engine YAMAHA CYGNUS 125 2005 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: CYGNUS 125, Model: YAMAHA CYGNUS 125 2005Pages: 76, PDF Size: 1.28 MB

Page 47 of 76

6-13

1

2

3

4

5

6

7

8

9

PERIODIC MAINTENANCE AND MINOR REPAIR

ZAUM00**

1

1. V-belt case air filter element4. Apply oil of the recommended type

to the entire surface of the sponge

material, and then squeeze the ex-

cess oil out.NOTE:

The air filter element should be wet but

not dripping.

Recommended oil:

Engine oil

5. Insert the element into the air filter

case.

6. Install the filter element holder by

installing the screw.

EAU21300

Adjusting the carburetorThe carburetor is an important part of

the engine and requires very sophisti-

cated adjustment. Therefore, all carbu-

retor adjustments should be left to a

Yamaha dealer, who has the necessary

professional knowledge and experience. 7. Install the V-belt air filter case cover

by installing the screws.

5ML-F8199-E1ch6.pmd2004/10/04, 20:08 13

Page 48 of 76

6-14

1

2

3

4

5

6

7

8

9

PERIODIC MAINTENANCE AND MINOR REPAIR

EAU21370

Adjusting the throttle cable

free playThe throttle cable free play should mea-

sure 3~5 mm (0.12~0.20 in) at the

throttle grip. Periodically check the

throttle cable free play and, if necessary,

adjust it as follows.NOTE:

The engine idling speed must be cor-

rectly adjusted before checking and ad-

justing the throttle cable free play.1. Loosen the locknut.

2. To increase the throttle cable free

play, turn the adjusting nut in direc-

tion (a). To decrease the throttle

cable free play, turn the adjusting

nut in direction (b).

ZAUM00**

1

2

(a)

(b)

1. Locknut

1. Adjusting nut3. Tighten the locknut.

EAU21401

Valve clearanceThe valve clearance changes with use,

resulting in improper air-fuel mixture and/

or engine noise. To prevent this from

occurring, the valve clearance must be

adjusted by a Yamaha dealer at the in-

tervals specified in the periodic mainte-

nance and lubrication chart.

5ML-F8199-E1ch6.pmd2004/10/04, 20:08 14

Page 54 of 76

6-20

1

2

3

4

5

6

7

8

9

PERIODIC MAINTENANCE AND MINOR REPAIR

EAU22720

Changing the brake fluidHave a Yamaha dealer change the brake

fluid at the intervals specified in the

NOTE after the periodic maintenance

and lubrication chart. In addition, have

the oil seals of the brake master cylin-

der and caliper as well as the brake hose

replaced at the intervals listed below or

whenever they are damaged or leaking.

8Oil seals: Replace every two years.

8Brake hose: Replace every four

years.

EAU23100

Checking and lubricating the

cablesThe operation of all control cables and

the condition of the cables should be

checked before each ride, and the

cables and cable ends should be lubri-

cated if necessary. If a cable is dam-

aged or does not move smoothly, have

a Yamaha dealer check or replace it.

Recommended lubricant:

Engine oil

EWA10720

wDamage to the outer sheath may in-

terfere with proper cable operation

and will cause the inner cable to rust.

Replace a damaged cable as soon as

possible to prevent unsafe condi-

tions.

8As the brake pads wear, it is nor-

mal for the brake fluid level to

gradually go down. However, if the

brake fluid level goes down sud-

denly, have a Yamaha dealer check

the cause.

5ML-F8199-E1ch6.pmd2004/10/04, 20:08 20

Page 56 of 76

6-22

1

2

3

4

5

6

7

8

9

PERIODIC MAINTENANCE AND MINOR REPAIR

EAU23271

Checking the front forkThe condition and operation of the front

fork must be checked as follows at the

intervals specified in the periodic main-

tenance and lubrication chart.

To check the condition

EWA10750

wSecurely support the motorcycle so

that there is no danger of it falling

over.Check the inner tubes for scratches,

damage and excessive oil leakage.

To check the operation

1. Place the motorcycle on a level sur-

face and hold it in an upright posi-

tion.

2. While applying the front brake, push

down hard on the handlebars sev-

eral times to check if the front fork

compresses and rebounds

smoothly.

ZAUM00**

ECA10590

cCIf any damage is found or the front

fork does not operate smoothly, have

a Yamaha dealer check or repair it.

EAU23280

Checking the steeringWorn or loose steering bearings may

cause danger. Therefore, the operation

of the steering must be checked as fol-

lows at the intervals specified in the

periodic maintenance and lubrication

chart.

1. Place a stand under the engine to

raise the front wheel off the ground.

EWA10750

wSecurely support the motorcycle so

that there is no danger of it falling

over.2. Hold the lower ends of the front fork

legs and try to move them forward

and backward. If any free play can

be felt, have a Yamaha dealer check

or repair the steering.

5ML-F8199-E1ch6.pmd2004/10/04, 20:08 22

Page 64 of 76

6-30

1

2

3

4

5

6

7

8

9

PERIODIC MAINTENANCE AND MINOR REPAIR

EAU25901

Troubleshooting chart

EWA10840

wKeep away open flames and do not smoke while checking or working on the fuel system.Check the fuel level in

the fuel tank.1. Fuel

There is enough fuel.

There is no fuel.

Check the compression.

Supply fuel.

The engine does not start.

Check the compression.

Operate the electric starter.2. Compression

There is compression.

There is no compression.

Check the ignition.

Have a Yamaha dealer

check the vehicle.

Remove the spark plug

and check the electrodes.3. Ignition

Wipe off with a dry cloth and correct the

spark plug gap, or replace the spark plug.

Have a Yamaha dealer check the vehicle.

The engine does not start.

Have a Yamaha dealer

check the vehicle.

The engine does not start.

Check the battery.

Operate the electric starter.4. Battery

The engine turns over

quickly.

The engine turns over

slowly.

The battery is good.Check the battery lead connections,

and charge the battery if necessary.

DryWet

Open the throttle halfway and operate

the electric starter.

5ML-F8199-E1ch6.pmd2004/10/04, 20:08 30

Page 65 of 76

7-1

1

2

3

4

5

6

7

8

9

SCOOTER CARE AND STORAGE

EAU26090

CareWhile the open design of a scooter re-

veals the attractiveness of the technol-

ogy, it also makes it more vulnerable.

Rust and corrosion can develop even if

high-quality components are used. A

rusty exhaust pipe may go unnoticed on

a car, however, it detracts from the over-

all appearance of a scooter. Frequent and

proper care does not only comply with

the terms of the warranty, but it will also

keep your scooter looking good, extend

its life and optimize its performance.

Before cleaning

1. Cover the muffler outlet with a plas-

tic bag after the engine has cooled

down.

2. Make sure that all caps and cov-

ers as well as all electrical couplers

and connectors, including the spark

plug cap, are tightly installed.

3. Remove extremely stubborn dirt,

like oil burnt onto the crankcase,

with a degreasing agent and a

brush, but never apply such prod-ucts onto seals, gaskets and wheel

axles. Always rinse the dirt and

degreaser off with water.

Cleaning

ECA10780

cC8 88 8

8Avoid using strong acidic wheel

cleaners, especially on spoked

wheels. If such products are used

on hard-to-remove dirt, do not

leave the cleaner on the affected

area any longer than instructed.

Also, thoroughly rinse the area

off with water, immediately dry

it, and then apply a corrosion

protection spray.

8 88 8

8Improper cleaning can damage

windshields, cowlings, panels

and other plastic parts. Use only

a soft, clean cloth or sponge with

mild detergent and water to clean

plastic.

8 88 8

8Do not use any harsh chemical

products on plastic parts. Be sure

to avoid using cloths or sponges

which have been in contact with

strong or abrasive cleaning prod-ucts, solvent or thinner, fuel

(gasoline), rust removers or in-

hibitors, brake fluid, antifreeze or

electrolyte.

8 88 8

8Do not use high-pressure wash-

ers or steam-jet cleaners since

they cause water seepage and

deterioration in the following ar-

eas: seals (of wheel and

swingarm bearings, fork and

brakes), electric components

(couplers, connectors, instru-

ments, switches and lights),

breather hoses and vents.

8 88 8

8For scooters equipped with a

windshield: Do not use strong

cleaners or hard sponges as they

will cause dulling or scratching.

Some cleaning compounds for

plastic may leave scratches on

the windshield. Test the product

on a small hidden part of the

windshield to make sure that it

does not leave any marks. If the

windshield is scratched, use a

quality plastic polishing com-

pound after washing.

EAU25990

SCOOTER CARE AND STORAGE

5ML-F8199-E1ch7.pmd2004/10/04, 20:09 1

Page 67 of 76

7-3

1

2

3

4

5

6

7

8

9

SCOOTER CARE AND STORAGE

8 88 8

8Avoid using abrasive polishing

compounds as they will wear

away the paint.NOTE:

Consult a Yamaha dealer for advice on

what products to use.

EAU26300

StorageShort-term

Always store your scooter in a cool, dry

place and, if necessary, protect it

against dust with a porous cover.

ECA10820

cC8 88 8

8Storing the scooter in a poorly

ventilated room or covering it

with a tarp, while it is still wet,

will allow water and humidity to

seep in and cause rust.

8 88 8

8To prevent corrosion, avoid

damp cellars, stables (because of

the presence of ammonia) and

areas where strong chemicals are

stored.Long-term

Before storing your scooter for several

months:

1. Follow all the instructions in the

“Care” section of this chapter.

2. Drain the carburetor float chamber

by loosening the drain bolt; this will

prevent fuel deposits from building

up. Pour the drained fuel into the

fuel tank.3. Fill up the fuel tank and add fuel

stabilizer (if available) to prevent the

fuel tank from rusting and the fuel

from deteriorating.

4. Perform the following steps to pro-

tect the cylinder, piston rings, etc.

from corrosion.

a. Remove the spark plug cap and

spark plug.

b. Pour a teaspoonful of engine oil

into the spark plug bore.

c. Install the spark plug cap onto

the spark plug, and then place

the spark plug on the cylinder

head so that the electrodes are

grounded. (This will limit spark-

ing during the next step.)

d. Turn the engine over several

times with the starter. (This will

coat the cylinder wall with oil.)

e. Remove the spark plug cap from

the spark plug, and then install

the spark plug and the spark plug

cap.

5ML-F8199-E1ch7.pmd2004/10/04, 20:09 3

Page 68 of 76

7-4

1

2

3

4

5

6

7

8

9

SCOOTER CARE AND STORAGE

EWA10950

wTo prevent damage or injury from

sparking, make sure to ground the

spark plug electrodes while turning

the engine over.5. Lubricate all control cables and the

pivoting points of all levers and

pedals as well as of the sidestand/

centerstand.

6. Check and, if necessary, correct

the tire air pressure, and then lift

the scooter so that both of its

wheels are off the ground. Alterna-

tively, turn the wheels a little every

month in order to prevent the tires

from becoming degraded in one

spot.

7. Cover the muffler outlet with a plas-

tic bag to prevent moisture from en-

tering it.

8. Remove the battery and fully charge

it. Store it in a cool, dry place and

charge it once a month. Do not store

the battery in an excessively cold

or warm place [less than 0 °C (30°F) or more than 30 °C (90 °F)]. For

more information on storing the

battery, see page 6-23.

NOTE:

Make any necessary repairs before stor-

ing the scooter.

5ML-F8199-E1ch7.pmd2004/10/04, 20:09 4

Page 69 of 76

8-1

1

2

3

4

5

6

7

8

9

SPECIFICATIONS

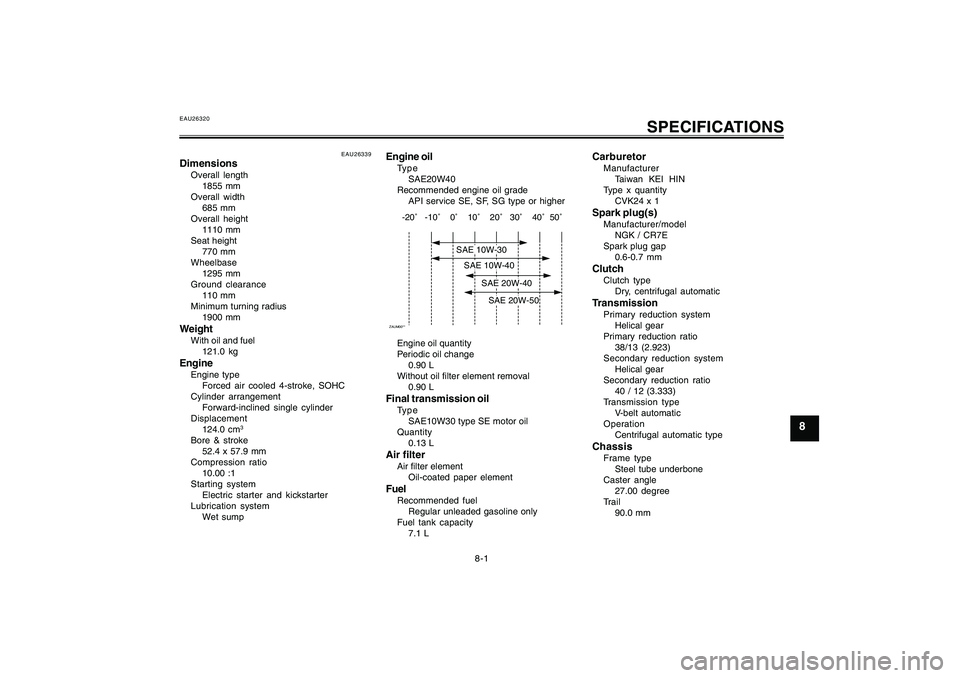

-20˚ -10˚ 0˚ 10˚ 20˚ 30˚ 40˚ 50˚

SAE 10W-30SAE 10W-40

SAE 20W-40SAE 20W-50

ZAUM00**

EAU26320

SPECIFICATIONS

EAU26339

DimensionsOverall length

1855 mm

Overall width

685 mm

Overall height

1110 mm

Seat height

770 mm

Wheelbase

1295 mm

Ground clearance

110 mm

Minimum turning radius

1900 mmWeightWith oil and fuel

121.0 kgEngineEngine type

Forced air cooled 4-stroke, SOHC

Cylinder arrangement

Forward-inclined single cylinder

Displacement

124.0 cm

3

Bore & stroke

52.4 x 57.9 mm

Compression ratio

10.00 :1

Starting system

Electric starter and kickstarter

Lubrication system

Wet sump

Engine oilType

SAE20W40

Recommended engine oil grade

API service SE, SF, SG type or higher

Engine oil quantity

Periodic oil change

0.90 L

Without oil filter element removal

0.90 LFinal transmission oilType

SAE10W30 type SE motor oil

Quantity

0.13 LAir filterAir filter element

Oil-coated paper elementFuelRecommended fuel

Regular unleaded gasoline only

Fuel tank capacity

7.1 L

CarburetorManufacturer

Taiwan KEI HIN

Type x quantity

CVK24 x 1Spark plug(s)Manufacturer/model

NGK / CR7E

Spark plug gap

0.6-0.7 mmClutchClutch type

Dry, centrifugal automaticTransmissionPrimary reduction system

Helical gear

Primary reduction ratio

38/13 (2.923)

Secondary reduction system

Helical gear

Secondary reduction ratio

40 / 12 (3.333)

Transmission type

V-belt automatic

Operation

Centrifugal automatic typeChassisFrame type

Steel tube underbone

Caster angle

27.00 degree

Trail

90.0 mm

5ML-F8199-E1ch8.pmd2004/10/04, 20:09 1

Page 74 of 76

1

2

3

4

5

6

7

8

9

INDEXAAcceleration and deceleration.................. 5-2

Air filter and V-belt case air filter

elements................................................6-11BBattery.....................................................6-23

Brake fluid level, checking ......................6-19

Brake fluid, changing ..............................6-20

Brake lever, front ...................................... 3-4

Brake lever, rear....................................... 3-4

Brake levers, lubricating.........................6-21

Brake pads and shoes, checking..........6-18

Braking...................................................... 5-2CCables, checking and lubricating ...........6-20

Carburetor,adjusting...............................6-13

Catalytic converter................................... 3-6

Centerstand and sidestand, checking and lu-

bricating.................................................6-21DDimmer switch.......................................... 3-4EEngine break-in ......................................... 5-3

Engine oil and oil strainer .......................... 6-8FFinal transmission oil ..............................6-10

Front brake lever free play, checking....6-17

Fuel........................................................... 3-6

Fuel consumption, tips for reducing ......... 5-3

Fuel gauge ................................................ 3-3

Fuel tank cap ............................................ 3-5

Fuses, replacing.....................................6-25

HHandlebar switches.................................. 3-3

Headlight bulb, replacing........................6-26

Helmet holder............................................ 3-8

High beam indicator light .......................... 3-2

Horn switch............................................... 3-4IIdentification numbers.............................. 9-1

Indicator lights........................................... 3-2KKey identification number......................... 9-1

Kickstarter................................................ 3-7LLuggage hook........................................... 3-9MMain switch/steering lock......................... 3-1

Model label................................................ 9-2PPanels, removing and installing................ 6-6

Parking...................................................... 5-4

Part locations............................................ 2-1

Periodic maintenance and lubrication

chart ........................................................ 6-3

Pre-operation check list........................... 4-2

Rear brake lever free play, adjusting .....6-18SSafe-riding points...................................... 1-4

Safety information..................................... 1-1

Seat ........................................................... 3-7

Sidestand................................................3-10

Sidestand switch operation check .........3-10Spark plug, checking................................ 6-7

Specifications............................................ 8-1

Speedometer unit..................................... 3-3

Start switch............................................... 3-4

Starting a cold engine ............................... 5-1

Starting off ................................................. 5-2

Storage...................................................... 7-3

Storage compartment............................... 3-8

TTail/brake light bulb, replacing ................6-27

Throttle cable free play, adjusting..........6-14

Throttle grip and cable, checking and lubricat-

ing ..........................................................6-21

Tires........................................................6-15

Tool kit ....................................................... 6-1

Troubleshooting......................................6-29

Troubleshooting chart.............................6-30

Turn signal indicator light.......................... 3-2

Turn signal light bulb (front), replacing ...6-28

Turn signal switch ..................................... 3-4VValve clearance......................................6-14

Vehicle identification number .................... 9-1WWheel bearings, checking ......................6-23

Wheels....................................................6-17

5ML-F8199-E1idx.pmd2004/10/05, 11:31 1