check engine YAMAHA FJR1300AE 2020 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2020, Model line: FJR1300AE, Model: YAMAHA FJR1300AE 2020Pages: 122, PDF Size: 3.93 MB

Page 59 of 122

Instrument and control functions

3-45

3

EAU15306

Sidestand

The sidestand is located on the left

side of the frame. Raise the sidestand

or lower it with your foot while holding

the vehicle upright.

TIP

The built-in sidestand switch is part of

the ignition circuit cut-off system,

which cuts the ignition in certain situa-

tions. (See the following section for an

explanation of the ignition circuit cut-

off system.)

WARNING

EWA10242

The vehicle must not be ridden with

the sidestand down, or if the side-

stand cannot be properly moved up

(or does not stay up), otherwise the

sidestand could contact the ground

and distract the operator, resulting

in a possible loss of control.

Yamaha’s ignition circuit cut-off

system has been designed to assist

the operator in fulfilling the respon-

sibility of raising the sidestand be-

fore starting off. Therefore, check

this system regularly and have a

Yamaha dealer repair it if it does not

function properly.

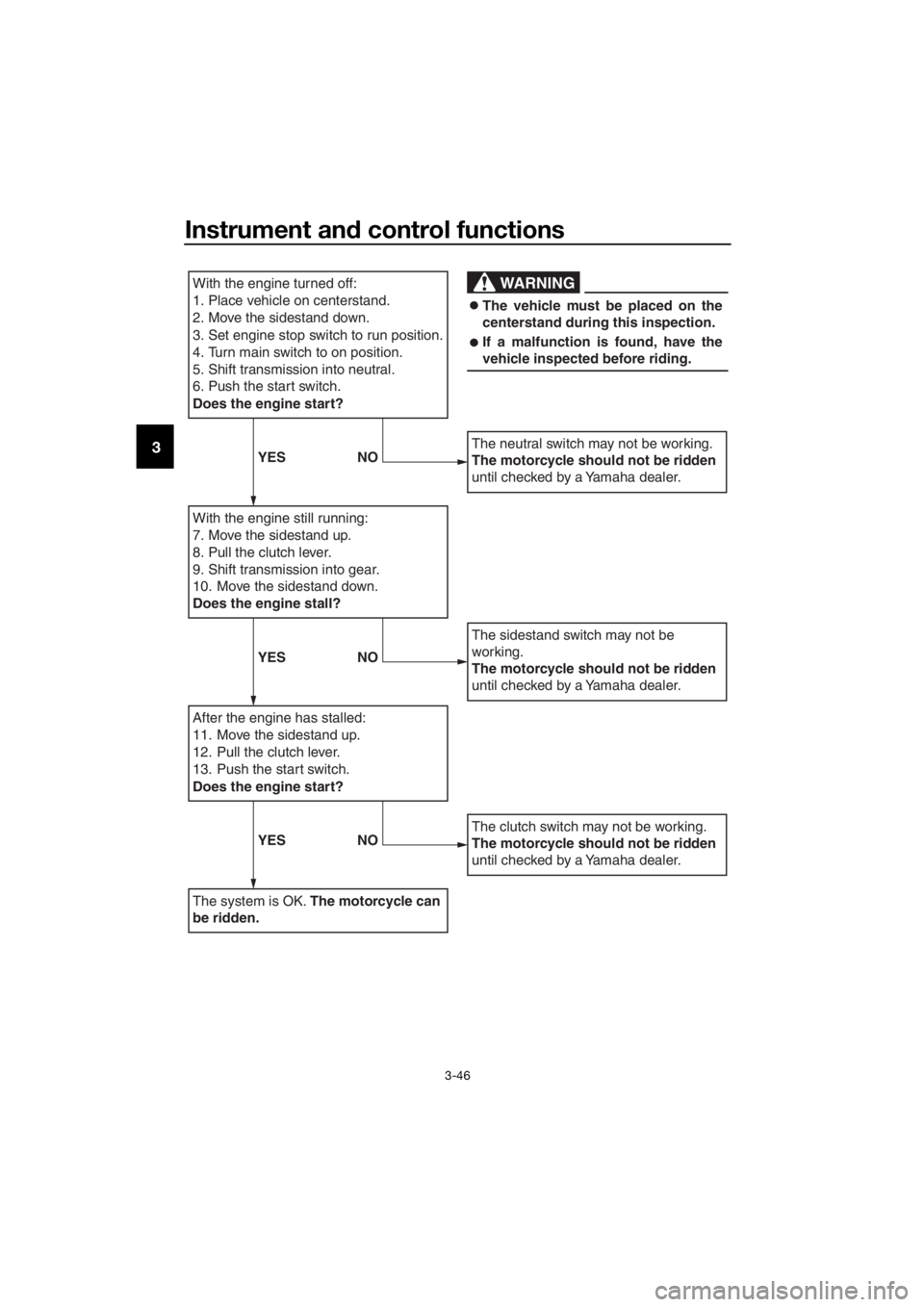

EAU63432

Ignition circuit cut-off system

This system prevents in-gear engine

starts unless the clutch lever is pulled

and the sidestand is up. Also, it will

stop the running engine should the

sidestand be lowered while the trans-

mission is in gear.

Periodically check the system via the

following procedure.

TIP

This check is most reliable if per-

formed with a warmed-up engine.

See pages 3-2 and 3-22 for switch

operation information.

UB96E2E0.book Page 45 Wednesday, September 18, 2019 10:21 AM

Page 60 of 122

Instrument and control functions

3-46

3

With the engine turned off:

1. Place vehicle on centerstand.

2. Move the sidestand down.

3.Set engine stop switch to run position.

4. Turn main switch to on position.

5.Shift transmission into neutral.

6. Push the start switch.

Does the engine start?

With the engine still running:

7. Move the sidestand up.

8. Pull the clutch lever.

9.Shift transmission into gear.

10. Move the sidestand down.

Does the engine stall?

After the engine has stalled:

11. Move the sidestand up.

12. Pull the clutch lever.

13. Push the start switch.

Does the engine start?

The system is OK. The motorcycle can

be ridden.

The neutral switch may not be working.

The motorcycle should not be ridden

until checked by a Yamaha dealer.

The sidestand switch may not be

working.

The motorcycle should not be ridden

until checked by a Yamaha dealer.

The clutch switch may not be working.

The motorcycle should not be ridden

until checked by a Yamaha dealer.

WARNING

YES NO

YES NO

YES NO

The vehicle must be placed on the

centerstand during this inspection.

If a malfunction is found, have the

vehicle inspected before riding. �z

�z

UB96E2E0.book Page 46 Wednesday, September 18, 2019 10:21 AM

Page 62 of 122

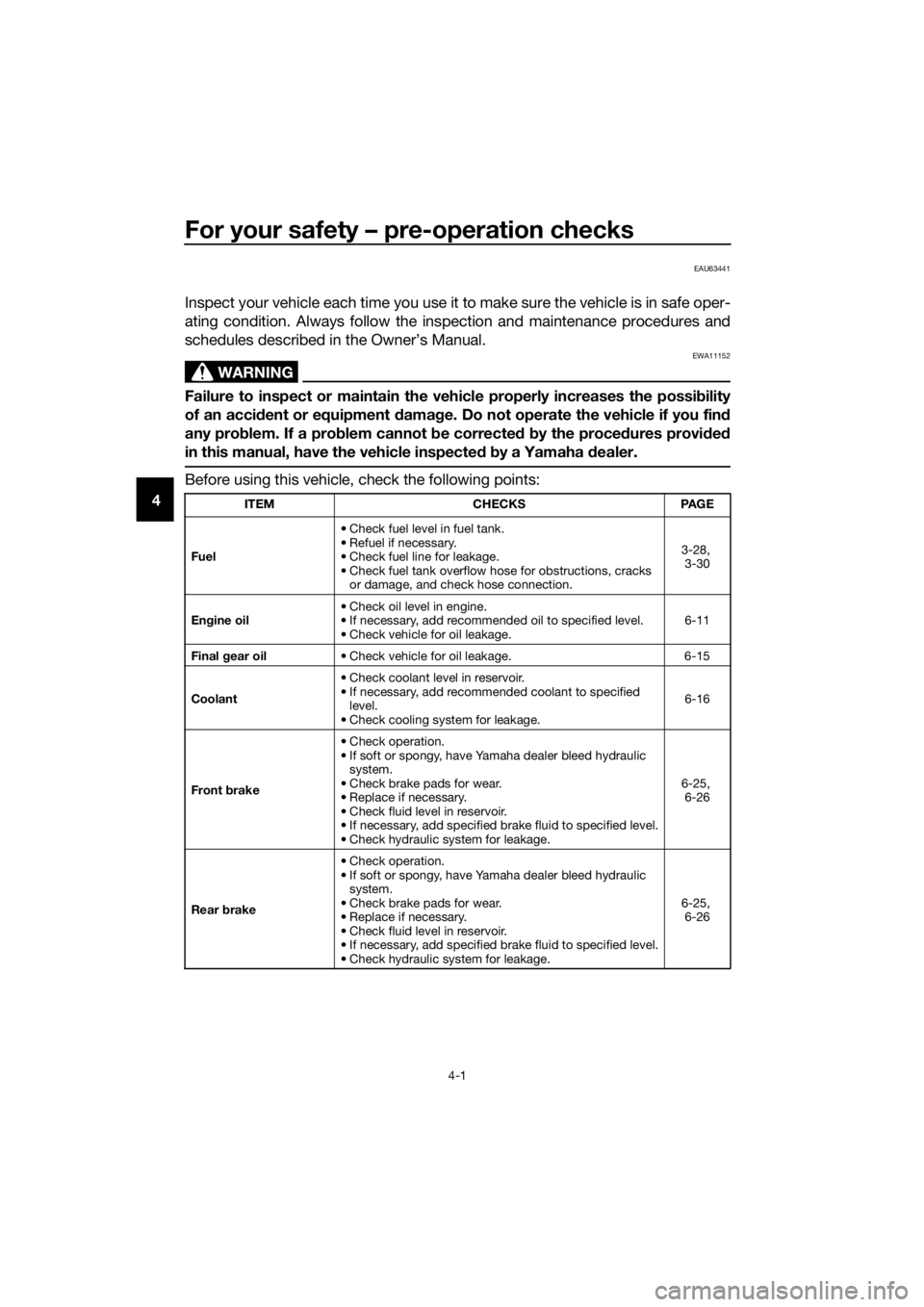

For your safety – pre-operation checks

4-1

4

EAU63441

Inspect your vehicle each time you use it to make sure the vehicle is in safe oper-

ating condition. Always follow the inspection and maintenance procedures and

schedules described in the Owner’s Manual.

WARNING

EWA11152

Failure to inspect or maintain the vehicle properly increases the possibility

of an accident or equipment damage. Do not operate the vehicle if you find

any problem. If a problem cannot be corrected by the procedures provided

in this manual, have the vehicle inspected by a Yamaha dealer.

Before using this vehicle, check the following points:

ITEM CHECKS PAGE

Fuel• Check fuel level in fuel tank.

• Refuel if necessary.

• Check fuel line for leakage.

• Check fuel tank overflow hose for obstructions, cracks

or damage, and check hose connection.3-28,

3-30

Engine oil• Check oil level in engine.

• If necessary, add recommended oil to specified level.

• Check vehicle for oil leakage.6-11

Final gear oil• Check vehicle for oil leakage. 6-15

Coolant• Check coolant level in reservoir.

• If necessary, add recommended coolant to specified

level.

• Check cooling system for leakage.6-16

Front brake• Check operation.

• If soft or spongy, have Yamaha dealer bleed hydraulic

system.

• Check brake pads for wear.

• Replace if necessary.

• Check fluid level in reservoir.

• If necessary, add specified brake fluid to specified level.

• Check hydraulic system for leakage.6-25,

6-26

Rear brake• Check operation.

• If soft or spongy, have Yamaha dealer bleed hydraulic

system.

• Check brake pads for wear.

• Replace if necessary.

• Check fluid level in reservoir.

• If necessary, add specified brake fluid to specified level.

• Check hydraulic system for leakage.6-25,

6-26

UB96E2E0.book Page 1 Wednesday, September 18, 2019 10:21 AM

Page 65 of 122

Operation and important riding points

5-2

5 If any engine trouble should oc-

cur during the engine break-in

period, immediately have a

Yamaha dealer check the vehi-

cle.

EAU86590

Starting the engine

The ignition circuit cut-off system will

enable starting when:

the transmission is in the neutral

position or

the transmission is in gear, the

sidestand is up, and the clutch le-

ver is pulled.

To start the engine

1. Turn the main switch on and set

the engine stop switch to the run

position.

2. Confirm the indicator and warning

light(s) come on for a few sec-

onds, and the go off. (See page

3-3.)

TIP

Do not start the engine if the en-

gine trouble warning light or the oil

level warning light remains on.

The ABS warning light should

come on and stay on until the ve-

hicle reaches a speed of 10 km/h

(6 mi/h).

NOTICE

ECA24110

If a warning or indicator light does

not work as described above, have a

Yamaha dealer check the vehicle.

3. Shift the transmission into the

neutral position.

4. Start the engine by pushing the

start switch.

5. Release the start switch when the

engine starts, or after 5 seconds.

Wait 10 seconds before pressing

the switch again to allow battery

voltage to restore.

UB96E2E0.book Page 2 Wednesday, September 18, 2019 10:21 AM

Page 72 of 122

Periodic maintenance and adjustment

6-3

6

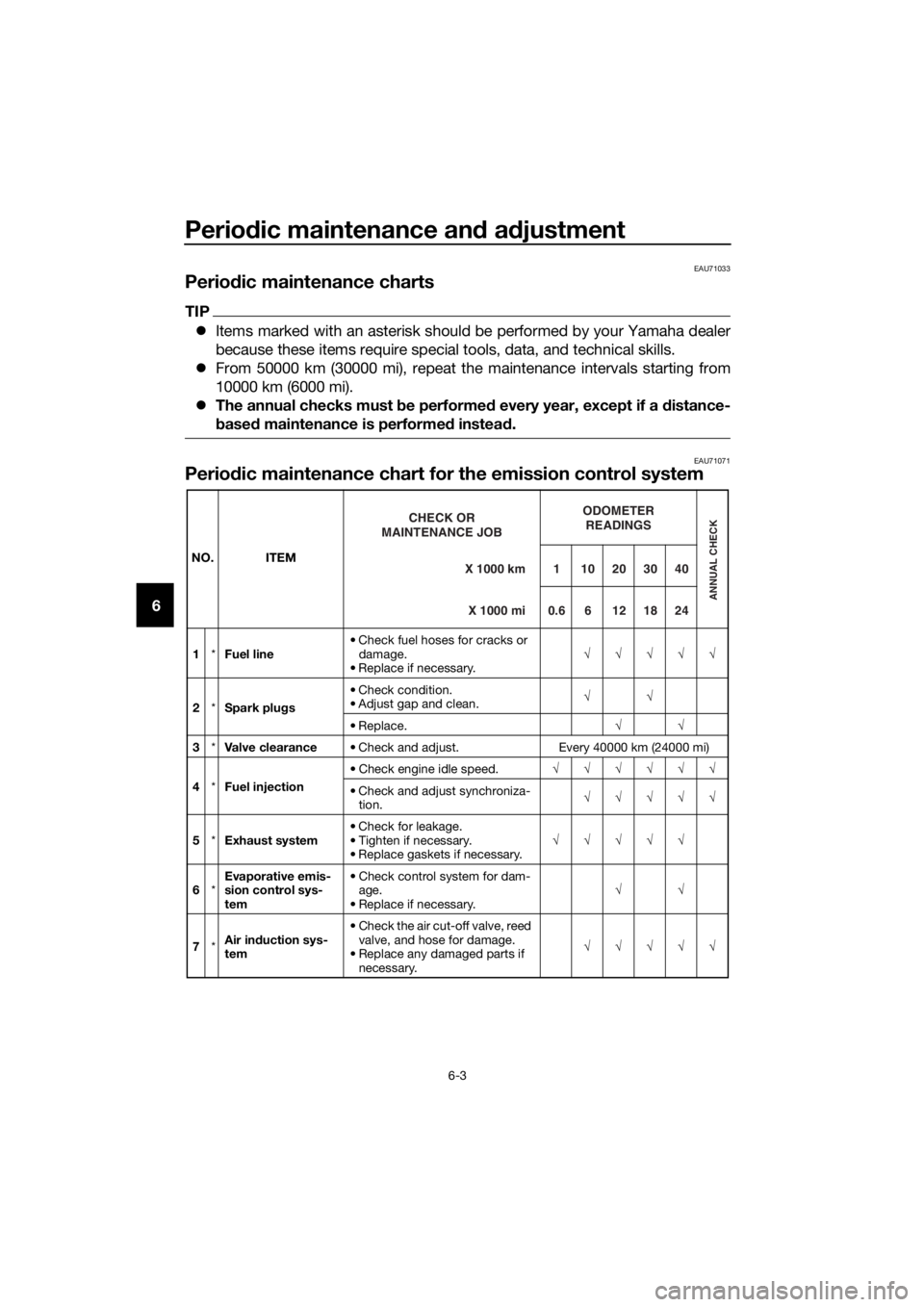

EAU71033

Periodic maintenance charts

TIP

Items marked with an asterisk should be performed by your Yamaha dealer

because these items require special tools, data, and technical skills.

From 50000 km (30000 mi), repeat the maintenance intervals starting from

10000 km (6000 mi).

The annual checks must be performed every year, except if a distance-

based maintenance is performed instead.

EAU71071

Periodic maintenance chart for the emission control system

NO. ITEM

1*Fuel line• Check fuel hoses for cracks or

damage.

• Replace if necessary.√√√√√

2*Spark plugs• Check condition.

• Adjust gap and clean.√√

• Replace.√√

3*Valve clearance• Check and adjust. Every 40000 km (24000 mi)

4*Fuel injection• Check engine idle speed.√√√√√√

• Check and adjust synchroniza-

tion.√√√√√

5*Exhaust system• Check for leakage.

• Tighten if necessary.

• Replace gaskets if necessary.√√√√√

6*Evaporative emis-

sion control sys-

tem• Check control system for dam-

age.

• Replace if necessary.√√

7*Air induction sys-

tem• Check the air cut-off valve, reed

valve, and hose for damage.

• Replace any damaged parts if

necessary.√√√√√X 1000 km CHECK OR

MAINTENANCE JOB

X 1000 miODOMETER

READINGS

ANNUAL CHECK

1 10203040

0.6 6 12 18 24

UB96E2E0.book Page 3 Wednesday, September 18, 2019 10:21 AM

Page 74 of 122

Periodic maintenance and adjustment

6-5

6

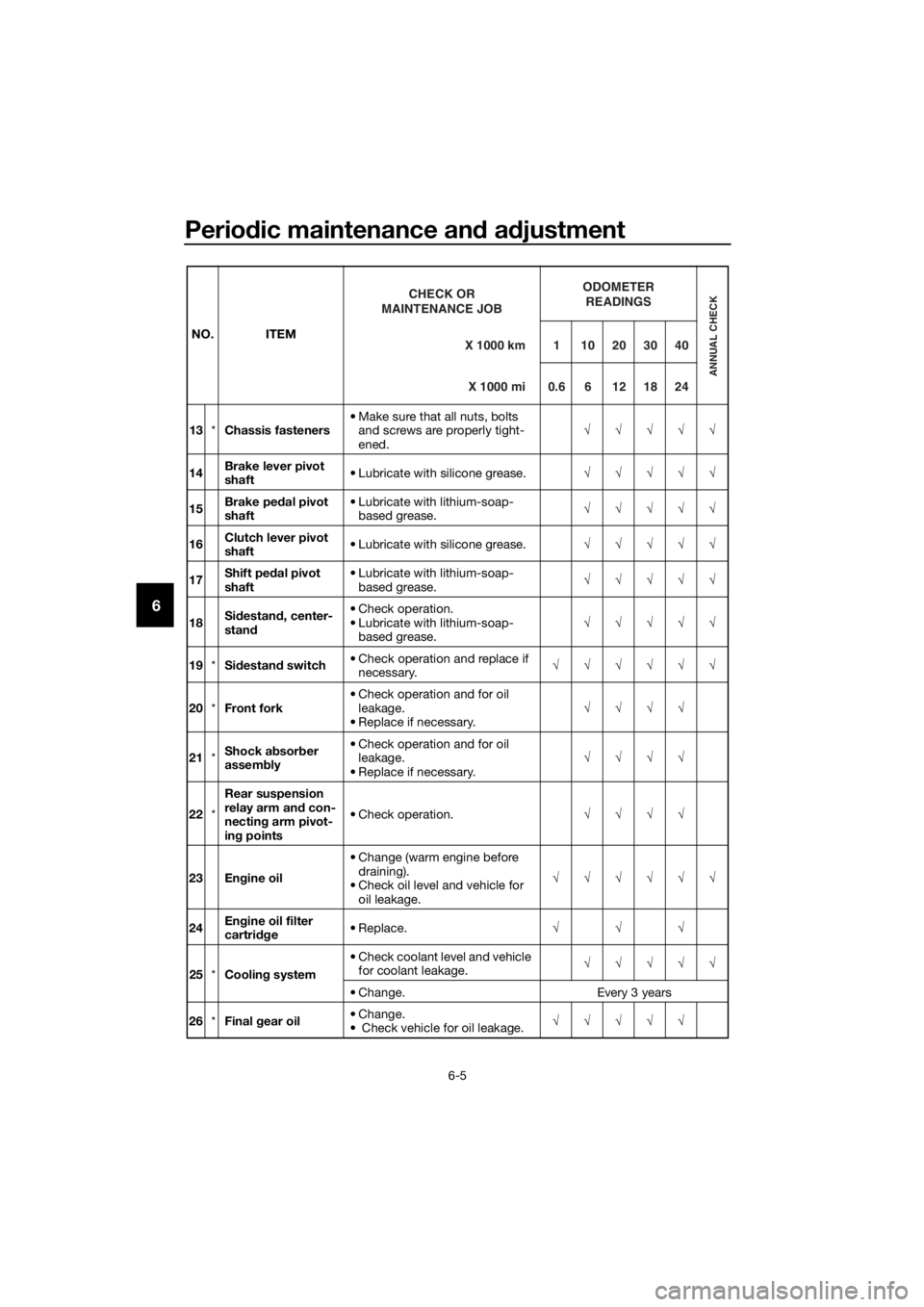

13*Chassis fasteners• Make sure that all nuts, bolts

and screws are properly tight-

ened.√√√√√

14Brake lever pivot

shaft• Lubricate with silicone grease.√√√√√

15Brake pedal pivot

shaft• Lubricate with lithium-soap-

based grease.√√√√√

16Clutch lever pivot

shaft• Lubricate with silicone grease.√√√√√

17Shift pedal pivot

shaft• Lubricate with lithium-soap-

based grease.√√√√√

18Sidestand, center-

stand• Check operation.

• Lubricate with lithium-soap-

based grease.√√√√√

19*Sidestand switch• Check operation and replace if

necessary.√√√√√√

20*Front fork• Check operation and for oil

leakage.

• Replace if necessary.√√√√

21*Shock absorber

assembly• Check operation and for oil

leakage.

• Replace if necessary.√√√√

22*Rear suspension

relay arm and con-

necting arm pivot-

ing points• Check operation.√√√√

23 Engine oil• Change (warm engine before

draining).

• Check oil level and vehicle for

oil leakage.√√√√√√

24Engine oil filter

cartridge• Replace.√√√

25*Cooling system• Check coolant level and vehicle

for coolant leakage.√√√√√

• Change. Every 3 years

26*Final gear oil• Change.

• Check vehicle for oil leakage.√√√√√ NO. ITEM

X 1000 km CHECK OR

MAINTENANCE JOB

X 1000 miODOMETER

READINGS

ANNUAL CHECK

110203040

0.6 6 12 18 24

UB96E2E0.book Page 5 Wednesday, September 18, 2019 10:21 AM

Page 79 of 122

Periodic maintenance and adjustment

6-10

6

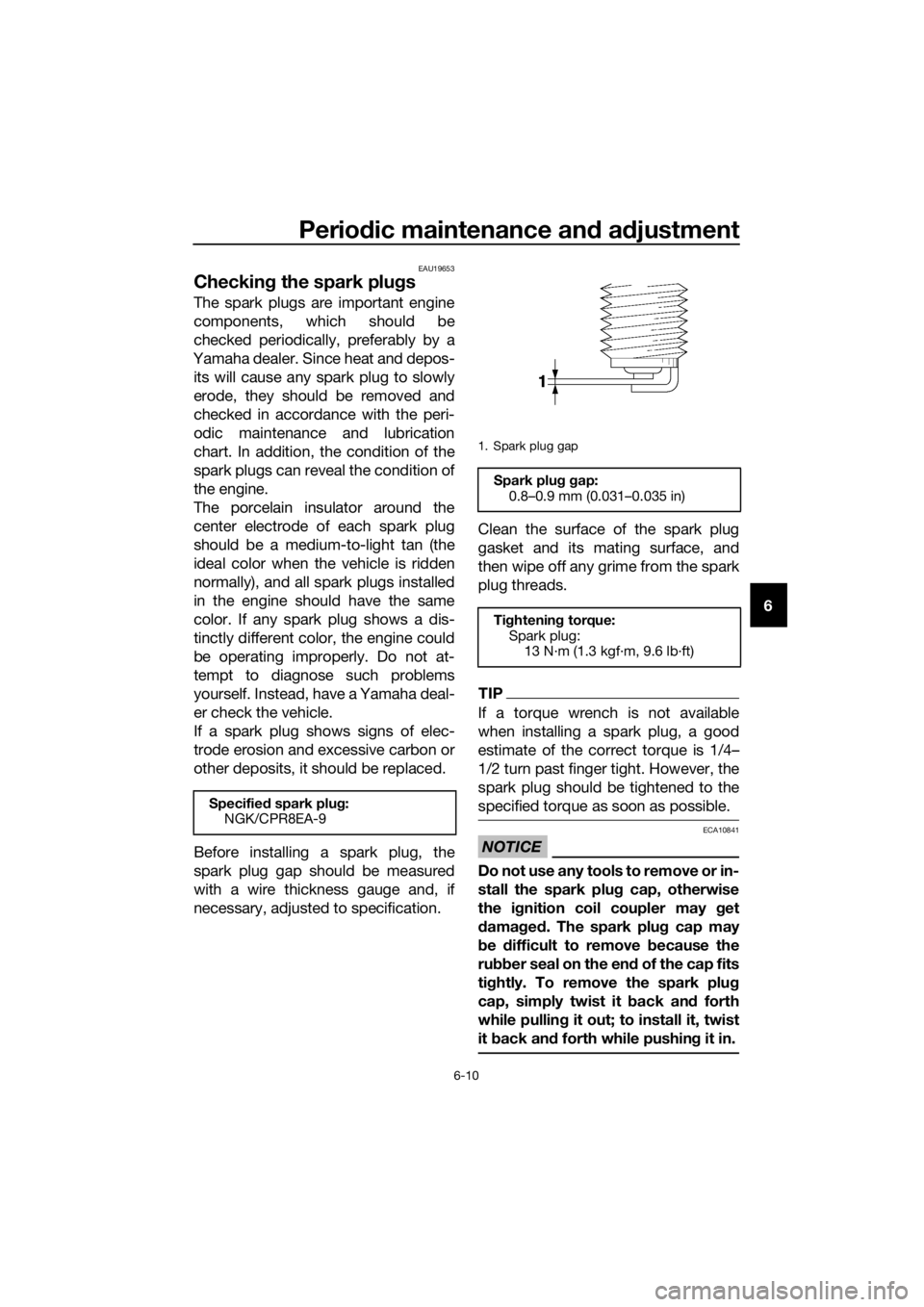

EAU19653

Checking the spark plugs

The spark plugs are important engine

components, which should be

checked periodically, preferably by a

Yamaha dealer. Since heat and depos-

its will cause any spark plug to slowly

erode, they should be removed and

checked in accordance with the peri-

odic maintenance and lubrication

chart. In addition, the condition of the

spark plugs can reveal the condition of

the engine.

The porcelain insulator around the

center electrode of each spark plug

should be a medium-to-light tan (the

ideal color when the vehicle is ridden

normally), and all spark plugs installed

in the engine should have the same

color. If any spark plug shows a dis-

tinctly different color, the engine could

be operating improperly. Do not at-

tempt to diagnose such problems

yourself. Instead, have a Yamaha deal-

er check the vehicle.

If a spark plug shows signs of elec-

trode erosion and excessive carbon or

other deposits, it should be replaced.

Before installing a spark plug, the

spark plug gap should be measured

with a wire thickness gauge and, if

necessary, adjusted to specification.Clean the surface of the spark plug

gasket and its mating surface, and

then wipe off any grime from the spark

plug threads.

TIP

If a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4…

1/2 turn past finger tight. However, the

spark plug should be tightened to the

specified torque as soon as possible.

NOTICE

ECA10841

Do not use any tools to remove or in-

stall the spark plug cap, otherwise

the ignition coil coupler may get

damaged. The spark plug cap may

be difficult to remove because the

rubber seal on the end of the cap fits

tightly. To remove the spark plug

cap, simply twist it back and forth

while pulling it out; to install it, twist

it back and forth while pushing it in.

Specified spark plug:

NGK/CPR8EA-9

1. Spark plug gap

Spark plug gap:

0.8–0.9 mm (0.031–0.035 in)

Tightening torque:

Spark plug:

13 N·m (1.3 kgf·m, 9.6 lb·ft)

UB96E2E0.book Page 10 Wednesday, September 18, 2019 10:21 AM

Page 80 of 122

Periodic maintenance and adjustment

6-11

6

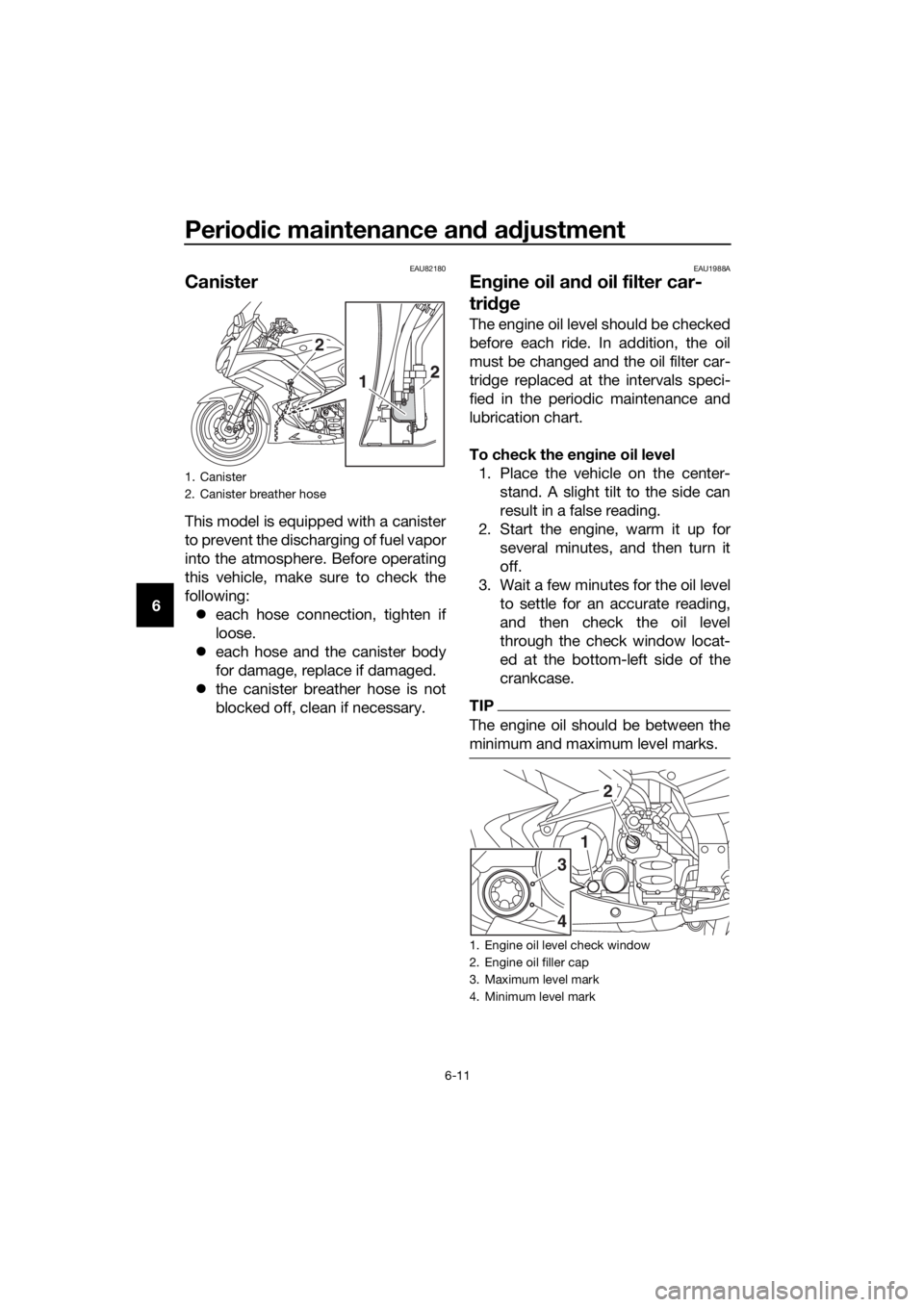

EAU82180

Canister

This model is equipped with a canister

to prevent the discharging of fuel vapor

into the atmosphere. Before operating

this vehicle, make sure to check the

following:

each hose connection, tighten if

loose.

each hose and the canister body

for damage, replace if damaged.

the canister breather hose is not

blocked off, clean if necessary.

EAU1988A

Engine oil and oil filter car-

tridge

The engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter car-

tridge replaced at the intervals speci-

fied in the periodic maintenance and

lubrication chart.

To check the engine oil level

1. Place the vehicle on the center-

stand. A slight tilt to the side can

result in a false reading.

2. Start the engine, warm it up for

several minutes, and then turn it

off.

3. Wait a few minutes for the oil level

to settle for an accurate reading,

and then check the oil level

through the check window locat-

ed at the bottom-left side of the

crankcase.

TIP

The engine oil should be between the

minimum and maximum level marks.

1. Canister

2. Canister breather hose

2121

2

1. Engine oil level check window

2. Engine oil filler cap

3. Maximum level mark

4. Minimum level mark

31

4

2

UB96E2E0.book Page 11 Wednesday, September 18, 2019 10:21 AM

Page 81 of 122

Periodic maintenance and adjustment

6-12

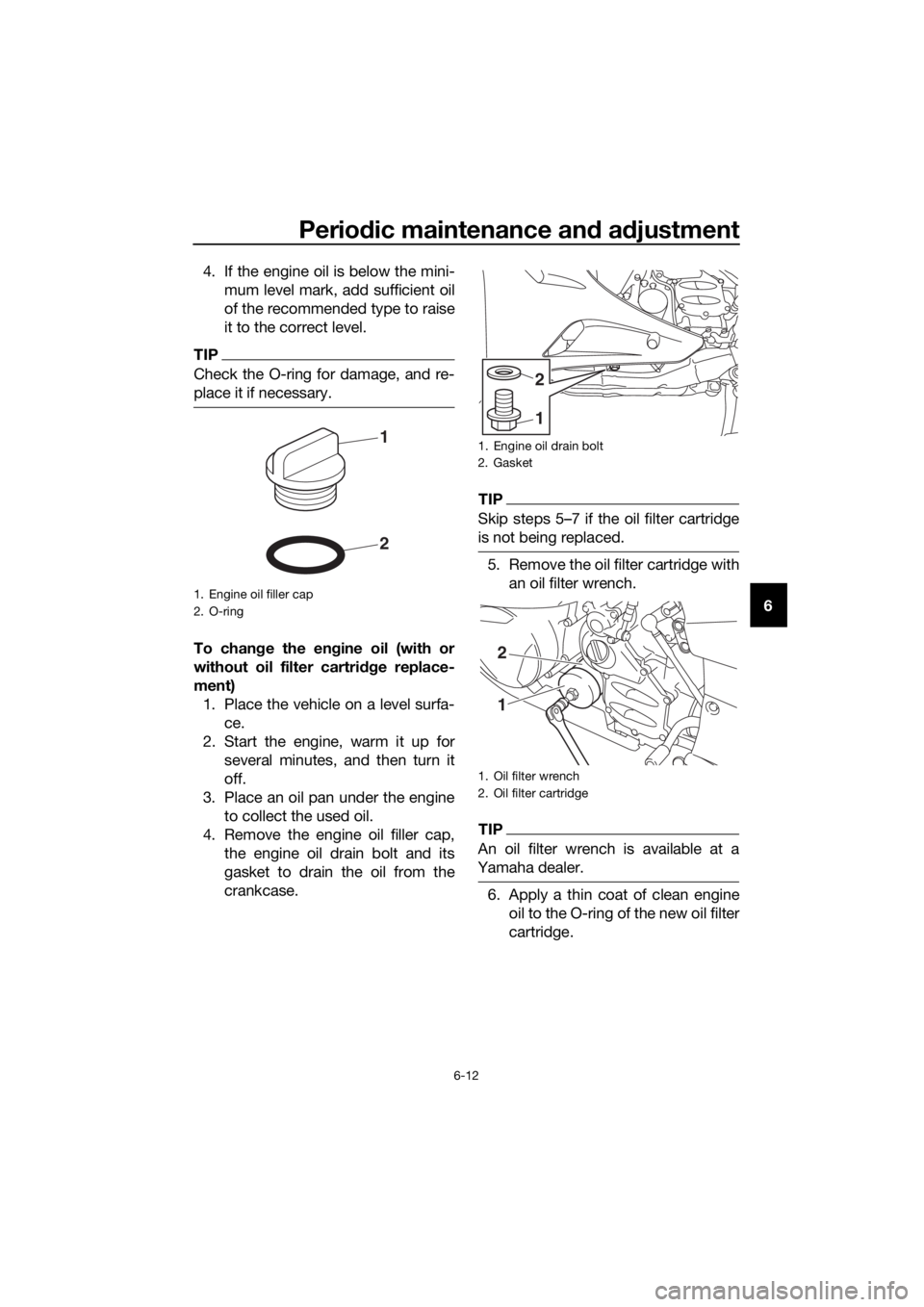

6 4. If the engine oil is below the mini-

mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.

TIP

Check the O-ring for damage, and re-

place it if necessary.

To change the engine oil (with or

without oil filter cartridge replace-

ment)

1. Place the vehicle on a level surfa-

ce.

2. Start the engine, warm it up for

several minutes, and then turn it

off.

3. Place an oil pan under the engine

to collect the used oil.

4. Remove the engine oil filler cap,

the engine oil drain bolt and its

gasket to drain the oil from the

crankcase.

TIP

Skip steps 5…7 if the oil filter cartridge

is not being replaced.

5. Remove the oil filter cartridge with

an oil filter wrench.

TIP

An oil filter wrench is available at a

Yamaha dealer.

6. Apply a thin coat of clean engine

oil to the O-ring of the new oil filter

cartridge.

1. Engine oil filler cap

2. O-ring

2

11. Engine oil drain bolt

2. Gasket

1. Oil filter wrench

2. Oil filter cartridge

1

2

1

2

UB96E2E0.book Page 12 Wednesday, September 18, 2019 10:21 AM

Page 82 of 122

Periodic maintenance and adjustment

6-13

6

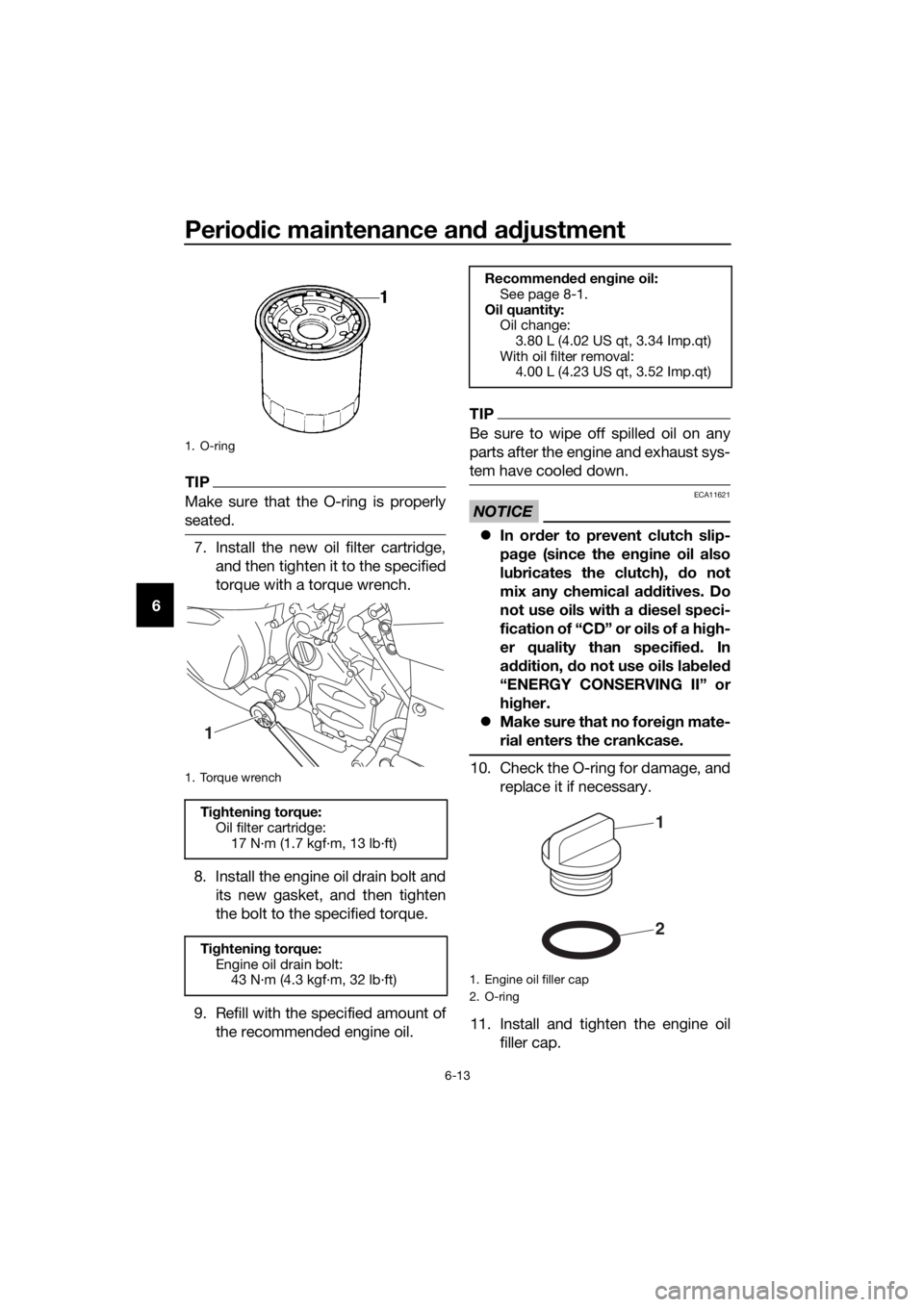

TIP

Make sure that the O-ring is properly

seated.

7. Install the new oil filter cartridge,

and then tighten it to the specified

torque with a torque wrench.

8. Install the engine oil drain bolt and

its new gasket, and then tighten

the bolt to the specified torque.

9. Refill with the specified amount of

the recommended engine oil.

TIP

Be sure to wipe off spilled oil on any

parts after the engine and exhaust sys-

tem have cooled down.

NOTICE

ECA11621

In order to prevent clutch slip-

page (since the engine oil also

lubricates the clutch), do not

mix any chemical additives. Do

not use oils with a diesel speci-

fication of “CD” or oils of a high-

er quality than specified. In

addition, do not use oils labeled

“ENERGY CONSERVING II” or

higher.

Make sure that no foreign mate-

rial enters the crankcase.

10. Check the O-ring for damage, and

replace it if necessary.

11. Install and tighten the engine oil

filler cap.

1. O-ring

1. Torque wrench

Tightening torque:

Oil filter cartridge:

17 N·m (1.7 kgf·m, 13 lb·ft)

Tightening torque:

Engine oil drain bolt:

43 N·m (4.3 kgf·m, 32 lb·ft)

1

Recommended engine oil:

See page 8-1.

Oil quantity:

Oil change:

3.80 L (4.02 US qt, 3.34 Imp.qt)

With oil filter removal:

4.00 L (4.23 US qt, 3.52 Imp.qt)

1. Engine oil filler cap

2. O-ring

2

1

UB96E2E0.book Page 13 Wednesday, September 18, 2019 10:21 AM