wheel YAMAHA BLASTER 200 2002 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2002, Model line: BLASTER 200, Model: YAMAHA BLASTER 200 2002Pages: 368, PDF Size: 4.89 MB

Page 303 of 368

8-55

EBU00595

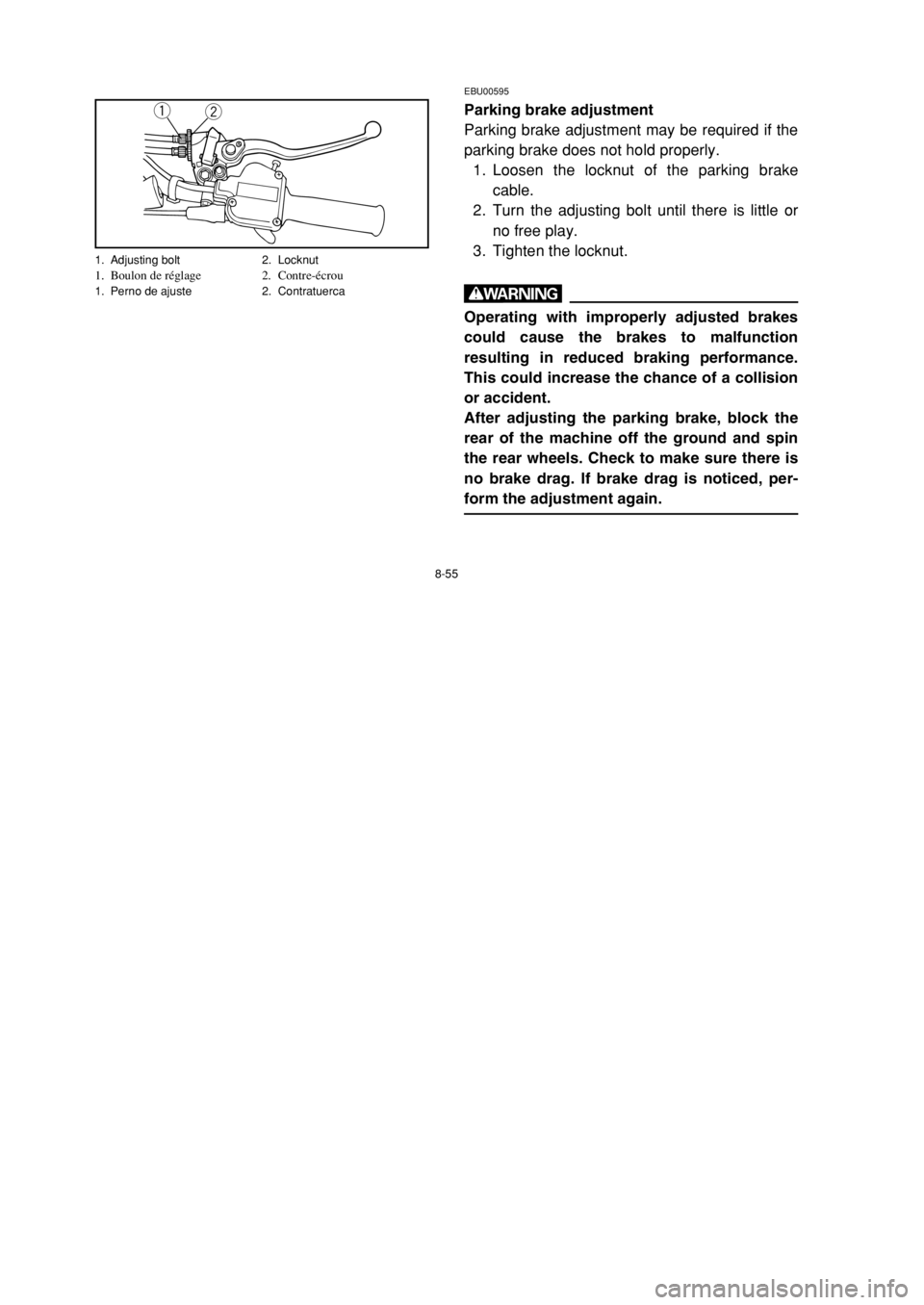

Parking brake adjustment

Parking brake adjustment may be required if the

parking brake does not hold properly.

1. Loosen the locknut of the parking brake

cable.

2. Turn the adjusting bolt until there is little or

no free play.

3. Tighten the locknut.

w

Operating with improperly adjusted brakes

could cause the brakes to malfunction

resulting in reduced braking performance.

This could increase the chance of a collision

or accident.

After adjusting the parking brake, block the

rear of the machine off the ground and spin

the rear wheels. Check to make sure there is

no brake drag. If brake drag is noticed, per-

form the adjustment again.

wq

1. Adjusting bolt 2. Locknut1. Boulon de réglage 2. Contre-écrou1. Perno de ajuste 2. Contratuerca

5KJ-62 (8 shou) 4/23/01 3:08 PM Page 56

Page 311 of 368

8-63

EBU00351

Drive chain slack adjustment

1. Loosen the rear wheel hub bolts.

2. Loosen the adjuster locknuts on each side.

To tighten the chain, turn the chain adjuster

clockwise. To loosen the chain, turn the

adjuster counterclockwise and push the

wheel forward. Turn each adjuster exactly

the same amount to maintain correct axle

alignment.

There are marks on each side of the

swingarm and on each chain adjuster. Use

them to check for proper alignment.

3. After adjusting, be sure to tighten the lock-

nuts and the wheel hub bolts.

q

w

e

q

wqw

1. Upper bolt (×2) 2. Lower bolt (×2)1. Boulon supérieur (×2) 2. Boulon inférieur (×2)1. Tornillo superior (×2) 2. Tornillo inferior (×2)

1. Locknut (×2) 2. Adjuster (×2)

3. Alignment marks

1. Contre-écrou (×2) 2. Dispositif de réglage (×2)

3. Repères d’alignement

1. Contratuerca (×2) 2. Tornillo de ajuste (×2)

3. Marcas de alineación

Upper wheel hub bolt:

50 Nm (5.0 m0kg)

Lower wheel hub bolt:

50 Nm (5.0 m0kg)

5KJ-62 (8 shou) 4/23/01 3:08 PM Page 64

Page 321 of 368

8-73

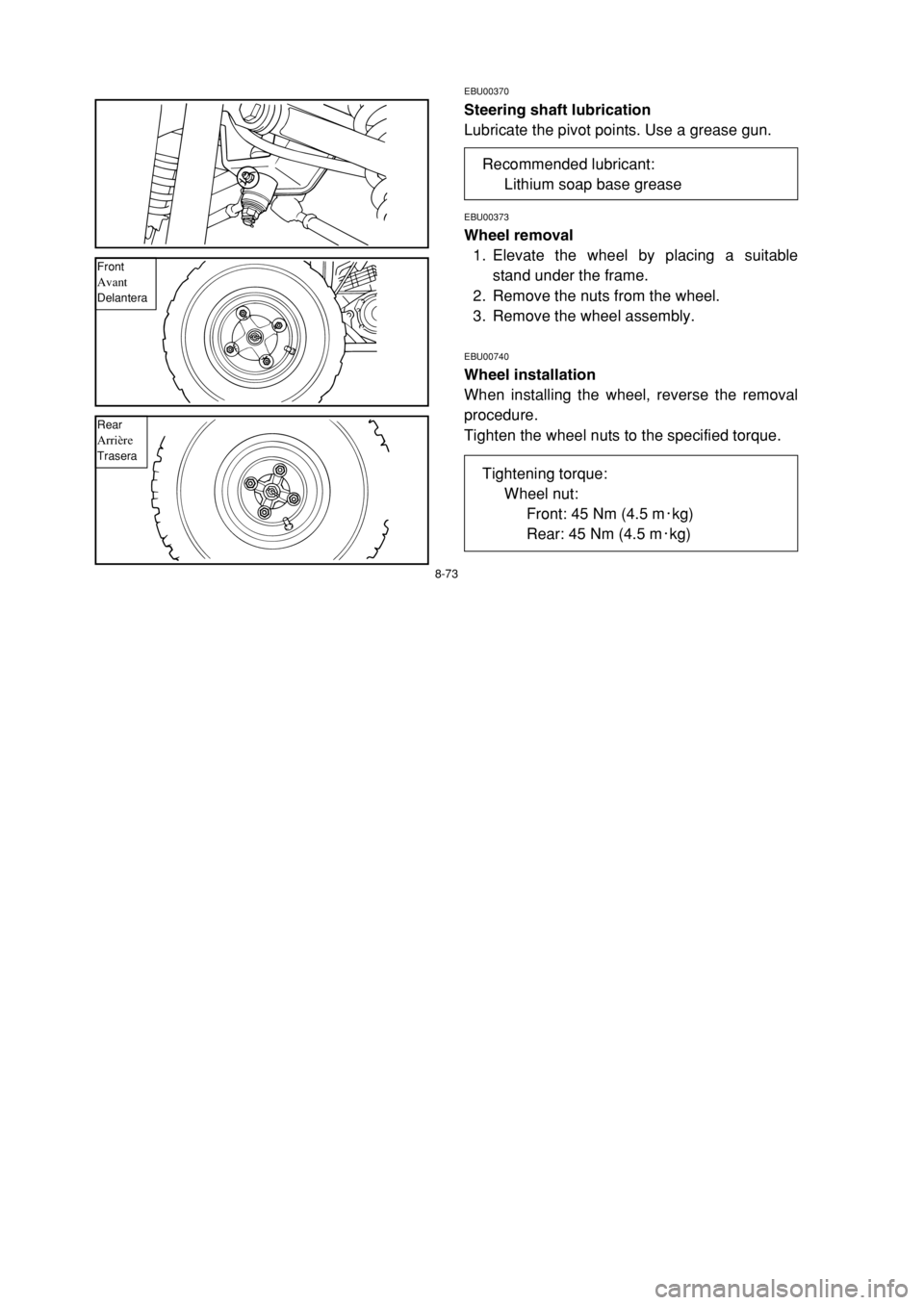

EBU00370

Steering shaft lubrication

Lubricate the pivot points. Use a grease gun.

EBU00373

Wheel removal

1. Elevate the wheel by placing a suitable

stand under the frame.

2. Remove the nuts from the wheel.

3. Remove the wheel assembly.

EBU00740

Wheel installation

When installing the wheel, reverse the removal

procedure.

Tighten the wheel nuts to the specified torque.

FrontAvantDelantera

RearArrièreTrasera

Recommended lubricant:

Lithium soap base grease

Tightening torque:

Wheel nut:

Front: 45 Nm (4.5 m0kg)

Rear: 45 Nm (4.5 m0kg)

5KJ-62 (8 shou) 4/23/01 3:08 PM Page 74

Page 339 of 368

9-1

EBU00418

CLEANING AND STORAGE

A. CLEANING

Frequent, thorough cleaning of your machine

will not only enhance its appearance but will

improve its general performance and extend the

useful life of many components.

1. Before cleaning the machine:

a. Block off the end of the exhaust pipe to pre-

vent water entry. A plastic bag and strong

rubber band may be used.

b. Make sure the spark plug and all filler caps

are properly installed.

2. If the engine case is excessively greasy,

apply degreaser with a paint brush. Do not

apply degreaser to the chain, sprockets or

wheel axles.

3. Rinse the dirt and degreaser off with a gar-

den hose. Use only enough pressure to do

the job.

5KJ-62 (9 shou ~) 4/23/01 3:09 PM Page 2

Page 341 of 368

9-3

cC

Excessive water pressure may cause water

seepage and deterioration of wheel bearings,

brakes, transmission seals and electrical

devices. Many expensive repair bills have

resulted from improper high pressure deter-

gent applications such as those available in

coin-operated car washers.

4. Once the majority of the dirt has been hosed

off, wash all surfaces with warm water and

mild, detergent-type soap. An old tooth-

brush or bottle brush is handy for hard-to-

get-at places.

5. Rinse the machine off immediately with

clean water and dry all surfaces with a

chamois, clean towel or soft absorbent

cloth.

6. Dry the chain and lubricate it to prevent rust.

5KJ-62 (9 shou ~) 4/23/01 3:09 PM Page 4

Page 347 of 368

9-9

4. Lubricate all control cables.

5. Block up the frame to raise all wheels off the

ground.

6. Tie a plastic bag over the exhaust pipe out-

let to prevent moisture from entering.

7. If storing in a humid or salt-air atmosphere,

coat all exposed metal surfaces with a light

film of oil. Do not apply oil to any rubber

parts or the seat cover.

NOTE:

Make any necessary repairs before storing the

machine.

5KJ-62 (9 shou ~) 4/23/01 3:09 PM Page 10

Page 349 of 368

10-1

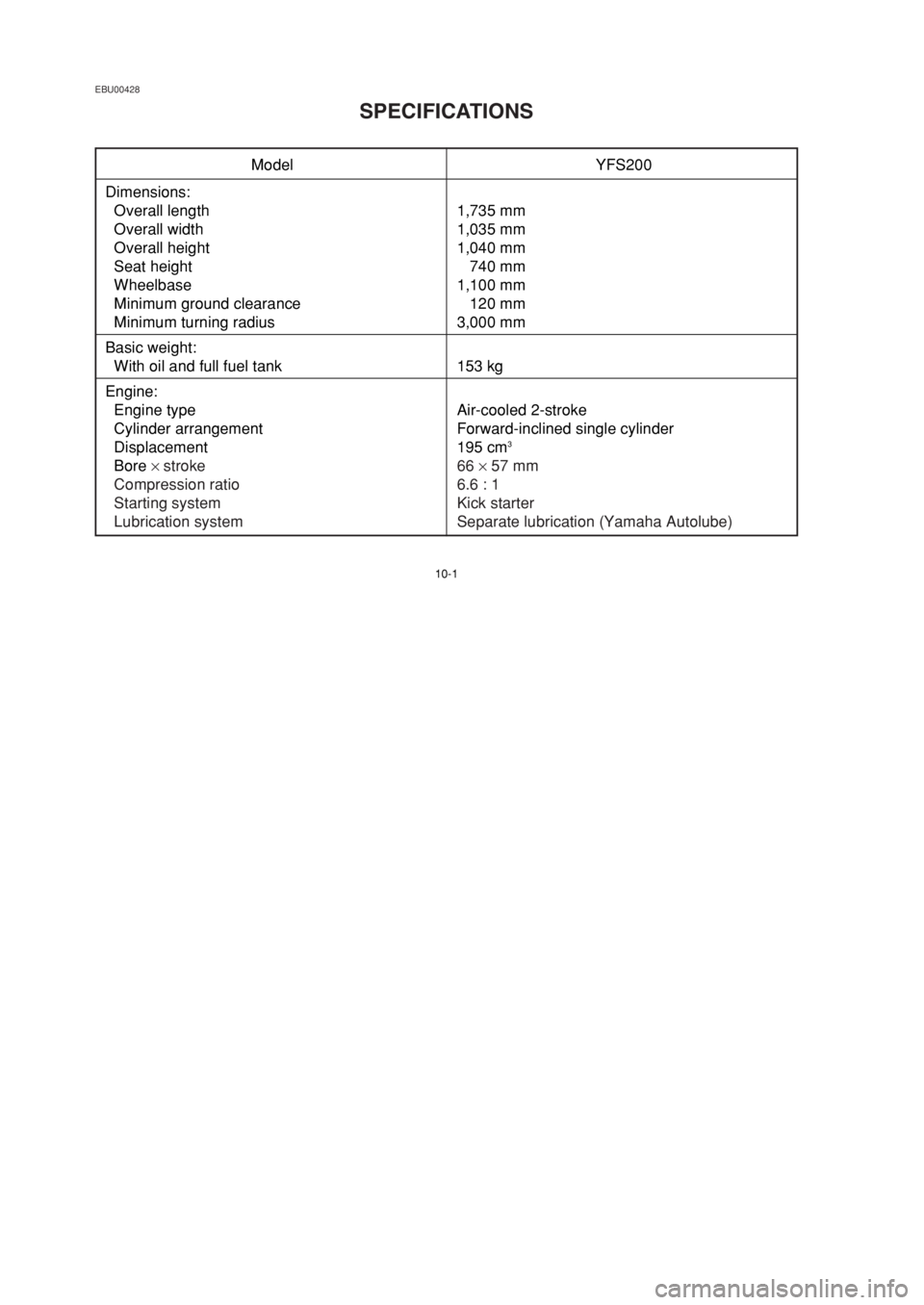

Model YFS200

Dimensions:

Overall length 1,735 mm

Overall width 1,035 mm

Overall height 1,040 mm

Seat height 740 mm

Wheelbase 1,100 mm

Minimum ground clearance 120 mm

Minimum turning radius 3,000 mm

Basic weight:

With oil and full fuel tank 153 kg

Engine:

Engine type Air-cooled 2-stroke

Cylinder arrangement Forward-inclined single cylinder

Displacement 195 cm

3

Bore × stroke 66 ×57 mm

Compression ratio 6.6 : 1

Starting system Kick starter

Lubrication system Separate lubrication (Yamaha Autolube)

EBU00428

SPECIFICATIONS

5KJ-62 (9 shou ~) 4/23/01 3:09 PM Page 12

Page 353 of 368

10-5

Model YFS200

Suspension:

Front suspension Double wishbone

Rear suspension Swingarm (monocross)

Shock absorber:

Front shock absorber Coil spring/Oil damper

Rear shock absorber Coil spring/Gas-oil damper

Wheel travel:

Front wheel travel 180 mm

Rear wheel travel 180 mm

Electrical:

Ignition system C.D.I.

Generator system C.D.I. magneto

Headlight type: Bulb type

Bulb voltage, wattage ×quantity:

Headlight 12V, 45 W/45 W ×1

Tail/brake light 12V, 5/21 W ×1

Indicator light:

Oil level 12V, 3.4 W ×1

5KJ-62 (9 shou ~) 4/23/01 3:09 PM Page 16