tires VOLVO C70 2008 Owner's Manual

[x] Cancel search | Manufacturer: VOLVO, Model Year: 2008, Model line: C70, Model: VOLVO C70 2008Pages: 246, PDF Size: 5.14 MB

Page 164 of 246

182 07 Wheels and tires

Tire rotation

Summer and winter tires

When switching between summer and winter tires, mark the tires to indicate where they were mounted on the car,

e.g. LF = left front, RR = right rear

Tires with tread designed to roll in only one direction are marked with an arrow on the sidewall.

Incorrectly mounted tires impair the car's braking properties and ability to force aside rain, snow and slush.

The tires with the most tread should always be at the rear (to reduce the risk of skidding).

Contact a Volvo workshop if you are unsure about the tread depth.

Tire rotation

Your vehicle has no recommended tire rotation. The following information is intended to help you understand why.

Tread set

As a tire ages and the rubber cures, front and rear tires set at different angles. Therefore, if tires are rotated, the tread

will eventually set at an angle that is a compromise. Even if ride, handling, and road noise may still seem acceptable,

they may not be optimal. Further, tires that are rotated, but not on a regular basis, may actually cause more tire noise,

faster tire wear, and unpleasant changes in steering feel and vehicle handling.

A tire that can fully adapt to its position will provide better steering feel, lower tire noise, and better fuel economy.

Braking stability performance

Your vehicle is driven mainly by the front tires, which will wear faster. This can be beneficial. Having more tread on

the rear tires will help reduce oversteer. Oversteer is when a vehicle wants to keep turning because of momentum and

dynamic forces on its suspension.

Suspension wear diagnostics

Every suspension needs periodic inspection and maintenance. A tire's wear pattern can be an aid in detecting a

suspension problem. Each tire, if left in place, tells a story about the suspension. Tire rotation, on the other hand, could

make suspension wear harder to detect. Early detection is very important, because suspension problems can make tire

wear worse.

If you do rotate your tires...

Please follow the tire manufacturer's recommendations, as outlined in the tire manufacturers tire warranty pamphlet.

ProCarManuals.com

Page 165 of 246

183 07 Wheels and tires

Temporary spare

Temporary spare (option)

The spare tire in your car is called a "Temporary Spare".

Recommended tire pressure (see the placard on the B-pillar) should be maintained irrespective of which position on

the car the temporary spare tire is used on.

In the event of damage to this tire, a new one can be purchased from your Volvo retailer.

Location of the optional spare wheel and tools

The spare wheel is packed in a storage bag and is located under the panel in the floor of the trunk.

On cars with a spare wheel, the jack and lug wrench are secured in a foam plastic block placed in the center of the

wheel.

CAUTION

The car must not be driven with wheels of different dimensions or with a spare tire other than the one that came with

the car. The use of different size wheels can seriously damage your car's transmission.

The retaining straps securing the spare wheel is attached to two eyelets in the floor of the spare wheel's storage

compartment.

WARNING

Current legislation prohibits the use of the "Temporary Spare" tire other than as a temporary replacement for a

punctured tire. It must be replaced as soon as possible by a standard tire. Road holding and handling may be affected

with the "Temporary Spare" in use.

184 07 Wheels and tires

Changing a wheel

Changing a wheel

ProCarManuals.com

Page 166 of 246

Accessing the spare wheel

1. Open the hatch in the floor of the trunk.

2. Release the retaining straps and lift out the spare wheel in its storage bag.

3. Open the zipper on the storage bag and lift out the spare wheel.

The wheel that was replaced by the temporary spare tire can then be placed in the storage bag.

Before raising the car

1. Engage the parking brake.

2. Put the gear selector in Park (P).

3. Block the wheels that are on the ground with wooden blocks or large stones.

4. Remove the wheel cap (where applicable) using the lug wrench in the tool bag.

5. With the car still on the ground, use the lug wrench to loosen the wheel nuts 1/2 - 1 turn by exerting downward

pressure. Turn the nuts counterclockwise to loosen.

185 07 Wheels and tires

Changing a wheel

ProCarManuals.com

Page 167 of 246

Positioning the jack1

There are two jack attachment points on each side of the car.

6. Position the jack correctly in the attachment (see illustration above) and crank while simultaneously guiding the base

of the jack to the ground. The base of the jack must be flat on a level, firm, non-slippery surface.

7. Before raising the car, check that the jack is still correctly positioned in the attachment.

1Not included on models equipped with the tire sealing system.

WARNING

The jack must correctly engage the jack attachment.

Be sure the jack is on a firm, level, non-slippery surface.

Never allow any part of your body to be extended under a car supported by a jack.

Use the jack intended for the car when changing a tire. For any other job, use stands to support the car.

Apply the parking brake and put the gear selector in the Park (P) position.

Block the wheels standing on the ground, use rigid wooden blocks or large stones.

The jack should be kept well-greased and clean, and should not be damaged.

No objects should be placed between the base of jack and the ground, or between the jack and the attachment bar

on the vehicle.

Removing the wheel

8. Raise the vehicle until the wheel to be changed is lifted off the ground.

9. Unscrew the wheel bolts completely and carefully remove the wheel so as not to damage the threads on the studs.

Installing a wheel

1. Clean the contact surfaces on the wheel and hub.

2. Lift the wheel and place it on the hub.

3. Install the wheel nuts and tighten hand -tight. Using the lug wrench, tighten crosswise until all nuts are snug.

4. Lower the vehicle to the ground and alternately tighten the bolts crosswise to 96 ft. lbs. (130 Nm).

5. Install the wheel cap (where applicable).

186 07 Wheels and tires

ProCarManuals.com

Page 168 of 246

Tire sealing system

Introduction

Certain models are equipped with a tire sealing system that enables you to temporarily seal a hole in the tread surface

and reinflate a flat tire, or to adjust a tire's inflation pressure.

The system consists of an air compressor, a container for the sealing compound, wiring to connect the system to the

vehicle's electrical system via one of the 12-volt sockets, and a hose used to connect the system to the tire's inflation

valve.

The 12-volt sockets are located in the front tunnel console and in the trunk (option). See pages 66

and 108.

Accessing the tire sealing system

The tire sealing system is stowed in the compartment in the rear side of the ski hatch in the center of the rear seat

backrest. See page 109

for information on opening this hatch

NOTE

The tire sealing system is only intended to seal holes on the tire's tread area, not the sidewall.

Tires with large holes or tears cannot be repaired with the tire sealing system.

WARNING

After using the tire sealing system, the vehicle should not be driven farther than approximately 120 miles (200

km). Have the tire replaced as soon as possible.

The vehicle should not be driven faster than 50 mph (80 km/h) while using a tire that has been temporarily

repaired with the tire sealing system.

After using the tire sealing system, drive carefully and avoid abrupt steering maneuvers and sudden stops.

187 07 Wheels and tires

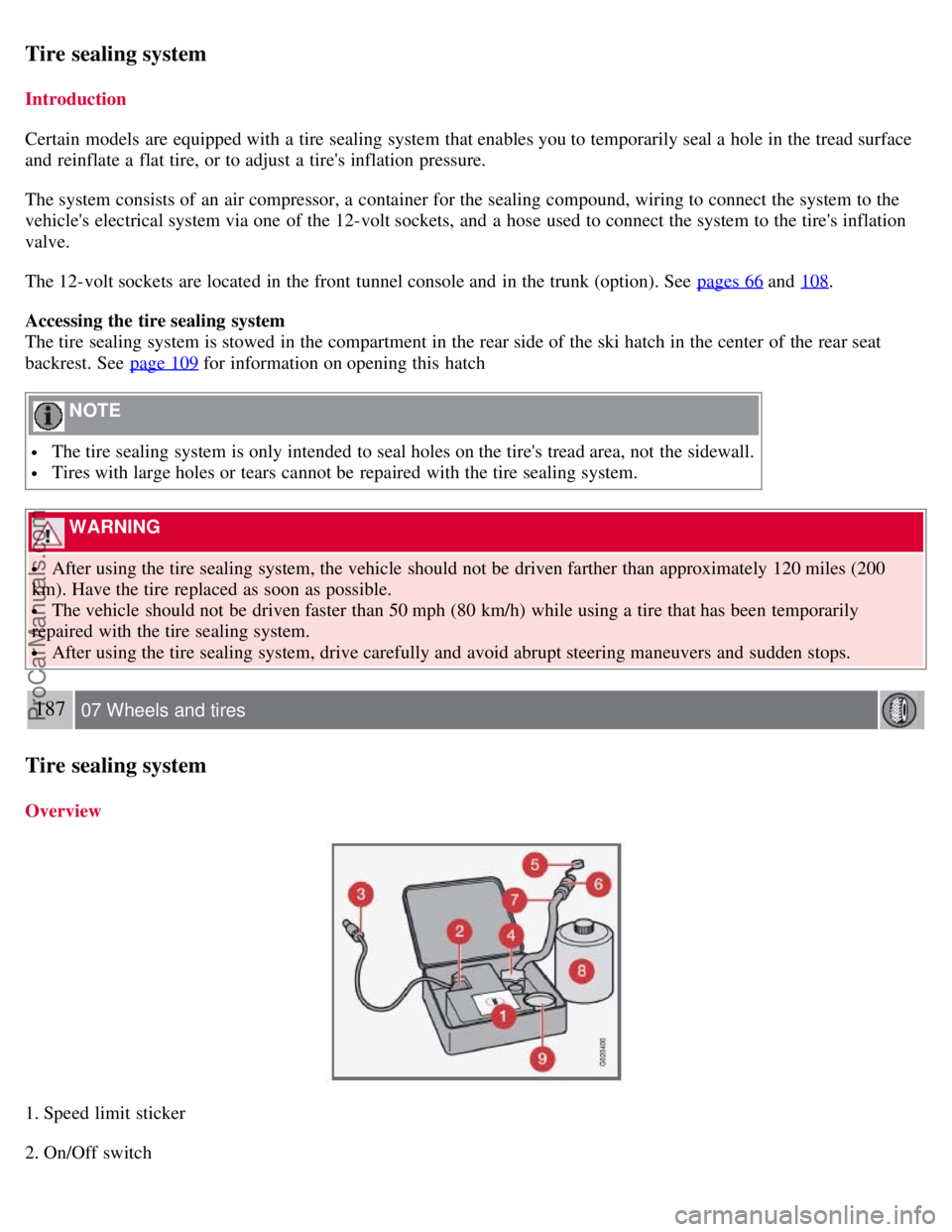

Tire sealing system

Overview

1. Speed limit sticker

2. On/Off switch

ProCarManuals.com

Page 169 of 246

3. Electrical wire

4. Bottle holder (orange cover)

5. Protective hose cover

6. Air release knob

7. Hose

8. Bottle with sealing compound

9. Air pressure gauge

WARNING

Please keep the following points in mind when using the tire sealing system:

The sealing compound bottle (no. 8 in the illustration) contains 1.2-Ethanol and natural rubber-latex. These

substances are harmful if swallowed.

The contents of this bottle may cause allergic skin reactions or otherwise be potentially harmful to the skin, the

central nervous system, and the eyes.

Precautions:

Keep out of reach of children.

Do not ingest the contents.

Avoid prolonged or repeated contact with the skin.

Hands should be washed thoroughly after handling.

First aid:

Skin: Wash affected areas of skin with soap and water. Get medical attention if symptoms occur.

Eyes: Flush with plenty of water for least 15 minutes, occasionally lifting the upper and lower eyelids. Get

medical attention if symptoms occur.

Inhalation: Move the person to fresh air. If irritation persists, get medical attention.

Inflating tires

The tire sealing system can be used to inflate the tires. To do so:

1. Park the car in a safe place.

2. The compressor should be switched off. Ensure that the on/off switch is in position 0 (the 0 side of the switch should

be pressed down).

3. Take out the electrical wire and hose.

4. Remove the valve cap from the tire's inflation valve and screw the hose connector onto the valve as tightly as

possible by hand.

5. Connect the electrical wire to the nearest 12-volt socket in the vehicle.

6. Start the vehicle's engine.

ProCarManuals.com

Page 170 of 246

WARNING

The vehicle's engine should be running when the tire sealing system is used to avoid battery drain. Therefore, be

sure the vehicle is parked in a well ventilated place, or outdoors, before using the system.

Children should never be left unattended in the vehicle when the engine is running.

7. Check the tire's inflation pressure on the gauge. Switch off the compressor briefly to get a clear reading from the

pressure gauge.

188 07 Wheels and tires

Tire sealing system

8. Refer to the tables on pages 172 and 173 for the correct tire inflation pressure. If the tire needs to be inflated, start

the tire sealing system's compressor (press the on/off switch to position I ). If necessary, release air from the tire by

turning the air release knob counterclockwise.

CAUTION

The compressor should not be used for more than 10 minutes at a time to avoid overheating.

9. Turn off the compressor (press the on/off switch to position 0) when the correct inflation pressure has been reached.

10. Unscrew the hose from the tire's inflation valve and reinstall the valve cap.

11. Disconnect the electrical wire from the 12-volt socket.

189 07 Wheels and tires

Tire sealing system

Tire sealing system-temporarily repairing a flat tire

ProCarManuals.com

Page 171 of 246

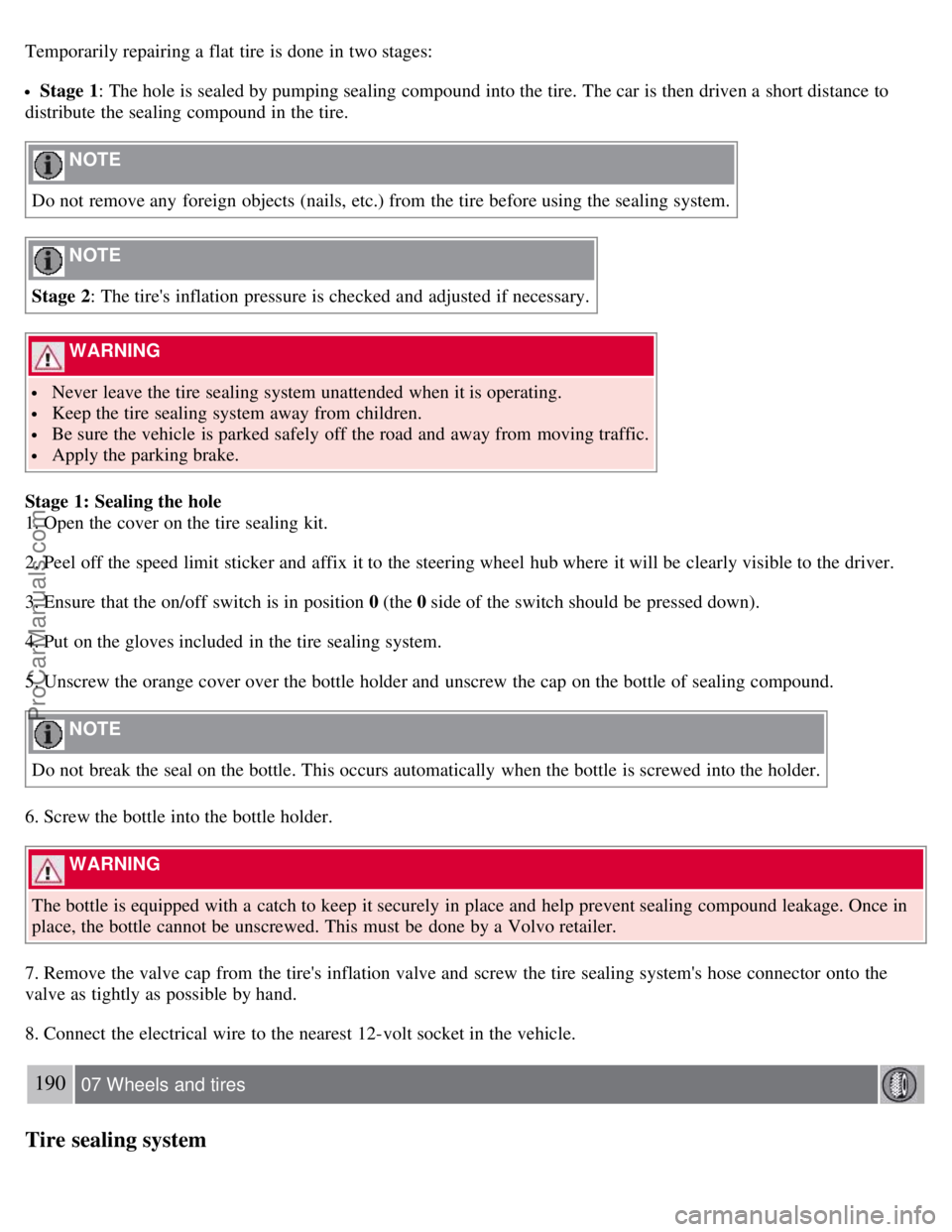

Temporarily repairing a flat tire is done in two stages:

Stage 1: The hole is sealed by pumping sealing compound into the tire. The car is then driven a short distance to

distribute the sealing compound in the tire.

NOTE

Do not remove any foreign objects (nails, etc.) from the tire before using the sealing system.

NOTE

Stage 2: The tire's inflation pressure is checked and adjusted if necessary.

WARNING

Never leave the tire sealing system unattended when it is operating.

Keep the tire sealing system away from children.

Be sure the vehicle is parked safely off the road and away from moving traffic.

Apply the parking brake.

Stage 1: Sealing the hole

1. Open the cover on the tire sealing kit.

2. Peel off the speed limit sticker and affix it to the steering wheel hub where it will be clearly visible to the driver.

3. Ensure that the on/off switch is in position 0 (the 0 side of the switch should be pressed down).

4. Put on the gloves included in the tire sealing system.

5. Unscrew the orange cover over the bottle holder and unscrew the cap on the bottle of sealing compound.

NOTE

Do not break the seal on the bottle. This occurs automatically when the bottle is screwed into the holder.

6. Screw the bottle into the bottle holder.

WARNING

The bottle is equipped with a catch to keep it securely in place and help prevent sealing compound leakage. Once in

place, the bottle cannot be unscrewed. This must be done by a Volvo retailer.

7. Remove the valve cap from the tire's inflation valve and screw the tire sealing system's hose connector onto the

valve as tightly as possible by hand.

8. Connect the electrical wire to the nearest 12-volt socket in the vehicle.

190 07 Wheels and tires

Tire sealing system

ProCarManuals.com

Page 173 of 246

vehicle in a safe place. Recheck the tire for bumps, cracks, or other visible damage, and recheck its inflation

pressure. If the pressure is below 19 psi (1.3 bar), do not continue driving. Have the vehicle towed to a workshop or

Volvo retailer.

Stage 2: Checking inflation pressure

1. Connect the tire sealing system as described in stage 1.

2. Refer to the tables on pages 172 and 173

for the correct tire inflation pressure. If the tire needs to be

191 07 Wheels and tires

Tire sealing system

inflated, start the tire sealing system's compressor. If necessary, release air from the tire by turning the air release knob

counterclockwise.

CAUTION

The compressor should not be used for more than 10 minutes at a time to avoid overheating.

WARNING

If you interrupt your trip for more than 1 hour, check the inflation pressure in the damaged tire again before

continuing.

Replacing the sealing compound container

The sealing compound container must be replaced if:

the tire sealing system has been used to repair a tire

NOTE

After use, the sealing compound bottle, the hose, and certain other system components must be replaced. Please

consult your Volvo retailer for replacement parts.

the container's expiration date has passed (see the date on decal).

NOTE

If the sealing compound bottle's expiration date has passed, please take it to a Volvo retailer or a recycling station

that can properly dispose of harmful substances.

192 07 Wheels and tires

Tire Pressure Monitoring System (TPMS)

Introduction

The tire pressure monitoring system uses sensors mounted in the tire valves to check inflation pressure levels. When

ProCarManuals.com

Page 174 of 246

the vehicle is moving at a speed of approximately 20 mph (30 km/h) or faster, these sensors transmit inflation pressure

data to a receiver located in the vehicle.

NOTE

USA - FCC ID: KR5S122780002

This device complies with part 15 of the FCC rules. Operation is subject to the following conditions: (1) This device

may not cause harmful interference, and (2) this device must accept any interference received, including interference

that may cause undesired operation.

When low inflation pressure is detected, TPMS will light up the tire pressure warning light (

) (also referred to as a

telltale) in the instrument panel, and will display a message in the text window. The wording of this message is

determined by the degree of inflation pressure loss.

NOTE

If a fault occurs in TPMS, the tire pressure warning light will flash for approximately 1 minute and TIRE PRESS

SYST SERVICE REQUIRED will be displayed.

Each tire, including the spare (if provided), should be checked monthly when cold and inflated to the inflation pressure

recommended by the vehicle manufacturer on the vehicle placard or tire inflation pressure label. (If your vehicle has

tires of a different size than the size indicated on the vehicle placard or tire inflation pressure label, you should

determine the proper tire inflation pressure for those tires.)

As an added safety feature, your vehicle has been equipped with a tire pressure monitoring system (TPMS) that

illuminates a low tire pressure telltale when one or more of your tires is significantly under-inflated. Accordingly,

when the low tire pressure telltale illuminates, you should stop and check your tires as soon as possible, and inflate

them to the proper pressure. Driving on a significantly under-inflated tire causes the tire to overheat and can lead to

tire failure. Under-inflation also reduces fuel efficiency and tire tread life, and may affect the vehicle's handling and

stopping ability.

Please note that the TPMS is not a substitute for proper tire maintenance, and it is the driver's responsibility to

maintain correct tire pressure, even if under-inflation has not reached the level to trigger illumination of the TPMS low

tire pressure telltale.

Your vehicle has also been equipped with a TPMS malfunction indicator to indicate when the system is not operating

properly. The TPMS malfunction indicator is combined with the low tire pressure telltale. When the system detects a

malfunction, the telltale will flash for approximately one minute and then remain continuously illuminated. This

sequence will continue upon subsequent vehicle start-ups as long as the malfunction exists. When the malfunction

indicator is illuminated, the system may not be able to detect or signal low tire pressure as intended. TPMS

malfunctions may occur for a variety of reasons, including the installation of replacement or alternate tires or wheels

on the vehicle that prevent the TPMS from functioning properly. Always check the TPMS malfunction telltale after

replacing one or more tires or wheels on your vehicle to ensure that the replacement or alternate tires and wheels allow

the TPMS to continue to function properly.

193 07 Wheels and tires

Tire Pressure Monitoring System (TPMS)

NOTE

ProCarManuals.com