ECU VOLVO S40 2009 Owner´s Manual

[x] Cancel search | Manufacturer: VOLVO, Model Year: 2009, Model line: S40, Model: VOLVO S40 2009Pages: 286, PDF Size: 7.08 MB

Page 163 of 286

06 Starting and driving

Transporting loads

06

163 Loading the vehicle

Your vehicle's load-carrying capacity is affec-

ted by factors such as:•

the number of passengers

•

tire inflation

•

the amount of optional or accessory equip-

ment installed

•

the amount of cargo.

See the chapter "Wheels and tires" for more

detailed information.

Before loading the car, turn off the engine, and

apply the parking brake when loading or

unloading long objects. The gear selector can

be inadvertently knocked out of position by

long cargo, causing the car to move.

Keep the following in mind when

loading the vehicle:•

Load objects in the trunk against the rear

seat backrest.

•

Load heavy cargo as low as possible.

•

Center wide loads.

•

Secure all cargo with restraining straps

anchored to the load securing eyelets.

•

Cover sharp edges on the load.

•

Seats can be folded down and head

restraints removed to extend the cargo

compartment, see page 113.

WARNING

•

Remember that an object weighing

44 lbs (20 kg) produces a force of

2,200 lbs (1,000 kg) in a head-on colli-

sion at 30 mph (50 km/h)!

•

When the rear backrest(s) are folded

down, the vehicle should not be loaded

to a level higher than 2 in. (5 cm) below

the upper edge of the rear side win-

dows. Objects placed higher than this

level could impede the function of the

Volvo Inflatable Curtain.

Load carriers (accessory)Load carriers are available as Volvo accesso-

ries. Follow the installation instructions sup-

plied with the load carriers.

Observe the following points when using load

carriers:•

To avoid damaging your car and to achieve

maximum safety when driving, we recom-

mend using the load carriers that Volvo has

developed especially for your car.

•

Volvo-approved removable roof racks are

designed to carry the maximum allowable

roof load for this vehicle: 165 lbs (75 kg).

For Non-Volvo roof racks, check the man-

ufacturer's weight limits for the rack.

•

Never exceed the rack manufacturer's

weigh limits and never exceed the maxi-

mum rated roof load of 165 lbs (75 kg).

•

Avoid single-point loads. Distribute loads

evenly.

•

Place heavier cargo at the bottom of the

load.

•

Secure the cargo correctly with appropri-

ate tie-down equipment.

•

Check periodically that the load carriers

and load are properly secured.

•

Remember that the car's center of gravity

and handling change when you carry a

load on the roof.

•

The car's wind resistance and fuel con-

sumption will increase with the size of the

load.

•

Drive smoothly. Avoid rapid starts, fast

cornering and hard braking.

Page 188 of 286

07 Wheels and tiresWheel nuts

07188

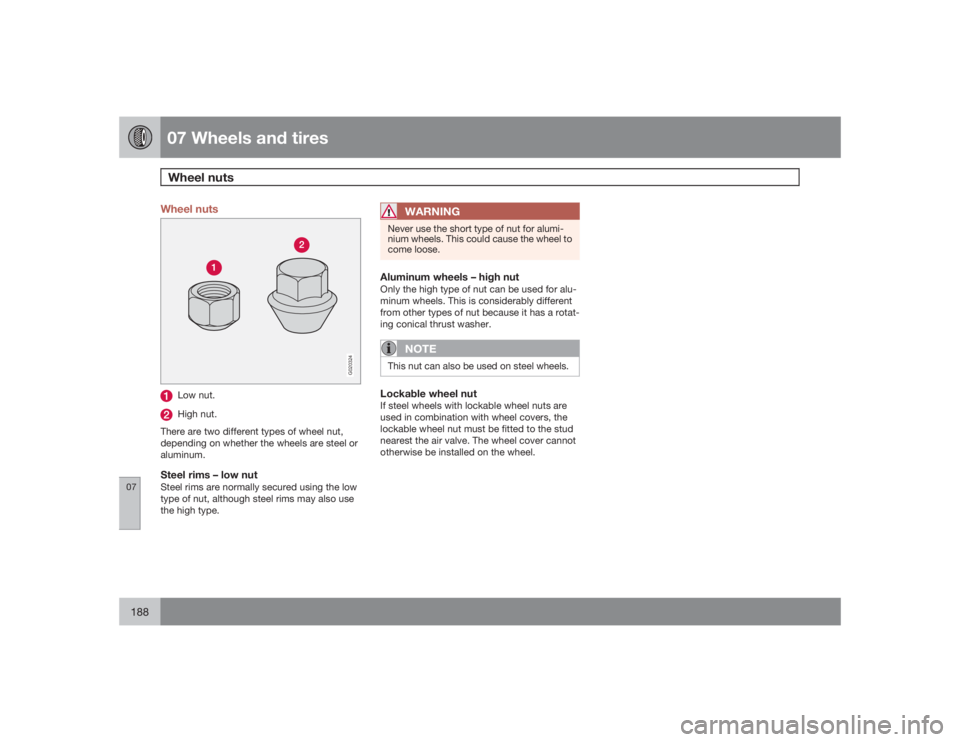

Wheel nuts

G020324

Low nut.High nut.

There are two different types of wheel nut,

depending on whether the wheels are steel or

aluminum.

Steel rims – low nutSteel rims are normally secured using the low

type of nut, although steel rims may also use

the high type.

WARNING

Never use the short type of nut for alumi-

nium wheels. This could cause the wheel to

come loose.Aluminum wheels – high nutOnly the high type of nut can be used for alu-

minum wheels. This is considerably different

from other types of nut because it has a rotat-

ing conical thrust washer.

NOTE

This nut can also be used on steel wheels.Lockable wheel nutIf steel wheels with lockable wheel nuts are

used in combination with wheel covers, the

lockable wheel nut must be fitted to the stud

nearest the air valve. The wheel cover cannot

otherwise be installed on the wheel.

Page 191 of 286

07 Wheels and tires

Changing a wheel

07

191

WARNING

•

The jack must correctly engage the jack

attachment.

•

Be sure the jack is on a firm, level, non-

slippery surface.

•

Never allow any part of your body to be

extended under a car supported by a

jack.

•

Use the jack intended for the car when

changing a tire. For any other job, use

stands to support the car.

•

Apply the parking brake and put the

gear selector in the Park (P) position or

reverse on models with a manual trans-

mission.

•

Block the wheels standing on the

ground, use rigid wooden blocks or

large stones.

•

The jack should be kept well-greased

and clean, and should not be damaged.

•

No objects should be placed between

the base of jack and the ground, or

between the jack and the attachment

bar on the vehicle.

Installing the wheel1. Clean the contact surfaces on the wheel

and hub.

2. Lift the wheel and place it on the hub.

3. Install the wheel nuts and tighten hand-

tight. Using the lug wrench, tighten cross-

wise until all nuts are snug.

4. Lower the vehicle to the ground and alter-

nately tighten the bolts crosswise to

81 ft. lbs. (110 Nm).

5. Install the wheel cap (where applicable).Returning the jack to its storage space

G029335

The jack (certain models) and tools should be

returned to their correct storage places after

use.•

On vehicles equipped with a jack and

spare wheel, the jack should be cranked

down to the position shown in the illustra-

tion.

•

On vehicles equipped with the tire sealing

system, the jack should be cranked down

as far as possible and returned to its stor-

age position in the foam block.WARNING

The jack and any tools should always be

returned to their proper storage compart-

ments after use to help keep them securely

in place in the event of sudden braking, etc.

Page 194 of 286

07 Wheels and tiresTire Sealing System

07194

3. Ensure that the on/off switch is in position

0 (the 0 side of the switch should be

pressed down).

4. Put on the gloves included in the tire seal-

ing system.

WARNING

Contact with the sealing compound may

cause skin irritation. If contact occurs, wash

the affected area immediately with soap and

water.5. Unscrew the orange cover over the bottle

holder and unscrew the cap on the bottle

of sealing compound.

NOTE

Do not break the seal on the bottle. This

occurs automatically when the bottle is

screwed into the holder.6. Screw the bottle into the bottle holder.

WARNING

The bottle is equipped with a catch to keep

it securely in place and help prevent sealing

compound leakage. Once in place, the bot-

tle cannot be unscrewed. This must be done

by a trained and qualified Volvo service

technician.7. Remove the valve cap from the tire’s infla-

tion valve and screw the tire sealing sys-

tem’s hose connector onto the valve as

tightly as possible by hand.

8. Connect the electrical wire to the nearest

12-volt socket in the vehicle.

9. Start the vehicle’s engine.

10. Start the tire sealing system’s compressor

by pressing the on/off switch to position I.

WARNING

•Never stand next to the tire being inflated

when the compressor is in operation.•If cracks, bubbles, etc. form on the tire,

switch off the compressor immediately.•If there is visible damage to the sidewall

or the rim, the tire cannot be repaired.

The vehicle should not be driven if this

occurs. Contact a towing service or

Volvo On Call Roadside Assistance if

applicable.NOTE

The air pressure gauge will temporarily

show an increase in pressure to approxi-

mately 88 psi (6 bar) while the sealing com-

pound is being pumped into the tire. The

pressure should return to a normal level

after approximately 30 seconds.11. Within seven minutes, inflate the tire to

between 22—44 psi (1.8—3.0 bar). Switch

off the compressor briefly to get a clear

reading from the pressure gauge. The

compressor should not be used for more

than 10 minutes at a time to avoid over-

heating.

Page 203 of 286

08 Car care

Washing and cleaning the car

08�`�`203

CAUTION

•

During high pressure washing, the

spray mouthpiece must never be closer

to the vehicle than 13" (30 cm). Do not

spray into the locks.

•

Dirt, snow, etc., on the headlights can

reduce lighting capacity considerably.

Clean the headlights regularly, for

example when refueling.

•

When washing or steam cleaning the

engine, avoid spraying water or steam

directly on the electrical components or

toward the rear side of the engine.

•

Always close the moonroof (option) and

sun shade before washing your vehicle.

•

Never use abrasive cleaning agents on

the moonroof.

•

Never use wax on the rubber seals

around the moonroof.

Automatic washing – simple and quickWe do NOT recommend washing your car in an

automatic wash during the first six months

(because the paint will not have hardened suf-

ficiently).

An automatic wash is a simple and quick way

to clean your car, but it is worth remembering

that it may not be as thorough as when you

yourself go over the car with sponge and water.Keeping the underbody clean is most impor-

tant, especially in the winter. Some automatic

washers do not have facilities for washing the

underbody.

CAUTION

•

Before driving into an automatic car

wash, turn off the optional rain sensor

to avoid damaging the windshield wip-

ers.

•

Make sure that side view mirrors, auxil-

iary lamps, etc, are secure, and that any

antenna(s) are retracted or removed.

Otherwise there is risk of the machine

dislodging them

•

Chromed wheels: Clean chrome-

plated wheels using the same deter-

gents used for the body of the vehicle.

Aggressive wheel-cleaning agents can

permanently stain chrome-plated

wheels.WARNING

•

When the car is driven immediately after

being washed, apply the brakes several

times in order to remove any moisture

from the brake linings.

•

Engine cleaning agents should not be

used when the engine is warm. This

constitutes a fire risk.

Exterior lightingCondensation may form temporarily on the

inside of the lenses of exterior lights such as

headlights, fog lights, or taillights. This is nor-

mal and the lights are designed to withstand

moisture. Normally, condensation will dissi-

pate after the lights have been on for a short

time.Polishing and Waxing•

Normally, polishing is not required during

the first year after delivery, however, wax-

ing may be beneficial.

•

Before applying polish or wax the vehicle

must be washed and dried. Tar spots can

be removed with kerosene or tar remover.

Difficult spots may require a fine rubbing

compound.

•

After polishing use liquid or paste wax.

•

Several commercially available products

contain both polish and wax.

•

Waxing alone does not substitute for pol-

ishing a dull surface.

•

A wide range of polymer-based waxes can

be purchased today. These waxes are easy

to use and produce a long-lasting, high-

gloss finish that protects the bodywork

against oxidation, road dirt and fading.

•

Do not polish or wax your vehicle in direct

sunlight (the surface of the vehicle should

not be warmer than 113 °F (45 °C).

Page 220 of 286

09 Maintenance and servicingWiper blades

09220

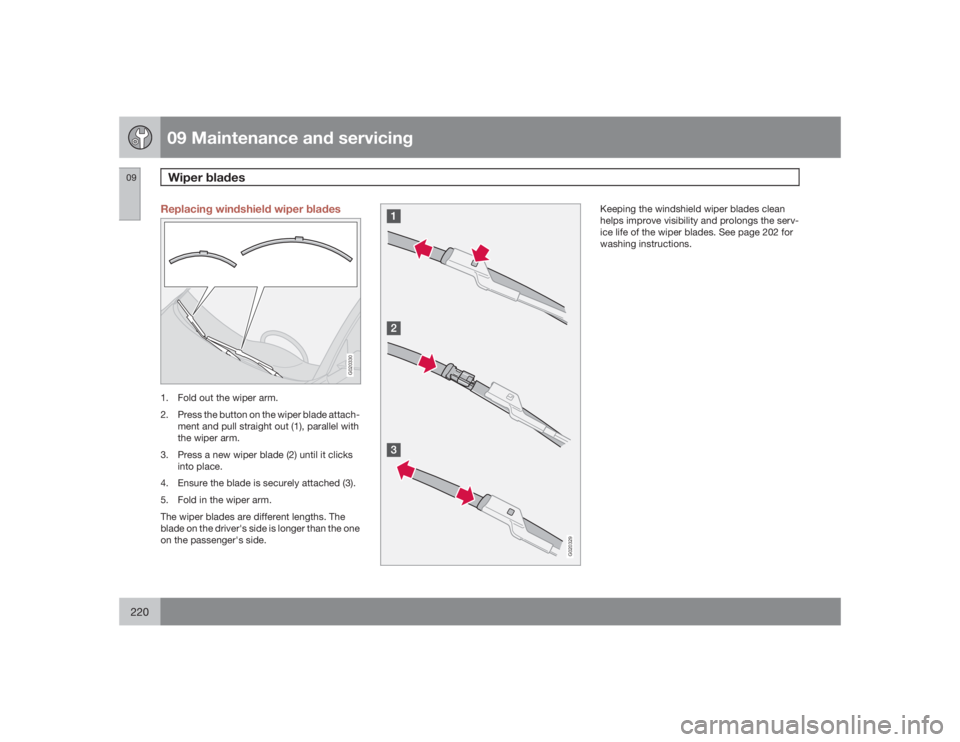

Replacing windshield wiper blades

G020330

1. Fold out the wiper arm.

2. Press the button on the wiper blade attach-

ment and pull straight out (1), parallel with

the wiper arm.

3. Press a new wiper blade (2) until it clicks

into place.

4. Ensure the blade is securely attached (3).

5. Fold in the wiper arm.

The wiper blades are different lengths. The

blade on the driver's side is longer than the one

on the passenger's side.

G020329

Keeping the windshield wiper blades clean

helps improve visibility and prolongs the serv-

ice life of the wiper blades. See page 202 for

washing instructions.

Page 221 of 286

09 Maintenance and servicing

Battery

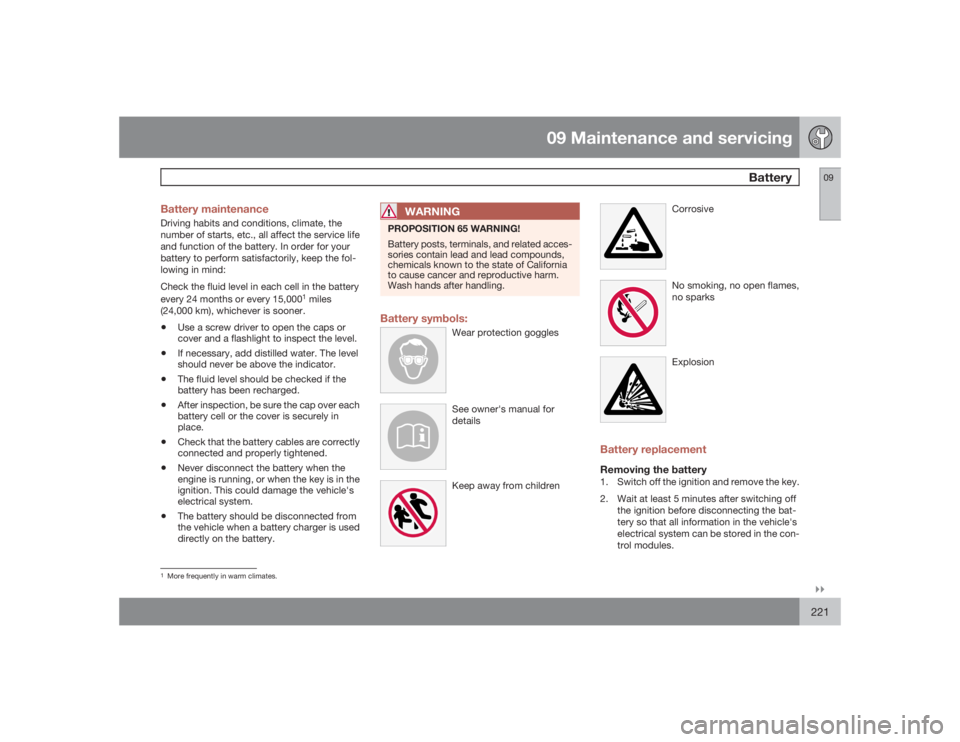

09�`�`221 Battery maintenance

Driving habits and conditions, climate, the

number of starts, etc., all affect the service life

and function of the battery. In order for your

battery to perform satisfactorily, keep the fol-

lowing in mind:

Check the fluid level in each cell in the battery

every 24 months or every 15,000

1 miles

(24,000 km), whichever is sooner.

•

Use a screw driver to open the caps or

cover and a flashlight to inspect the level.

•

If necessary, add distilled water. The level

should never be above the indicator.

•

The fluid level should be checked if the

battery has been recharged.

•

After inspection, be sure the cap over each

battery cell or the cover is securely in

place.

•

Check that the battery cables are correctly

connected and properly tightened.

•

Never disconnect the battery when the

engine is running, or when the key is in the

ignition. This could damage the vehicle's

electrical system.

•

The battery should be disconnected from

the vehicle when a battery charger is used

directly on the battery.

WARNING

PROPOSITION 65 WARNING!

Battery posts, terminals, and related acces-

sories contain lead and lead compounds,

chemicals known to the state of California

to cause cancer and reproductive harm.

Wash hands after handling.Battery symbols:

Wear protection gogglesSee owner's manual for

detailsKeep away from children

CorrosiveNo smoking, no open flames,

no sparksExplosion

Battery replacementRemoving the battery1. Switch off the ignition and remove the key.

2. Wait at least 5 minutes after switching off

the ignition before disconnecting the bat-

tery so that all information in the vehicle's

electrical system can be stored in the con-

trol modules.

1More frequently in warm climates.

Page 234 of 286

09 Maintenance and servicingFuses

09234

Fuse box in the passenger compartment

G020601

The fuse box in the passenger compartment is

located under the glove compartment.

To access the fuses:

1. Remove the upholstery covering the fuse

box by first pressing in the center pins in

the mounting clips approximately 0.5 in

(1 cm) with a small screwdriver and then

pulling the pins out.

2. Turn both retaining screws (2) counter-

clockwise until they release.

3. Fold down the fuse box (3) half way. Pull it

toward the seat until it stops. Fold it down

completely. The fuse box can be unhooked

completely.

4. Replace the blown fuse.

5. Close the fuse box in reverse order.6. Pull the center pins fully out of the mount-

ing clips, secure the upholstery with the

mounting clips and press the pins into the

mounting clips again. The mounting clips

then expand, holding the upholstery in

position.

Page 246 of 286

10 AudioRadio functions

10246

(see also "Selecting a channel" in the right

column).

2. Call Sirius at 1-888-539-SIRIUS (7474).

3. When asked for the Sirius ID number press

AUTO to display this number. It is also

possible to retrieve the Sirius ID from the

MENU.

4.

"UPDATING SUBSCRIPTION

" will be

displayed while the subscription is being

updated, after which the display will return

to the normal view.

SIRUS ID

The SIRIUS ID is required when contacting the

Sirius Call Center. It is used to activate your

account and when making any account trans-

actions. The SIRIUS ID is sometimes referred

to as the Electronic Serial Number (ESN).

Selecting a channel category1. Select Sirius radio mode as described

above.

2.

PressENTER.

3. Use the up/down arrow keys to scroll

through the list of categories.

4.

PressENTER or the right arrow key to

select a category.5. Use the left or right arrow keys to select a

channel in the currently chosen category.

6.

PressENTER to listen to a channel.

NOTE

•

The category "All" is default, which ena-

bles you to scroll through the entire list

of available satellite channels.

•

The channel categories are automati-

cally updated several times a year. This

takes approximately two minutes and

will interrupt normal broadcasting. A

message will be displayed while updat-

ing is in progress. Information on chan-

nel or feature updates is available at

www.sirius.com.

Selecting a channelThere are three ways of tuning in a channel:•

Using the left and right arrow keys

•

By turning the tuning control

•

Through direct channel entry

Direct channel entryThe Sirius satellite channels are numbered

consecutively throughout all of the categories.

To access a channel directly:1.

PressMENU and scroll to "Direct channel

entry."

2. Use the numerical keypad to enter the

channel's number.

3.

PressENTER. The radio will tune to this

channel, even if it belongs to a category

other than the currently selected one.

NOTE

•

The numbers of skipped or locked

channels will not be displayed.

•

If a channel is locked, the access code

must be entered before the channel can

be selected. See "Unlocking a channel"

on page 247.

Scanning

NOTE

SCAN automatically searches through the

list of satellite channels. see page 245 for

more detailed information.Storing a channel•

Along press on one of the number keys

stores the currently tuned channel on that

key.

•

Ashort press on a number key while the

radio is in Sirius 1or 2 mode will tune to the