engine VOLVO 700 1982 Service Owner's Guide

[x] Cancel search | Manufacturer: VOLVO, Model Year: 1982, Model line: 700, Model: VOLVO 700 1982Pages: 168, PDF Size: 54.28 MB

Page 39 of 168

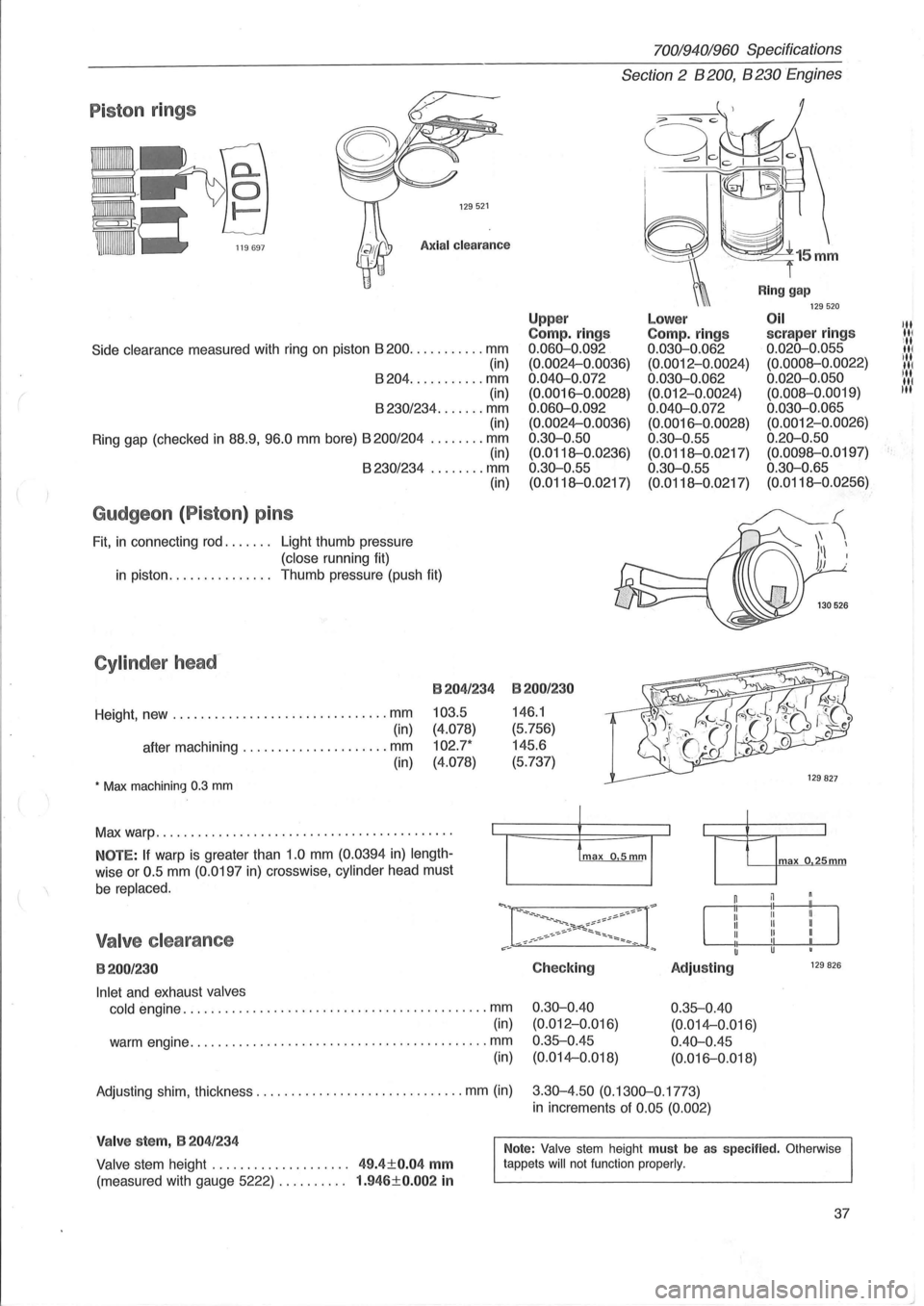

Piston rings

129521

Axial clearance

Side clearance measured with ring on piston 8200 ........... mm

(in)

8204 ........... mm

(in)

8230/234 ....... mm (in)

Ring gap (checked

in 88.9, 96.0 mm bore) 8200/204 ........ mm (in) 8230/234 ........ mm

Gudgeon (Piston) pins

Fit, in connecting rod. . . . . .. Light thumb pressure

(close running fit) (in)

in piston.

. . . . . . . . . . . . .. Thumb pressure (push fit)

Cylinder head-

Height, new ............................... mm

(in)

after machining

..................... mm

(in)

• Max machining 0.3 mm

B204/234

103.5

(4.078)

102.7*

(4.078)

Max warp .......................................... .

NOTE: If warp is greater than 1.0 mm (0.0394 in) length

wise or 0.5 mm (0.0197 in) crosswise, cylinder head must

be replaced.

Valve clearance

B200/230

Inlet and exhaust valves

cold

engine ............................................ mm

(in)

warm engine

........................................... mm

(in)

70019401960 Specifications

Section 2 B 200, B 230 Engines

Upp er Compo rings 0.060-0.092

(0.0024-0.0036)

0.040-0.072 (0.0016-0.0028)

0.060-0.092 (0.0024-0.0036)

0.30-0.50

(0.0118--0.0236)

0.30-0.55

(0.0118--0.0217)

B200/230

146.1

(5.756)

145.6

(5.737)

Checking

0.30-0.40 (0.012-0.Q16)

0.35--0.45 (0.014-0.018)

Lower Compo rings 0.030-0.062 (0.0012-0.0024)

0.030-0.062 (0.012-0.0024)

0.040-0.072 (0.0016-0.0028)

0 .30-0.55

(0.0118--0.0217)

0.30-0.55

(0.0118--0.0217)

Adjusting

0.35--0.40

(0.014-0.016)

0.40-0.45 (0.016-0.018)

Ring gap 129520 Oil scraper rings 0.020-0.055

(0.0008--0.0022)

0.020-0.050 (0.008--0.0019)

0.030-0.065 (0.0012-0.0026)

0.20-0.50 (0.0098--0.0197)

0.30-0.65 (0.0118--0.0256)

max o 25mm

129 826

Adjusting shim, thickness .............................. mm (in) 3.30-4.50 (0.1300-0.1773)

in increments of 0.05 (0.002)

Valve stem, B 204/234

Valve stem height . . . . . . . . . . . . . . . . . . .. 49.4±0.04 mm

(measured with gauge 5222) . . . . . . . . .. 1.946±0.002 in

Note: Valve stem height must be as specified. Otherwise

tappets will not function properly.

37

III III

ill III ill

IN liN

t·

Page 40 of 168

70019401960 Specifications

Section 2 B 200, B 230 Engines

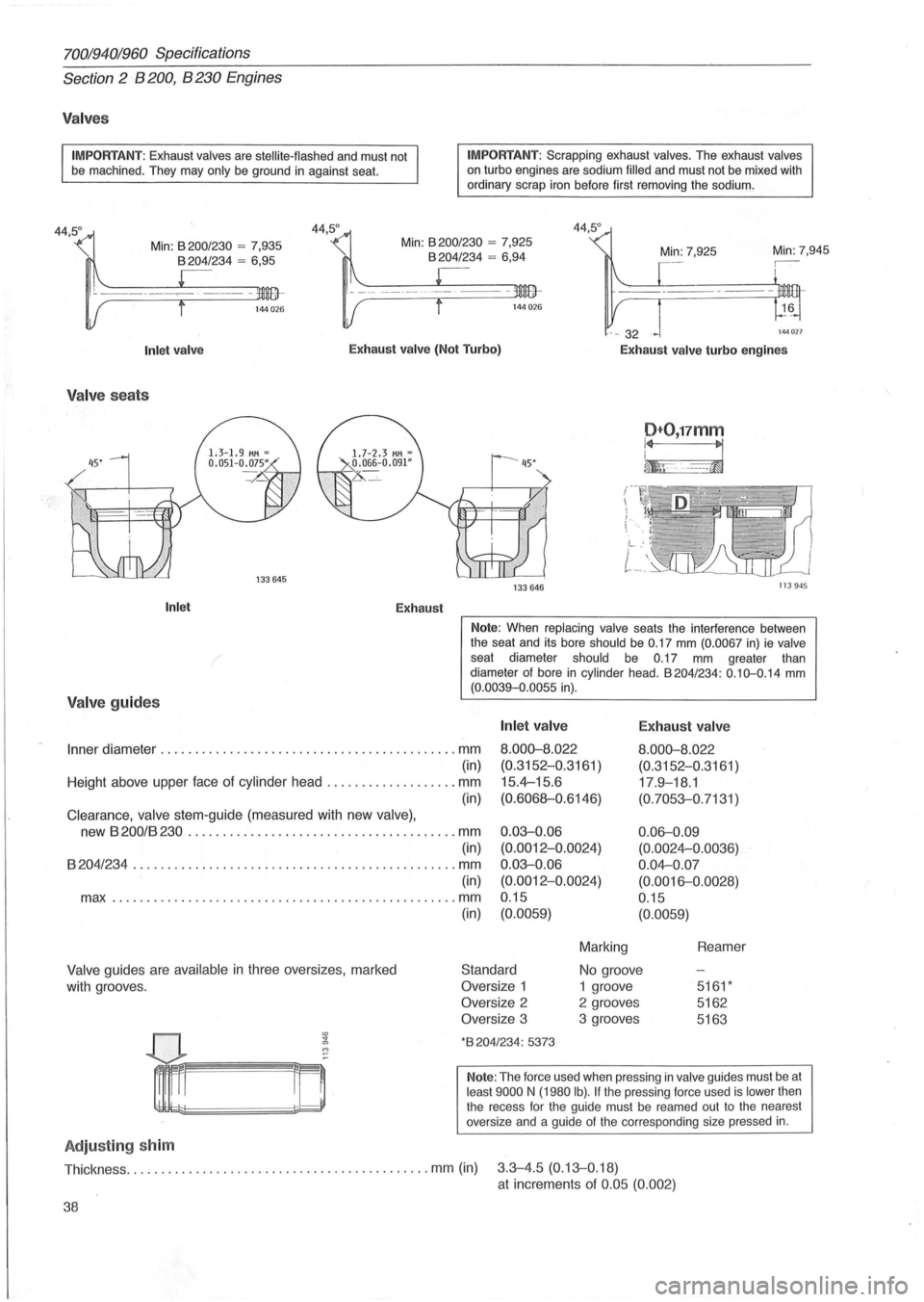

Valves

IMPORTANT: Exhaust valves are stellite-flashed and must not

be machined . They may only be ground in against seat.

Min:

8200/ 230 = 7,935 8204/234 = 6 ,95

IMPORTANT : Scrapping exhaust valves. The exhaust valves on turbo engines are sodium filled and must not be mixed with

ordinary scrap iron before first removing the sodium.

Min: 7,945

144 027

Inlet valve Exhaust valve (Not Turbo)

Exhaust valve turbo engines

Valv e sea ts

Inlet Exhaust

Valve guides

D+O,17mm

~F-~

133 646 113945

Note: When replacing valve seats the interference between

the seat and its bore should be 0.17 mm (0.0067 in) ie valve seat diameter should be 0.17 mm greater than

diameter of bore in cylinder head . 8204/234: 0.10-0.14 mm (0.0039-0 .0055 in).

Inner diameter ........................................... mm

Inlet valve

8.000-8.022

(0.3152-0.3161 )

15.4--15.6

(0.6068-0.6146)

E xhaust valve

8.000-8.022

(0.3152-0 .3161 )

17 .9-18.1

(0.7053-0. 7131 )

(in)

Height above upper face of cylinder head

................... mm

(in)

Clearance, valve stem-guide (measured with new valve),

new 8200/8230 ....................................... mm 0.03-0.06

(0.0012-0.0024)

0.03-0.06

(0.0012-0.0024)

0.15 0

.

06-0.09

(0.0024--0.0036)

0 .04--0 .07

(0.0016-0 .0028)

0.15

(in)

8204/234 ....... ........................................ mm

(in)

max

.............. .................................... mm

Valve guides are available in three oversizes , marked

with grooves.

Adju sting sh im

(in) (0.0059)

Standard

Oversize 1

Oversize 2

Oversize 3

*8204/234: 5373

(0.0059)

Marking

No groove

1 groove

2 grooves

3 grooves Reamer

5161 *

5162

5163

Note:

The force used when pressing in valve guides must be at least 9000 N (1980 Ib). If the pressing force used is lower then

the recess for the guide must be reamed out to the nearest

oversize and a guide

of the corresponding size pressed in.

Thickness ............................................ mm (in) 3.3-4.5 (0.13-0. 18)

at increments of 0.05 (0.002)

38

Page 41 of 168

70019401960 Specifications

Section

2 B 200 , B 230 Engines

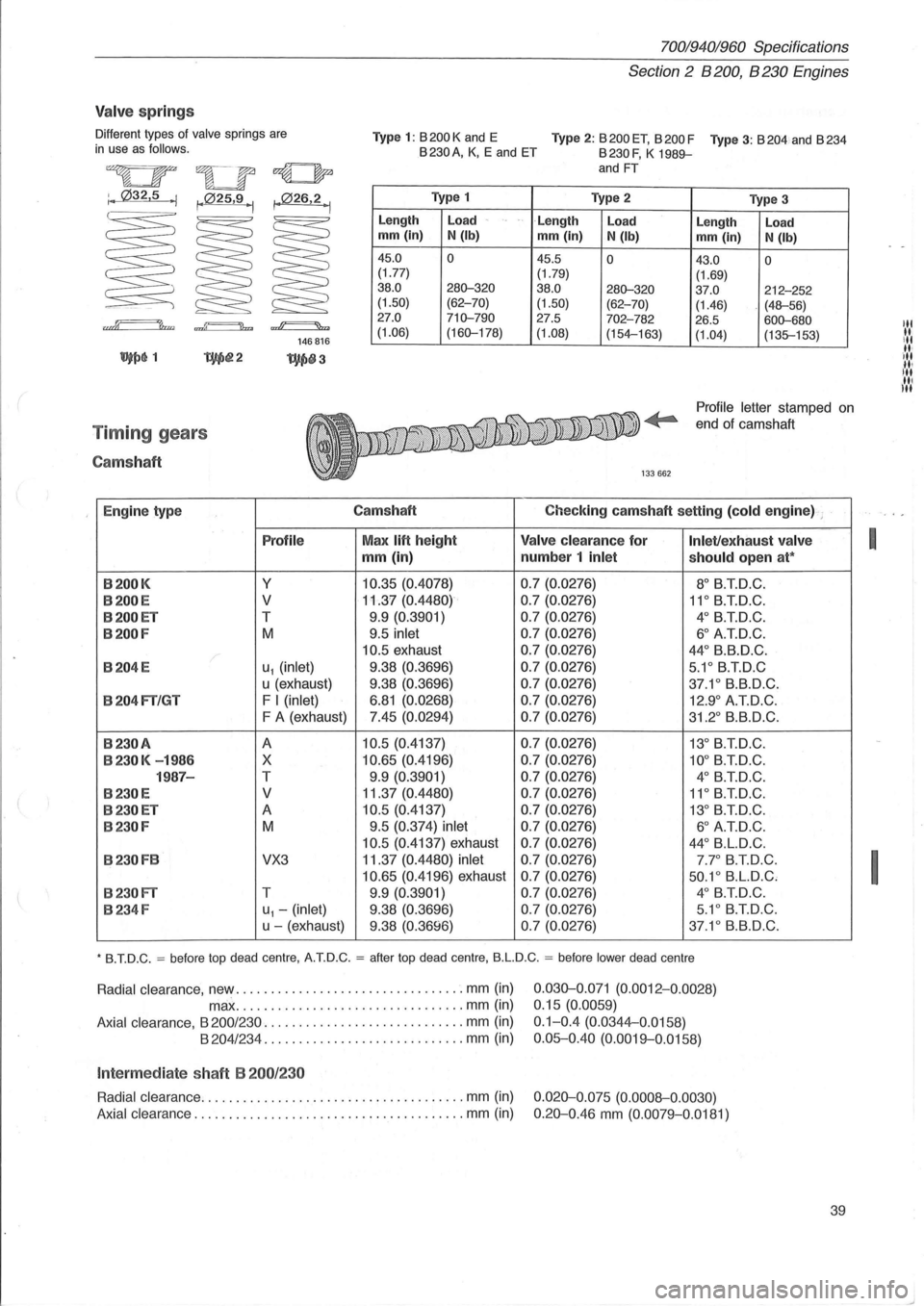

Valve springs

Different types of valve springs are in use as follows. Typ

e 1: B 200 K and E Type 2: B 200 ET, B 200 F Type 3: B 204 and B 234

~LF~

:. 032,5'1 1,025,9"1 1.026,2 "I

~~

1 46816

L e ng th

B230A, K, E and ET B230F, K 1989-and FT

Type 1

Type 2

Lo ad

-. L e n gth

Load

mm (in)

N (Ib) mm (in)

N (Ib)

45.0

0 45.5 0 (1.77)

(1.79) 38.0 280-320 38.0

280-320

(1.50) (62-70)

(1.50)

(62-70)

27.0 710-790 27.5 702-782 (1.06) (160-178) (1.08) (154-163) T

yp e 3

L e ngth

Load

mm (in)

N

(Ib)

43.0 0

(1.69) 37.0 212-252

(1.46) . (48--56) 26.5 600-680

(1.04) (135-153)

Tim ing gears

Cams haft

Profile letter stamped on

end of camshaft

E ng in e

type Ca

msh aft C hecking cam sh aft setting (cold en gine) ;

Pr

ofile Max lift h

eight V alve clea rance for Inl et/exha u st valve

mm (in) numbe r 1 inlet

should open at*

B200 K y 10.35 (0.4078) 0.7 (0.0276) 8° B.T.D.C .

B200E V 11.37 (0.4480) 0.7 (0.0276) 11° B.TD.C.

B200 ET T 9.9 (0.3901)

0.7 (0.0276)

4° B.T.D.C.

B200 F M 9.5 inlet 0.7

(0.0276)

6° A.T.D.C.

10 .5 exhaust 0.7 (0.0276)

44° B.B.D.C.

B204E u, (inlet) 9.38 (0. 3696) 0

.7 (0.0276) 5.1° B.T.D .C

u (exhaust) 9.38

(0.3696)

0.7 (0.0276) 37.1 ° B.BD.C.

B204 FT/G T F I (inlet) 6.81 (0.0268) 0.7 (0.0276)

12.9° A.T.D.C .

F A (exhaust) 7.45 (0.0294)

0.7 (0 .0276) 31. 2 ° B .B.D .C.

B230A A 10.5

(0.4137) 0.7 (0.0276)

13° B.T.D.C.

B

2 30 K - 198 6 X 10.65 (0.4196) 0.7 (0.0276)

10° B.T.D.C.

1987 -T 9.9 (0.3901)

0.7 (0.0276)

4° B.T.D.C.

B230 E V 11.37 (0.4480)

0.7 (0.0276) 11 ° B.T.D .C.

B230ET A 10.5 (0.4137) 0.7 (0.0276)

13° B.T.D .C .

B230 F M 9.5 (0.374) inlet 0.7 (0.0276)

6° A .T.D.C.

10 .5 (0.4137) exhaust 0.7 (0.0276)

44° B.L.D.C.

B230FB VX3 11.37 (0.4480) inlet 0.7 (0.0276) 7.7" B.T .D.C.

10.65 (0.4196) exhaust 0.7 (0.0276) 50.1° B.L.D.C ;

B230FT T

9.9 (0.3901) 0.7 (0.0276) 4° B .T.D.C.

B234F u, -(inlet) 9 .38 (0.3696) 0.7 (0.0276) 5.1 ° B.TD.C .

u - (exhaust)

9.38

(0.3696) 0.7

(0.0276)

37.1 ° B.B .D .C .

• B.TD.C. = before top dead centre, A.T.D.C. = after top dead centre, B.L.D.C. = before lower dead centre

Radial clearance , new ........... .. .................... mm (in)

max ............. .................... mm (in)

Axial clearance, B 200/230 ......... .................... mm (in)

B 204/234 ............... .. ............ mm (in)

Inte rmed iate s h aft B 200 /230

Radial clearance .................. .................... mm (in)

Axial clearance ....................... ................ mm (in)

0.030-0.071 (0.0012-0.0028)

0.15 (0.0059)

0.1-0.4 (0.0344-0.0158)

0 .05-0.40 (0.0019--0 .0158)

0.020-0.075 (0.0008--0.0030)

0 .

20-0.46 mm (0.0079-0.0181)

39

I

I

III II ill II,

II' /I , III

\'.'1

Page 42 of 168

70019401960 Specifications

Section 2 B 200, B 230 Engines

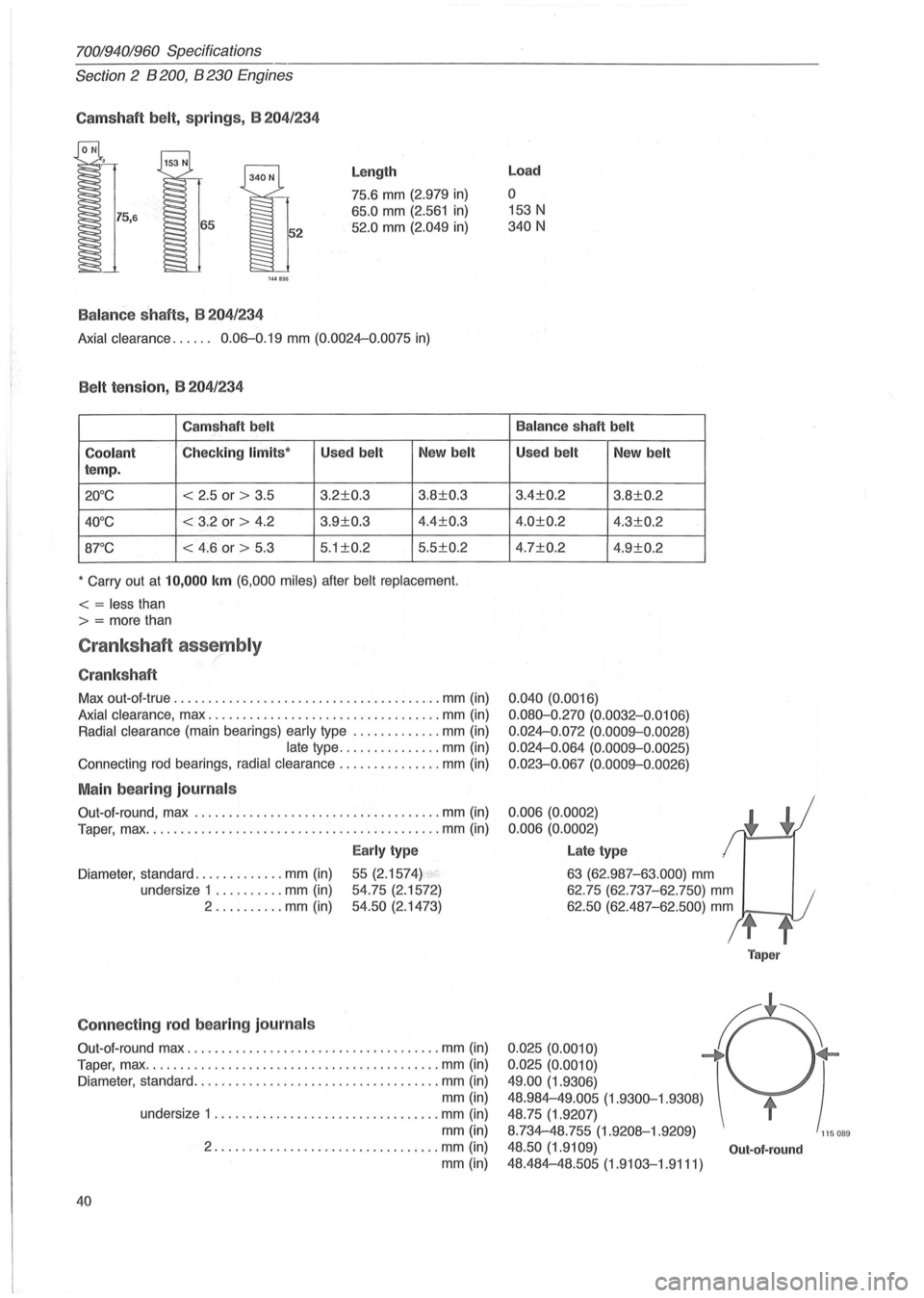

Camshaft belt, sp ring s, B 204/234

144B!Hi

Balanc e shaf ts , B 204 /234

Length

75.6 mm (2.979 in)

65.0 mm (2.561 in)

52.0 mm (2.049 in)

Axial clearance. . . . .. 0.06-0.19 mm (0.0024-0.0075 in)

Belt tension, B 204/ 234

Camshaft belt

Coolant

Checking limits ' Used belt New belt

temp.

20°C < 2 .5 or > 3.5 3.2±0.3 3.8±0.3

40°C < 3.2 or > 4.2 3.9±0.3 4.4±0.3

8rC < 4.6 or > 5.3 5

.1 ±0.2 5 .5±0.2

• Carry out at 10,000 km (6,000 miles) after belt replacement.

< = less than

> = more than

Crankshaft assembly ,/

Cranksh aft

Max out-at -true .................................. ..... mm (in)

Axial clearance, max .................................. mm (in)

Radial clearance (main bearings) early type ............. mm (in)

late type ............... mm (in)

Connecting rod bearings, radial clearance ............... mm (in)

Main bearing journals

Out-at-round , max ................................ .... mm (in)

Taper, max

........................................... mm (in)

Early type

Diameter , standard ............. mm (in) 55 (2.1574)

54.75 (2.1572)

54.50 (2. 1473)

undersize

1

.......... mm (in)

2 .......... mm (in)

Connecting rod bearing journa ls

Out-at-round max ..................................... mm (in)

Taper, max .

.......................................... mm (in)

Diameter, standard .

............ , ...................... mm (in)

mm (in)

40

undersize 1 ................................. mm (in)

mm (in)

2 ................. ................ mm (in)

mm (in)

Load

o

153 N

340 N

Balance shaft belt

Used belt New belt

3.4±0.2 3.8±0.2

4.0±0.2 4.3±0.2

4.7±0.2 4.9±0.2

0 .040 (0.0016)

0.080-0 .270 (0.0032-0.0106)

0 .

024-0.072 (0.0009--0 .0028)

0.024-0.064 (0.0009--0.0025)

0.023-0.067

(0. 0009--0.0026)

0.006 (0.0002)

0.006 (0.0002)

Late type

63 (62.987-63 .000) mm

62.75 (62.737-62.750) mm

62.50 (62.487-62.500) mm

t

Taper

0.025(0.0010) f ~

0.025 (0.0010) ) 49.00 (1.9306)

48.984-49.005

(1.9300-1.9308)

48.75 (1.9207)

8.734-48.755 (1.9208-1.9209)

115 089

48.50 (1.9109) Out-ot-round

48.484-48.505 (1.9103-1.9111)

Page 43 of 168

(

70019401960 Specifications

Section

2 B 200, B 230 Engines

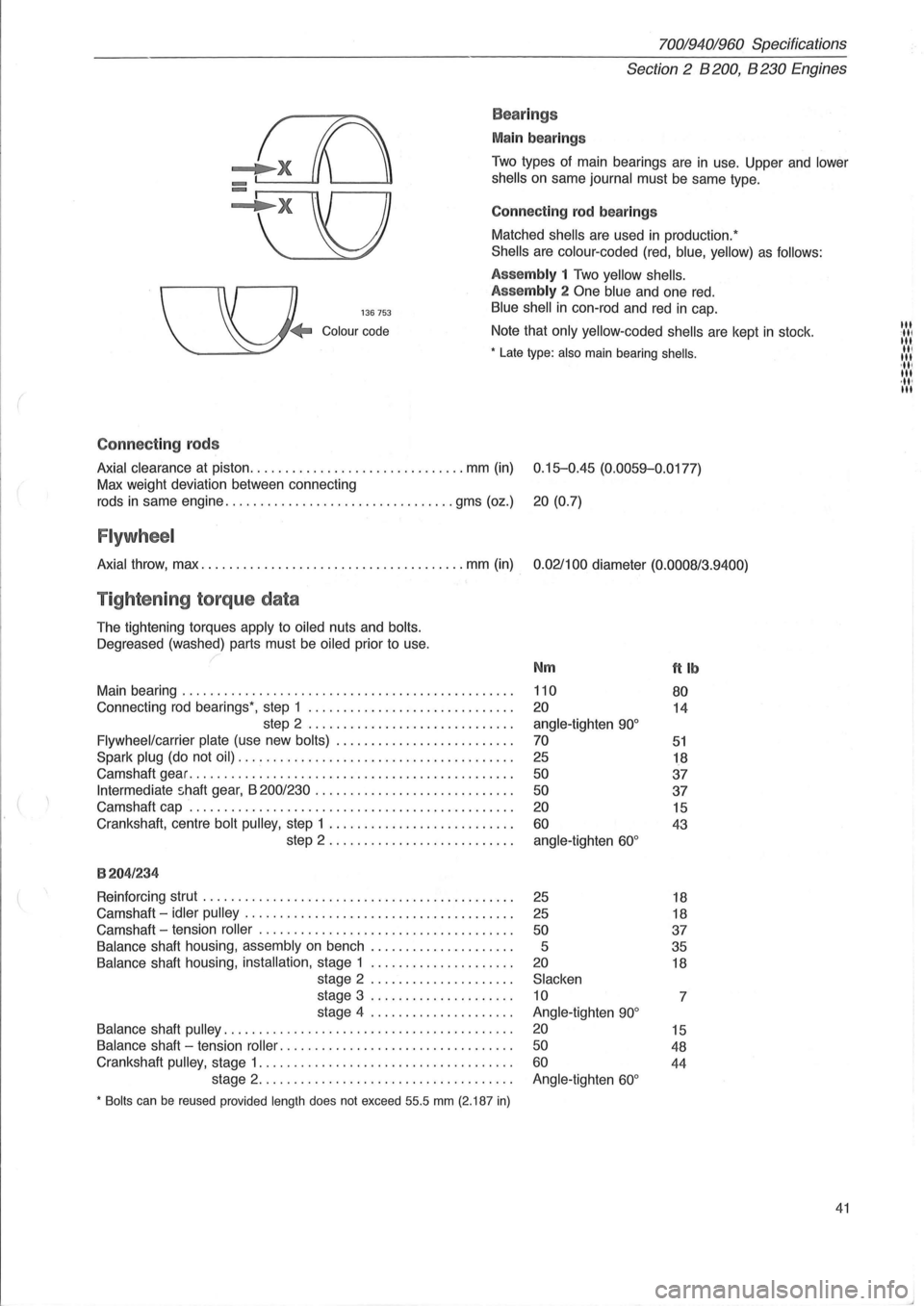

Bea rings

Main bearings

Two types of main bearings are in use. Upper and lower

shells

on same journal must be same type.

Connect

ing rod bearings

Matched

shells are used in production:

Shells are colour -coded (red, blue, yellow) as follows:

136753

Assembly 1 Two yellow shells.

Assembly

2 One blue and one red.

Blue shell in con-rod and red in cap.

Colour code Note that only yellow-coded shells are kept in stock .

• Late type: also main bearing shells .

Connect ing rods

Axial clearance at piston ............................... mm (in) 0.15-0.45 (0.0059-0.0177)

Max weight deviation between connecting

rods

in same engine ................................. gms (oz.) 20 (0.7)

Flywheel

Axial throw, max ...................................... mm (in) 0.021100 diameter (0.0008/3.9400)

Tightening torque data

The tightening torques apply to oiled nuts and bolts.

Oegreased

(washed) parts must be oiled prior to use.

Main bearing

............................................... .

Connecting

rod bearings', step 1 ............................. .

step 2

............................. .

Flywheel/carrier plate (use new bolts) ...................... ... .

Spark plug (do not oil) ....................................... .

Camshaft gear

.............................................. .

Intermediate shaft gear, B 200/230 ............................ .

Camshaft cap

.............................................. .

Crankshaft, centre

bolt pulley, step 1 .......................... .

step 2 .

.. ....................... .

8204/234

Reinforcing strut ............................................ .

Camshaft -

idler pulley ...................................... .

Camshaft -tension

roller .................................... .

Balance shaft housing, assembly on bench .................... .

Balance shaft housing, installation, stage 1 .................... .

stage 2

.................... .

stage 3

.................... .

stage 4

.................... .

Balance shaft pulley ......................................... .

Balance shaft -tension roller .. ............................... .

Crankshaft

pulley, stage 1 .................................... .

stage 2

.................................... .

• Bolts can be reused provided length does not exceed 55.5 mm (2.187 in)

Nm

110

20

angle-tighten 90°

70

25

50

50

20

60

angle-tighten 60°

25

25

50

5

20

Slacken

10

Angle-tighten

90°

20

50

60

Angle-tighten 60°

ftlb

80

14

51

18

37

37

15

43

18

18

37

35

18

7

15

48

44

41

III :11' III II, III 'III III ,11' III

Page 44 of 168

70019401960 Specifications

Section 2 B 200, B 230 Engines

8204/234

Cam carrier (centre fasteners) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 15

Oil pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 7

Oil pump, inlet ..... , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 8

Oil pump -pulley, step 1 ..................................... 20 15

step 2 .......... . . . . . . . . . . . . . . . . . . . . . . . . . . . angle-tighten 60 °

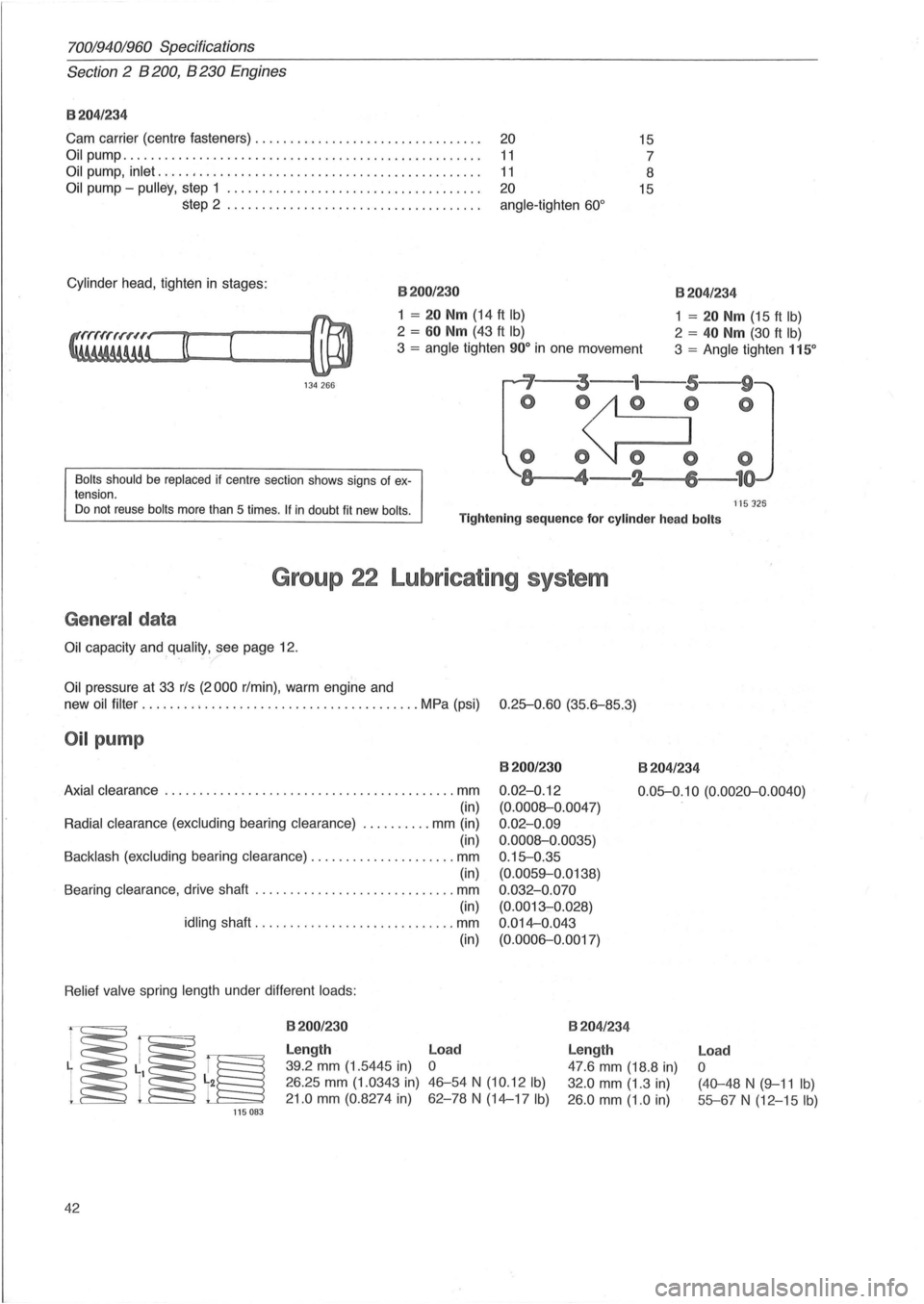

Cylinder head , tighten in stages : 8200/230

1 = 20 Nm (14 ft Ib)

2 = 60 Nm (43 ft Ib)

3 = angle tighten 90° in one movement

8204/234

1 = 20 Nm (15 ft Ib)

2 = 40 Nm (30 ft Ib)

3 = Angle tighten 115°

134 266 ~'--~3---1---5,---w9'~

Bolts should be replaced if centre section shows signs of ex

tension.

o ~O

o O~ 0

-~8,---..... 4-2 6 1

ns 125 Do not reuse bolts more than 5 times . If in doubt fit new bolls . Tightening sequence for cylinder head bolts

Group 22 Lubricating system

General data

Oil capacity and quality, see page 12.

Oil pressure at 33 rls (2000 rim in), warm engine and

new oil

filter ........ ; ............................... MPa (psi) 0.25-0.60 (35.6-85.3)

Oil pump

8200/230

0.02-0. 12

(0.0008-0.0047)

0 .

02-0.09

0.0008-0.0035)

0 .

15-0.35

(0.0059-0.0138)

0 .

032-0.070

(0.0013-0.028)

0 .

014-0.043

(0.0006-0.0017)

8204/234

Axial clearance ................ ... ....................... mm

(in)

Radial clearance (excluding bearing clearance) . ......... mm (in)

(in)

Backlash (excluding bearing clearance) ..................... mm

(in)

Bearing clearance , drive shaft

............................. mm

(in)

idling shaft .................... ......... mm

Relief valve spring length under different loads:

115083

42

8200/230

Length

39.2 mm (1.5445 in)

26.25 mm (1. 0343 in)

21.0 mm (0.8274 in) (in)

Load

o

46-54 N (10.12 Ib)

62-78 N (14-17 Ib)

0.05-0.

10 (0.0020-0.0040)

8204/ 234

Length

47.6 mm (18.8 in)

32.0 mm (1.3 in)

26 .0 mm (1.0 in)

Load

o

(40-48 N (9-11 Ib)

55-67 N (12-15 Ib)

Page 45 of 168

(

70019401960 SpecHications

Section

2 B 200, B 230 Engines

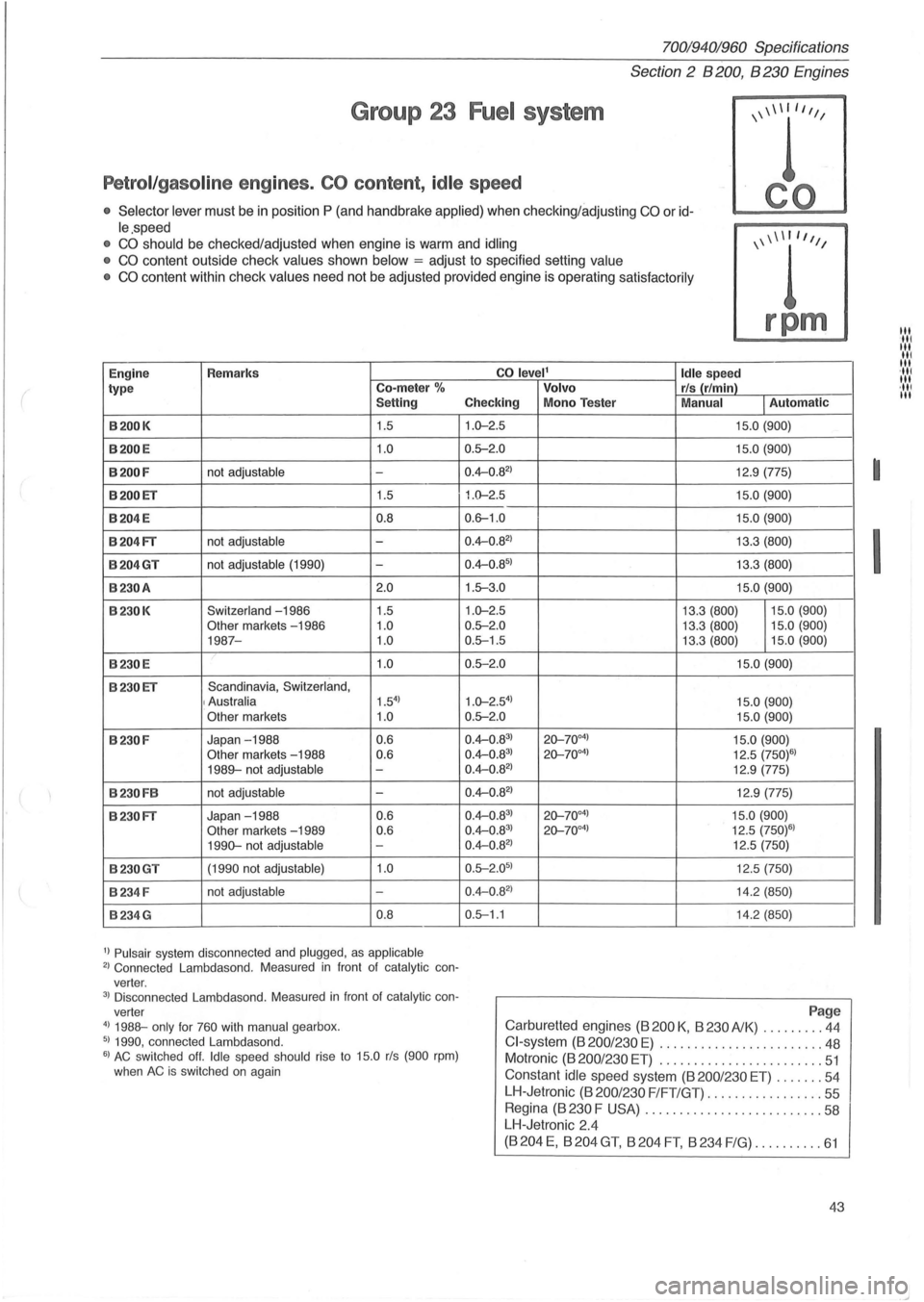

Group 23 Fuel system

Petrol/gasoline engines . CO content, idle speed

• Selector lever must be in position P (and handbrake applied) when checking/adjusting CO or id-

le.speed

•

CO should be checked/adjusted when engine is warm and idling

•

CO content outside check values shown below = adjust to specified setting value

• CO content within check values need not be adjusted provided engine is operating satisfactorily

Engine Remarks

type Co-meter % Setting

B200K 1

.5

B200E 1.0

B200F not adjustable -

B200ET 1.5

B204E 0 .8

B204FT not adjustable -

B204GT not adjustable (1990) -

B230A 2.0

B230K Switzerland -1986 1 .5 Other markets -1986 1.0 1987-1.0

B230 E 1

.0

B230ET Scandinavia , Switzerland, I Australia 1.54

)

Other markets 1.0

B230F Japan -1988 0.6

Other markets -1988 0 .6 1989-not adjustable -

B230FB not adjustable -

B230FT Japan -1988 0.6

Other markets -1989 0 .6 1990-not adjustable -

B230GT (1990 not

adjustable) 1.0

B234F not adjustable -

B234G 0.8

I) Pulsair system disconnected and plugged, as applicable 2) Connected Lambdasond . Measured in front of catalytic converter . 3) Disconnected Lambdasond . Measured in front of catalytic con-

verter 4) 1988-only for 760 with manual gearbox . 5) 1990, connected Lambdasond. 6) AC switched off. Idle speed should rise to 15.0 r ls (900 rpm) when AC is switched on again

CO leveP

Idle speed

Volvo rls (r/min)

Checking Mono Tester

Manual Automatic

1.0-2

.5 15.0 (900)

0 .5-2.0

15.0 (900)

0.4-0.8

2 ) 12.9 (775)

1.0-2.5 15.0 (900)

0.6-1.0 15.0 (900)

0.4-0 .8

2

) 13.3 (800)

0.4-0.8

5 ) 13.3 (800)

1.5-3 .0 15.0 (900)

1 .

0-2.5 13.3 (800) 15. 0 (900)

0 .5-2.0 13.3 (800) 15. 0 (900)

0.5-1 .5 13.3 (800) 15. 0 (900)

0.5-2.0 15.0

(900)

1.0-2.54

) 15.0 (900)

0 .5-2.0 15.0 (900)

0 .4-0.8

3

) 20-7004

) 15.0 (900)

0 .4-0.83

) 20-7004 ) 12.5 (750)6) 0.4-0 .82

) 12.9 (775)

0.4-0 .82

) 12.9 (775)

0.4-0.83

) 20-7004 ) 15.0 (900)

0 .4-0.83

) 20-7004 ) 12.5 (750)6) 0.4-0.82

) 12.5 (750)

0 .

5-2.05

) 12.5 (750)

0

.4-0.82 ) 14.2 (850)

0 .5-1.1

14.2 (850)

Page

Carburetted engines

(8200 K, 8230 NK) .. ....... 44

CI-system (8200/230 E) ........................ 48

Motronic (8200/2 30 ET) ...... ... .. .. .......... . 51

Constant idle speed system (8200/230 ET) ....... 54

LH-Jetronic (8200/230 F/FT/GT) ................. 55

Regina (8230 F USA) .......................... 58

LH-Jetronic 2.4

(8204 E, 8204 GT, 8204 FT, B 234 F/G) .. ........ 61

43

I

I

III 'III III III III ,III III ,III III

Page 46 of 168

70019401960 Specifications

Section 2 B 200, B 230 Engines

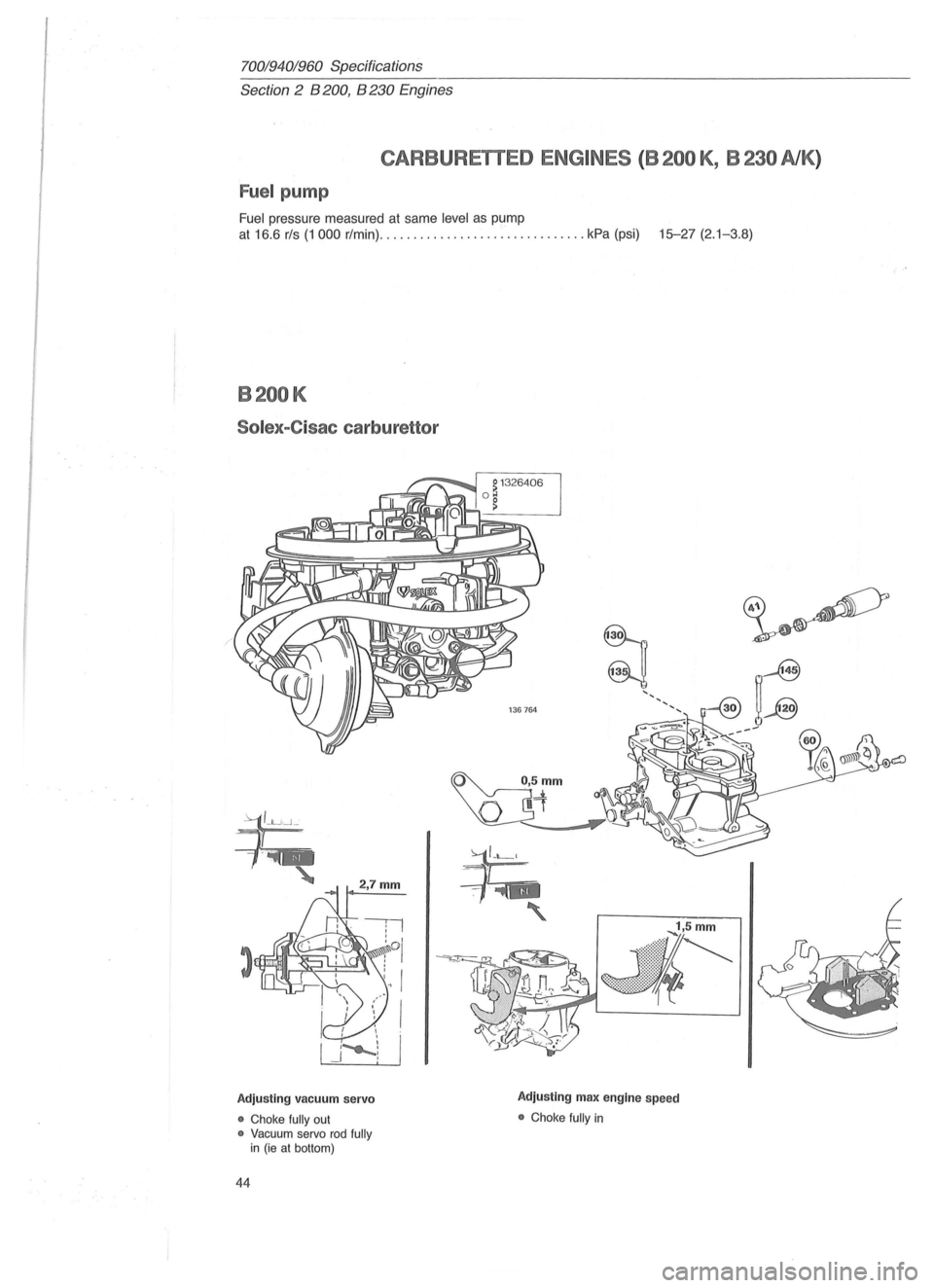

CARBURETTED ENGINES ( B 200 K , B 230 AlK )

Fuel pump

Fuel pressure measured at same level as pump

at 16.6 rls (1 000 r/min) ............................... kPa (psi) 15-27 (2.1-3.8)

B200K

Solex-C isac carburettor

2,7mm

--n ---~~ : I

'~I

1'1I~1~:·,1

I { I

IJ ......... j I

Adjusting vacuum servo

• Choke fully out • Vacuum servo rod fully in (ie at bottom)

44

~_m_m_ .....

Adjusting max engine s peed

• Choke fully in

Page 47 of 168

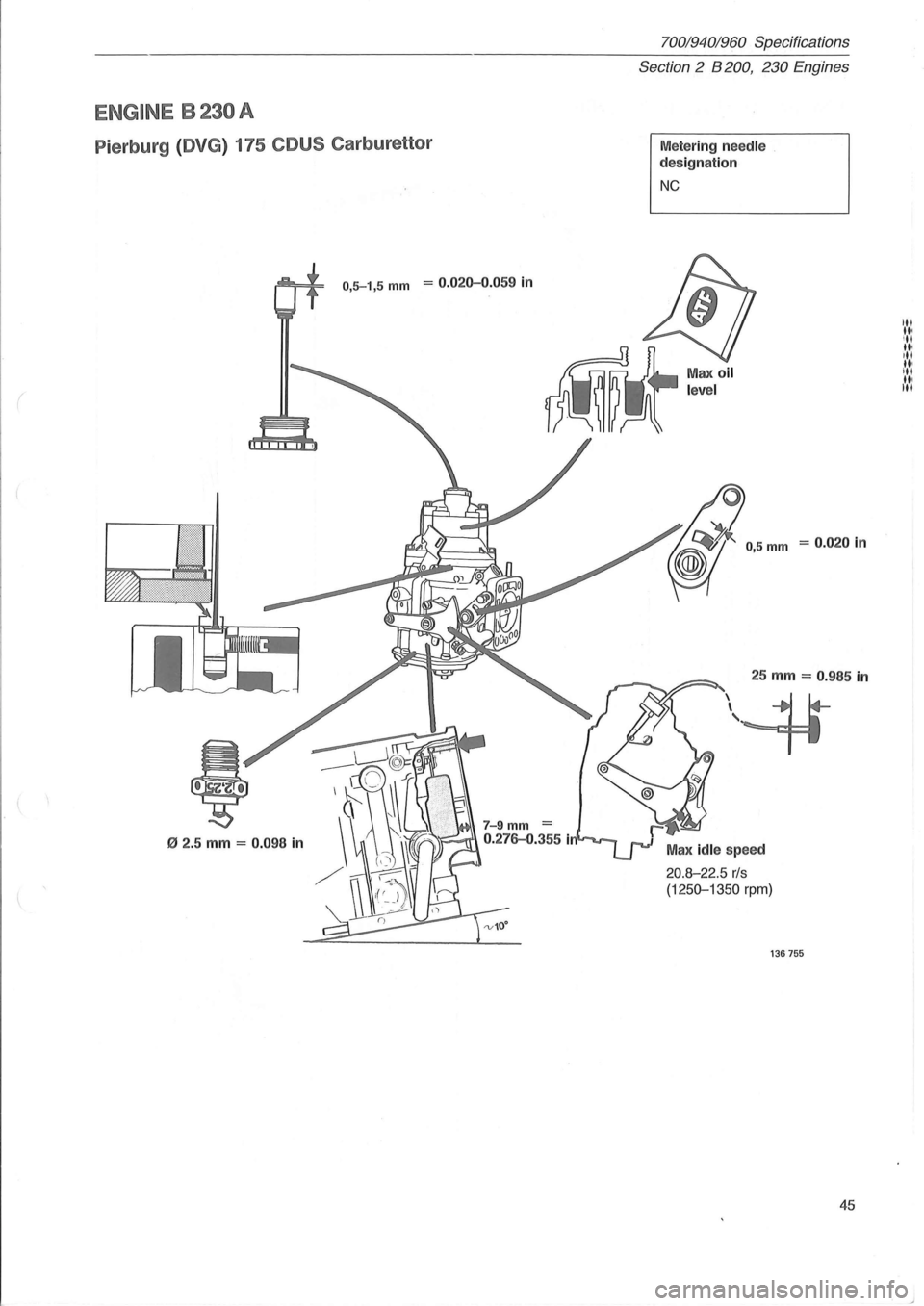

ENGINE B 230 A

Pierburg (OVG) 175 COUS Carburettor

0,5--1, 5 mm = 0.020-0.059 in

(

" 2.5 mm = 0.0 98 in

70019401960 Specifications

Section

2 B 200, 230 Engines

Me te rin g need le

des ig natio n

NC

= 0.0 20 in

25 mm = 0.985 in

Max idl e speed

20.8-22 .5 rls

(1250-1350 rpm)

136755

4 5

III III

ill III

III II, ill III III

Page 48 of 168

70019401960 Specifications

Section 2 B 200, B 230 Engines

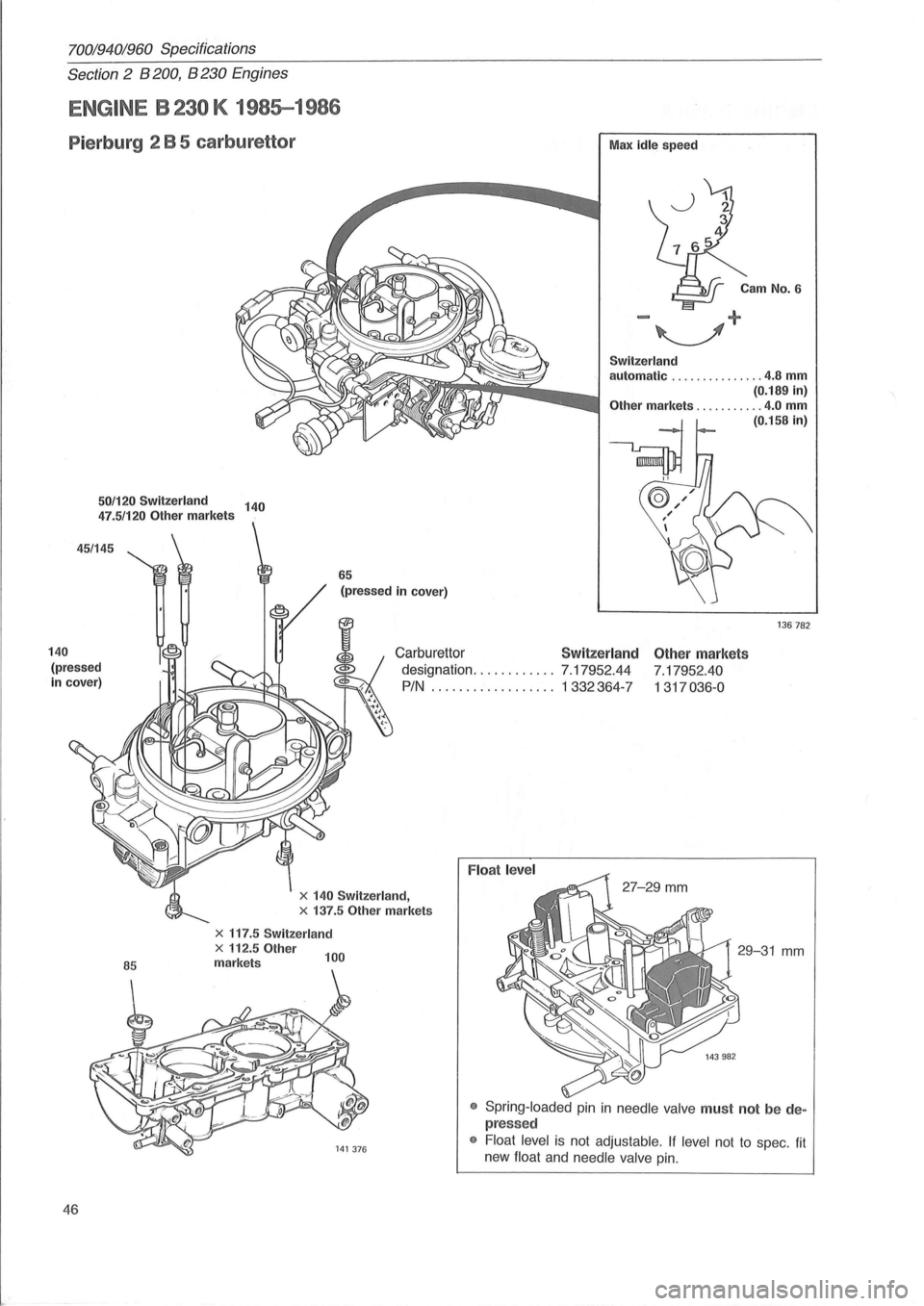

ENGINE B 230 K 1985-1986

Pierburg 2 B 5 carburettor Max idle speed

Cam No.6

- +

~

Switzerland automatic ............... 4.8 mm (0.189 in) Other markets ..... ...... 4.0 mm (0.158 in)

50/120 Switzerland 140 47.5/120 Other markets

45/145

65

(pres sed in cover)

140

(pre ssed

in cover)

46

85

13 6 78 2

Carburettor Switze rland Other markets

designation .

........... 7 .17952.44 7.17952.40

PIN .................. 1 332364-7 1 317036-0

F

loat le v e l

x 140 S witzerland, x 137. 5 Other mark ets

x

117.5 S witzerland x 112.5 Other 100 markets

143982

• Spring-loaded pin in needle valve must not be de

p ressed

• Float level is not adjustable. If level not to spec. fit

new float and needle valve pin.