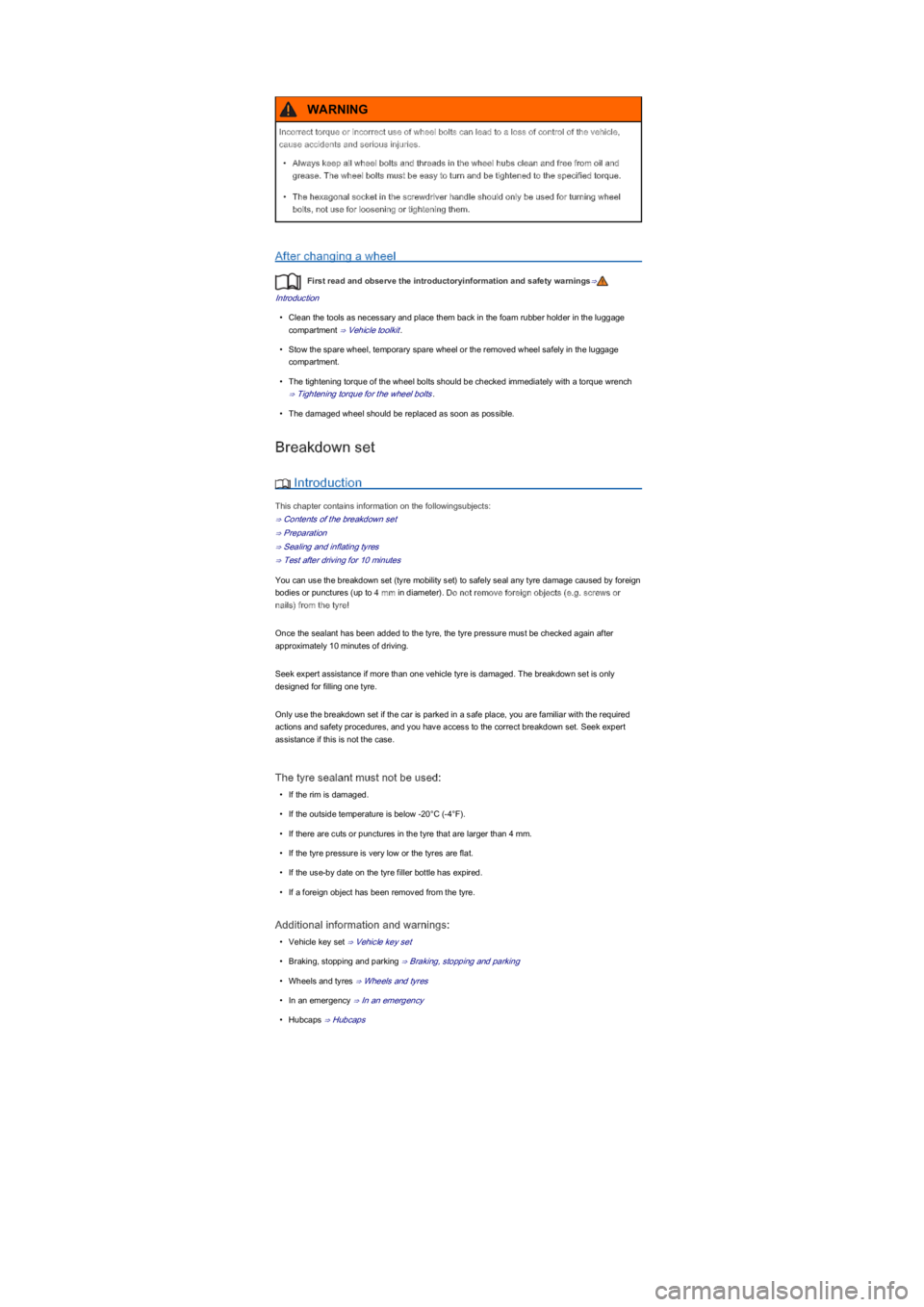

Fig. 156 Changing a wheel: removing the wheel bolts with the screwdriver handle

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Removing the wheel

•Read the checklist ⇒ Preparation for changing a wheel.

•Loosen the wheel bolts ⇒ Wheel bolts.

•Jack up the vehicle ⇒ Lifting the vehicle with the jack.

•Using the hexagonal socket in the screwdriver handle ⇒ Fig. 156, unscrew the loosened wheel

bolts, remove and place on a clean surface.

•Remove the wheel.

Fitting the spare wheel or temporary spare wheel

Note any specific tyre running direction ⇒ Wheels and tyres.

•Position the spare wheel / temporary spare wheel.

•Screw in the wheel bolts in a clockwise direction and use the hexagonal socket in the

screwdriver handle to tighten them gently.

•Use the adapter for anti-theft wheel bolts where appropriate.

•Lower the vehicle with the jack.

•Use the box spanner to tighten all the wheel bolts securely in a clockwise direction ⇒. Do not

tighten the bolts in clockwise or anticlockwise sequence. Tighten them in diagonal sequence.

•Fit the cover caps, centre covers or wheel covers ⇒ Hubcaps.

Incorrect use of the vehicle jack can cause the vehicle to slip off the jack, which can lead to

severe injuries. Please note the following to help reduce the risk of injuries:

•Only use vehicle jacks that have been approved by Volkswagen for your vehicle type.

Other vehicle jacks could slip out of position – this includes vehicle jacks supplied with

other Volkswagen models.

•The ground must be firm and level. Soft ground or surfaces at an incline under the vehicle

jack may cause the vehicle to slip off the jack. If necessary use a large, strong board or

similar support for the vehicle jack.

•On a hard, slippery surface (such as tiles) use a rubber mat or similar to prevent the

vehicle jack from slipping.

•Fit the vehicle jack only at the points described. The vehicle jack claw must grip the

vertical rib under the door sill securely ⇒ Fig. 155.

•Never place any part of your body (e.g. an arm or leg) underneath the vehicle if the latter

is only supported by the vehicle jack.

•If you have to work underneath the vehicle, use suitable stands to provide extra support

for the vehicle.

•Never lift the vehicle when the engine is running, or if the vehicle is tilted to the side or on

a gradient.

•Never start the engine when the vehicle is raised on a vehicle jack. Engine vibrations can

cause the vehicle to fall off the vehicle jack.

WARNING

Ignoring any of the items on this important safety checklist can lead to accidents and severe

injuries.

•Always follow the instructions in the checklist and observe the general safety procedures.

WARNING

Page 193 of 211

After changing a wheel

First read and observe the introductoryinformation and safety warnings⇒

Introduction

•Clean the tools as necessary and place them back in the foam rubber holder in the luggage

compartment ⇒ Vehicle toolkit.

•Stow the spare wheel, temporary spare wheel or the removed wheel safely in the luggage

compartment.

•The tightening torque of the wheel bolts should be checked immediately with a torque wrench

⇒ Tightening torque for the wheel bolts.

•The damaged wheel should be replaced as soon as possible.

Breakdown set

Introduction

This chapter contains information on the followingsubjects:

⇒ Contents of the breakdown set

⇒ Preparation

⇒ Sealing and inflating tyres

⇒ Test after driving for 10 minutes

You can use the breakdown set (tyre mobility set) to safely seal any tyre damage caused by foreign

bodies or punctures (up to 4 mm in diameter). Do not remove foreign objects (e.g. screws or

nails) from the tyre!

Once the sealant has been added to the tyre, the tyre pressure must be checked again after

approximately 10 minutes of driving.

Seek expert assistance if more than one vehicle tyre is damaged. The breakdown set is only

designed for filling one tyre.

Only use the breakdown set if the car is parked in a safe place, you are familiar with the required

actions and safety procedures, and you have access to the correct breakdown set. Seek expert

assistance if this is not the case.

The tyre sealant must not be used:

•If the rim is damaged.

•If the outside temperature is below -20°C (-4°F).

•If there are cuts or punctures in the tyre that are larger than 4 mm.

•If the tyre pressure is very low or the tyres are flat.

•If the use-by date on the tyre filler bottle has expired.

•If a foreign object has been removed from the tyre.

Additional information and warnings:

•Vehicle key set ⇒ Vehicle key set

•Braking, stopping and parking ⇒ Braking, stopping and parking

•Wheels and tyres ⇒ Wheels and tyres

•In an emergency ⇒ In an emergency

•Hubcaps ⇒ Hubcaps

Incorrect torque or incorrect use of wheel bolts can lead to a loss of control of the vehicle,

cause accidents and serious injuries.

•Always keep all wheel bolts and threads in the wheel hubs clean and free from oil and

grease. The wheel bolts must be easy to turn and be tightened to the specified torque.

•The hexagonal socket in the screwdriver handle should only be used for turning wheel

bolts, not use for loosening or tightening them.

WARNING

Page 196 of 211

•Insert the plug ⇒ Fig. 157⑨ into one of the vehicle's 12-volt sockets ⇒ Socket.

•Use the on/off switch ⇒ Fig. 157⑧ to switch on the air compressor.

•Run the compressor until the tyre pressure has reached 2.0 – 2.5 bar (29 – 36 psi / 200 –

250 kPa) ⇒. The maximum running time is 8 minutes⇒.

•Switch off the air compressor.

•If a pressure level of 2.0 – 2.5 bar (29 – 36 psi / 200 – 250 kPa) cannot be achieved unscrew

the tyre filler hose from the tyre valve.

•Drive (or reverse) the vehicle approximately 10 metres so that the sealing compound is more

evenly distributed in the tyre.

•Screw the tyre filler hose for the air compressor firmly back onto the tyre valve and inflate the

tyre again.

•If the required pressure still cannot be reached, the tyre is too badly damaged. The tyre cannot

be sealed with the breakdown set. Do not drive on. Seek expert assistance ⇒.

•Disconnect the air compressor and unscrew the tyre filler hose from the tyre valve.

•Drive the vehicle no faster than 80 km/h (50 mph) once a tyre pressure of 2.0 – 2.5 bar

(29 – 36 psi / 200 – 250 kPa) has been reached.

•Check the tyre pressure after driving for 10 minutes⇒ Test after driving for 10 minutes.

Test after driving for 10 minutes

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Reconnect the tyre filler hose ⇒ Fig. 157⑤ and check the tyre pressure on the tyre pressure

display ⑥.

1.3 bar (19 psi / 130 kPa) and lower:

•Do not drive on! The tyre cannot be sealed adequately with the breakdown set.

•Seek expert assistance ⇒.

1.4 bar (20 psi / 140 kPa) and higher:

•Set the tyre pressure back to the correct value ⇒ Wheels and tyres.

•Resume your journey to the nearest qualified workshop. Do not exceed a maximum speed of

80 km/h (50 mph).

•Have the damaged tyre replaced at the workshop.

Fuses

Introduction

This chapter contains information on the followingsubjects:

⇒ Fuses in the vehicle

⇒ Changing a blown fuse

At the time of print we are unable to provide an up-to-date overview of the locations of the fuses for

the electrical consumers. This is because the vehicle is under constant development, because

fuses are assigned differently depending on the vehicle equipment level and because several

consumers may use a single fuse. You can get more information about the fuse layout from a

Volkswagen dealership.

The tyre filler hose and the air compressor can get hot during inflation.

•Protect your hands and skin from the hot components.

•Do not place the hot tyre filler hose or the hot air compressor on any inflammable

materials.

•Allow the device to cool down fully before stowing.

•If the tyre will not inflate to at least 2.0 bar (29 psi / 200 kPa), the tyre is too damaged. The

sealant is unable to seal the tyre. Do not drive on. Seek expert assistance.

WARNING

Switch the air compressor off after a maximum of 8 minutes to avoid overheating. Let the air

compressor cool down for a few minutes before switching it back on.

NOTICE

Driving with an unsealed tyre is dangerous as it can cause accidents and serious injuries.

•Do not carry on driving if the tyre pressure is 1.3 bar (19 psi / 130 kPa) or lower.

•Seek expert assistance.

WARNING

Page 202 of 211

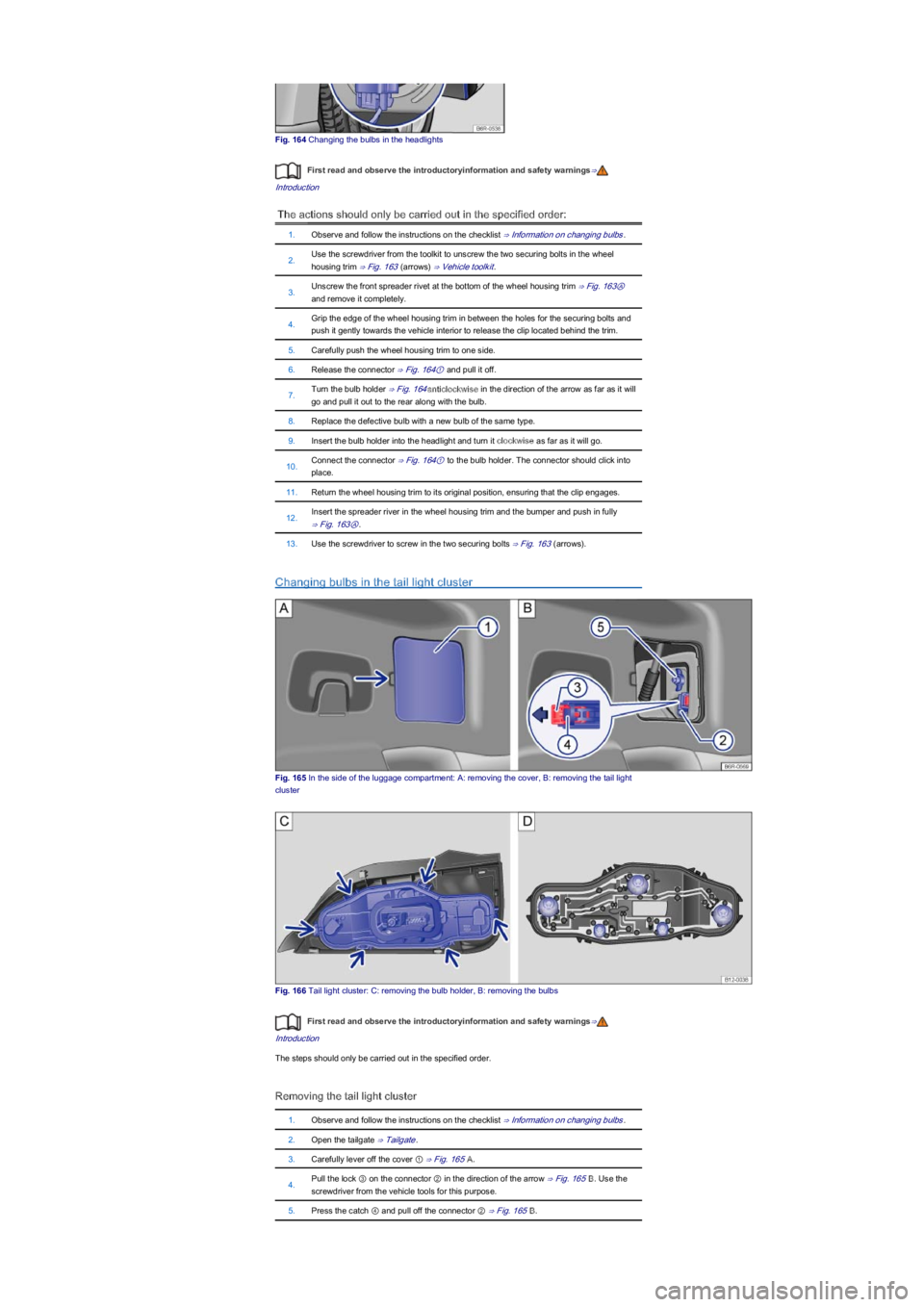

Fig. 164 Changing the bulbs in the headlights

First read and observe the introductoryinformation and safety warnings⇒

Introduction

The actions should only be carried out in the specified order:

1.Observe and follow the instructions on the checklist ⇒ Information on changing bulbs.

2.Use the screwdriver from the toolkit to unscrew the two securing bolts in the wheel

housing trim ⇒ Fig. 163 (arrows) ⇒ Vehicle toolkit.

3.Unscrew the front spreader rivet at the bottom of the wheel housing trim ⇒ Fig. 163Ⓐ

and remove it completely.

4.Grip the edge of the wheel housing trim in between the holes for the securing bolts and

push it gently towards the vehicle interior to release the clip located behind the trim.

5.Carefully push the wheel housing trim to one side.

6.Release the connector ⇒ Fig. 164① and pull it off.

7.Turn the bulb holder ⇒ Fig. 164anticlockwise in the direction of the arrow as far as it will

go and pull it out to the rear along with the bulb.

8.Replace the defective bulb with a new bulb of the same type.

9.Insert the bulb holder into the headlight and turn it clockwise as far as it will go.

10.Connect the connector ⇒ Fig. 164① to the bulb holder. The connector should click into

place.

11.Return the wheel housing trim to its original position, ensuring that the clip engages.

12.Insert the spreader river in the wheel housing trim and the bumper and push in fully

⇒ Fig. 163Ⓐ.

13.Use the screwdriver to screw in the two securing bolts ⇒ Fig. 163 (arrows).

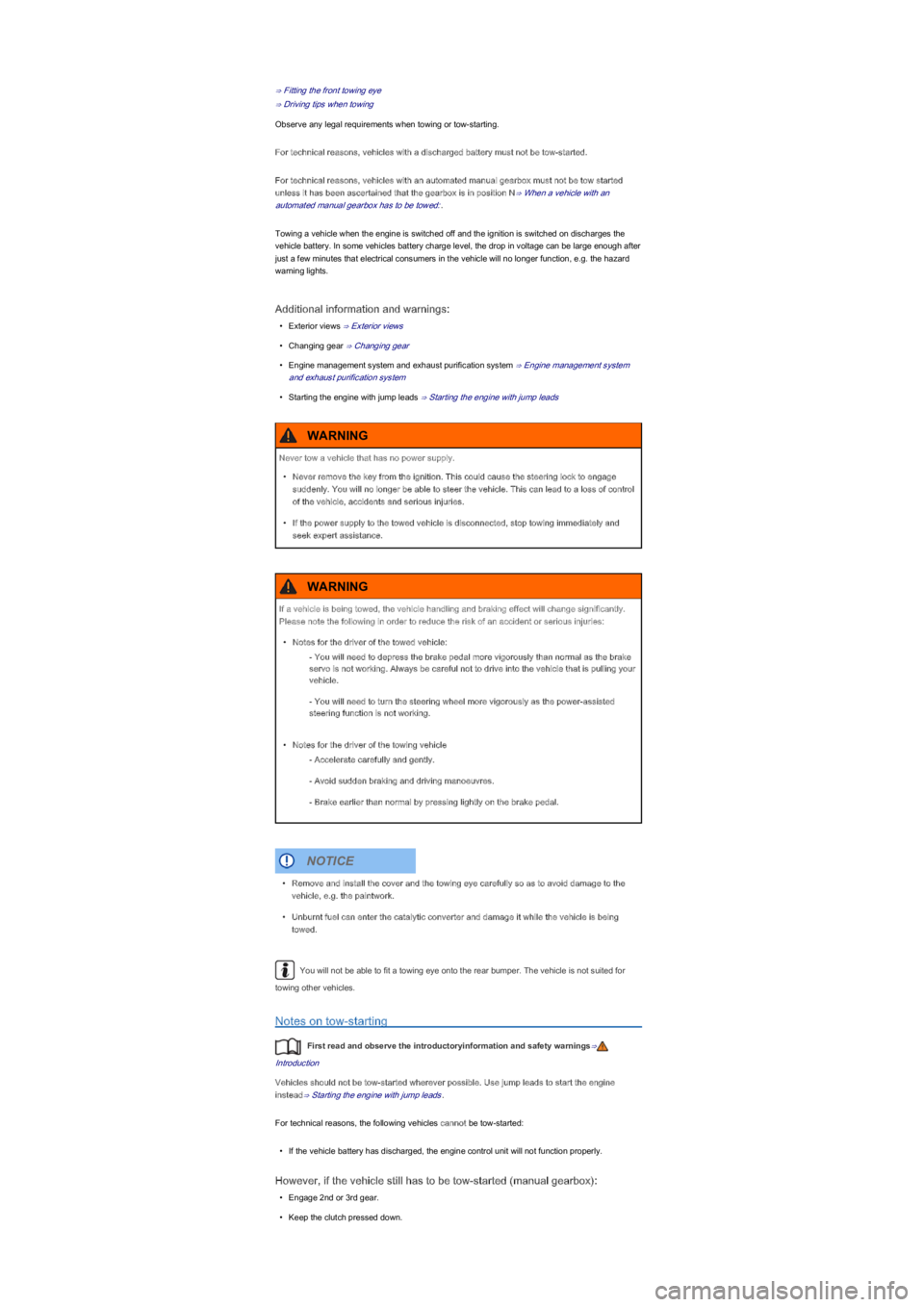

Changing bulbs in the tail light cluster

Fig. 165 In the side of the luggage compartment: A: removing the cover, B: removing the tail light

cluster

Fig. 166 Tail light cluster: C: removing the bulb holder, B: removing the bulbs

First read and observe the introductoryinformation and safety warnings⇒

Introduction

The steps should only be carried out in the specified order.

Removing the tail light cluster

1.Observe and follow the instructions on the checklist ⇒ Information on changing bulbs.

2.Open the tailgate ⇒ Tailgate.

3.Carefully lever off the cover ① ⇒ Fig. 165A.

4.Pull the lock ③ on the connector ② in the direction of the arrow ⇒ Fig. 165B. Use the

screwdriver from the vehicle tools for this purpose.

5.Press the catch ④ and pull off the connector ② ⇒ Fig. 165B.

Page 207 of 211

⇒ Fitting the front towing eye

⇒ Driving tips when towing

Observe any legal requirements when towing or tow-starting.

For technical reasons, vehicles with a discharged battery must not be tow-started.

For technical reasons, vehicles with an automated manual gearbox must not be tow started

unless it has been ascertained that the gearbox is in position N⇒ When a vehicle with an

automated manual gearbox has to be towed:.

Towing a vehicle when the engine is switched off and the ignition is switched on discharges the

vehicle battery. In some vehicles battery charge level, the drop in voltage can be large enough after

just a few minutes that electrical consumers in the vehicle will no longer function, e.g. the hazard

warning lights.

Additional information and warnings:

•Exterior views ⇒ Exterior views

•Changing gear ⇒ Changing gear

•Engine management system and exhaust purification system ⇒ Engine management system

and exhaust purification system

•Starting the engine with jump leads ⇒ Starting the engine with jump leads

You will not be able to fit a towing eye onto the rear bumper. The vehicle is not suited for

towing other vehicles.

Notes on tow-starting

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Vehicles should not be tow-started wherever possible. Use jump leads to start the engine

instead⇒ Starting the engine with jump leads.

For technical reasons, the following vehicles cannot be tow-started:

•If the vehicle battery has discharged, the engine control unit will not function properly.

However, if the vehicle still has to be tow-started (manual gearbox):

•Engage 2nd or 3rd gear.

•Keep the clutch pressed down.

Never tow a vehicle that has no power supply.

•Never remove the key from the ignition. This could cause the steering lock to engage

suddenly. You will no longer be able to steer the vehicle. This can lead to a loss of control

of the vehicle, accidents and serious injuries.

•If the power supply to the towed vehicle is disconnected, stop towing immediately and

seek expert assistance.

WARNING

If a vehicle is being towed, the vehicle handling and braking effect will change significantly.

Please note the following in order to reduce the risk of an accident or serious injuries:

•Notes for the driver of the towed vehicle:

- You will need to depress the brake pedal more vigorously than normal as the brake

servo is not working. Always be careful not to drive into the vehicle that is pulling your

vehicle.

- You will need to turn the steering wheel more vigorously as the power-assisted

steering function is not working.

•Notes for the driver of the towing vehicle

- Accelerate carefully and gently.

- Avoid sudden braking and driving manoeuvres.

- Brake earlier than normal by pressing lightly on the brake pedal.

WARNING

•Remove and install the cover and the towing eye carefully so as to avoid damage to the

vehicle, e.g. the paintwork.

•Unburnt fuel can enter the catalytic converter and damage it while the vehicle is being

towed.

NOTICE

Page 208 of 211

•Switch on the ignition and the hazard warning lights.

•Once both vehicles are in motion, release the clutch.

•As soon as the engine starts, press the clutch and put the gear into neutral. This helps to

prevent driving into the towing vehicle.

However, if the vehicle still has to be tow-started (automated manual

gearbox):

•Switch on the ignition and the hazard warning lights.

•Place the selector lever in position N.

•When both vehicles are in motion and the brake pedal indicator lamp goes out, move the

selector lever to position D.

•As soon as the engine starts, press the brake pedal and move the selector lever to position N.

This helps to prevent driving into the towing vehicle.

Notes on towing

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Tow rope or tow bar

It is easier and safer to tow a vehicle with a tow bar. Only use a tow rope if you do not have a tow

bar.

The tow rope should be slightly elastic to reduce the strain on both vehicles. It is advisable to use a

tow rope made of synthetic fibre or similarly elastic material.

Only attach the tow rope or tow bar to the specially provided towing eyes or to the towing bracket.

When a vehicle with a manual gearbox has to be towed:

Check whether the vehicle can be towed ⇒ When should your vehicle not be towed?.

•Move the gear stick to neutral ⇒ Changing gear.

•Do not allow the vehicle to be towed at speeds faster than 50 km/h (30 mph).

•Do not have the vehicle towed further than 50 km (30 miles).

When a vehicle with an automated manual gearbox has to be towed:

Check whether the vehicle can be towed ⇒ When should your vehicle not be towed?

•Switch on the ignition.

•Move the selector lever to N⇒ Changing gear.

•Check whether the automated manual gearbox is really in neutral. To do this drive the car a few

metres as a test. The automated manual gearbox is in neutral if the vehicle can be easily

moved.

•Seek expert assistance if the automated manual gearbox cannot be put into neutral ⇒.

•Do not allow the vehicle to be towed at speeds faster than 50 km/h (30 mph).

•Do not have the vehicle towed further than 50 km (30 miles).

•If a breakdown truck is used, the vehicle must be towed with the front wheels raised.

When should your vehicle not be towed?

•If, due to damage, the vehicle gearbox no longer contains any lubricant.

•If the automated manual gearbox cannot be put into neutral ⇒.

•If the distance to be towed is further than 50 km - applies to vehicles with an automated manual

gearbox only.

•If the steering function or the operating clearance of the wheels cannot be ensured, e.g. after an

accident.

The vehicle can only be towed when the handbrake and steering lock are not engaged.

Fitting the front towing eye

When tow-starting, unburnt fuel can enter the catalytic converter and damage it.

NOTICE

Never tow a vehicle with automated manual gearbox if the automated manual gearbox cannot

be put into neutral. Otherwise, the gearbox and engine can suffer considerable damage.

NOTICE

Page 209 of 211

Fig. 173 On the right-hand side of the front bumper: releasing and removing the cover

Fig. 174 Front bumper, right-hand side: screwing in the towing eye

First read and observe the introductoryinformation and safety warnings⇒

Introduction

The towing eye is screwed into a threaded hole behind a cover on the right of the front bumper

⇒ Fig. 173.

The towing eye must always be kept in the vehicle.

Comply with the notes on towing ⇒ Notes on towing.

Fitting the towing eye at front

•Remove the towing eye from the vehicle toolkit in the luggage compartment ⇒ Vehicle toolkit.

•Press at the bottom of the cover ⇒ Fig. 173① to release the cover.

•Pull the cover forwards to remove it ② and leave it to hang on the vehicle.

•Turn the towing eye anticlockwise into the threaded hole and tighten as far as possible

⇒ Fig. 174⇒. Use a suitable object to screw the towing eye fully and securely into the

mounting.

•After you have finished towing, remove the towing eye by unscrewing it clockwise.

•Insert the lower locking lug in the opening in the bumper and guide the upper locking lug

carefully over the edge of the opening. If necessary, press the upper locking lug from above.

•Push on the upper area of the cover until the lower locking lug engages in the bumper.

Driving tips when towing

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Towing requires some experience, especially when using a tow rope. Both drivers should be

familiar with the technique required for towing. Inexperienced drivers should not attempt to tow.

When driving, ensure that you do not pull too hard on the towing vehicle and take care to avoid

jerking movements. When towing on an unpaved road, there is always a risk of overloading and

damaging the anchorage points.

You can still use the turn signals if your vehicle is towed with the hazard warning lights and ignition

switched on. Move the turn signal lever to signal the required direction. The hazard warning lights

will not flash while the turn signal is being used. The hazard warning lights will start flashing

automatically as soon as the turn signal lever is moved back to the neutral position.

Notes for the driver of the towed vehicle:

•Leave the ignition switched on to prevent the steering wheel from locking, and so that the turn

signals, horn, windscreen wipers and washers can be used.

•As the power assisted steering does not work if the engine is not running, you will need more

strength to steer than you normally would.

The towing eye must always be screwed firmly into the mounting. Otherwise, the towing eye

can be ripped out of the mounting when the vehicle is being tow-started or towed.

NOTICE