flat tire VOLVO XC90 2014 Owner´s Manual

[x] Cancel search | Manufacturer: VOLVO, Model Year: 2014, Model line: XC90, Model: VOLVO XC90 2014Pages: 308, PDF Size: 13.31 MB

Page 196 of 308

07 Wheels and tires

Tire Sealing System

07

194

WARNING

•Never leave the tire sealing system unattended when it is operating.

• Keep the tire sealing system awayfrom children.

• Be sure the vehicle is parked safely offthe road and away from moving traffic.

• Apply the parking brake.

Stage 1: Sealing the hole1. Peel off the speed limit sticker and affix it

to the steering wheel hub where it will be clearly visible to the driver.

2. Ensure that the on/off switch is in position 0 (the 0 side of the switch should be

pressed down).

3. Put on the gloves included in the tire sealing system.

WARNING

Contact with the sealing compound may cause skin irritation. If contact occurs,wash the affected area immediately withsoap and water.

4. Unscrew the orange cover over the bottleholder and unscrew the cap on the bottle of sealing compound.

NOTE

Do not break the seal on the bottle. This occurs automatically when the bottle isscrewed into the holder.

5. Screw the bottle into the bottle holder.

WARNING

The bottle is equipped with a catch to keep it securely in place and help preventsealing compound leakage. Once in place,the bottle cannot be unscrewed. This mustbe done by a trained and qualified Volvoservice technician.

6. Remove the valve cap from the tire’sinflation valve and screw the tire sealing system’s hose connector onto the valveas tightly as possible by hand.

7. Connect the electrical wire to the nearest 12-volt socket in the vehicle.

NOTE

Be sure that none of the other 12-volt sockets is being used while the compres-sor is in operation.

8. Start the vehicle’s engine.

9. Start the tire sealing system’s compres- sor by pressing the on/off switch to posi- tion I.

WARNING

• Never stand next to the tire being infla- ted when the compressor is in opera-tion.

• If cracks, bubbles, etc. form on the tire,switch off the compressor immediately.

• If there is visible damage to the sidewallor the rim, the tire cannot be repaired.The vehicle should not be driven if thisoccurs. Contact a towing service orVolvo On Call Roadside Assistance ifapplicable.

Page 197 of 308

07 Wheels and tires

Tire Sealing System

07

195

NOTE

The air pressure gauge will temporarily show an increase in pressure to approxi-mately 88 psi (6 bar) while the sealingcompound is being pumped into the tire.The pressure should return to a normallevel after approximately 30 seconds.

10. Within seven minutes, inflate the tire tobetween 22—44 psi (1.8—3.0 bar). Switch off the compressor briefly to get aclear reading from the pressure gauge.

CAUTION

The compressor should not be used for more than 10 minutes at a time to avoidoverheating.

WARNING

If the pressure remains below 22 psi (1.8 bar) after approximately sevenminutes, turn off the compressor. In thiscase, the hole is too large to be sealed andthe vehicle should not be driven.

11. Switch off the compressor and discon-nect the electrical wire from the 12-volt socket. 12. Unscrew the hose from the tire’s inflation

valve and reinstall the valve cap.

CAUTION

•After pumping the tires, always reinstall the valve cap to help avoid damage tothe valve from dirt, gravel, etc.

• Use plastic valve caps only. Metal capscould corrode and become difficult toremove.

13. Immediately drive the vehicle for approxi-

mately 2 miles (3 km) at a maximum speed of 50 mph (80 km/h) to distributethe sealing compound in the tire.

CAUTION

If your vehicle is equipped with the Tire Pressure Monitoring System (TPMS), theuse of the sealing compound may lead toincorrect tire pressure readings or in rarecases, damage to the tire pressure sensor.Use the tire sealing system to check andadjust the damaged tire's inflation pres-sure.

NOTE

•Safely stow the tire sealing system in a convenient place as it will soon beused again to check the tire’s inflationpressure.

• The empty bottle of sealing compoundcannot be removed from the bottleholder. Consult a trained and qualifiedVolvo service technician to have thebottle removed and properly disposedof.

WARNING

If heavy vibrations, unsteady steering behavior, or noises should occur whiledriving, reduce speed and park the vehiclein a safe place. Recheck the tire forbumps, cracks, or other visible damage,and recheck its inflation pressure. If thepressure is below 19 psi (1.3 bar), do notcontinue driving. Have the vehicle towedto a trained and qualified Volvo servicetechnician.

Stage 2: Checking inflation pressure1. Connect the tire sealing system as

described in stage 1.

2. Refer to the inflation pressure tables for the correct inflation pressure. If the tire needs to be inflated, start the tire sealing

Page 198 of 308

07 Wheels and tires

Tire Sealing System

07

196

system’s compressor. If necessary, release air from the tire by turning the airrelease knob counterclockwise.

CAUTION

The compressor should not be used for more than 10 minutes at a time to avoidoverheating.

WARNING

If you interrupt your trip for more than 1 hour, check the inflation pressure in thedamaged tire again before continuing.

Replacing the sealing compound container

The sealing compound container must be replaced if:• the tire sealing system has been used to repair a tire

• the container’s expiration date haspassed (see the date on decal).

NOTE

• After use, the sealing compound bot- tle, the hose, and certain other systemcomponents must be replaced. Pleaseconsult your Volvo retailer for replace-ment parts.

• If the sealing compound bottle’s expi-ration date has passed, please take itto a Volvo retailer or a recycling stationthat can properly dispose of harmfulsubstances.

Inflating tires

The tire sealing system can be used to inflate the tires. To do so:

1. Park the car in a safe place.

2. The compressor should be switched off.

Ensure that the on/off switch is in position 0 (the 0 side of the switch should be

pressed down).

3. Take out the electrical wire and hose.

4. Remove the valve cap from the tire’s inflation valve and screw the hose con- nector onto the valve as tightly as possi-ble by hand.

5. Connect the electrical wire to the nearest 12-volt socket in the vehicle. 6. Start the vehicle’s engine.

WARNING

•

The vehicle’s engine should be running when the tire sealing system is used toavoid battery drain. Therefore, be surethe vehicle is parked in a well ventilatedplace, or outdoors, before using thesystem. The parking brake should besecurely applied and the gear selectorshould be in the

P (park) position.

• Children should never be left unatten-ded in the vehicle when the engine isrunning.

7. Check the tire’s inflation pressure on the

gauge. Switch off the compressor briefly to get a clear reading from the pressuregauge.

8. Refer to the tire inflation tables for the correct inflation pressure. If the tire needsto be inflated, start the tire sealing sys-tem’s compressor (press the on/offswitch to position I). If necessary, releaseair from the tire by turning the air releaseknob counterclockwise.

Page 199 of 308

07 Wheels and tires

Tire Sealing System

07

197

CAUTION

The compressor should not be used for more than 10 minutes at a time to avoidoverheating.

9. Turn off the compressor (press the on/offswitch to position 0) when the correct

inflation pressure has been reached.

10. Unscrew the hose from the tire’s inflation valve and reinstall the valve cap.

CAUTION

•After pumping the tires, always reinstall the valve cap to help avoid damage tothe valve from dirt, gravel, etc.

• Use plastic valve caps only. Metal capscould corrode and become difficult toremove.

11. Disconnect the electrical wire from the

12-volt socket.

Page 201 of 308

07 Wheels and tires

Changing wheels

07

199

WARNING

When raising or lowering the spare wheel, please keep in mind that components inthe exhaust system may be very hot.

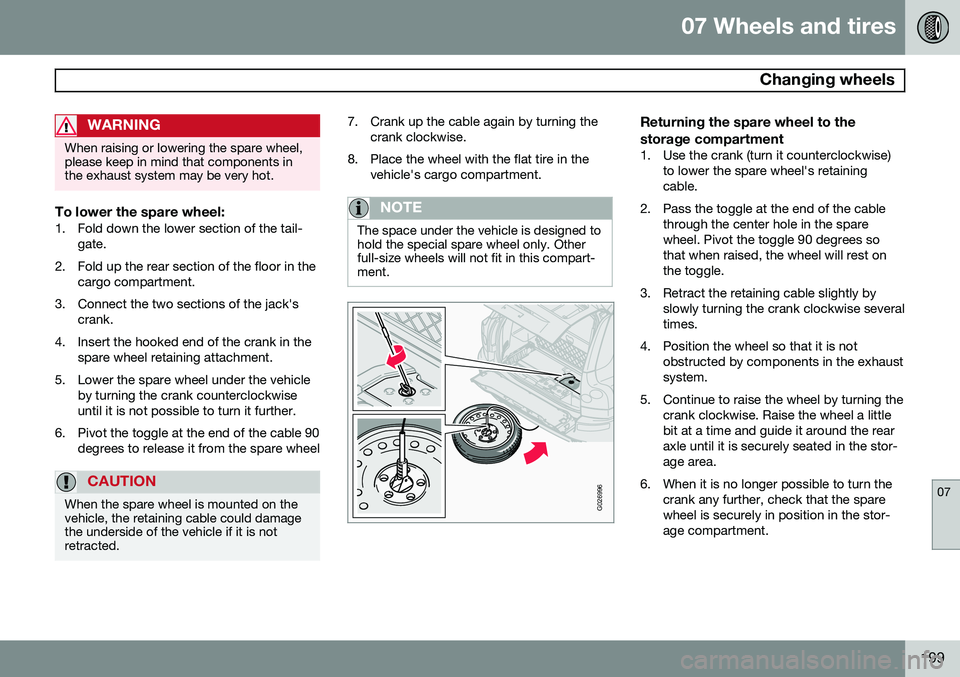

To lower the spare wheel:1. Fold down the lower section of the tail-gate.

2. Fold up the rear section of the floor in the cargo compartment.

3. Connect the two sections of the jack's crank.

4. Insert the hooked end of the crank in the spare wheel retaining attachment.

5. Lower the spare wheel under the vehicle by turning the crank counterclockwise until it is not possible to turn it further.

6. Pivot the toggle at the end of the cable 90 degrees to release it from the spare wheel

CAUTION

When the spare wheel is mounted on the vehicle, the retaining cable could damagethe underside of the vehicle if it is notretracted.

7. Crank up the cable again by turning thecrank clockwise.

8. Place the wheel with the flat tire in the vehicle's cargo compartment.

NOTE

The space under the vehicle is designed to hold the special spare wheel only. Otherfull-size wheels will not fit in this compart-ment.

G026996

Returning the spare wheel to the storage compartment

1. Use the crank (turn it counterclockwise) to lower the spare wheel's retaining cable.

2. Pass the toggle at the end of the cable through the center hole in the sparewheel. Pivot the toggle 90 degrees sothat when raised, the wheel will rest onthe toggle.

3. Retract the retaining cable slightly by slowly turning the crank clockwise severaltimes.

4. Position the wheel so that it is not obstructed by components in the exhaustsystem.

5. Continue to raise the wheel by turning the crank clockwise. Raise the wheel a littlebit at a time and guide it around the rearaxle until it is securely seated in the stor-age area.

6. When it is no longer possible to turn the crank any further, check that the sparewheel is securely in position in the stor-age compartment.

Page 202 of 308

07 Wheels and tires

Changing wheels

07

200

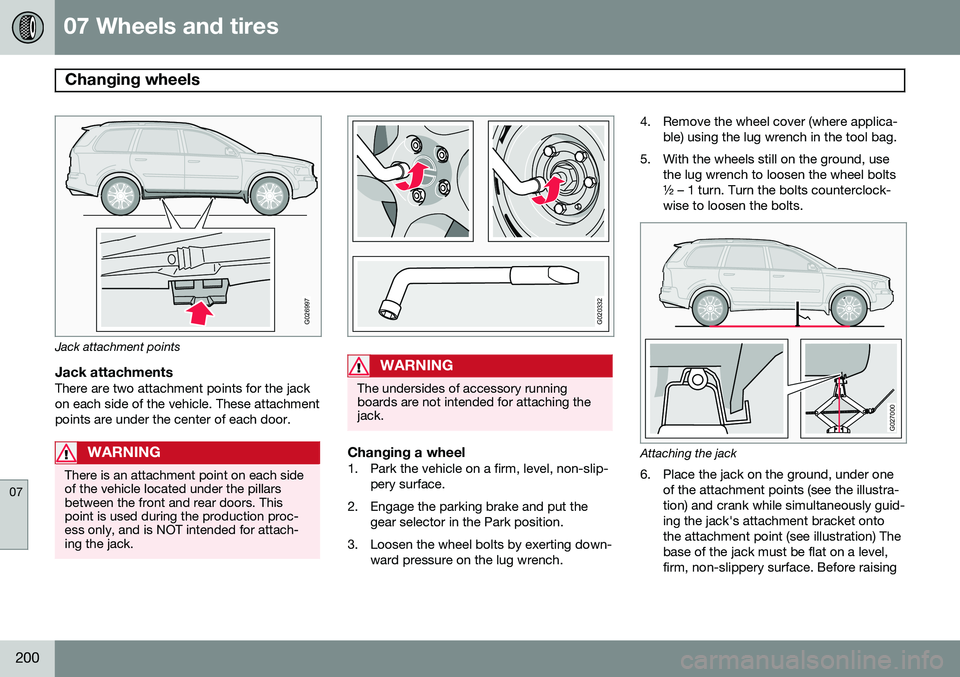

G026997

Jack attachment points

Jack attachmentsThere are two attachment points for the jack on each side of the vehicle. These attachmentpoints are under the center of each door.

WARNING

There is an attachment point on each side of the vehicle located under the pillarsbetween the front and rear doors. Thispoint is used during the production proc-ess only, and is NOT intended for attach-ing the jack.

G020332

WARNING

The undersides of accessory running boards are not intended for attaching thejack.

Changing a wheel1. Park the vehicle on a firm, level, non-slip-pery surface.

2. Engage the parking brake and put the gear selector in the Park position.

3. Loosen the wheel bolts by exerting down- ward pressure on the lug wrench. 4. Remove the wheel cover (where applica-

ble) using the lug wrench in the tool bag.

5. With the wheels still on the ground, use the lug wrench to loosen the wheel bolts ½ – 1 turn. Turn the bolts counterclock-wise to loosen the bolts.

G027000

Attaching the jack

6. Place the jack on the ground, under oneof the attachment points (see the illustra- tion) and crank while simultaneously guid-ing the jack's attachment bracket ontothe attachment point (see illustration) Thebase of the jack must be flat on a level,firm, non-slippery surface. Before raising

Page 204 of 308

07 Wheels and tires

Changing wheels

07

202

NOTE

The jack provided with your vehicle is intended to be used only in temporary sit-uations such as changing wheels in theevent of a flat tire. Only the jack that camewith your particular model should be usedto lift the vehicle. If the vehicle needs to belifted more frequently or for a prolongedperiod, using a garage jack or hoist is rec-ommended. Always follow this device’sinstructions for use.

The jack and tools should be returned to their storage spaces. The jack should be crankeddown fully so that it fits into the intendedspace.

Page 205 of 308

07 Wheels and tires

Tire Pressure Monitoring System (TPMS)

07

203

The tire pressure monitoring system

1

uses

sensors mounted in the tire valves to check inflation pressure levels. When the vehicle ismoving at a speed of approximately 20 mph(30 km/h) or faster, these sensors transmitinflation pressure data to a receiver located inthe vehicle.

USA – FCC ID: MRXG403MA4 A

This device complies with part 15 of the

FCC rules. Operation is subject to the fol- lowing conditions: (1) This device may notcause harmful interference, and (2) thisdevice must accept any interferencereceived, including interference that maycause undesired operation. When low inflation pressure is detected, TPMS will light up the tire pressure warn-ing light (also referred to as a telltale) in theinstrument panel (see page 61), and willdisplay a message in the text window. Thewording of this message is determined bythe degree of inflation pressure loss.

A On certain models, the FCC code is MRXTG315AM04

When low inflation pressure is detected, TPMS will light up the tire pressure warning light

(also referred to as a telltale) in the instrument panel and will display one of the following messages in the text window:

LOW

TIRE PRESS. CHECK TIRES or VERY LOW

TIRE PRESSURE.

NOTE

If a fault occurs in TPMS, the tire pressure warning light will flash for approximately 1 minute and

TIRE PRESS SYST

SERVICE REQUIRED will be displayed.

Each tire, including the spare (if provided), should be checked monthly when cold andinflated to the inflation pressure recom-mended by the vehicle manufacturer on thevehicle placard or tire inflation pressure label.(If your vehicle has tires of a different sizethan the size indicated on the vehicle placardor tire inflation pressure label, you shoulddetermine the proper tire inflation pressure forthose tires.) As an added safety feature, your vehicle has been equipped with a tire pressure monitor-ing system (TPMS) that illuminates a low tirepressure telltale when one or more of yourtires is significantly under-inflated. Accord-ingly, when the low tire pressure telltale illu-minates, you should stop and check yourtires as soon as possible, and inflate them to the proper pressure. Driving on a significantlyunder-inflated tire causes the tire to overheatand can lead to tire failure. Under-inflationalso reduces fuel efficiency and tire tread life,and may affect the vehicle's handling andstopping ability. Please note that the TPMS is not a substitute for proper tire maintenance, and it is the driv-er's responsibility to maintain correct tirepressure, even if under-inflation has notreached the level to trigger illumination of theTPMS low tire pressure telltale. Your vehicle has also been equipped with a TPMS malfunction indicator to indicate whenthe system is not operating properly. TheTPMS malfunction indicator is combined withthe low tire pressure telltale. When the sys-tem detects a malfunction, the telltale willflash for approximately one minute and thenremain continuously illuminated. Thissequence will continue upon subsequentvehicle start-ups as long as the malfunctionexists. When the malfunction indicator is illu-minated, the system may not be able todetect or signal low tire pressure as intended.TPMS malfunctions may occur for a variety ofreasons, including the installation of replace-ment or alternate tires or wheels on the vehi-cle that prevent the TPMS from functioning

1

This system is standard on U.S. models and optional on Canadian models

Page 206 of 308

07 Wheels and tires

Tire Pressure Monitoring System (TPMS)

07

204

properly. Always check the TPMS malfunc- tion telltale after replacing one or more tiresor wheels on your vehicle to ensure that thereplacement or alternate tires and wheelsallow the TPMS to continue to function prop-erly.

NOTE

TPMS indicates low tire pressure but does not replace normal tire maintenance. Forinformation on correct tire pressure, pleaserefer to the tire inflation pressure table inthis chapter or consult your Volvo retailer.

Erasing warning messagesWhen a low tire pressure warning message has been displayed, and the tire pressurewarning light has come on:

1. Use a tire pressure gauge to check theinflation pressure of all four tires.

2. Re-inflate the tire(s) to the correct pres- sure (consult the tire pressure placard or the table see page 183).

3. Drive the vehicle for several minutes at a speed of 20 mph (30 km/h) or faster.

> This will erase the warning text and thewarning light will go out.

WARNING

Incorrect inflation pressure could lead to tire failure, resulting in a loss of control ofthe vehicle.

Changing wheels with TPMSPlease note the following when changing or replacing the factory installed TPMS wheels/tires on the vehicle:

• Only the factory-mounted wheels are equipped with TPMS sensors in thevalves.

• If the vehicle is equipped with a tempo-rary spare tire, this tire does not have aTPMS sensor.

• If wheels without TPMS sensors are mounted on the vehicle,

TIRE PRESS

SYST. SERVICE REQUIRED will be dis-

played each time the vehicle is driven above 25 mph (40 km/h) for 10 minutes ormore.

• Once TPMS sensors are properly instal-led, the warning message should notreappear.

• Volvo recommends that TPMS sensorsbe fitted on all wheels used on the vehi-cle. Volvo does not recommend movingsensors back and forth between sets ofwheels.

NOTE

If a tire is changed or if the TPMS sensor is moved to another wheel, the sensor’svalve and valve core should be replaced.

CAUTION

When inflating tires with TPMS valves, press the pump's mouthpiece straightonto the valve to help avoid bending orotherwise damaging the valve.

Recalibrating TPMS (Canadian models only)

In certain cases, it may be necessary to reca- librate TPMS to conform to Volvo's recom-mended tire inflation pressures (see the infla-tion pressure table on page 183), for exam-ple, if higher inflation pressure is necessarywhen transporting heavy loads, etc. To recalibrate:

1. Switch off the engine.

2. Inflate the tires to the desired pressure

and turn the ignition key to position I or II

(see page 145 for additional information).

3. Turn the thumb wheel on the left-side steering wheel lever until

Tire pressure

Calibration appears in the display.

Page 207 of 308

07 Wheels and tires

Tire Pressure Monitoring System (TPMS)

07

* Option/accessory, for more information, see Introduction.205

4. Press and hold the

Reset button on the

left-side steering wheel lever until

TIRE

PRESSURE CALIBRATED is displayed.

Activating/deactivating TPMS (Canadian models only)

1. Switch off the engine.

2. Turn the ignition key to position I or II.

3. Press and hold the Reset button on the

left-side steering wheel lever until

TIRE

PRESS SYST OFF is displayed.

Repeat steps 1-3 to turn TPMS on again.

Self-supporting run flat tires (SST)*

Self-supporting run flat tires are available as optional equipment. The vehicle must beequipped with the Tire Pressure MonitoringSystem (TPMS) if tires of this type are instal-led. Tires of this type have specially reinforced sidewalls that make it possible to continuedriving to a limited extent even though the tirehas lost some or all of its inflation pressure.These tires are mounted on special rims (nor-mal tires can also be mounted on these rims). If an SST tire loses inflation pressure, the yel- low TPMS symbol illuminates in the instru-ment panel and a text message is also dis-played. If this happens, reduce speed to not more than 50 mph (80 km/h). The tire shouldbe replaced as soon as possible. Drive carefully; it may be difficult to determine which tire is damaged. To find the damagedtire, check the inflation pressure in all fourtires.

WARNING

•

SST tires should only be mounted by service technicians who are familiarwith tires of this type.

• SST tires may only be mounted onvehicles equipped with TPMS.

• Do not drive faster than 50 mph(80 km/h) if TPMS indicates that a tirehas lost inflation pressure.

• Do not drive farther than 50 miles(80 km) before replacing a damagedSST tire.

• Drive carefully and avoid e.g., hardbraking or fast turns.

• SST tires must be replaced if they aredamaged. A tire of this type cannot berepaired.