towing VOLVO S90 2017 Owner´s Manual

[x] Cancel search | Manufacturer: VOLVO, Model Year: 2017, Model line: S90, Model: VOLVO S90 2017Pages: 548, PDF Size: 11.42 MB

Page 454 of 548

||

WHEELS AND TIRES

* Option/accessory.

452

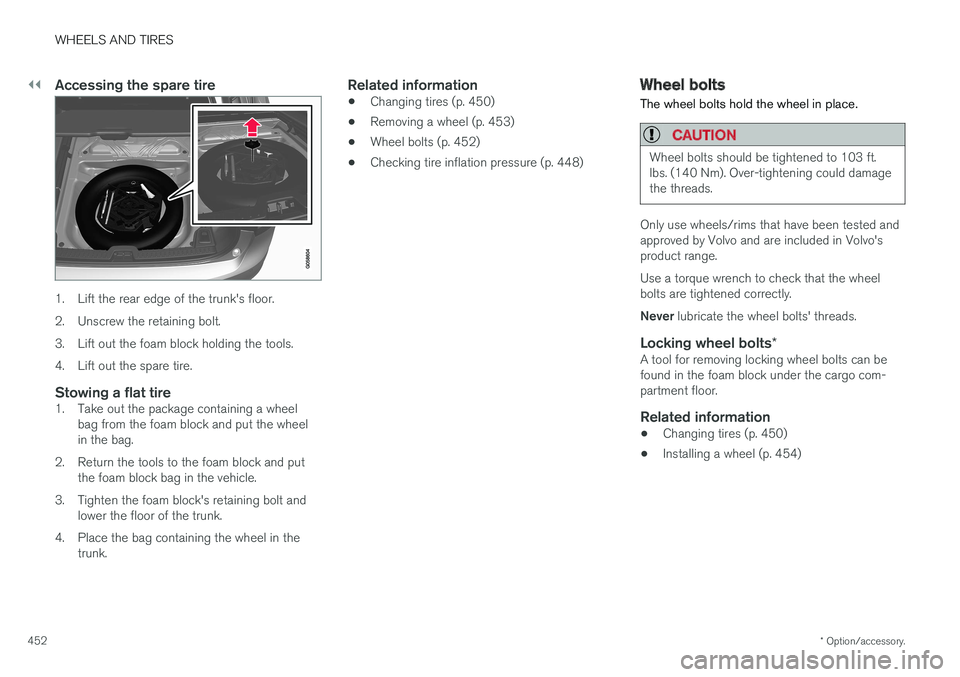

Accessing the spare tire

1. Lift the rear edge of the trunk's floor.

2. Unscrew the retaining bolt.

3. Lift out the foam block holding the tools.

4. Lift out the spare tire.

Stowing a flat tire1. Take out the package containing a wheel

bag from the foam block and put the wheel in the bag.

2. Return the tools to the foam block and put the foam block bag in the vehicle.

3. Tighten the foam block's retaining bolt and lower the floor of the trunk.

4. Place the bag containing the wheel in the trunk.

Related information

• Changing tires (p. 450)

• Removing a wheel (p. 453)

• Wheel bolts (p. 452)

• Checking tire inflation pressure (p. 448)

Wheel bolts

The wheel bolts hold the wheel in place.

CAUTION

Wheel bolts should be tightened to 103 ft. lbs. (140 Nm). Over-tightening could damagethe threads.

Only use wheels/rims that have been tested and approved by Volvo and are included in Volvo'sproduct range. Use a torque wrench to check that the wheel bolts are tightened correctly. Never lubricate the wheel bolts' threads.

Locking wheel bolts *A tool for removing locking wheel bolts can be found in the foam block under the cargo com-partment floor.

Related information

•Changing tires (p. 450)

• Installing a wheel (p. 454)

Page 456 of 548

||

WHEELS AND TIRES

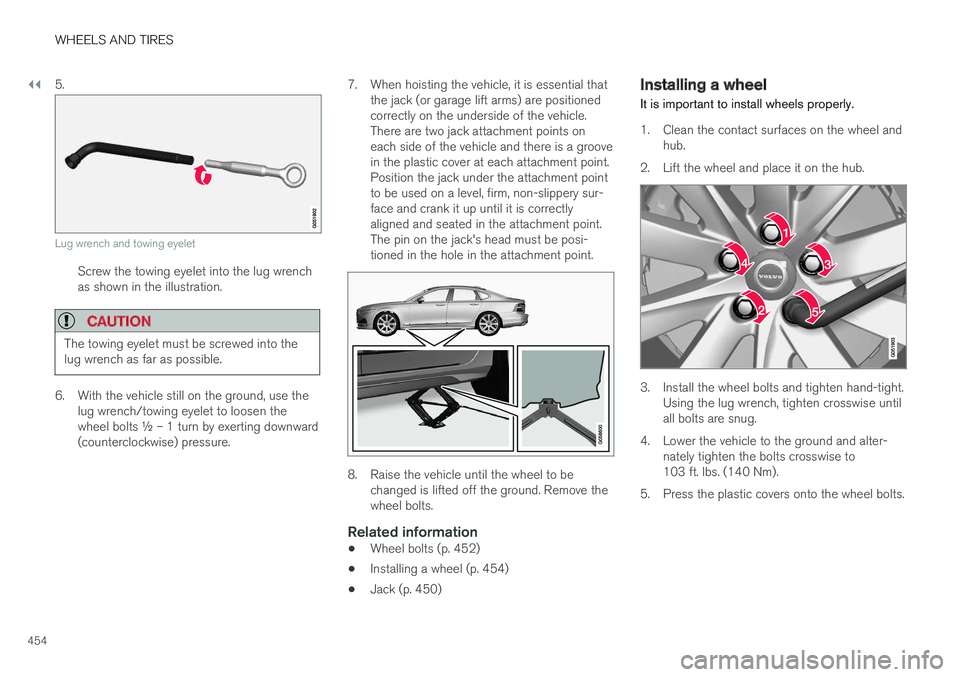

4545.

Lug wrench and towing eyelet

Screw the towing eyelet into the lug wrench as shown in the illustration.

CAUTION

The towing eyelet must be screwed into the lug wrench as far as possible.

6. With the vehicle still on the ground, use the

lug wrench/towing eyelet to loosen the wheel bolts ½ – 1 turn by exerting downward(counterclockwise) pressure. 7. When hoisting the vehicle, it is essential that

the jack (or garage lift arms) are positionedcorrectly on the underside of the vehicle.There are two jack attachment points oneach side of the vehicle and there is a groovein the plastic cover at each attachment point.Position the jack under the attachment pointto be used on a level, firm, non-slippery sur-face and crank it up until it is correctlyaligned and seated in the attachment point.The pin on the jack's head must be posi-tioned in the hole in the attachment point.

8. Raise the vehicle until the wheel to bechanged is lifted off the ground. Remove the wheel bolts.

Related information

• Wheel bolts (p. 452)

• Installing a wheel (p. 454)

• Jack (p. 450)

Installing a wheel

It is important to install wheels properly.

1. Clean the contact surfaces on the wheel and hub.

2. Lift the wheel and place it on the hub.

3. Install the wheel bolts and tighten hand-tight. Using the lug wrench, tighten crosswise until all bolts are snug.

4. Lower the vehicle to the ground and alter- nately tighten the bolts crosswise to103 ft. lbs. (140 Nm).

5. Press the plastic covers onto the wheel bolts.

Page 528 of 548

||

SPECIFICATIONS

526

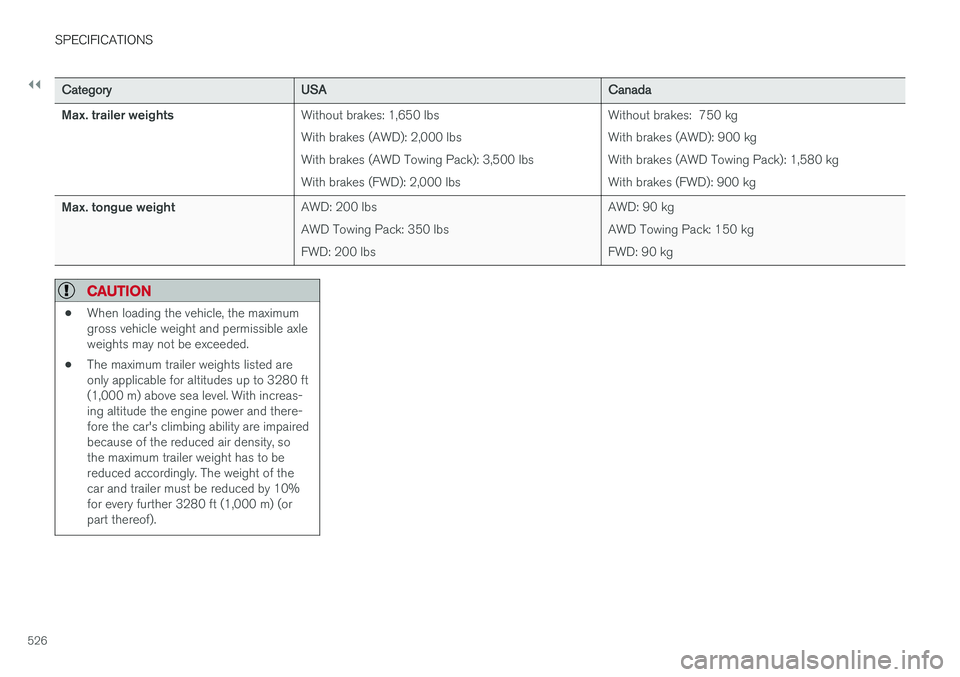

CategoryUSA Canada

Max. trailer weights Without brakes: 1,650 lbs With brakes (AWD): 2,000 lbsWith brakes (AWD Towing Pack): 3,500 lbsWith brakes (FWD): 2,000 lbs Without brakes: 750 kgWith brakes (AWD): 900 kgWith brakes (AWD Towing Pack): 1,580 kgWith brakes (FWD): 900 kg

Max. tongue weight AWD: 200 lbsAWD Towing Pack: 350 lbsFWD: 200 lbs AWD: 90 kgAWD Towing Pack: 150 kgFWD: 90 kg

CAUTION

•

When loading the vehicle, the maximum gross vehicle weight and permissible axleweights may not be exceeded.

• The maximum trailer weights listed areonly applicable for altitudes up to 3280 ft(1,000 m) above sea level. With increas-ing altitude the engine power and there-fore the car's climbing ability are impairedbecause of the reduced air density, sothe maximum trailer weight has to bereduced accordingly. The weight of thecar and trailer must be reduced by 10%for every further 3280 ft (1,000 m) (orpart thereof).

Page 540 of 548

INDEX

538Engine

overheating 356

Start/Stop 379, 381

starting 372

turning off 374

Engine compartment fuses 482

Engine compartment overview 504

Engine oil 531 checking 505, 506

Engine specifications 529

Environment 15Eyelet towing 357

Eyelets for anchoring loads 207

F

Federal Clean Air Act 468 Flat tires repairing with tire sealing system 459, 461 , 465

Floor mats placing correctly 372

Fluid specifications 527, 528, 533

Fog lights front 144

rear 145, 498

Front airbags 65 disconnecting passenger

Page 545 of 548

INDEX

543

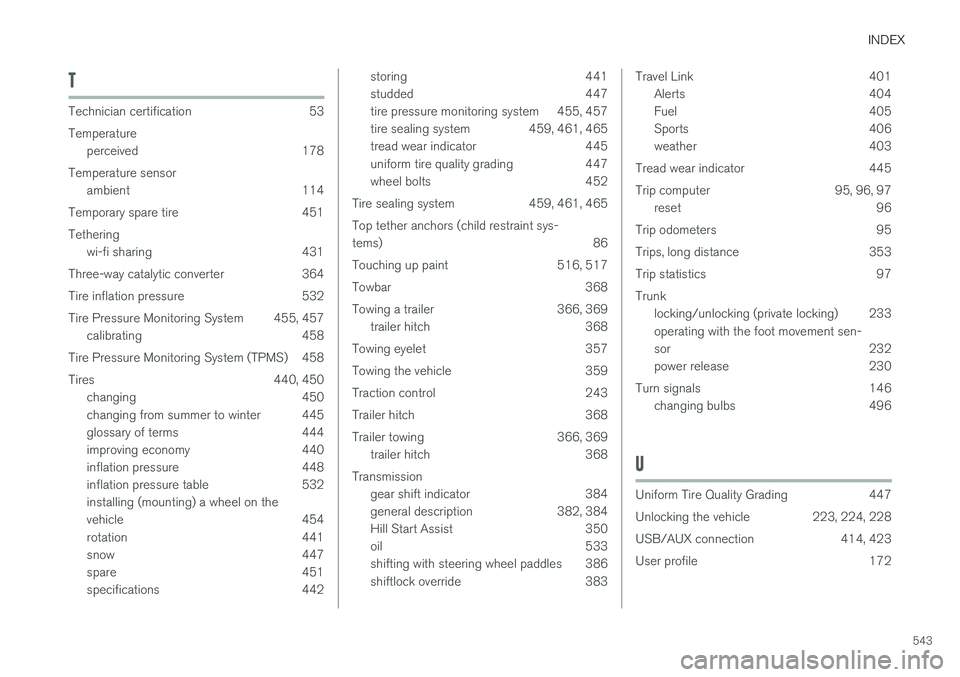

T

Technician certification 53 Temperatureperceived 178

Temperature sensor ambient 114

Temporary spare tire 451Tethering wi-fi sharing 431

Three-way catalytic converter 364

Tire inflation pressure 532

Tire Pressure Monitoring System 455, 457 calibrating 458

Tire Pressure Monitoring System (TPMS) 458

Tires 440, 450 changing 450

changing from summer to winter 445

glossary of terms 444

improving economy 440

inflation pressure 448

inflation pressure table 532installing (mounting) a wheel on the

vehicle 454

rotation 441

snow 447

spare 451

specifications 442

storing 441

studded 447

tire pressure monitoring system 455, 457

tire sealing system 459, 461, 465

tread wear indicator 445

uniform tire quality grading 447

wheel bolts 452

Tire sealing system 459, 461, 465 Top tether anchors (child restraint sys- tems) 86

Touching up paint 516, 517

Towbar 368

Towing a trailer 366, 369 trailer hitch 368

Towing eyelet 357

Towing the vehicle 359

Traction control 243

Trailer hitch 368

Trailer towing 366, 369 trailer hitch 368

Transmission gear shift indicator 384

general description 382, 384

Hill Start Assist 350

oil 533

shifting with steering wheel paddles 386

shiftlock override 383Travel Link 401Alerts 404

Fuel 405

Sports 406

weather 403

Tread wear indicator 445

Trip computer 95, 96, 97 reset 96

Trip odometers 95

Trips, long distance 353

Trip statistics 97Trunk locking/unlocking (private locking) 233 operating with the foot movement sen-

sor 232

power release 230

Turn signals 146 changing bulbs 496

U

Uniform Tire Quality Grading 447

Unlocking the vehicle 223, 224, 228

USB/AUX connection 414, 423

User profile 172