steering VOLVO S60 2014 Owner´s Manual

[x] Cancel search | Manufacturer: VOLVO, Model Year: 2014, Model line: S60, Model: VOLVO S60 2014Pages: 386, PDF Size: 11.24 MB

Page 274 of 386

07 During your trip

Driving recommendations

07

272

WARNING

The cooling fan may start or continue to operate (for up to 6 minutes) after theengine has been switched off.

•Remove any auxiliary lights from in front of the grille when driving in hot weatherconditions.

• Do not exceed engine speeds of4500 rpm if driving with a trailer in hillyterrain. The oil temperature could becometoo high.

Conserving electrical currentKeep the following in mind to help minimize battery drain:

• When the engine is not running, avoid using ignition mode

II. Many electrical

systems (the audio system, the optionalnavigation system, power windows, etc)will function in ignition modes 0 and I.

These modes reduce drain on the battery.

• Please keep in mind that using systems,accessories, etc., that consume a greatdeal of current when the engine is notrunning could result in the battery beingcompletely drained. Driving or having theengine running for approximately15 minutes will help keep the batterycharged.

Before a long distance tripIt is always worthwhile to have your vehicle checked by a trained and qualified Volvoservice technician before driving long dis-tances. Your retailer will also be able to sup-ply you with bulbs, fuses, spark plugs andwiper blades for your use in the event thatproblems occur. As a minimum, the following items should be checked before any long trip:

• Check that engine runs smoothly and that fuel consumption is normal.

• Check for fuel, oil, and fluid leakage

• Have the transmission oil level checked.

• Check condition of drive belts.

• Check state of the battery's charge.

• Examine tires carefully (the spare tire aswell), and replace those that are worn.Check tire pressures.

• The brakes, front wheel alignment, andsteering gear should be checked by atrained and qualified Volvo service techni-cian only.

• Check all lights, including high beams.

• Reflective warning triangles are legallyrequired in some states/provinces.

• Have a word with a trained and qualifiedVolvo service technician if you intend to drive in countries where it may be difficultto obtain the correct fuel.

• Consider your destination. If you will bedriving through an area where snow or iceare likely to occur, consider snow tires.

Cold weather precautionsIf you wish to check your vehicle before the approach of cold weather, the followingadvice is worth noting:

• Make sure that the engine coolant con- tains 50 percent antifreeze. Any othermixture will reduce freeze protection. Thisgives protection against freezing down to–31 °F (–35 °C). The use of "recycled"antifreeze is not approved by Volvo. Dif-ferent types of antifreeze must not bemixed.

• Volvo recommends using only genuineVolvo antifreeze in your vehicle's radiator.

• Try to keep the fuel tank well filled – thishelps prevent the formation of condensa-tion in the tank. In addition, in extremelycold weather conditions it is worthwhileto add fuel line de-icer before refueling.

• The viscosity of the engine oil is impor-tant. Oil with low viscosity (thinner oil)improves cold-weather starting as well asdecreasing fuel consumption while theengine is warming up. Full synthetic

Page 285 of 386

07 During your trip

Towing a trailer

07

283

NOTE

•When parking the vehicle with a trailer on a hill, apply the parking brakebefore putting the gear selector in

P.

Always follow the trailer manufactur-er's recommendations for wheelchocking.

• When starting on a hill, put the gearselector in

D before releasing the park-

ing brake. See also page 133 for moredetailed information about starting offon a hill while towing a trailer.

• If you use the manual (Geartronic) shiftpositions while towing a trailer, makesure the gear you select does not puttoo much strain on the engine (usingtoo high a gear).

• The drawbar assembly/trailer hitchmay be rated for trailers heavier thanthe vehicle is designed to tow. Pleaseadhere to Volvo's recommended trailerweights.

• Avoid driving with a trailer on inclinesof more than 15%.

Trailer cableAn adapter is required if the vehicle's trailer hitch has a 13-pin connector and the trailerhas 7 pins. Use an adapter cable approved by Volvo. Make sure the cable does not dragon the ground.

Trailer Stability Assist (TSA)

Trailer Stability Assist is a system designed to help stabilize a vehicle that is towing a trailerwhen the vehicle and trailer have begun tosway and is part of the Dynamic Stability andTraction Control system (DSTC). See page138 for information on DSTC.

FunctionA vehicle towing a trailer may begin to swayfor various reasons. Normally this only occursat high speeds but, for example, if the traileris overloaded or if the load is unevenly dis-tributed in the trailer, there is risk of swayingat speeds between approximately 45-55 mph(70-90 km/h). Swaying may be caused by factors such as: •

The vehicle and trailer are hit by a sud- den, strong crosswind

• The vehicle and trailer are traveling on anuneven road surface or drive over a bump

• Sudden movements of the steering wheel

Facts about TSA

•

TSA intervenes at speeds above approxi-mately 40 mph (60 km/h)

• The DSTC symbol (

) in the instru-

ment panel will flash when TSA is working

• If the driver switches off the DSTC sys- tem's Spin Control function, TSA will alsobe switched off (but will be on again thenext time the engine is started)

• TSA may not intervene when the vehicleand trailer begin to sway if the driver triesto compensate for the swaying motion bymoving the steering wheel rapidly

How TSA worksOnce swaying has begun, it can be very diffi- cult to stop, which makes it difficult to controlthe vehicle and trailer. The TSA system continuously monitors the vehicle's movements, particularly lateralmovement. If the system detects a tendencyto sway, the brakes are applied individuallyon the front wheels, which has a stabilizingeffect on the vehicle and trailer. This is oftenenough to enable the driver to regain controlof the vehicle. If this is not adequate to stop the swaying motion, the brakes are applied to all of thewheels on the vehicle and on the trailer if it isequipped with brakes, and engine power is

Page 287 of 386

07 During your trip

Emergency towing

07

285

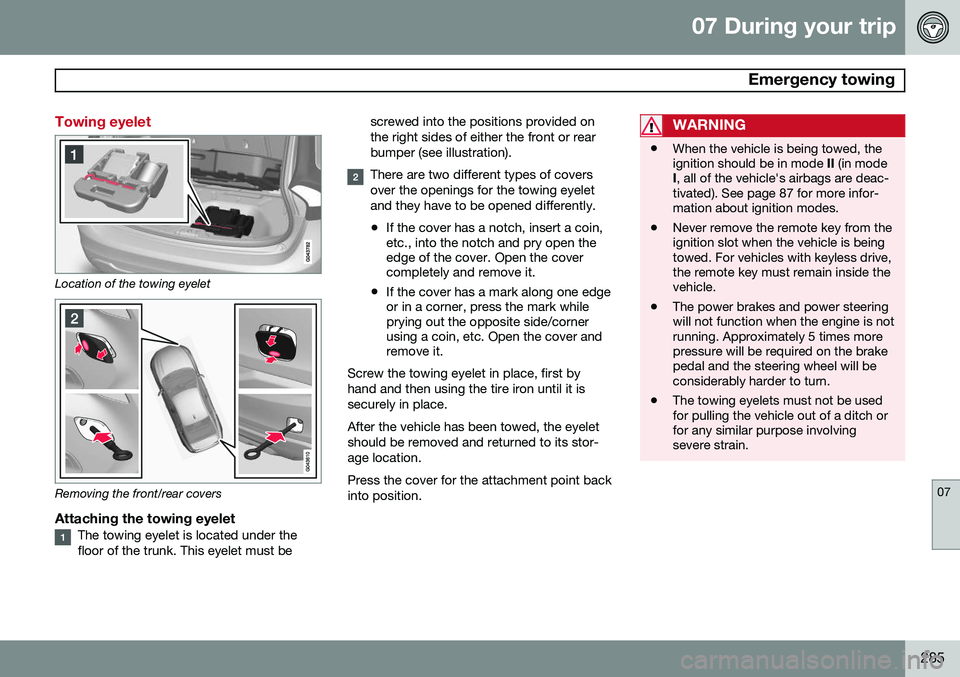

Towing eyelet

Location of the towing eyelet

Removing the front/rear covers

Attaching the towing eyeletThe towing eyelet is located under the floor of the trunk. This eyelet must bescrewed into the positions provided onthe right sides of either the front or rearbumper (see illustration).

There are two different types of covers over the openings for the towing eyeletand they have to be opened differently.

• If the cover has a notch, insert a coin, etc., into the notch and pry open theedge of the cover. Open the covercompletely and remove it.

• If the cover has a mark along one edgeor in a corner, press the mark whileprying out the opposite side/cornerusing a coin, etc. Open the cover andremove it.

Screw the towing eyelet in place, first by hand and then using the tire iron until it issecurely in place. After the vehicle has been towed, the eyelet should be removed and returned to its stor-age location. Press the cover for the attachment point back into position.

WARNING

• When the vehicle is being towed, the ignition should be in mode

II (in mode

I , all of the vehicle's airbags are deac-

tivated). See page 87 for more infor-mation about ignition modes.

• Never remove the remote key from theignition slot when the vehicle is beingtowed. For vehicles with keyless drive,the remote key must remain inside thevehicle.

• The power brakes and power steeringwill not function when the engine is notrunning. Approximately 5 times morepressure will be required on the brakepedal and the steering wheel will beconsiderably harder to turn.

• The towing eyelets must not be usedfor pulling the vehicle out of a ditch orfor any similar purpose involvingsevere strain.

Page 310 of 386

08 Wheels and tires

Tire Sealing System*

08

308* Option/accessory, for more information, see Introduction.

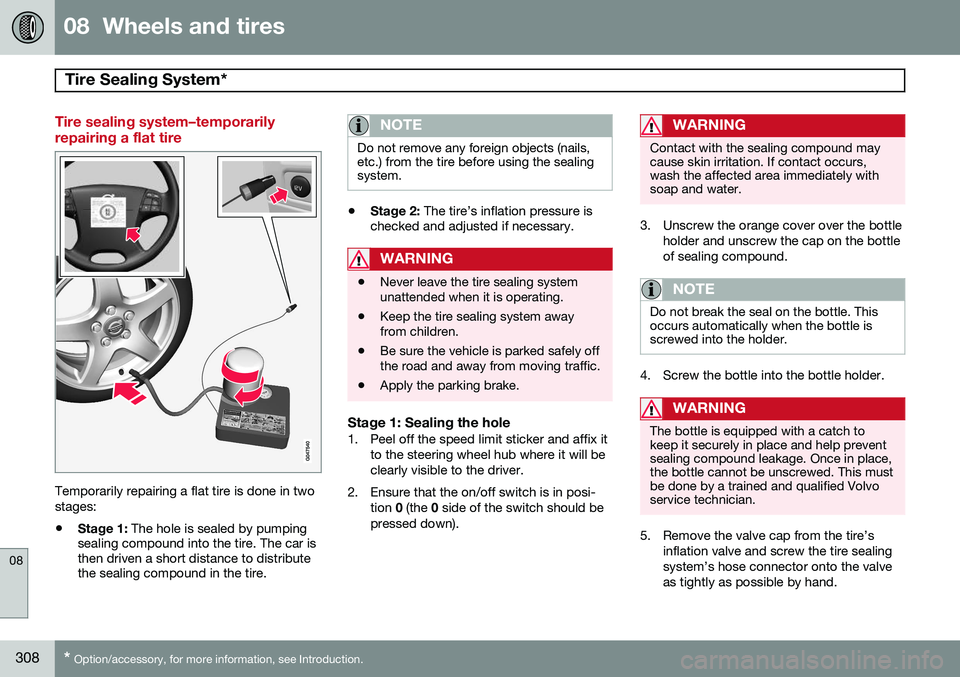

Tire sealing system–temporarily repairing a flat tire

Temporarily repairing a flat tire is done in two stages:

• Stage 1:

The hole is sealed by pumping

sealing compound into the tire. The car is then driven a short distance to distributethe sealing compound in the tire.

NOTE

Do not remove any foreign objects (nails, etc.) from the tire before using the sealingsystem.

• Stage 2:

The tire’s inflation pressure is

checked and adjusted if necessary.

WARNING

• Never leave the tire sealing system unattended when it is operating.

• Keep the tire sealing system awayfrom children.

• Be sure the vehicle is parked safely offthe road and away from moving traffic.

• Apply the parking brake.

Stage 1: Sealing the hole1. Peel off the speed limit sticker and affix it

to the steering wheel hub where it will be clearly visible to the driver.

2. Ensure that the on/off switch is in posi- tion 0 (the 0 side of the switch should be

pressed down).

WARNING

Contact with the sealing compound may cause skin irritation. If contact occurs,wash the affected area immediately withsoap and water.

3. Unscrew the orange cover over the bottle holder and unscrew the cap on the bottle of sealing compound.

NOTE

Do not break the seal on the bottle. This occurs automatically when the bottle isscrewed into the holder.

4. Screw the bottle into the bottle holder.

WARNING

The bottle is equipped with a catch to keep it securely in place and help preventsealing compound leakage. Once in place,the bottle cannot be unscrewed. This mustbe done by a trained and qualified Volvoservice technician.

5. Remove the valve cap from the tire’sinflation valve and screw the tire sealing system’s hose connector onto the valveas tightly as possible by hand.

Page 312 of 386

08 Wheels and tires

Tire Sealing System*

08

310* Option/accessory, for more information, see Introduction.

speed of 50 mph (80 km/h) to distribute the sealing compound in the tire.

CAUTION

If your vehicle is equipped with the Tire Pressure Monitoring System (TPMS), theuse of the sealing compound may lead toincorrect tire pressure readings or in rarecases, damage to the tire pressure sensor.Use the tire sealing system to check andadjust the damaged tire's inflation pres-sure.

NOTE

• Safely stow the tire sealing system in a convenient place as it will soon beused again to check the tire’s inflationpressure.

• The empty bottle of sealing compoundcannot be removed from the bottleholder. Consult a trained and qualifiedVolvo service technician to have thebottle removed and properly disposedof.

WARNING

If heavy vibrations, unsteady steering behavior, or noises should occur whiledriving, reduce speed and park the vehiclein a safe place. Recheck the tire forbumps, cracks, or other visible damage,and recheck its inflation pressure. If thepressure is below 19 psi (1.3 bar), do notcontinue driving. Have the vehicle towedto a trained and qualified Volvo servicetechnician.

Stage 2: Checking inflation pressure1. Connect the tire sealing system as

described in stage 1.

2. Refer to the inflation pressure table in this chapter for the correct inflation pressure. If the tire needs to be inflated, start thetire sealing system’s compressor. If nec-essary, release air from the tire by turningthe air release knob counterclockwise.

CAUTION

The compressor should not be used for more than 10 minutes at a time to avoidoverheating.

WARNING

If you interrupt your trip for more than 1 hour, check the inflation pressure in thedamaged tire again before continuing.

Replacing the sealing compound container

The sealing compound container must be replaced if:

• the tire sealing system has been used to repair a tire

• the container’s expiration date haspassed (see the date on decal).

NOTE

• After use, the sealing compound bot- tle, the hose, and certain other systemcomponents must be replaced. Pleaseconsult your Volvo retailer for replace-ment parts.

• If the sealing compound bottle’s expi-ration date has passed, please take itto a Volvo retailer or a recycling stationthat can properly dispose of harmfulsubstances.

Page 327 of 386

09 Maintenance and specifications

Hood and engine compartment09

325

Opening and closing the hood

Turn the handle located under the left side of the dash approximately 20-25degrees clockwise to release the hoodlock.

Lift the hood slightly. Press the release control (located under the right front edgeof the hood) to the left, and lift the hood.

WARNING

Check that the hood locks properly when closed.

Engine compartment, overview

Coolant expansion tank

Power steering fluid reservoir

Dipstick-engine oil

Filler cap-engine oil

Cover over brake fluid reservoir

Battery

Relay/fuse box

Washer fluid reservoirThe appearance of the engine compartment may vary depending on engine model.

WARNING

The cooling fan (located at the front of the engine compartment, behind the radiator)may start or continue to operate (for up to6 minutes) after the engine has beenswitched off.

WARNING

Before performing any operations in the engine compartment, the ignition shouldalways be completely switched off (inmode

0, see page 87) and there should be

no remote keys in the passenger compart-ment. The gear selector should be in the P

(park) position. If the engine has been run-ning, wait until it has cooled before touch-ing any components in the engine com-partment. The distributor ignition system operates at very high voltages. Special safety precau-tions must be followed to prevent injury.Always turn the ignition off when:

• Replacing distributor ignition compo- nents e.g. plugs, coil, etc.

• Do not touch any part of the distributorignition system while the engine is run-ning. This may result in unintendedmovements and body injury.

Page 331 of 386

09 Maintenance and specifications

Fluids09

329

The brake fluid should always be between the MIN

and MAX marks on the inside of the res-

ervoir. Check, without removing the cap, thatthere is sufficient fluid in the reservoir. Fluid type : DOT 4 boiling point >536 °F

(>280 °C).Replace : The fluid should be replaced

according to the intervals specified in the Warranty and Service Records Informationbooklet. When driving under extremely hard condi- tions (mountain driving, etc), it may be neces-sary to replace the fluid more often. Consult atrained and qualified Volvo service technician. Always entrust brake fluid changing to a trained and qualified Volvo service technician.

WARNING

• If the fluid level is below the

MIN mark

in the reservoir or if a brake-related message is shown in the informationdisplay: DO NOT DRIVE . Have the car

towed to a trained and qualified Volvoservice technician and have the brakesystem inspected.

• Dot 4 should never be mixed with anyother type of brake fluid.

Filling1. Turn and open the cover.

2. Unscrew the reservoir cap and fill the

fluid. The level must be between the MIN

and MAX marks.

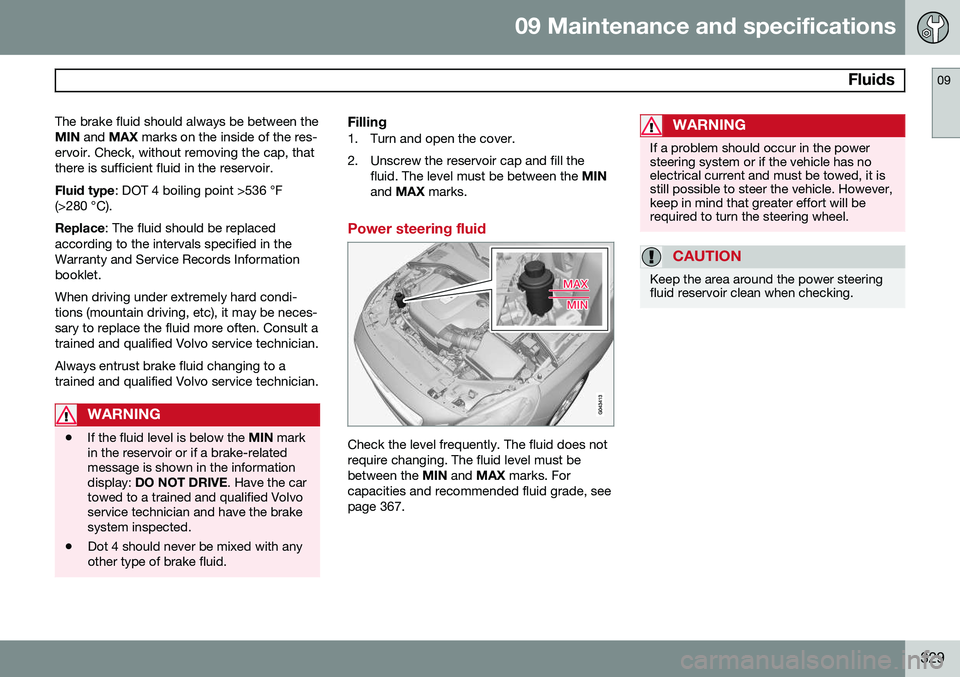

Power steering fluid

Check the level frequently. The fluid does not require changing. The fluid level must bebetween the MIN and MAX marks. For

capacities and recommended fluid grade, seepage 367.

WARNING

If a problem should occur in the power steering system or if the vehicle has noelectrical current and must be towed, it isstill possible to steer the vehicle. However,keep in mind that greater effort will berequired to turn the steering wheel.

CAUTION

Keep the area around the power steering fluid reservoir clean when checking.

Page 339 of 386

09 Maintenance and specifications

Wiper blades and washer fluid09

337

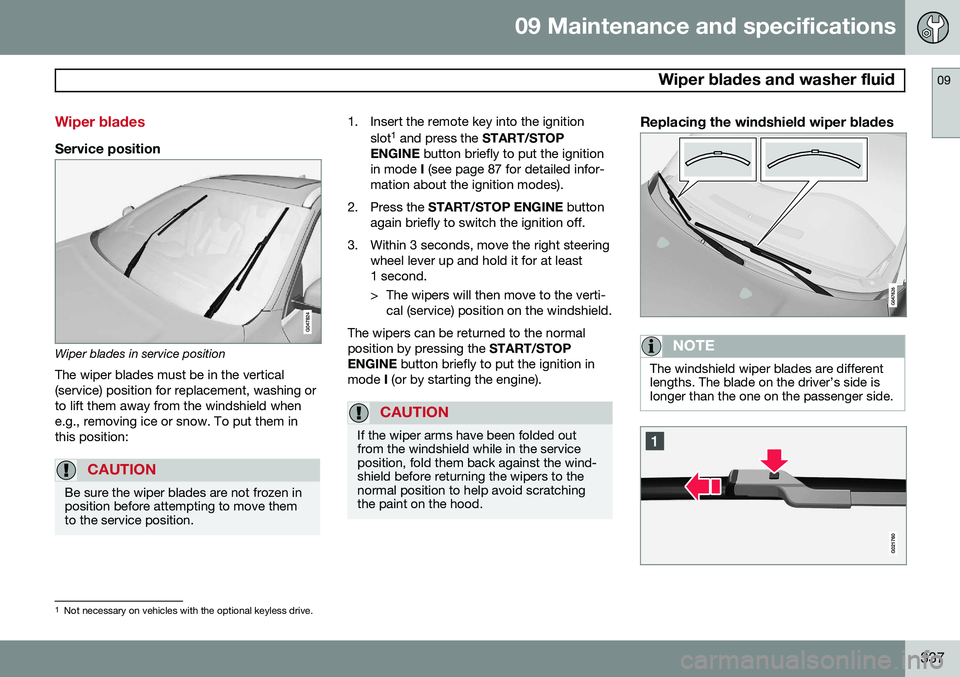

Wiper blades

Service position

Wiper blades in service positionThe wiper blades must be in the vertical (service) position for replacement, washing orto lift them away from the windshield whene.g., removing ice or snow. To put them inthis position:

CAUTION

Be sure the wiper blades are not frozen in position before attempting to move themto the service position.

1. Insert the remote key into the ignition slot1

and press the START/STOP

ENGINE button briefly to put the ignition

in mode I (see page 87 for detailed infor-

mation about the ignition modes).

2. Press the START/STOP ENGINE button

again briefly to switch the ignition off.

3. Within 3 seconds, move the right steering wheel lever up and hold it for at least 1 second.

> The wipers will then move to the verti-cal (service) position on the windshield.

The wipers can be returned to the normal position by pressing the START/STOP

ENGINE button briefly to put the ignition in

mode I (or by starting the engine).

CAUTION

If the wiper arms have been folded out from the windshield while in the serviceposition, fold them back against the wind-shield before returning the wipers to thenormal position to help avoid scratchingthe paint on the hood.

Replacing the windshield wiper blades

NOTE

The windshield wiper blades are different lengths. The blade on the driver’s side islonger than the one on the passenger side.

1

Not necessary on vehicles with the optional keyless drive.

Page 347 of 386

09 Maintenance and specifications

Fuses09

* Option/accessory, for more information, see Introduction.345

Engine compartment, upper

Engine compartment, front

Engine compartment, lower

PositionsThese fuses are all located in the engine com- partment box. Fuses in

are located under

.

A decal on the inside of the cover shows the positions of the fuses.

NOTE

• Fuses 16 – 33 and 35 – 41 may be changed at any time when necessary.

• Fuses 1 – 15, 34 and 42 – 44 arerelays/circuit breakers and should onlybe removed or replaced by a trainedand qualified Volvo service technician.

• There is a special fuse removal tool onthe underside of the cover.

PosFunctionA

Circuit breaker50

Circuit breaker50

Circuit breaker60

PosFunctionA

Circuit breaker60

Circuit breaker60

–

–

Headed windshield*, driver's side40

Windshield wipers30

–

Climate system blower40

Headed windshield*, passenger's side40

ABS pump40

ABS valves20

Headlight washers20

Active Bending Lights- headlight leveling*10

Central electrical mod- ule20

PosFunctionA

ABS5

Speed-dependent steering force*5

Engine Control Module (ECM), transmission,SRS10

Heated washer noz- zles*10

Vacuum pump (5-cyl- inder engine)5

Lighting panel5

-

-

-

Relay - engine com- partment box5

Auxiliary lights*20

Horn15

Engine Control Module (ECM)10

Page 348 of 386

09 Maintenance and specifications

Fuses 09

346

PosFunctionA

Control module - auto- matic transmission15

A/C compressor15

Relay-coils5

Starter motor relay30

Ignition coils20

Engine Control Module10

Injection system, mass air meter, engine con-trol module15

A/C compressor, engine valves, enginecontrol module (6-cyl.),solenoids (6-cyl. non-turbo only), mass airmeter (5-cyl. only)10

EVAP valve, heated oxygen sensor15

Vacuum pump/crank- case ventilation heater(5-cylinder engine)10

PosFunctionA

Fuel leakage detection5

–

Cooling fan60 (5-cyl. engine) 80 (6-cyl. engine)

Electro-hydraulic power steering100