ECU VOLVO XC90 2013 Owner´s Manual

[x] Cancel search | Manufacturer: VOLVO, Model Year: 2013, Model line: XC90, Model: VOLVO XC90 2013Pages: 310, PDF Size: 8.62 MB

Page 193 of 310

07 Wheels and tires

Tire Sealing System

07

191

WARNING

•Never leave the tire sealing system

unattended when it is operating.

•Keep the tire sealing system away from

children.

•Be sure the vehicle is parked safely off

the road and away from moving traffic.

•Apply the parking brake.

Stage 1: Sealing the hole1. Open the cover on the tire sealing kit.

2. Peel off the speed limit sticker and affix it

to the steering wheel hub where it will be

clearly visible to the driver.

3. Ensure that the on/off switch is in position

0 (the 0 side of the switch should be

pressed down).

4. Put on the gloves included in the tire seal-

ing system.

WARNING

Contact with the sealing compound may

cause skin irritation. If contact occurs, wash

the affected area immediately with soap and

water.

5. Unscrew the orange cover over the bottle

holder and unscrew the cap on the bottle

of sealing compound.

NOTE

Do not break the seal on the bottle. This

occurs automatically when the bottle is

screwed into the holder.

6. Screw the bottle into the bottle holder.

WARNING

The bottle is equipped with a catch to keep

it securely in place and help prevent sealing

compound leakage. Once in place, the bot-

tle cannot be unscrewed. This must be done

by a trained and qualified Volvo service

technician.

7. Remove the valve cap from the tire’s infla-

tion valve and screw the tire sealing sys-

tem’s hose connector onto the valve as

tightly as possible by hand.

8. Connect the electrical wire to the nearest

12-volt socket in the vehicle.

NOTE

Be sure that none of the other 12-volt sock-

ets is being used while the compressor is in

operation.

9. Start the vehicle’s engine.

10. Start the tire sealing system’s compressor

by pressing the on/off switch to position I.

WARNING

•Never stand next to the tire being inflated

when the compressor is in operation.

•If cracks, bubbles, etc. form on the tire,

switch off the compressor immediately.

•If there is visible damage to the sidewall

or the rim, the tire cannot be repaired.

The vehicle should not be driven if this

occurs. Contact a towing service or

Volvo On Call Roadside Assistance if

applicable.

Page 195 of 310

07 Wheels and tires

Tire Sealing System

07

193

Replacing the sealing compound

container

The sealing compound container must be

replaced if:

•the tire sealing system has been used to

repair a tire

•the container’s expiration date has passed

(see the date on decal).

NOTE

•After use, the sealing compound bottle,

the hose, and certain other system

components must be replaced. Please

consult your Volvo retailer for replace-

ment parts.

•If the sealing compound bottle’s expi-

ration date has passed, please take it to

a Volvo retailer or a recycling station

that can properly dispose of harmful

substances.

Inflating tires

The tire sealing system can be used to inflate

the tires. To do so:

1. Park the car in a safe place.

2. The compressor should be switched off.

Ensure that the on/off switch is in position

0 (the 0 side of the switch should be

pressed down).

3. Take out the electrical wire and hose.

4. Remove the valve cap from the tire’s infla-

tion valve and screw the hose connector

onto the valve as tightly as possible by

hand.

5. Connect the electrical wire to the nearest

12-volt socket in the vehicle.

6. Start the vehicle’s engine.WARNING

•The vehicle’s engine should be running

when the tire sealing system is used to

avoid battery drain. Therefore, be sure

the vehicle is parked in a well ventilated

place, or outdoors, before using the sys-

tem. The parking brake should be

securely applied and the gear selector

should be in the P (park) position.

•Children should never be left unattended

in the vehicle when the engine is running.

7. Check the tire’s inflation pressure on the

gauge. Switch off the compressor briefly to

get a clear reading from the pressure

gauge.

8. Refer to the tire inflation tables for the cor-

rect inflation pressure. If the tire needs to

be inflated, start the tire sealing system’s

compressor (press the on/off switch to

position I). If necessary, release air from the

tire by turning the air release knob coun-

terclockwise.

CAUTION

The compressor should not be used for

more than 10 minutes at a time to avoid

overheating.

Page 198 of 310

07 Wheels and tires

Changing wheels

07

196

WARNING

When raising or lowering the spare wheel,

please keep in mind that components in the

exhaust system may be very hot.

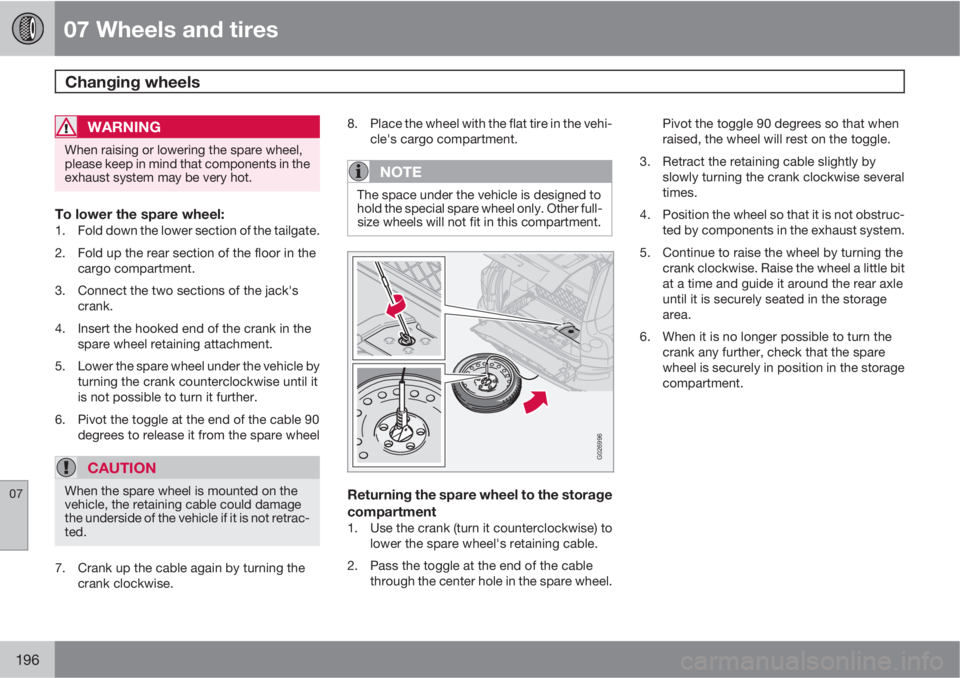

To lower the spare wheel:1. Fold down the lower section of the tailgate.

2. Fold up the rear section of the floor in the

cargo compartment.

3. Connect the two sections of the jack's

crank.

4. Insert the hooked end of the crank in the

spare wheel retaining attachment.

5. Lower the spare wheel under the vehicle by

turning the crank counterclockwise until it

is not possible to turn it further.

6. Pivot the toggle at the end of the cable 90

degrees to release it from the spare wheel

CAUTION

When the spare wheel is mounted on the

vehicle, the retaining cable could damage

the underside of the vehicle if it is not retrac-

ted.

7. Crank up the cable again by turning the

crank clockwise.8. Place the wheel with the flat tire in the vehi-

cle's cargo compartment.

NOTE

The space under the vehicle is designed to

hold the special spare wheel only. Other full-

size wheels will not fit in this compartment.

G026996

Returning the spare wheel to the storage

compartment

1. Use the crank (turn it counterclockwise) to

lower the spare wheel's retaining cable.

2. Pass the toggle at the end of the cable

through the center hole in the spare wheel.Pivot the toggle 90 degrees so that when

raised, the wheel will rest on the toggle.

3. Retract the retaining cable slightly by

slowly turning the crank clockwise several

times.

4. Position the wheel so that it is not obstruc-

ted by components in the exhaust system.

5. Continue to raise the wheel by turning the

crank clockwise. Raise the wheel a little bit

at a time and guide it around the rear axle

until it is securely seated in the storage

area.

6. When it is no longer possible to turn the

crank any further, check that the spare

wheel is securely in position in the storage

compartment.

Page 209 of 310

08 Car care

Washing and cleaning the vehicle

08

207

CAUTION

•Avoid waxing or polishing plastic or rub-

ber components

•Polishing chromed strips can wear

away or damage the surface

•Polishes containing abrasive sub-

stances should not be used

NOTE

When washing the vehicle, remember to

remove dirt from the drain holes in the doors

and sills.

WARNING

•When the vehicle is driven immediately

after being washed, apply the brakes

several times in order to remove any

moisture from the brake linings.

•Engine cleaning agents should not be

used when the engine is warm. This

constitutes a fire risk.

Automatic washing – simple and quick

•We do NOT recommend washing your

vehicle in an automatic wash during thefirst few months (because the paint will not

have hardened sufficiently).

•An automatic wash is a simple and quick

way to clean your vehicle, but it is worth

remembering that it may not be as thor-

ough as when you yourself go over the

vehicle with sponge and water. Keeping

the underbody clean is most important,

especially in the winter. Some automatic

washers do not have facilities for washing

the underbody.

•Before driving into an automatic car wash,

make sure that side view mirrors, auxiliary

lamps, etc, are secure, and that any

antenna(s) are retracted or removed. Oth-

erwise there is risk of the machine dislodg-

ing them.

Exterior lightingCondensation may form temporarily on the

inside of the lenses of exterior lights such as

headlights, fog lights, or tail lights. This is nor-

mal and the lights are designed to withstand

moisture. Normally, condensation will dissi-

pate after the lights have been on for a short

time.

Polishing and waxing

•Normally, polishing is not required during

the first year after delivery, however, wax-

ing may be beneficial.

•Before applying polish or wax the vehicle

must be washed and dried. Tar spots can

be removed with kerosene or tar remover.

Difficult spots may require a fine rubbing

compound.

•After polishing use liquid or paste wax.

•Several commercially available products

contain both polish and wax.

•Waxing alone does not substitute for pol-

ishing a dull surface.

•A wide range of polymer-based car waxes

can be purchased today. These waxes are

easy to use and produce a long-lasting,

high-gloss finish that protects the body-

work against oxidation, road dirt and fad-

ing.

•Do not polish or wax your vehicle in direct

sunlight (the surface of the vehicle should

not be warmer than 113° F (45° C).

Page 226 of 310

09 Maintenance and servicing

Wiper blades 09

224

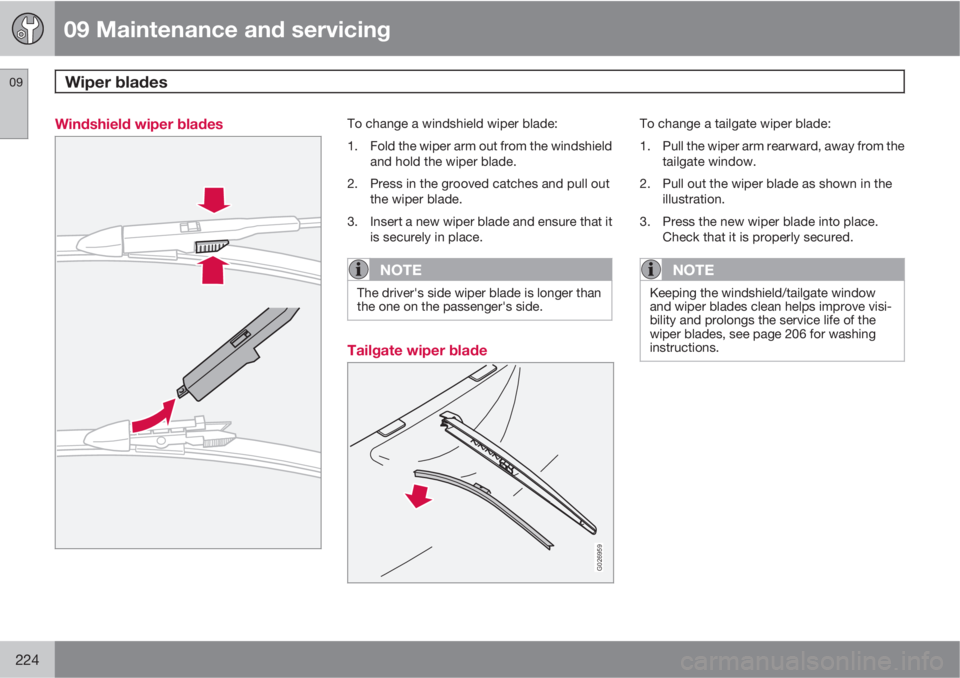

Windshield wiper bladesTo change a windshield wiper blade:

1. Fold the wiper arm out from the windshield

and hold the wiper blade.

2. Press in the grooved catches and pull out

the wiper blade.

3. Insert a new wiper blade and ensure that it

is securely in place.

NOTE

The driver's side wiper blade is longer than

the one on the passenger's side.

Tailgate wiper blade

G026959

To change a tailgate wiper blade:

1. Pull the wiper arm rearward, away from the

tailgate window.

2. Pull out the wiper blade as shown in the

illustration.

3. Press the new wiper blade into place.

Check that it is properly secured.

NOTE

Keeping the windshield/tailgate window

and wiper blades clean helps improve visi-

bility and prolongs the service life of the

wiper blades, see page 206 for washing

instructions.

Page 227 of 310

09 Maintenance and servicing

Battery09

225 Battery maintenance

The battery in your vehicle is located under the

floor of the cargo compartment.

Driving habits and conditions, climate, the

number of starts, etc. all affect the service life

and function of the battery. In order for your

battery to perform satisfactorily, keep the fol-

lowing in mind:

•Use a screw driver to open the caps or

cover and a flashlight to inspect the level.

•If necessary, add distilled water. The level

should never be above the indicator.

•The fluid level should be checked if the

battery has been recharged.

•After inspection, be sure the cap over each

battery cell or the cover is securely in

place.

•Check that the battery cables are correctly

connected and properly tightened.

•Never disconnect the battery when the

engine is running, or when the key is in the

ignition. This could damage the vehicle's

electrical system.

•The battery should be disconnected from

the vehicle when a battery charger is used

directly on the battery.

•To help keep the battery in good condition,

the vehicle should be driven for at least 15minutes a week or connected to a charger

with an automatic charging function.

•If the battery is fully discharged a number

of times, this may shorten its service life.

Keeping the battery fully charged helps

prolong its service life.

•The service life of a battery is affected by

factors such as driving conditions and cli-

mate. Extreme cold may also further

decrease the battery’s starting capacity.

•Because the battery’s starting capacity

decreases with time, it may be necessary

to recharge it if the vehicle is not driven for

an extended period of time or if the vehicle

is usually only driven short distances.

•

WARNING

PROPOSITION 65 WARNING!

Battery posts, terminals, and related acces-

sories contain lead and lead compounds,

chemicals known to the state of California

to cause cancer and reproductive harm.

Wash hands after handling.

WARNING

•Never expose the battery to open flame

or electric spark.

•Do not smoke near the battery.

•Battery fluid contains sulfuric acid. Do

not allow battery fluid to contact eyes,

skin, fabrics or painted surfaces. If con-

tact occurs, flush the affected area

immediately with water. Obtain medical

help immediately if eyes are affected.

NOTE

Used batteries should be properly disposed

of at a recycling station or similar facility, or

taken to your Volvo retailer.

Page 229 of 310

09 Maintenance and servicing

Battery09

227

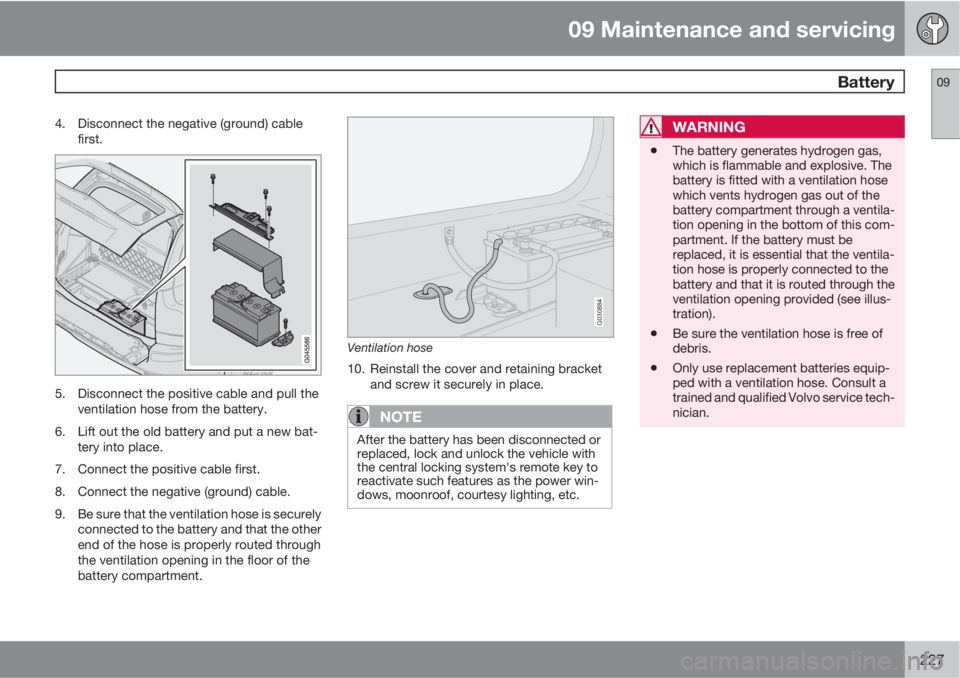

4. Disconnect the negative (ground) cable

first.

5. Disconnect the positive cable and pull the

ventilation hose from the battery.

6. Lift out the old battery and put a new bat-

tery into place.

7. Connect the positive cable first.

8. Connect the negative (ground) cable.

9. Be sure that the ventilation hose is securely

connected to the battery and that the other

end of the hose is properly routed through

the ventilation opening in the floor of the

battery compartment.

G030884

Ventilation hose

10. Reinstall the cover and retaining bracket

and screw it securely in place.

NOTE

After the battery has been disconnected or

replaced, lock and unlock the vehicle with

the central locking system's remote key to

reactivate such features as the power win-

dows, moonroof, courtesy lighting, etc.

WARNING

•The battery generates hydrogen gas,

which is flammable and explosive. The

battery is fitted with a ventilation hose

which vents hydrogen gas out of the

battery compartment through a ventila-

tion opening in the bottom of this com-

partment. If the battery must be

replaced, it is essential that the ventila-

tion hose is properly connected to the

battery and that it is routed through the

ventilation opening provided (see illus-

tration).

•Be sure the ventilation hose is free of

debris.

•Only use replacement batteries equip-

ped with a ventilation hose. Consult a

trained and qualified Volvo service tech-

nician.

Page 238 of 310

09 Maintenance and servicing

Fuses 09

236* Option/accessory, for more information, see Introduction.

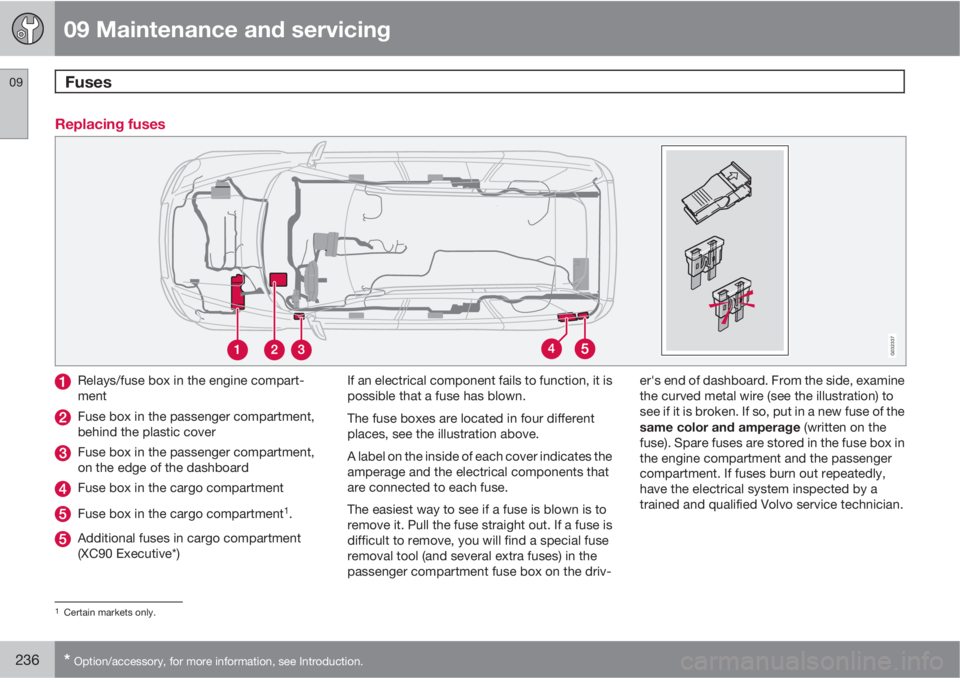

Replacing fuses

G032337

Relays/fuse box in the engine compart-

ment

Fuse box in the passenger compartment,

behind the plastic cover

Fuse box in the passenger compartment,

on the edge of the dashboard

Fuse box in the cargo compartment

Fuse box in the cargo compartment1.

Additional fuses in cargo compartment

(XC90 Executive*)If an electrical component fails to function, it is

possible that a fuse has blown.

The fuse boxes are located in four different

places, see the illustration above.

A label on the inside of each cover indicates the

amperage and the electrical components that

are connected to each fuse.

The easiest way to see if a fuse is blown is to

remove it. Pull the fuse straight out. If a fuse is

difficult to remove, you will find a special fuse

removal tool (and several extra fuses) in the

passenger compartment fuse box on the driv-er's end of dashboard. From the side, examine

the curved metal wire (see the illustration) to

see if it is broken. If so, put in a new fuse of the

same color and amperage (written on the

fuse). Spare fuses are stored in the fuse box in

the engine compartment and the passenger

compartment. If fuses burn out repeatedly,

have the electrical system inspected by a

trained and qualified Volvo service technician.

1Certain markets only.

Page 244 of 310

09 Maintenance and servicing

Fuses 09

242* Option/accessory, for more information, see Introduction.

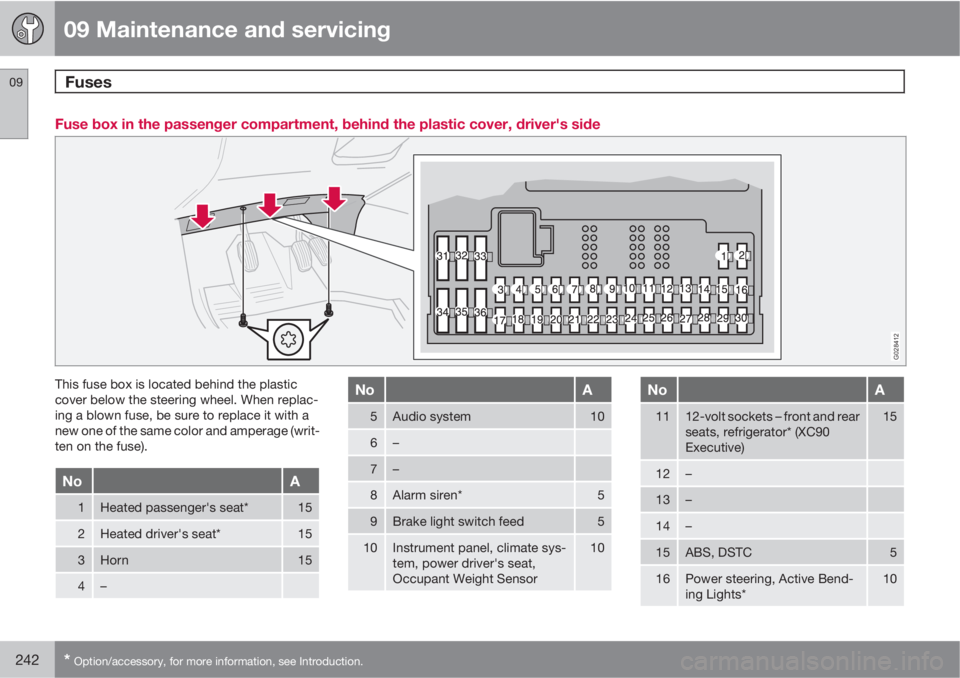

Fuse box in the passenger compartment, behind the plastic cover, driver's side

G028412

This fuse box is located behind the plastic

cover below the steering wheel. When replac-

ing a blown fuse, be sure to replace it with a

new one of the same color and amperage (writ-

ten on the fuse).

NoA

1Heated passenger's seat*15

2Heated driver's seat*15

3Horn15

4–

NoA

5Audio system10

6–

7–

8Alarm siren*5

9Brake light switch feed5

10Instrument panel, climate sys-

tem, power driver's seat,

Occupant Weight Sensor10

NoA

1112-volt sockets – front and rear

seats, refrigerator* (XC90

Executive)15

12–

13–

14–

15ABS, DSTC5

16Power steering, Active Bend-

ing Lights*10

Page 248 of 310

09 Maintenance and servicing

Fuses 09

246* Option/accessory, for more information, see Introduction.

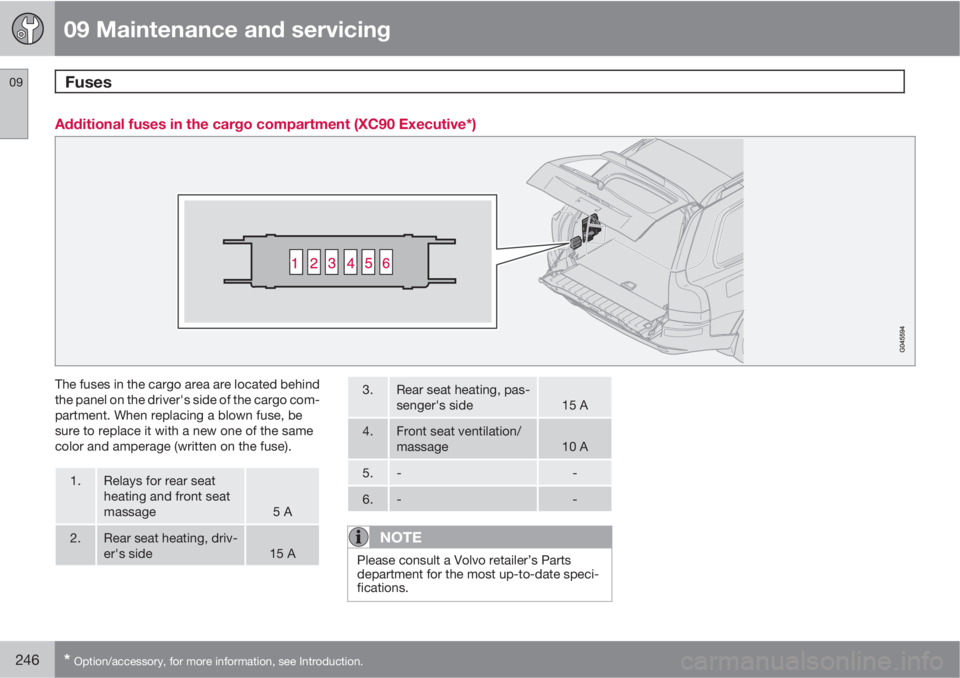

Additional fuses in the cargo compartment (XC90 Executive*)

The fuses in the cargo area are located behind

the panel on the driver's side of the cargo com-

partment. When replacing a blown fuse, be

sure to replace it with a new one of the same

color and amperage (written on the fuse).

1.Relays for rear seat

heating and front seat

massage

5 A

2.Rear seat heating, driv-

er's side15 A

3.Rear seat heating, pas-

senger's side15 A

4.Front seat ventilation/

massage10 A

5.--

6.--

NOTE

Please consult a Volvo retailer’s Parts

department for the most up-to-date speci-

fications.