ECU VOLVO XC60 2015 Owner´s Manual

[x] Cancel search | Manufacturer: VOLVO, Model Year: 2015, Model line: XC60, Model: VOLVO XC60 2015Pages: 406, PDF Size: 11.03 MB

Page 296 of 406

07 During your trip

Loading

07

294

Roof loads

Using load carriersLoad carriers are available as Volvo accesso- ries. Observe the following points when inuse:

• To avoid damaging your vehicle and to achieve maximum safety when driving,we recommend using the load carriersthat Volvo has developed especially foryour vehicle.

• Volvo-approved removable roof racks aredesigned to carry the maximum allowableroof load for this vehicle: 220 lbs (100 kg).For non-Volvo roof racks, check the man-ufacturer's weight limits for the rack.

• Never exceed the rack manufacturer'sweigh limits and never exceed the maxi-mum rated roof load of 220 lbs (100 kg).

• Avoid single-point loads. Distribute loadsevenly.

• Place heavier cargo at the bottom of theload.

• Secure the cargo correctly with appropri-ate tie-down equipment.

• Check periodically that the load carriersand load are properly secured.

• Remember that the vehicle's center ofgravity and handling change when youcarry a load on the roof. •

The vehicle's wind resistance and fuelconsumption will increase with the size ofthe load.

• Drive smoothly. Avoid rapid starts, fastcornering and hard braking.

Page 297 of 406

07 During your trip

Cargo area

07

}}

* Option/accessory, for more information, see Introduction.295

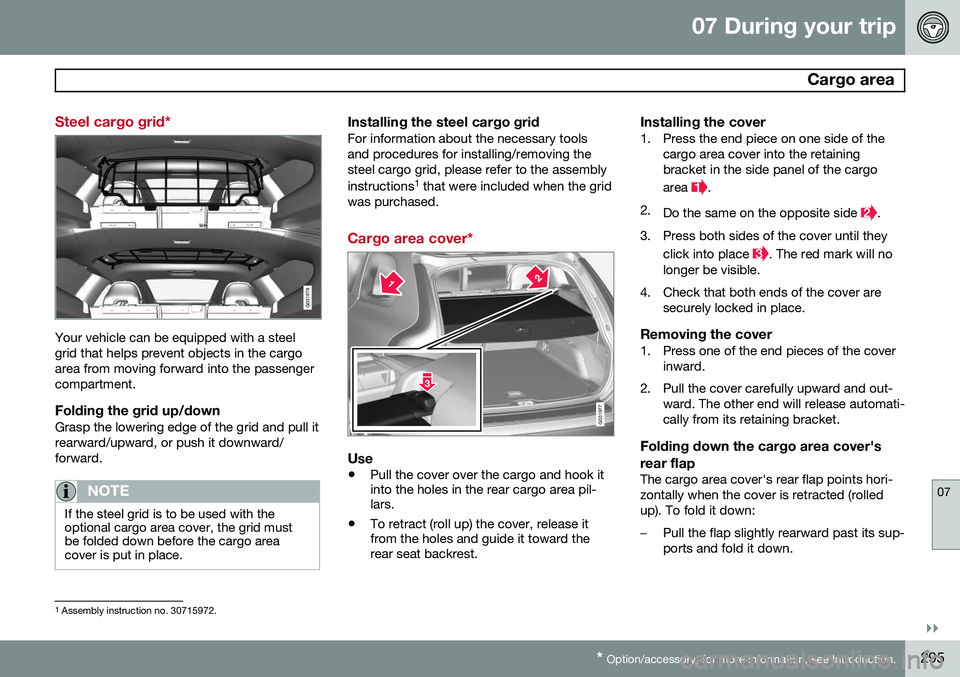

Steel cargo grid*

G031978

Your vehicle can be equipped with a steel grid that helps prevent objects in the cargoarea from moving forward into the passengercompartment.

Folding the grid up/downGrasp the lowering edge of the grid and pull itrearward/upward, or push it downward/forward.

NOTE

If the steel grid is to be used with the optional cargo area cover, the grid mustbe folded down before the cargo areacover is put in place.

Installing the steel cargo gridFor information about the necessary tools and procedures for installing/removing thesteel cargo grid, please refer to the assembly instructions 1

that were included when the grid

was purchased.

Cargo area cover*

G031977

Use

• Pull the cover over the cargo and hook it into the holes in the rear cargo area pil-lars.

• To retract (roll up) the cover, release itfrom the holes and guide it toward therear seat backrest.

Installing the cover1. Press the end piece on one side of the

cargo area cover into the retaining bracket in the side panel of the cargo area

.

2. Do the same on the opposite side

.

3. Press both sides of the cover until they click into place

. The red mark will no

longer be visible.

4. Check that both ends of the cover are securely locked in place.

Removing the cover1. Press one of the end pieces of the coverinward.

2. Pull the cover carefully upward and out- ward. The other end will release automati- cally from its retaining bracket.

Folding down the cargo area cover's rear flap

The cargo area cover's rear flap points hori- zontally when the cover is retracted (rolledup). To fold it down:

–Pull the flap slightly rearward past its sup- ports and fold it down.

1Assembly instruction no. 30715972.

Page 298 of 406

07 During your trip

Cargo area

07

296* Option/accessory, for more information, see Introduction.

NOTE

On models equipped with this cover, it should be removed before a child seat isattached to the child restraint anchors.

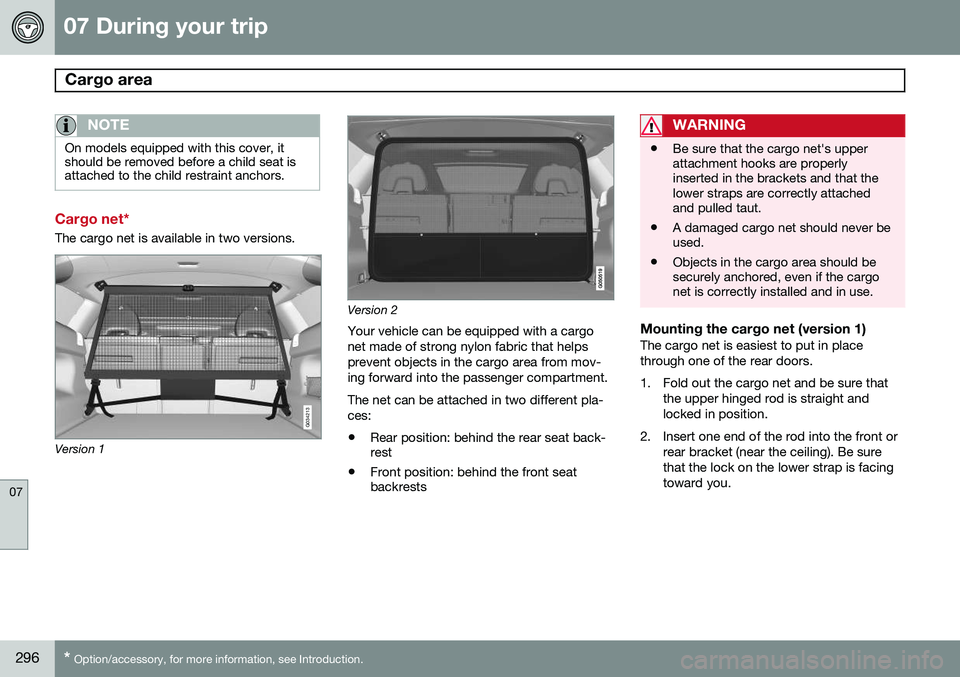

Cargo net*

The cargo net is available in two versions.

G034213

Version 1

Version 2

Your vehicle can be equipped with a cargo net made of strong nylon fabric that helpsprevent objects in the cargo area from mov-ing forward into the passenger compartment. The net can be attached in two different pla- ces:

• Rear position: behind the rear seat back- rest

• Front position: behind the front seatbackrests

WARNING

• Be sure that the cargo net's upper attachment hooks are properlyinserted in the brackets and that thelower straps are correctly attachedand pulled taut.

• A damaged cargo net should never beused.

• Objects in the cargo area should besecurely anchored, even if the cargonet is correctly installed and in use.

Mounting the cargo net (version 1)The cargo net is easiest to put in place through one of the rear doors.

1. Fold out the cargo net and be sure that

the upper hinged rod is straight and locked in position.

2. Insert one end of the rod into the front or rear bracket (near the ceiling). Be surethat the lock on the lower strap is facingtoward you.

Page 304 of 406

07 During your trip

Emergency towing

07

302

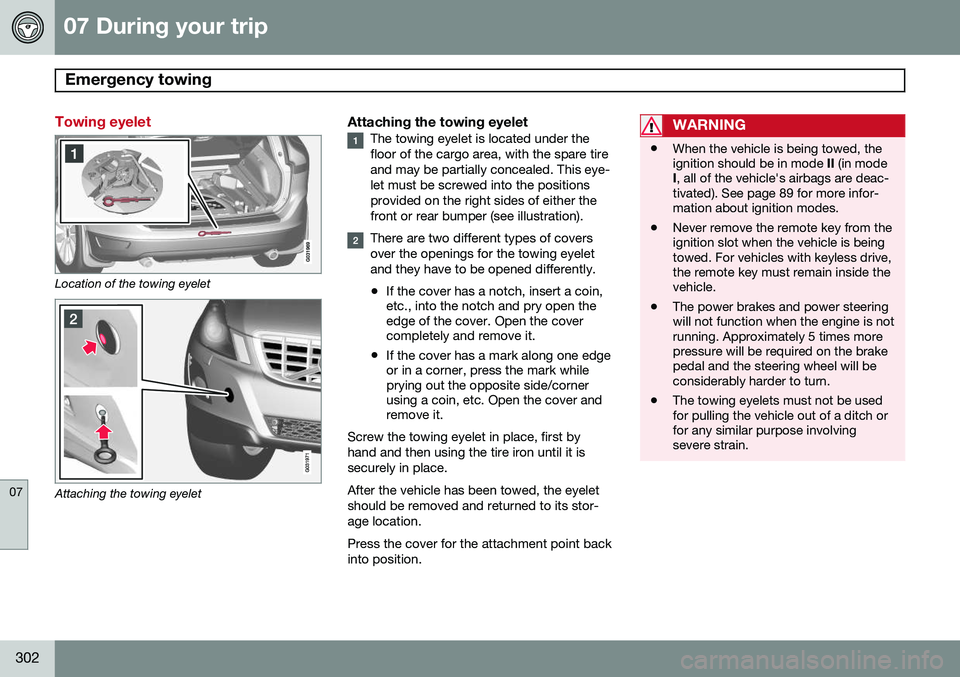

Towing eyelet

Location of the towing eyelet

Attaching the towing eyelet

Attaching the towing eyeletThe towing eyelet is located under the floor of the cargo area, with the spare tireand may be partially concealed. This eye-let must be screwed into the positionsprovided on the right sides of either thefront or rear bumper (see illustration).

There are two different types of covers over the openings for the towing eyeletand they have to be opened differently.

• If the cover has a notch, insert a coin, etc., into the notch and pry open theedge of the cover. Open the covercompletely and remove it.

• If the cover has a mark along one edgeor in a corner, press the mark whileprying out the opposite side/cornerusing a coin, etc. Open the cover andremove it.

Screw the towing eyelet in place, first by hand and then using the tire iron until it issecurely in place. After the vehicle has been towed, the eyelet should be removed and returned to its stor-age location. Press the cover for the attachment point back into position.

WARNING

• When the vehicle is being towed, the ignition should be in mode

II (in mode

I , all of the vehicle's airbags are deac-

tivated). See page 89 for more infor-mation about ignition modes.

• Never remove the remote key from theignition slot when the vehicle is beingtowed. For vehicles with keyless drive,the remote key must remain inside thevehicle.

• The power brakes and power steeringwill not function when the engine is notrunning. Approximately 5 times morepressure will be required on the brakepedal and the steering wheel will beconsiderably harder to turn.

• The towing eyelets must not be usedfor pulling the vehicle out of a ditch orfor any similar purpose involvingsevere strain.

Page 325 of 406

08 Wheels and tires

Tire Sealing System*

08

}}

* Option/accessory, for more information, see Introduction.323

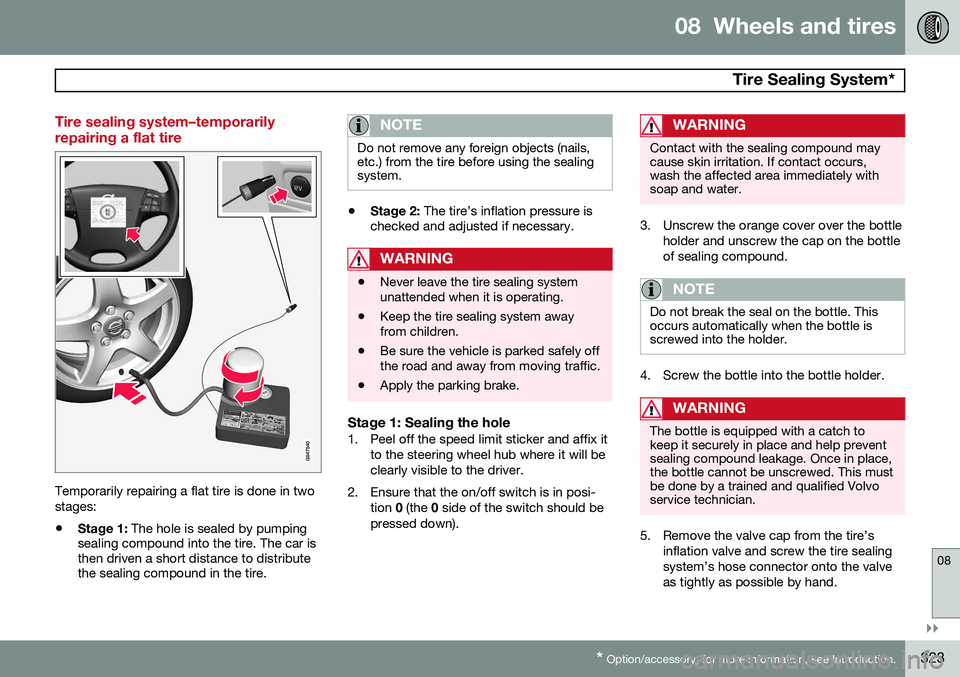

Tire sealing system–temporarily repairing a flat tire

Temporarily repairing a flat tire is done in two stages:

• Stage 1:

The hole is sealed by pumping

sealing compound into the tire. The car is then driven a short distance to distributethe sealing compound in the tire.

NOTE

Do not remove any foreign objects (nails, etc.) from the tire before using the sealingsystem.

• Stage 2:

The tire’s inflation pressure is

checked and adjusted if necessary.

WARNING

• Never leave the tire sealing system unattended when it is operating.

• Keep the tire sealing system awayfrom children.

• Be sure the vehicle is parked safely offthe road and away from moving traffic.

• Apply the parking brake.

Stage 1: Sealing the hole1. Peel off the speed limit sticker and affix it

to the steering wheel hub where it will be clearly visible to the driver.

2. Ensure that the on/off switch is in posi- tion 0 (the 0 side of the switch should be

pressed down).

WARNING

Contact with the sealing compound may cause skin irritation. If contact occurs,wash the affected area immediately withsoap and water.

3. Unscrew the orange cover over the bottle holder and unscrew the cap on the bottle of sealing compound.

NOTE

Do not break the seal on the bottle. This occurs automatically when the bottle isscrewed into the holder.

4. Screw the bottle into the bottle holder.

WARNING

The bottle is equipped with a catch to keep it securely in place and help preventsealing compound leakage. Once in place,the bottle cannot be unscrewed. This mustbe done by a trained and qualified Volvoservice technician.

5. Remove the valve cap from the tire’sinflation valve and screw the tire sealing system’s hose connector onto the valveas tightly as possible by hand.

Page 328 of 406

08 Wheels and tires

Tire Sealing System*

08

326* Option/accessory, for more information, see Introduction.

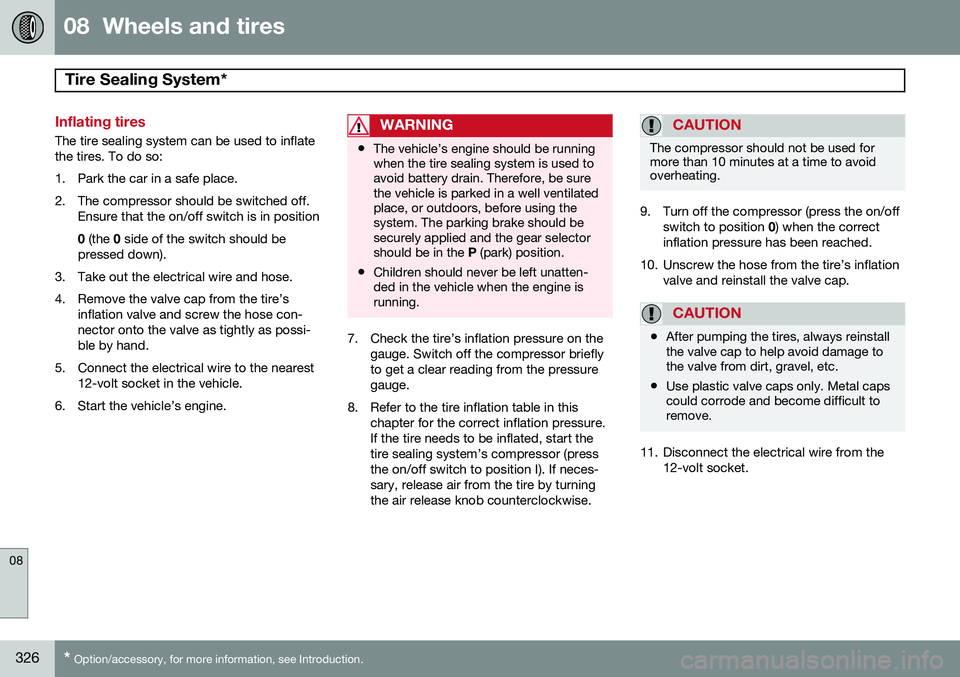

Inflating tires

The tire sealing system can be used to inflate the tires. To do so:

1. Park the car in a safe place.

2. The compressor should be switched off.

Ensure that the on/off switch is in position0 (the 0 side of the switch should be

pressed down).

3. Take out the electrical wire and hose.

4. Remove the valve cap from the tire’s inflation valve and screw the hose con- nector onto the valve as tightly as possi-ble by hand.

5. Connect the electrical wire to the nearest 12-volt socket in the vehicle.

6. Start the vehicle’s engine.WARNING

• The vehicle’s engine should be running when the tire sealing system is used toavoid battery drain. Therefore, be surethe vehicle is parked in a well ventilatedplace, or outdoors, before using thesystem. The parking brake should besecurely applied and the gear selectorshould be in the

P (park) position.

• Children should never be left unatten-ded in the vehicle when the engine isrunning.

7. Check the tire’s inflation pressure on the

gauge. Switch off the compressor briefly to get a clear reading from the pressuregauge.

8. Refer to the tire inflation table in this chapter for the correct inflation pressure.If the tire needs to be inflated, start thetire sealing system’s compressor (pressthe on/off switch to position I). If neces-sary, release air from the tire by turningthe air release knob counterclockwise.

CAUTION

The compressor should not be used for more than 10 minutes at a time to avoidoverheating.

9. Turn off the compressor (press the on/off switch to position 0) when the correct

inflation pressure has been reached.

10. Unscrew the hose from the tire’s inflation valve and reinstall the valve cap.

CAUTION

•After pumping the tires, always reinstall the valve cap to help avoid damage tothe valve from dirt, gravel, etc.

• Use plastic valve caps only. Metal capscould corrode and become difficult toremove.

11. Disconnect the electrical wire from the

12-volt socket.

Page 329 of 406

08 Wheels and tires

Changing a wheel

08

}}

* Option/accessory, for more information, see Introduction.327

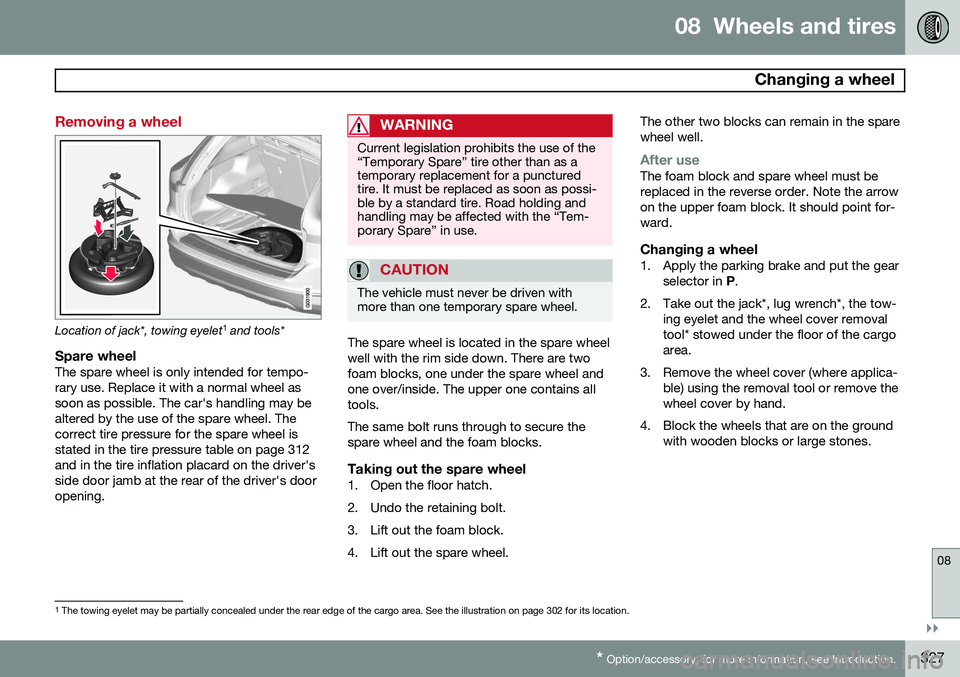

Removing a wheel

Location of jack*, towing eyelet 1

and tools*

Spare wheelThe spare wheel is only intended for tempo- rary use. Replace it with a normal wheel assoon as possible. The car's handling may bealtered by the use of the spare wheel. Thecorrect tire pressure for the spare wheel isstated in the tire pressure table on page 312and in the tire inflation placard on the driver'sside door jamb at the rear of the driver's dooropening.

WARNING

Current legislation prohibits the use of the “Temporary Spare” tire other than as atemporary replacement for a puncturedtire. It must be replaced as soon as possi-ble by a standard tire. Road holding andhandling may be affected with the “Tem-porary Spare” in use.

CAUTION

The vehicle must never be driven with more than one temporary spare wheel.

The spare wheel is located in the spare wheel well with the rim side down. There are twofoam blocks, one under the spare wheel andone over/inside. The upper one contains alltools. The same bolt runs through to secure the spare wheel and the foam blocks.

Taking out the spare wheel1. Open the floor hatch.

2. Undo the retaining bolt.

3. Lift out the foam block.

4. Lift out the spare wheel. The other two blocks can remain in the spare wheel well.

After useThe foam block and spare wheel must be replaced in the reverse order. Note the arrowon the upper foam block. It should point for-ward.

Changing a wheel1. Apply the parking brake and put the gear

selector in P.

2. Take out the jack*, lug wrench*, the tow- ing eyelet and the wheel cover removaltool* stowed under the floor of the cargoarea.

3. Remove the wheel cover (where applica- ble) using the removal tool or remove thewheel cover by hand.

4. Block the wheels that are on the ground with wooden blocks or large stones.

1The towing eyelet may be partially concealed under the rear edge of the cargo area. See the illustration on page 302 for its location.

Page 351 of 406

09 Maintenance and specifications

Replacing bulbs09

}}

349

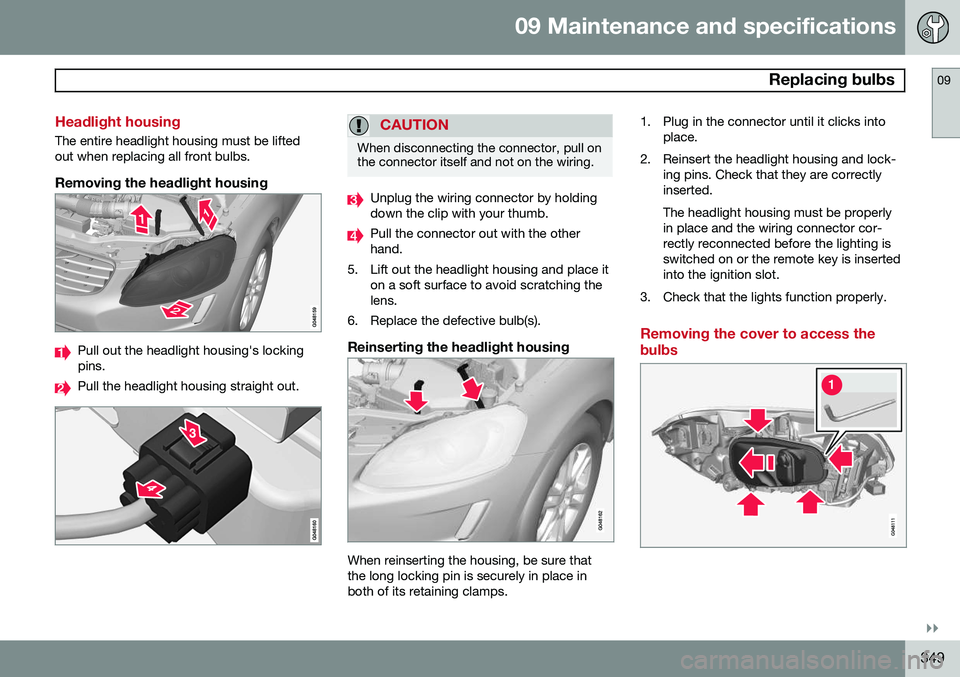

Headlight housing

The entire headlight housing must be lifted out when replacing all front bulbs.

Removing the headlight housing

Pull out the headlight housing's locking pins.

Pull the headlight housing straight out.

CAUTION

When disconnecting the connector, pull on the connector itself and not on the wiring.

Unplug the wiring connector by holding down the clip with your thumb.

Pull the connector out with the other hand.

5. Lift out the headlight housing and place it on a soft surface to avoid scratching thelens.

6. Replace the defective bulb(s).

Reinserting the headlight housing

When reinserting the housing, be sure that the long locking pin is securely in place inboth of its retaining clamps. 1. Plug in the connector until it clicks into

place.

2. Reinsert the headlight housing and lock- ing pins. Check that they are correctlyinserted. The headlight housing must be properly in place and the wiring connector cor-rectly reconnected before the lighting isswitched on or the remote key is insertedinto the ignition slot.

3. Check that the lights function properly.

Removing the cover to access the bulbs

Page 352 of 406

09 Maintenance and specifications

Replacing bulbs 09

350

NOTE

Before starting to replace a bulb, see page 348.

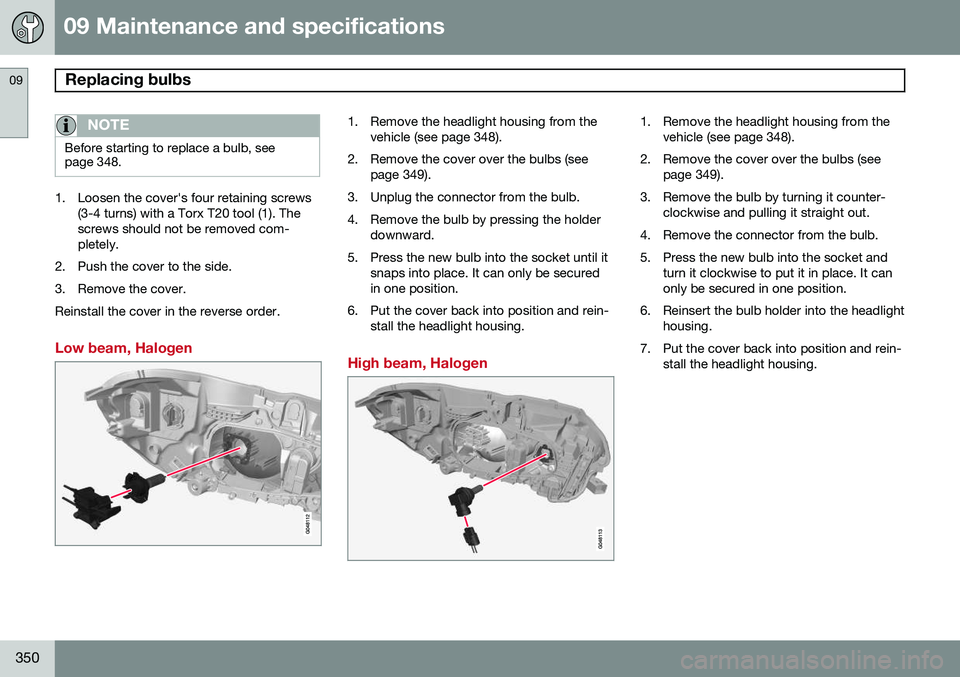

1. Loosen the cover's four retaining screws(3-4 turns) with a Torx T20 tool (1). The screws should not be removed com-pletely.

2. Push the cover to the side.

3. Remove the cover.Reinstall the cover in the reverse order.

Low beam, Halogen

1. Remove the headlight housing from the vehicle (see page 348).

2. Remove the cover over the bulbs (see page 349).

3. Unplug the connector from the bulb.

4. Remove the bulb by pressing the holder downward.

5. Press the new bulb into the socket until it snaps into place. It can only be secured in one position.

6. Put the cover back into position and rein- stall the headlight housing.

High beam, Halogen

1. Remove the headlight housing from the vehicle (see page 348).

2. Remove the cover over the bulbs (see page 349).

3. Remove the bulb by turning it counter- clockwise and pulling it straight out.

4. Remove the connector from the bulb.

5. Press the new bulb into the socket and turn it clockwise to put it in place. It can only be secured in one position.

6. Reinsert the bulb holder into the headlight housing.

7. Put the cover back into position and rein- stall the headlight housing.

Page 358 of 406

09 Maintenance and specifications

Wiper blades and washer fluid 09

356

With the wipers in the service position, fold out the wiper arm from the wind-shield. Press the button on the wiperblade attachment and pull the wiperblade straight out, parallel with the wiperarm.

Slide in the new wiper blade until it clicks into place.

Check that the blade is securely in place.4. Press the wipers back against the wind-

shield.

To return the wipers from the service position to the normal position, fold the wipers backagainst the windshield and press the START/

STOP ENGINE button briefly to put the igni-

tion in mode I (or start the engine).

CleaningKeeping the windshield and wiper bladesclean helps improve visibility and prolongsthe service life of the wiper blades. Clean thewiper blades with a stiff-bristle brush andlukewarm soap solution or car washing deter-gent.

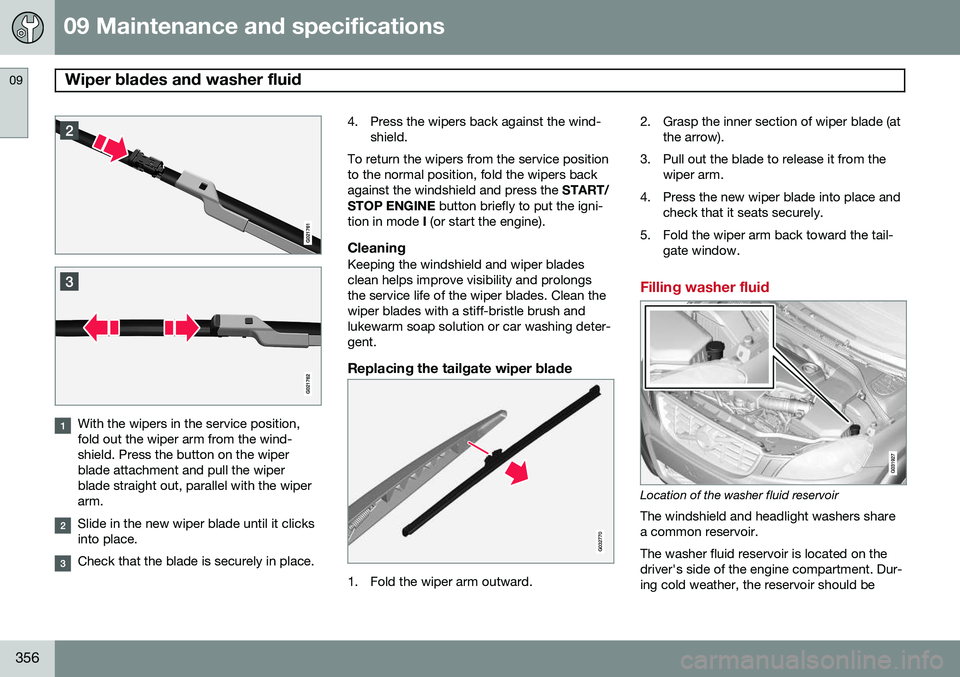

Replacing the tailgate wiper blade

G032770

1. Fold the wiper arm outward. 2. Grasp the inner section of wiper blade (at

the arrow).

3. Pull out the blade to release it from the wiper arm.

4. Press the new wiper blade into place and check that it seats securely.

5. Fold the wiper arm back toward the tail- gate window.

Filling washer fluid

Location of the washer fluid reservoir

The windshield and headlight washers share a common reservoir. The washer fluid reservoir is located on the driver's side of the engine compartment. Dur-ing cold weather, the reservoir should be