lock VOLVO XC90 2013 Owner´s Manual

[x] Cancel search | Manufacturer: VOLVO, Model Year: 2013, Model line: XC90, Model: VOLVO XC90 2013Pages: 310, PDF Size: 8.62 MB

Page 155 of 310

06 Starting and driving

Brake system

06

* Option/accessory, for more information, see Introduction.153 BRAKE Brake circuit malfunction

The brake system is a hydraulic system con-

sisting of two master cylinders and two sepa-

rate brake circuits. If a problem should occur in

one of these circuits, it is still possible to stop

the vehicle with the other brake circuit.

If the brake pedal must be depressed farther

than normal and requires greater foot pressure,

the stopping distance will be longer.

A warning light in the instrument panel will light

up to warn the driver that a fault has occurred.

If this light comes on while driving or braking,

stop immediately and check the brake fluid

level in the reservoir.

NOTE

Press the brake pedal hard and maintain

pressure on the pedal – do not pump the

brakes.

WARNING

If the fluid level is below the MIN mark in the

reservoir or if a BRAKE FAILURE STOP

SAFELY message is displayed in the text

window: DO NOT DRIVE. Have the vehicle

towed to a trained and qualified Volvo serv-

ice technician and have the brake system

inspected.

NOTE

When the vehicle is at a standstill and the

engine is idling, e.g. at a traffic light and the

brake pedal is depressed, the pedal may go

down slightly. This is a normal function of

the power-assisted brake system.

Brake pad inspectionOn vehicles equipped with a jack*, the condi-

tion of the brake pads can be checked by rais-

ing the vehicle (see page 195 for information

about using the jack and removing a wheel)

and performing a visual inspection of the brake

pads.

WARNING

•If the vehicle has been driven immedi-

ately prior to a brake pad inspection, the

wheel hub, brake components, etc., will

be very hot. Allow time for these com-

ponents to cool before carrying out the

inspection.

•Apply the parking brake and put the

gear selector in the Park (P) position.

•Block the wheels standing on the

ground, use rigid wooden blocks or

large stones.

WARNING

•Use the jack intended for the vehicle

when changing a tire. For any other job,

use stands to support the vehicle.

•The jack should be kept well-greased

and clean, and should not be damaged.

•Be sure the jack is on a firm, level, non-

slippery surface.

•No objects should be placed between

the base of jack and the ground, or

between the jack and the attachment

bar on the vehicle.

•The jack must correctly engage the jack

attachment.

•Never allow any part of your body to be

extended under a vehicle supported by

a jack.

Power brakes function only when the

engine is running

The power brakes utilize vacuum pressure

which is only created when the engine is run-

ning. Never let the vehicle roll to a stop with the

engine switched off.

If the power brakes are not working, consider-

ably higher pressure will be required on the

brake pedal to compensate for the lack of

power assistance. This can happen for exam-

ple when towing your vehicle or if the engine is

Page 156 of 310

06 Starting and driving

Brake system

06

154

switched off when the vehicle is rolling. The

brake pedal feels harder than usual.

Water on brake discs and brake pads

affects braking

Driving in rain and slush or passing through an

automatic car wash can cause water to collect

on the brake discs and pads. This will cause a

delay in braking effect when the pedal is

depressed. To avoid such a delay when the

brakes are needed, depress the pedal occa-

sionally when driving through rain, slush etc.

This will remove the water from the brakes.

Check that brake application feels normal. This

should also be done after washing or starting

in very damp or cold weather.

Severe strain on the brake systemThe brakes will be subject to severe strain

when driving in mountains or hilly areas, or

when towing a trailer. Vehicle speed is usually

slower, which means that the cooling of the

brakes is less efficient than when driving on

level roads. To reduce the strain on the brakes,

shift into a lower gear and let the engine help

with the braking. Do not forget that, if you are

towing a trailer, the brakes will be subjected to

a greater than normal load.

Anti-lock brakes (ABS)If the ABS warning lamp lights up there is a

malfunction in the ABS system (the standardbraking system will however function) and the

vehicle should be driven cautiously to a trained

and qualified Volvo service technician for

inspection. The Anti-lock Braking System

(ABS) helps to improve vehicle control (stop-

ping and steering) during severe braking con-

ditions by limiting brake lockup. When the sys-

tem "senses" impending lockup, braking pres-

sure is automatically modulated in order to help

prevent lockup, which could lead to a skid.

The system performs a self-diagnostic test

when the engine is started and when the

vehicle first reaches a speed of approxi-

mately 12 mph (20 km/h). The brake pedal will

pulsate several times and a sound may be

audible from the ABS control module. This is

normal.

To obtain optimal effect from the ABS system,

constant pressure should be kept on the brake

pedal. Do not pump the brake pedal.

The switching of the ABS modulator will be

audible and the brake pedal will pulsate during

braking. Please be aware that ABS does not

increase the absolute braking potential of the

vehicle. While control will be enhanced, ABS

will not shorten stopping distances on slippery

surfaces.

ABS with EBD (Electronic Brake Force

Distribution)

EBD is an integrated part of the ABS system.

EBD regulates the hydraulic pressure to the

rear brakes to help provide optimal braking

capacity. The brake pedal will pulsate during

braking, which is normal.

If the BRAKE and ABS warning lights come on

at the same time, this could indicate a fault in

the brake system.

1. Stop the vehicle in a suitable place and

switch off the engine.

2. Restart the engine.

•If both warning lights go off, no further

action is required.

•If both lights are still on after the engine has

been restarted, switch off the engine again

and check the brake fluid level (see

page 223 for the location of the brake fluid

reservoir).

WARNING

If the fluid level is below the MIN mark in the

reservoir or if a Brake failure – Service

urgent message is displayed in the text

window: DO NOT DRIVE. Have the vehicle

towed to a trained and qualified Volvo serv-

ice technician and have the brake system

inspected.

Page 163 of 310

06 Starting and driving

Towing

06

161

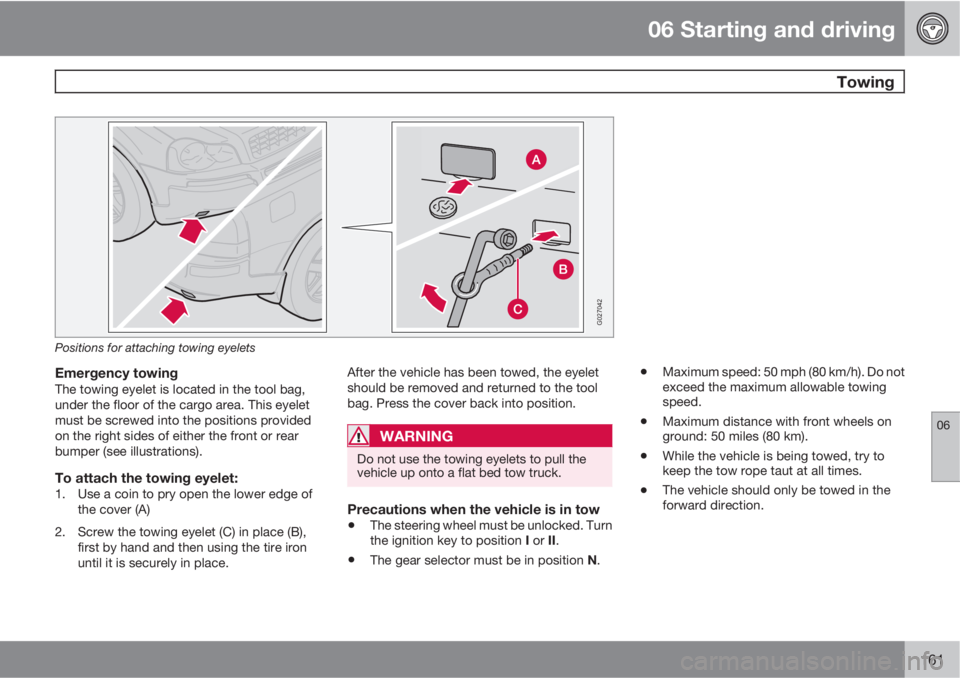

G027042

Positions for attaching towing eyelets

Emergency towingThe towing eyelet is located in the tool bag,

under the floor of the cargo area. This eyelet

must be screwed into the positions provided

on the right sides of either the front or rear

bumper (see illustrations).

To attach the towing eyelet:1. Use a coin to pry open the lower edge of

the cover (A)

2. Screw the towing eyelet (C) in place (B),

first by hand and then using the tire iron

until it is securely in place.After the vehicle has been towed, the eyelet

should be removed and returned to the tool

bag. Press the cover back into position.

WARNING

Do not use the towing eyelets to pull the

vehicle up onto a flat bed tow truck.

Precautions when the vehicle is in tow

•The steering wheel must be unlocked. Turn

the ignition key to position I or II.

•The gear selector must be in position N.

•Maximum speed: 50 mph (80 km/h). Do not

exceed the maximum allowable towing

speed.

•Maximum distance with front wheels on

ground: 50 miles (80 km).

•While the vehicle is being towed, try to

keep the tow rope taut at all times.

•The vehicle should only be towed in the

forward direction.

Page 168 of 310

06 Starting and driving

Detachable trailer hitch

06

166

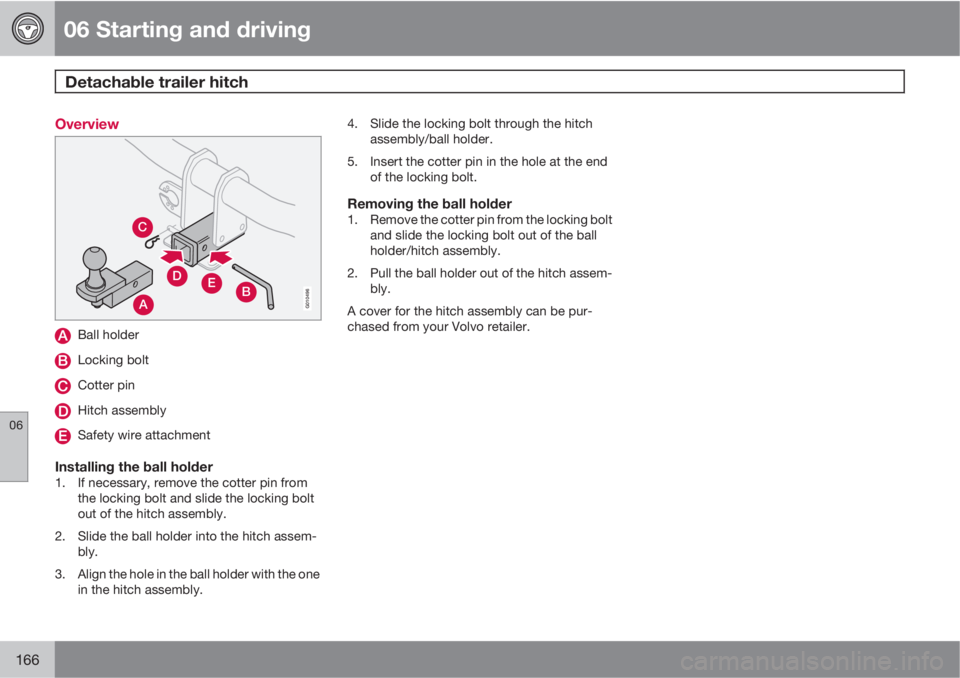

Overview

A

C

EDBG010496

Ball holder

Locking bolt

Cotter pin

Hitch assembly

Safety wire attachment

Installing the ball holder1. If necessary, remove the cotter pin from

the locking bolt and slide the locking bolt

out of the hitch assembly.

2. Slide the ball holder into the hitch assem-

bly.

3. Align the hole in the ball holder with the one

in the hitch assembly.4. Slide the locking bolt through the hitch

assembly/ball holder.

5. Insert the cotter pin in the hole at the end

of the locking bolt.

Removing the ball holder1. Remove the cotter pin from the locking bolt

and slide the locking bolt out of the ball

holder/hitch assembly.

2. Pull the ball holder out of the hitch assem-

bly.

A cover for the hitch assembly can be pur-

chased from your Volvo retailer.

Page 170 of 310

06 Starting and driving

Cold weather precautions

06

168

If you wish to check your vehicle before the

approach of cold weather, the following advice

is worth noting:

•Make sure that the engine coolant contains

50 percent antifreeze. Any other mixture

will reduce freeze protection. This gives

protection against freezing down to –31 °F

(–35 °C). See section "Coolant".

•The use of "recycled" antifreeze is not

approved by Volvo. Different types of

antifreeze must not be mixed.

•Volvo recommends using only genuine

Volvo antifreeze in your vehicle's radiator.

Your Volvo retailer stocks plenty of Volvo

engine coolant to protect your vehicle dur-

ing cold weather.

•Try to keep the fuel tank well filled – this

prevents the formation of condensation in

the tank. In addition, in extremely cold

weather conditions it is worthwhile to add

fuel line de-icer before refueling.

•The viscosity of the engine oil is important.

Oil with low viscosity (thinner oil) improves

cold-weather starting as well as decreas-

ing fuel consumption while the engine is

warming up. 0W-30 oil is recommended for

driving in areas with sustained low temper-

atures.

•The load placed on the battery is greater

during the winter since the windshield wip-

ers, lighting, etc. are used more often.Moreover, the capacity of the battery

decreases as the temperature drops. In

very cold weather, a poorly charged bat-

tery can freeze and be damaged. It is there-

fore advisable to check the state of charge

more frequently and spray an antirust oil on

the battery posts.

•Volvo recommends the use of snow tires

on all four wheels for winter driving – see

section "Wheels and tires."

•To prevent the washer fluid reservoir

from freezing, add washer solvents con-

taining antifreeze (see page 222 for the

location of the washer fluid reservoir). This

is important since dirt is often splashed on

the windshield during winter driving,

requiring the frequent use of the washers

and wipers. Volvo Washer Solvent should

be diluted as follows:

•Down to 14 ° F (–10 ° C): 1 part washer

solvent and 4 parts water

•Down to 5 ° F (–15 ° C): 1 part washer sol-

vent and 3 parts water

•Down to 0 ° F (–18 ° C):1 part washer sol-

vent and 2 parts water

•Down to –18 ° F (–28 ° C): 1 part washer

solvent and 1 part water

•Use Volvo Teflon Lock Spray in the locks.

NOTE

Avoid the use of de-icing sprays as they can

cause damage to the locks.

W – Winter/Wet driving mode – enhanced

vehicle traction

•Mode W will only function if the gear selec-

tor is in the (D)rive position.

•Press the button at the base of the gear

selector to engage/disengage this driving

mode.

•An LED in the button will light up to indicate

that W is engaged and this will also be dis-

played in the instrument panel (see

page 58).

•This mode may be selected for starting/

moving off on slippery roads.

Page 174 of 310

06 Starting and driving

Blind Spot Information System*

06

172* Option/accessory, for more information, see Introduction.

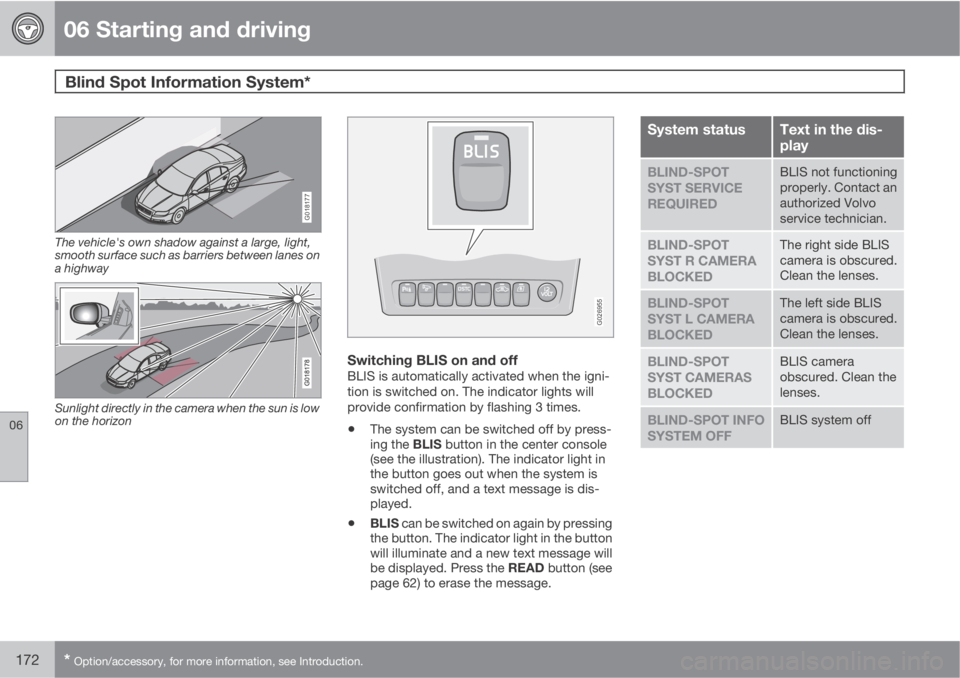

G018177

The vehicle's own shadow against a large, light,

smooth surface such as barriers between lanes on

a highway

Sunlight directly in the camera when the sun is low

on the horizon

G026955

Switching BLIS on and offBLIS is automatically activated when the igni-

tion is switched on. The indicator lights will

provide confirmation by flashing 3 times.

•The system can be switched off by press-

ing the BLIS button in the center console

(see the illustration). The indicator light in

the button goes out when the system is

switched off, and a text message is dis-

played.

•BLIS can be switched on again by pressing

the button. The indicator light in the button

will illuminate and a new text message will

be displayed. Press the READ button (see

page 62) to erase the message.

System statusText in the dis-

play

BLIND-SPOT

SYST SERVICE

REQUIREDBLIS not functioning

properly. Contact an

authorized Volvo

service technician.

BLIND-SPOT

SYST R CAMERA

BLOCKEDThe right side BLIS

camera is obscured.

Clean the lenses.

BLIND-SPOT

SYST L CAMERA

BLOCKEDThe left side BLIS

camera is obscured.

Clean the lenses.

BLIND-SPOT

SYST CAMERAS

BLOCKEDBLIS camera

obscured. Clean the

lenses.

BLIND-SPOT INFO

SYSTEM OFFBLIS system off

Page 189 of 310

07 Wheels and tires

Snow chains, snow tires, studded tires

07

187 Snow chains

Snow chains can be used on your Volvo with

the following restrictions:

•Snow chains should be installed on front

wheels only. Use only Volvo approved

snow chains.

•If accessory, aftermarket or "custom" tires

and wheels are installed and are of a size

different than the original tires and wheels,

chains in some cases CANNOT be used.

Sufficient clearances between chains and

brakes, suspension and body components

must be maintained.

•Some strap-on type chains will interfere

with brake components and therefore

CANNOT be used.

•All Wheel Drive models: Snow chains

should only be installed on the front

wheels.

•Certain size tires may not allow the assem-

bly of snow chains/traction devices.

Consult your Volvo retailer for additional snow

chain information.

CAUTION

•Check local regulations regarding the

use of snow chains before installing.

•Always follow the chain manufacturer's

installation instructions carefully. Install

chains as tightly as possible and

retighten periodically.

•Never exceed the chain manufacturer's

specified maximum speed limit. (Under

no circumstances should you exceed

31 mph (50 km/h)).

•Avoid bumps, holes or sharp turns

when driving with snow chains.

•The handling of the vehicle can be

adversely affected when driving with

chains. Avoid fast or sharp turns as well

as locked wheel braking.

Snow tires, studded tires1

Tires for winter use:

•Owners who live in or regularly commute

through areas with sustained periods of

snow or icy driving conditions are strongly

advised to fit suitable winter tires to help

retain the highest degree of traction.

•It is important to install winter tires on all

four wheels to help retain traction duringcornering, braking, and accelerating. Fail-

ure to do so could reduce traction to an

unsafe level or adversely affect handling.

•Do not mix tires of different design as this

could also negatively affect overall tire road

grip.

•Winter tires wear more quickly on dry roads

in warm weather. They should be removed

when the winter driving season has ended.

•Studded tires should be run-in

300-600 miles (500-1000 km) during which

the vehicle should be driven as smoothly

as possible to give the studs the opportu-

nity to seat properly in the tires. The tires

should have the same rotational direction

throughout their entire lifetime.

NOTE

Please consult state or provincial regula-

tions restricting the use of studded winter

tires before installing such tires.

1Where permitted

Page 194 of 310

07 Wheels and tires

Tire Sealing System

07

192

NOTE

The air pressure gauge will temporarily

show an increase in pressure to approxi-

mately 88 psi (6 bar) while the sealing com-

pound is being pumped into the tire. The

pressure should return to a normal level

after approximately 30 seconds.

11. Within seven minutes, inflate the tire to

between 22—44 psi (1.8—3.0 bar). Switch

off the compressor briefly to get a clear

reading from the pressure gauge.

CAUTION

The compressor should not be used for

more than 10 minutes at a time to avoid

overheating.

WARNING

If the pressure remains below 22 psi

(1.8 bar) after approximately seven minutes,

turn off the compressor. In this case, the

hole is too large to be sealed and the vehicle

should not be driven.

12. Switch off the compressor and disconnect

the electrical wire from the 12-volt socket.13. Unscrew the hose from the tire’s inflation

valve and reinstall the valve cap.

14. Immediately drive the vehicle for approxi-

mately 2 miles (3 km) at a maximum speed

of 50 mph (80 km/h) to distribute the seal-

ing compound in the tire.

CAUTION

If your vehicle is equipped with the Tire

Pressure Monitoring System (TPMS), the

use of the sealing compound may lead to

incorrect tire pressure readings or in rare

cases, damage to the tire pressure sensor.

Use the tire sealing system to check and

adjust the damaged tire's inflation pressure.

NOTE

•Safely stow the tire sealing system in a

convenient place as it will soon be used

again to check the tire’s inflation pres-

sure.

•The empty bottle of sealing compound

cannot be removed from the bottle

holder. Consult a trained and qualified

Volvo service technician to have the

bottle removed and properly disposed

of.

WARNING

If heavy vibrations, unsteady steering

behavior, or noises should occur while driv-

ing, reduce speed and park the vehicle in a

safe place. Recheck the tire for bumps,

cracks, or other visible damage, and

recheck its inflation pressure. If the pressure

is below 19 psi (1.3 bar), do not continue

driving. Have the vehicle towed to a trained

and qualified Volvo service technician.

Stage 2: Checking inflation pressure1. Connect the tire sealing system as descri-

bed in stage 1.

2. Refer to the inflation pressure tables for the

correct inflation pressure. If the tire needs

to be inflated, start the tire sealing system’s

compressor. If necessary, release air from

the tire by turning the air release knob

counterclockwise.

CAUTION

The compressor should not be used for

more than 10 minutes at a time to avoid

overheating.

WARNING

If you interrupt your trip for more than 1

hour, check the inflation pressure in the

damaged tire again before continuing.

Page 195 of 310

07 Wheels and tires

Tire Sealing System

07

193

Replacing the sealing compound

container

The sealing compound container must be

replaced if:

•the tire sealing system has been used to

repair a tire

•the container’s expiration date has passed

(see the date on decal).

NOTE

•After use, the sealing compound bottle,

the hose, and certain other system

components must be replaced. Please

consult your Volvo retailer for replace-

ment parts.

•If the sealing compound bottle’s expi-

ration date has passed, please take it to

a Volvo retailer or a recycling station

that can properly dispose of harmful

substances.

Inflating tires

The tire sealing system can be used to inflate

the tires. To do so:

1. Park the car in a safe place.

2. The compressor should be switched off.

Ensure that the on/off switch is in position

0 (the 0 side of the switch should be

pressed down).

3. Take out the electrical wire and hose.

4. Remove the valve cap from the tire’s infla-

tion valve and screw the hose connector

onto the valve as tightly as possible by

hand.

5. Connect the electrical wire to the nearest

12-volt socket in the vehicle.

6. Start the vehicle’s engine.WARNING

•The vehicle’s engine should be running

when the tire sealing system is used to

avoid battery drain. Therefore, be sure

the vehicle is parked in a well ventilated

place, or outdoors, before using the sys-

tem. The parking brake should be

securely applied and the gear selector

should be in the P (park) position.

•Children should never be left unattended

in the vehicle when the engine is running.

7. Check the tire’s inflation pressure on the

gauge. Switch off the compressor briefly to

get a clear reading from the pressure

gauge.

8. Refer to the tire inflation tables for the cor-

rect inflation pressure. If the tire needs to

be inflated, start the tire sealing system’s

compressor (press the on/off switch to

position I). If necessary, release air from the

tire by turning the air release knob coun-

terclockwise.

CAUTION

The compressor should not be used for

more than 10 minutes at a time to avoid

overheating.

Page 197 of 310

07 Wheels and tires

Changing wheels

07

195

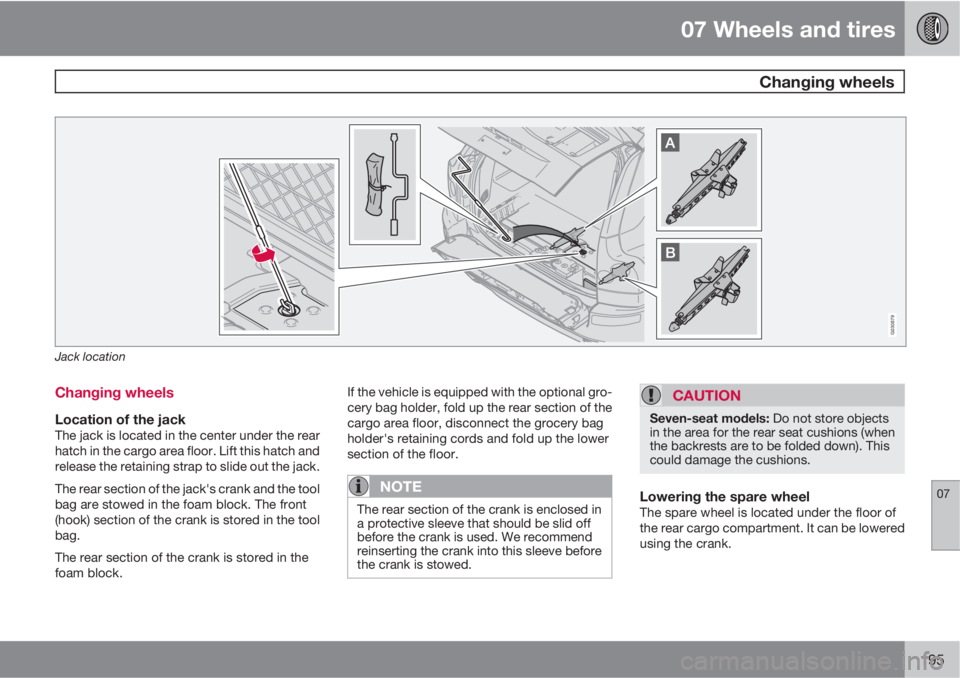

G030879

Jack location

Changing wheels

Location of the jackThe jack is located in the center under the rear

hatch in the cargo area floor. Lift this hatch and

release the retaining strap to slide out the jack.

The rear section of the jack's crank and the tool

bag are stowed in the foam block. The front

(hook) section of the crank is stored in the tool

bag.

The rear section of the crank is stored in the

foam block.If the vehicle is equipped with the optional gro-

cery bag holder, fold up the rear section of the

cargo area floor, disconnect the grocery bag

holder's retaining cords and fold up the lower

section of the floor.

NOTE

The rear section of the crank is enclosed in

a protective sleeve that should be slid off

before the crank is used. We recommend

reinserting the crank into this sleeve before

the crank is stowed.

CAUTION

Seven-seat models: Do not store objects

in the area for the rear seat cushions (when

the backrests are to be folded down). This

could damage the cushions.

Lowering the spare wheelThe spare wheel is located under the floor of

the rear cargo compartment. It can be lowered

using the crank.