brake VOLVO XC90 2013 Owner´s Manual

[x] Cancel search | Manufacturer: VOLVO, Model Year: 2013, Model line: XC90, Model: VOLVO XC90 2013Pages: 310, PDF Size: 8.62 MB

Page 171 of 310

06 Starting and driving

Before a long distance trip

06

169

It is always worthwhile to have your vehicle

checked by a trained and qualified Volvo serv-

ice technician before driving long distances.

Your retailer or service technician will also be

able to supply you with bulbs, fuses, spark

plugs and wiper blades for your use in the event

that problems occur.

As a minimum, the following items should be

checked before any long trip:

•Check that engine runs smoothly and that

fuel consumption is normal.

•Check for fuel, oil, and fluid leakage.

•Check transmission oil level1.

•Check condition of drive belts.

•Check state of the battery's charge.

•Examine tires carefully (the spare tire as

well), and replace those that are worn.

Check tire pressures.

•The brakes, front wheel alignment, and

steering gear should be checked by a

trained and qualified Volvo service techni-

cian only.

•Check all lights, including high beams.

•Reflective warning triangles are legally

required in some states/provinces.

•Have a word with your Volvo retailer if you

intend to drive in countries where it may be

difficult to obtain the correct fuel.

•Consider your destination. If you will be

driving through an area where snow or ice

are likely to occur, consider snow tires.

1To prevent injury from contact with hot surfaces, do not inspect your vehicle’s transmission fluid yourself. Have your vehicle’s transmission fluid level inspected by a qualified Volvo service technician.

Page 189 of 310

07 Wheels and tires

Snow chains, snow tires, studded tires

07

187 Snow chains

Snow chains can be used on your Volvo with

the following restrictions:

•Snow chains should be installed on front

wheels only. Use only Volvo approved

snow chains.

•If accessory, aftermarket or "custom" tires

and wheels are installed and are of a size

different than the original tires and wheels,

chains in some cases CANNOT be used.

Sufficient clearances between chains and

brakes, suspension and body components

must be maintained.

•Some strap-on type chains will interfere

with brake components and therefore

CANNOT be used.

•All Wheel Drive models: Snow chains

should only be installed on the front

wheels.

•Certain size tires may not allow the assem-

bly of snow chains/traction devices.

Consult your Volvo retailer for additional snow

chain information.

CAUTION

•Check local regulations regarding the

use of snow chains before installing.

•Always follow the chain manufacturer's

installation instructions carefully. Install

chains as tightly as possible and

retighten periodically.

•Never exceed the chain manufacturer's

specified maximum speed limit. (Under

no circumstances should you exceed

31 mph (50 km/h)).

•Avoid bumps, holes or sharp turns

when driving with snow chains.

•The handling of the vehicle can be

adversely affected when driving with

chains. Avoid fast or sharp turns as well

as locked wheel braking.

Snow tires, studded tires1

Tires for winter use:

•Owners who live in or regularly commute

through areas with sustained periods of

snow or icy driving conditions are strongly

advised to fit suitable winter tires to help

retain the highest degree of traction.

•It is important to install winter tires on all

four wheels to help retain traction duringcornering, braking, and accelerating. Fail-

ure to do so could reduce traction to an

unsafe level or adversely affect handling.

•Do not mix tires of different design as this

could also negatively affect overall tire road

grip.

•Winter tires wear more quickly on dry roads

in warm weather. They should be removed

when the winter driving season has ended.

•Studded tires should be run-in

300-600 miles (500-1000 km) during which

the vehicle should be driven as smoothly

as possible to give the studs the opportu-

nity to seat properly in the tires. The tires

should have the same rotational direction

throughout their entire lifetime.

NOTE

Please consult state or provincial regula-

tions restricting the use of studded winter

tires before installing such tires.

1Where permitted

Page 193 of 310

07 Wheels and tires

Tire Sealing System

07

191

WARNING

•Never leave the tire sealing system

unattended when it is operating.

•Keep the tire sealing system away from

children.

•Be sure the vehicle is parked safely off

the road and away from moving traffic.

•Apply the parking brake.

Stage 1: Sealing the hole1. Open the cover on the tire sealing kit.

2. Peel off the speed limit sticker and affix it

to the steering wheel hub where it will be

clearly visible to the driver.

3. Ensure that the on/off switch is in position

0 (the 0 side of the switch should be

pressed down).

4. Put on the gloves included in the tire seal-

ing system.

WARNING

Contact with the sealing compound may

cause skin irritation. If contact occurs, wash

the affected area immediately with soap and

water.

5. Unscrew the orange cover over the bottle

holder and unscrew the cap on the bottle

of sealing compound.

NOTE

Do not break the seal on the bottle. This

occurs automatically when the bottle is

screwed into the holder.

6. Screw the bottle into the bottle holder.

WARNING

The bottle is equipped with a catch to keep

it securely in place and help prevent sealing

compound leakage. Once in place, the bot-

tle cannot be unscrewed. This must be done

by a trained and qualified Volvo service

technician.

7. Remove the valve cap from the tire’s infla-

tion valve and screw the tire sealing sys-

tem’s hose connector onto the valve as

tightly as possible by hand.

8. Connect the electrical wire to the nearest

12-volt socket in the vehicle.

NOTE

Be sure that none of the other 12-volt sock-

ets is being used while the compressor is in

operation.

9. Start the vehicle’s engine.

10. Start the tire sealing system’s compressor

by pressing the on/off switch to position I.

WARNING

•Never stand next to the tire being inflated

when the compressor is in operation.

•If cracks, bubbles, etc. form on the tire,

switch off the compressor immediately.

•If there is visible damage to the sidewall

or the rim, the tire cannot be repaired.

The vehicle should not be driven if this

occurs. Contact a towing service or

Volvo On Call Roadside Assistance if

applicable.

Page 195 of 310

07 Wheels and tires

Tire Sealing System

07

193

Replacing the sealing compound

container

The sealing compound container must be

replaced if:

•the tire sealing system has been used to

repair a tire

•the container’s expiration date has passed

(see the date on decal).

NOTE

•After use, the sealing compound bottle,

the hose, and certain other system

components must be replaced. Please

consult your Volvo retailer for replace-

ment parts.

•If the sealing compound bottle’s expi-

ration date has passed, please take it to

a Volvo retailer or a recycling station

that can properly dispose of harmful

substances.

Inflating tires

The tire sealing system can be used to inflate

the tires. To do so:

1. Park the car in a safe place.

2. The compressor should be switched off.

Ensure that the on/off switch is in position

0 (the 0 side of the switch should be

pressed down).

3. Take out the electrical wire and hose.

4. Remove the valve cap from the tire’s infla-

tion valve and screw the hose connector

onto the valve as tightly as possible by

hand.

5. Connect the electrical wire to the nearest

12-volt socket in the vehicle.

6. Start the vehicle’s engine.WARNING

•The vehicle’s engine should be running

when the tire sealing system is used to

avoid battery drain. Therefore, be sure

the vehicle is parked in a well ventilated

place, or outdoors, before using the sys-

tem. The parking brake should be

securely applied and the gear selector

should be in the P (park) position.

•Children should never be left unattended

in the vehicle when the engine is running.

7. Check the tire’s inflation pressure on the

gauge. Switch off the compressor briefly to

get a clear reading from the pressure

gauge.

8. Refer to the tire inflation tables for the cor-

rect inflation pressure. If the tire needs to

be inflated, start the tire sealing system’s

compressor (press the on/off switch to

position I). If necessary, release air from the

tire by turning the air release knob coun-

terclockwise.

CAUTION

The compressor should not be used for

more than 10 minutes at a time to avoid

overheating.

Page 199 of 310

07 Wheels and tires

Changing wheels

07

197

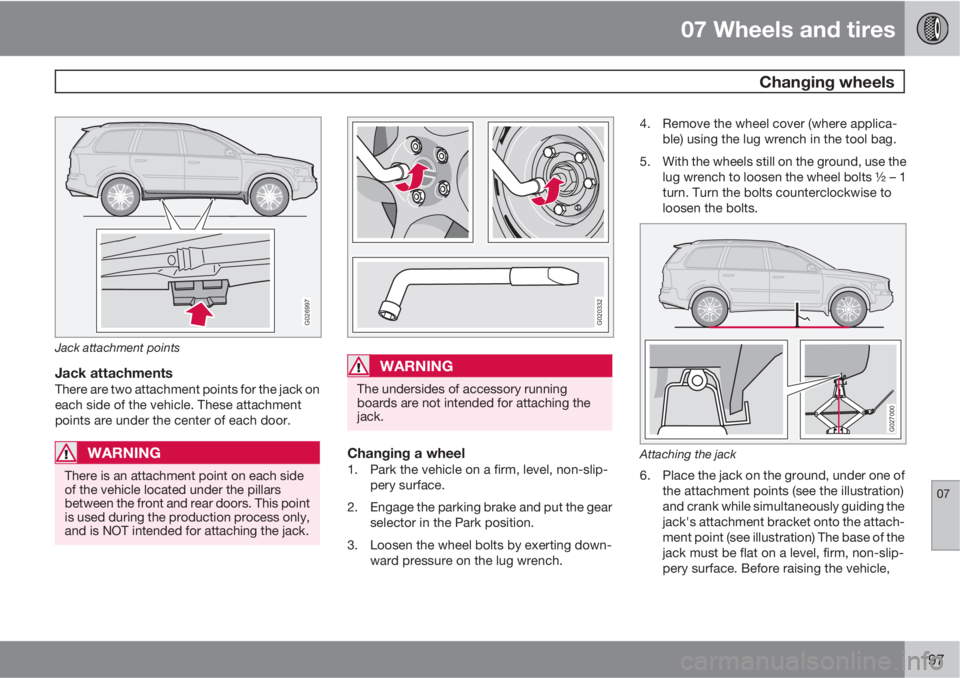

G026997

Jack attachment points

Jack attachmentsThere are two attachment points for the jack on

each side of the vehicle. These attachment

points are under the center of each door.

WARNING

There is an attachment point on each side

of the vehicle located under the pillars

between the front and rear doors. This point

is used during the production process only,

and is NOT intended for attaching the jack.

G020332

WARNING

The undersides of accessory running

boards are not intended for attaching the

jack.

Changing a wheel1. Park the vehicle on a firm, level, non-slip-

pery surface.

2. Engage the parking brake and put the gear

selector in the Park position.

3. Loosen the wheel bolts by exerting down-

ward pressure on the lug wrench.4. Remove the wheel cover (where applica-

ble) using the lug wrench in the tool bag.

5. With the wheels still on the ground, use the

lug wrench to loosen the wheel bolts ½ – 1

turn. Turn the bolts counterclockwise to

loosen the bolts.

G027000

Attaching the jack

6. Place the jack on the ground, under one of

the attachment points (see the illustration)

and crank while simultaneously guiding the

jack's attachment bracket onto the attach-

ment point (see illustration) The base of the

jack must be flat on a level, firm, non-slip-

pery surface. Before raising the vehicle,

Page 200 of 310

07 Wheels and tires

Changing wheels

07

198

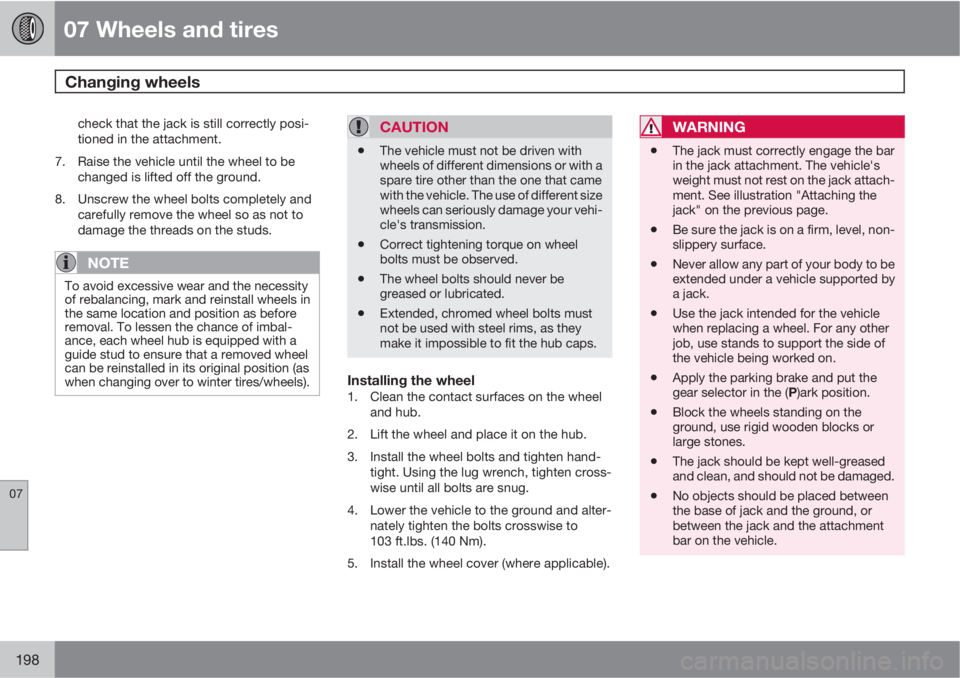

check that the jack is still correctly posi-

tioned in the attachment.

7. Raise the vehicle until the wheel to be

changed is lifted off the ground.

8. Unscrew the wheel bolts completely and

carefully remove the wheel so as not to

damage the threads on the studs.

NOTE

To avoid excessive wear and the necessity

of rebalancing, mark and reinstall wheels in

the same location and position as before

removal. To lessen the chance of imbal-

ance, each wheel hub is equipped with a

guide stud to ensure that a removed wheel

can be reinstalled in its original position (as

when changing over to winter tires/wheels).

CAUTION

•The vehicle must not be driven with

wheels of different dimensions or with a

spare tire other than the one that came

with the vehicle. The use of different size

wheels can seriously damage your vehi-

cle's transmission.

•Correct tightening torque on wheel

bolts must be observed.

•The wheel bolts should never be

greased or lubricated.

•Extended, chromed wheel bolts must

not be used with steel rims, as they

make it impossible to fit the hub caps.

Installing the wheel1. Clean the contact surfaces on the wheel

and hub.

2. Lift the wheel and place it on the hub.

3. Install the wheel bolts and tighten hand-

tight. Using the lug wrench, tighten cross-

wise until all bolts are snug.

4. Lower the vehicle to the ground and alter-

nately tighten the bolts crosswise to

103 ft.lbs. (140 Nm).

5. Install the wheel cover (where applicable).

WARNING

•The jack must correctly engage the bar

in the jack attachment. The vehicle's

weight must not rest on the jack attach-

ment. See illustration "Attaching the

jack" on the previous page.

•Be sure the jack is on a firm, level, non-

slippery surface.

•Never allow any part of your body to be

extended under a vehicle supported by

a jack.

•Use the jack intended for the vehicle

when replacing a wheel. For any other

job, use stands to support the side of

the vehicle being worked on.

•Apply the parking brake and put the

gear selector in the (P)ark position.

•Block the wheels standing on the

ground, use rigid wooden blocks or

large stones.

•The jack should be kept well-greased

and clean, and should not be damaged.

•No objects should be placed between

the base of jack and the ground, or

between the jack and the attachment

bar on the vehicle.

Page 209 of 310

08 Car care

Washing and cleaning the vehicle

08

207

CAUTION

•Avoid waxing or polishing plastic or rub-

ber components

•Polishing chromed strips can wear

away or damage the surface

•Polishes containing abrasive sub-

stances should not be used

NOTE

When washing the vehicle, remember to

remove dirt from the drain holes in the doors

and sills.

WARNING

•When the vehicle is driven immediately

after being washed, apply the brakes

several times in order to remove any

moisture from the brake linings.

•Engine cleaning agents should not be

used when the engine is warm. This

constitutes a fire risk.

Automatic washing – simple and quick

•We do NOT recommend washing your

vehicle in an automatic wash during thefirst few months (because the paint will not

have hardened sufficiently).

•An automatic wash is a simple and quick

way to clean your vehicle, but it is worth

remembering that it may not be as thor-

ough as when you yourself go over the

vehicle with sponge and water. Keeping

the underbody clean is most important,

especially in the winter. Some automatic

washers do not have facilities for washing

the underbody.

•Before driving into an automatic car wash,

make sure that side view mirrors, auxiliary

lamps, etc, are secure, and that any

antenna(s) are retracted or removed. Oth-

erwise there is risk of the machine dislodg-

ing them.

Exterior lightingCondensation may form temporarily on the

inside of the lenses of exterior lights such as

headlights, fog lights, or tail lights. This is nor-

mal and the lights are designed to withstand

moisture. Normally, condensation will dissi-

pate after the lights have been on for a short

time.

Polishing and waxing

•Normally, polishing is not required during

the first year after delivery, however, wax-

ing may be beneficial.

•Before applying polish or wax the vehicle

must be washed and dried. Tar spots can

be removed with kerosene or tar remover.

Difficult spots may require a fine rubbing

compound.

•After polishing use liquid or paste wax.

•Several commercially available products

contain both polish and wax.

•Waxing alone does not substitute for pol-

ishing a dull surface.

•A wide range of polymer-based car waxes

can be purchased today. These waxes are

easy to use and produce a long-lasting,

high-gloss finish that protects the body-

work against oxidation, road dirt and fad-

ing.

•Do not polish or wax your vehicle in direct

sunlight (the surface of the vehicle should

not be warmer than 113° F (45° C).

Page 221 of 310

09 Maintenance and servicing

Engine compartment09

219

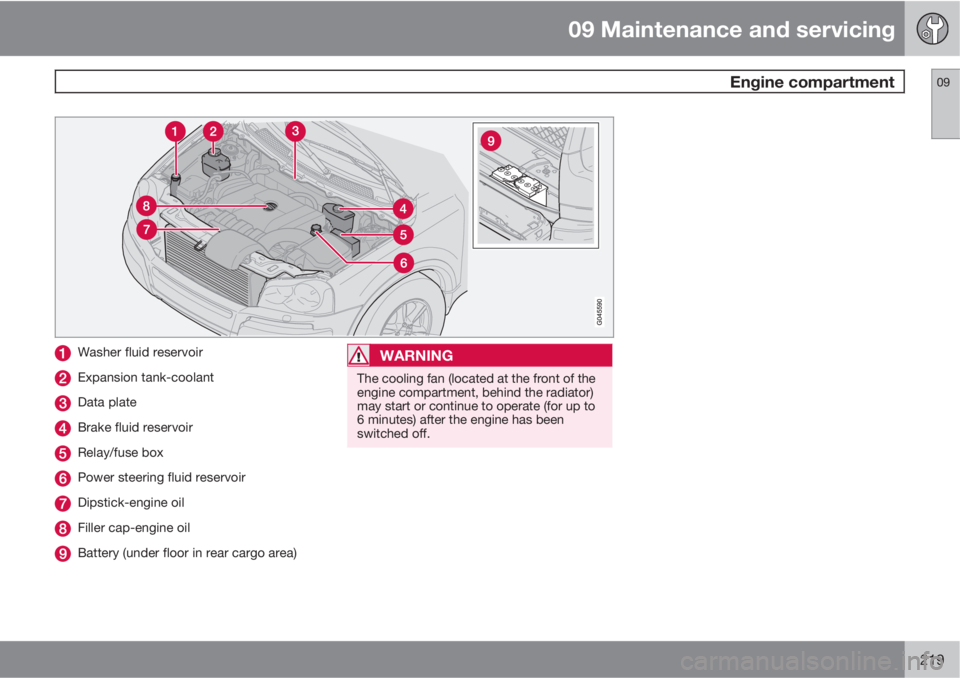

Washer fluid reservoir

Expansion tank-coolant

Data plate

Brake fluid reservoir

Relay/fuse box

Power steering fluid reservoir

Dipstick-engine oil

Filler cap-engine oil

Battery (under floor in rear cargo area)

WARNING

The cooling fan (located at the front of the

engine compartment, behind the radiator)

may start or continue to operate (for up to

6 minutes) after the engine has been

switched off.

Page 225 of 310

09 Maintenance and servicing

Fluids09

223

WARNING

•Never remove the coolant reservoir cap

while the engine is warm. Wait until the

engine cools.

•If it is necessary to top up the coolant

when the engine is warm, unscrew the

coolant reservoir cap slowly so that the

overpressure dissipates.

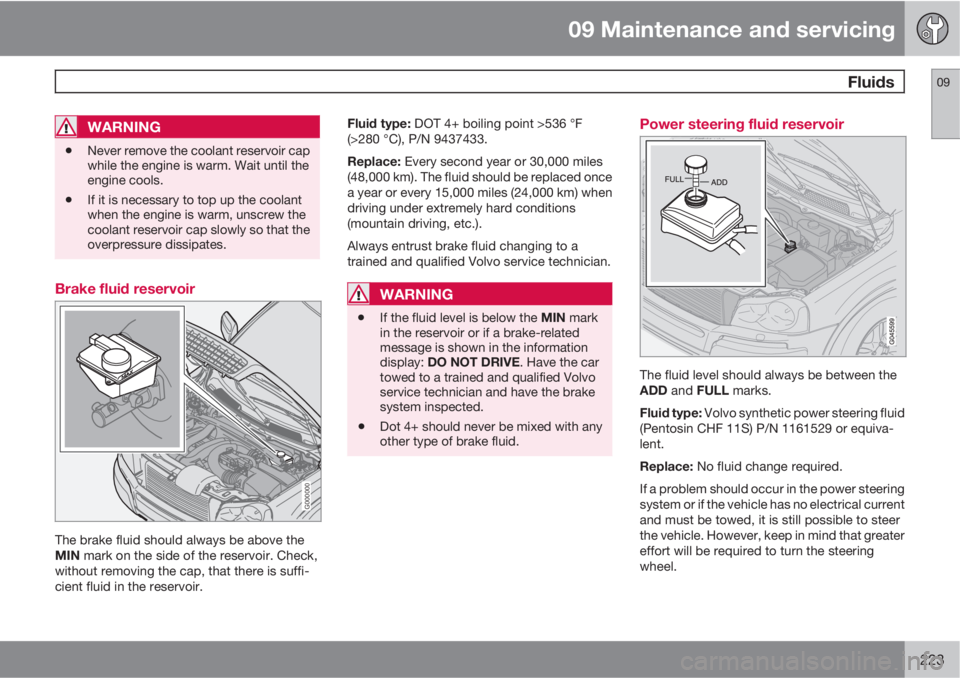

Brake fluid reservoir

G000000

The brake fluid should always be above the

MIN mark on the side of the reservoir. Check,

without removing the cap, that there is suffi-

cient fluid in the reservoir.Fluid type: DOT 4+ boiling point >536 °F

(>280 °C), P/N 9437433.

Replace: Every second year or 30,000 miles

(48,000 km). The fluid should be replaced once

a year or every 15,000 miles (24,000 km) when

driving under extremely hard conditions

(mountain driving, etc.).

Always entrust brake fluid changing to a

trained and qualified Volvo service technician.

WARNING

•If the fluid level is below the MIN mark

in the reservoir or if a brake-related

message is shown in the information

display: DO NOT DRIVE. Have the car

towed to a trained and qualified Volvo

service technician and have the brake

system inspected.

•Dot 4+ should never be mixed with any

other type of brake fluid.

Power steering fluid reservoir

The fluid level should always be between the

ADD and FULL marks.

Fluid type: Volvo synthetic power steering fluid

(Pentosin CHF 11S) P/N 1161529 or equiva-

lent.

Replace: No fluid change required.

If a problem should occur in the power steering

system or if the vehicle has no electrical current

and must be towed, it is still possible to steer

the vehicle. However, keep in mind that greater

effort will be required to turn the steering

wheel.

Page 230 of 310

09 Maintenance and servicing

Replacing bulbs 09

228* Option/accessory, for more information, see Introduction.

When replacing bulbs, keep the following

points in mind:

•Never touch the glass of bulbs with your

fingers. Grease and oils from your fingers

vaporize in the heat and will leave a deposit

on the reflector, which will damage it.

•The optional Active Bending Light bulbs

contain trace amounts of mercury. These

bulbs should always be disposed of by an

authorized Volvo retailer.

The following bulbs should only be replaced by

a trained and qualified Volvo service techni-

cian:

•Active Bending Lights (ABL)

•Daytime running lights (DRL) under the

front bumper

•Turn signals and courtesy lights in the side

door mirrors

•Reading lights and glove compartment

light

•Courtesy (dome) lighting

•Rear parking lights

•Brake lights

•High-mounted brake lights

If a problem occurs with the daytime running

lights (DRL) under the front bumper, the entire

lamp housing will have to be replaced.If a problem occurs with the rear parking lights

or the brake lights, the entire taillight housing

will have to be replaced.

See page 234 for a list of bulb specifications.

Replacing high/low beams/turn signal/

parking light bulbs

WARNING

•The engine should not be running when

changing bulbs.

•If the engine has been running just prior

to replacing bulbs in the headlight hous-

ing, please keep in mind that compo-

nents in the engine compartment will be

hot.

WARNING

Active Bending Lights* - due to the high

voltage used by these headlights, these

bulbs should only be replaced by a trained

and qualified Volvo service technician.

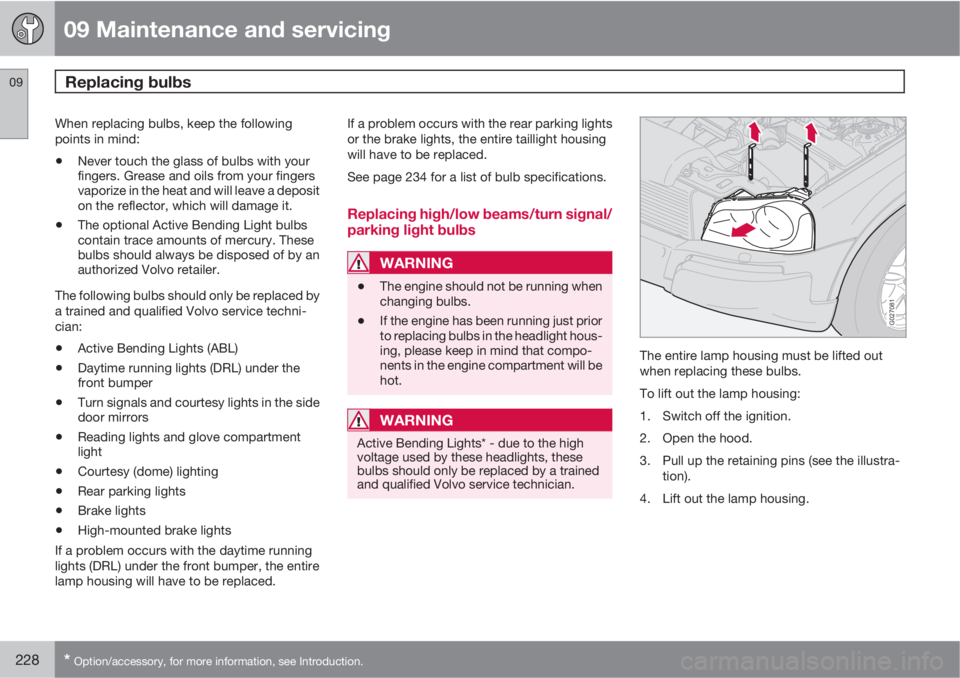

G027081

The entire lamp housing must be lifted out

when replacing these bulbs.

To lift out the lamp housing:

1. Switch off the ignition.

2. Open the hood.

3. Pull up the retaining pins (see the illustra-

tion).

4. Lift out the lamp housing.