YAMAHA FX SHO 2012 Manual PDF

Manufacturer: YAMAHA, Model Year: 2012, Model line: FX SHO, Model: YAMAHA FX SHO 2012Pages: 116, PDF Size: 4.49 MB

Page 71 of 116

Pre-operation checks

65

EJU31981

WARNING

EWJ00411

Failure to inspect or maintain the watercraft properly increases the possibility of an ac-

cident or damage to the watercraft. Do not operate the watercraft if you find any prob-

lem. If a problem cannot be corrected by the procedures provided in this manual, have

the watercraft inspected by a Yamaha dealer.

EJU41232Pre-operation checklist

Before using this watercraft, be sure to perform the checks in the following checklist.

ITEM ROUTINE PAGE

PRE-LAUNCH CHECKS

Engine compartmentVentilate the engine compartment.

Check inside the engine compartment for damage.67

Fuel systemCheck the fuel system for leakage.

Check the fuel level in the fuel tank.67

Water separatorCheck the water separator for water. 67

Engine unitCheck the exterior of the engine unit for damage. 68

Engine oil levelCheck the engine oil level. 68

Bilge waterCheck the engine compartment for bilge water. 68

BatteryCheck the battery connections and electrolyte level. 68

Steering systemCheck the steering system for proper operation. 69

Adjustable tilt steering sys-

temCheck the adjustable tilt steering system for proper

operation and check that the handlebars are secure-

ly locked in place.70

Q.S.T.S.Check the Q.S.T.S. for proper operation and check

that the Q.S.T.S. selector is securely locked in place.70

Shift systemCheck the shift system for proper operation. 71

Throttle leverCheck the throttle lever for proper operation. 71

Remote control transmitterCheck the remote control transmitter for proper op-

eration.72

Engine shut-off cord (lan-

yard)Check the engine shut-off cord (lanyard) for dam-

age.72

SwitchesCheck the start switch, engine stop switch, and en-

gine shut-off switch for proper operation.72

Storage compartmentsCheck the storage compartments for damage and

water.72

Fire extinguisher holder,

cover, and bandCheck the fire extinguisher holder, cover, and band

for damage.73

Fire extinguisherCheck the condition of the fire extinguisher. 73

Safety equipmentCheck that safety equipment meeting the applicable

regulations is on board.73

Hull and deckCheck the hull and deck for damage. 73

UF2S70E0.book Page 65 Wednesday, December 7, 2011 3:56 PM

Page 72 of 116

Pre-operation checks

66

TIP:

To ensure safety and reliability, pre-operation checks should be made each time the watercraft

is used.

Jet intakeCheck the jet intake for damage and clogging. 73

Stern drain plugsCheck the stern drain plugs for damage and foreign

material and check that they are securely installed.73

HoodCheck that the hood is securely closed. 74

Front and rear seatsCheck that the seats are securely installed. 49

POST-LAUNCH CHECKS

Cooling water pilot outletCheck that water is discharged from the port (left)

cooling water pilot outlet while the engine is running.74

Multifunction information

centerCheck the multifunction information center for proper

operation.74

Engine idling speedCheck the engine idling speed. 74 ITEM ROUTINE PAGE

UF2S70E0.book Page 66 Wednesday, December 7, 2011 3:56 PM

Page 73 of 116

Pre-operation checks

67

EJU32281

Pre-operation check points EJU42380Pre-launch checks

Perform the pre-launch checks in the pre-op-

eration checklist while the watercraft is on

land.

To perform the pre-launch checks:

(1) Remove the seats and removable water-

tight storage compartment. (See page 49

for seat removal and installation proce-

dures and page 55 for information on the

removable watertight storage compart-

ment.)

(2) Perform the checks and make sure that

there are no malfunctioning items or oth-

er problems.

(3) After completing these checks, securely

install the removable watertight storage

compartment and seats in their original

positions.

EJU32333Engine compartment check

WARNING

EWJ00461

Failure to ventilate the engine compart-

ment could result in a fire or explosion. Do

not start the engine if there is a fuel leak.

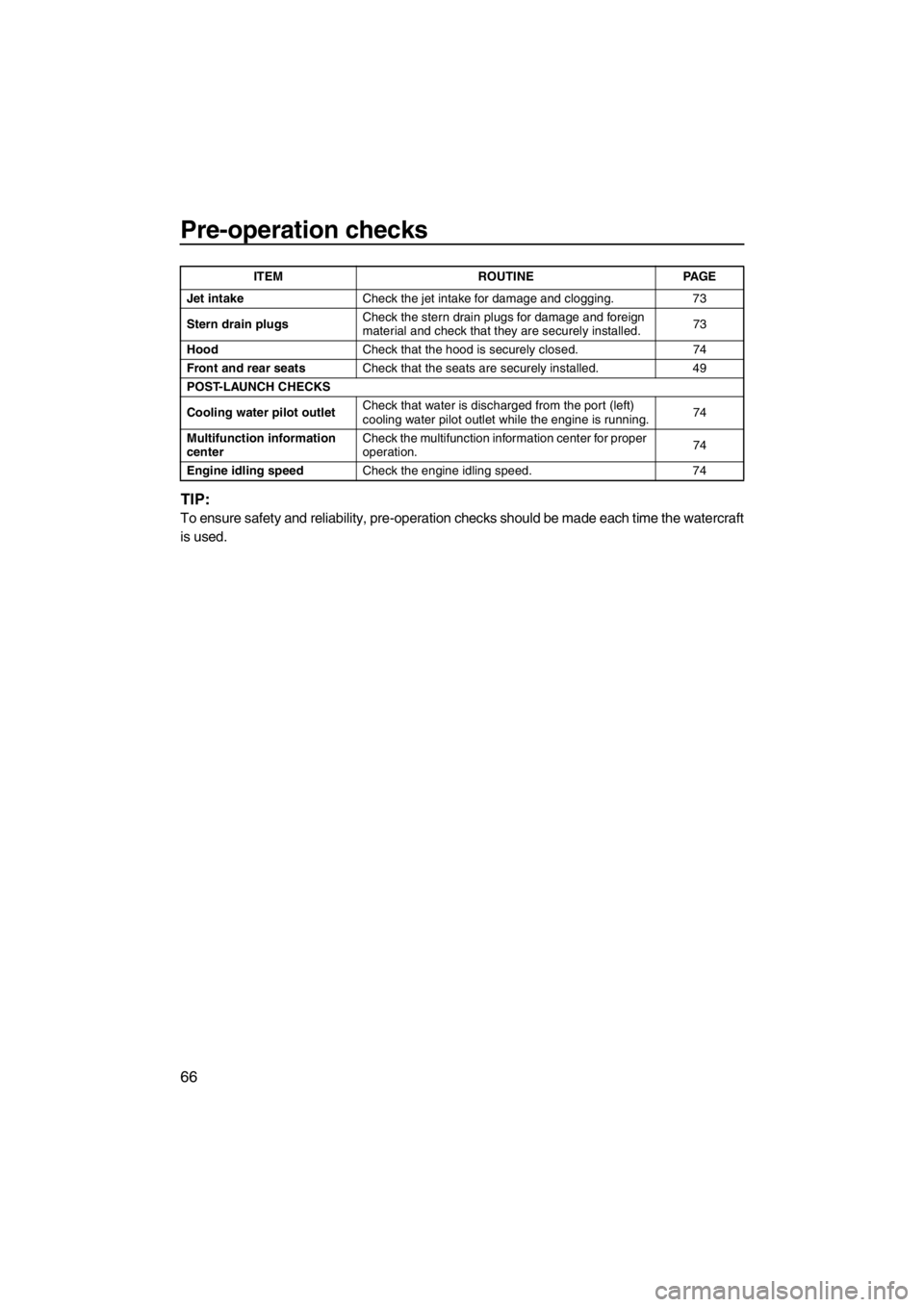

Ventilate the engine compartment. Leave the

engine compartment open for a few minutes

to allow any fuel vapors to escape.Make sure that there is no damage inside the

engine compartment.

EJU34214Fuel system checks

WARNING

EWJ00381

Leaking fuel can result in fire or explosion.

●Check for fuel leakage regularly.

●If any fuel leakage is found, the fuel sys-

tem must be repaired by a qualified me-

chanic. Improper repairs can make the

watercraft unsafe to operate.

Make sure that there is no damage, leakage,

or other problem in the fuel system.

Check:

●Fuel filler cap and seal for damage

●Fuel tank for damage and leakage

●Fuel hoses and joints for damage and leak-

age

●Fuel tank breather hose for damage and

leakage

EJU36874Fuel level check

Check the fuel level in the fuel tank.

Add fuel if necessary. (See page 58 for infor-

mation on filling the fuel tank.)

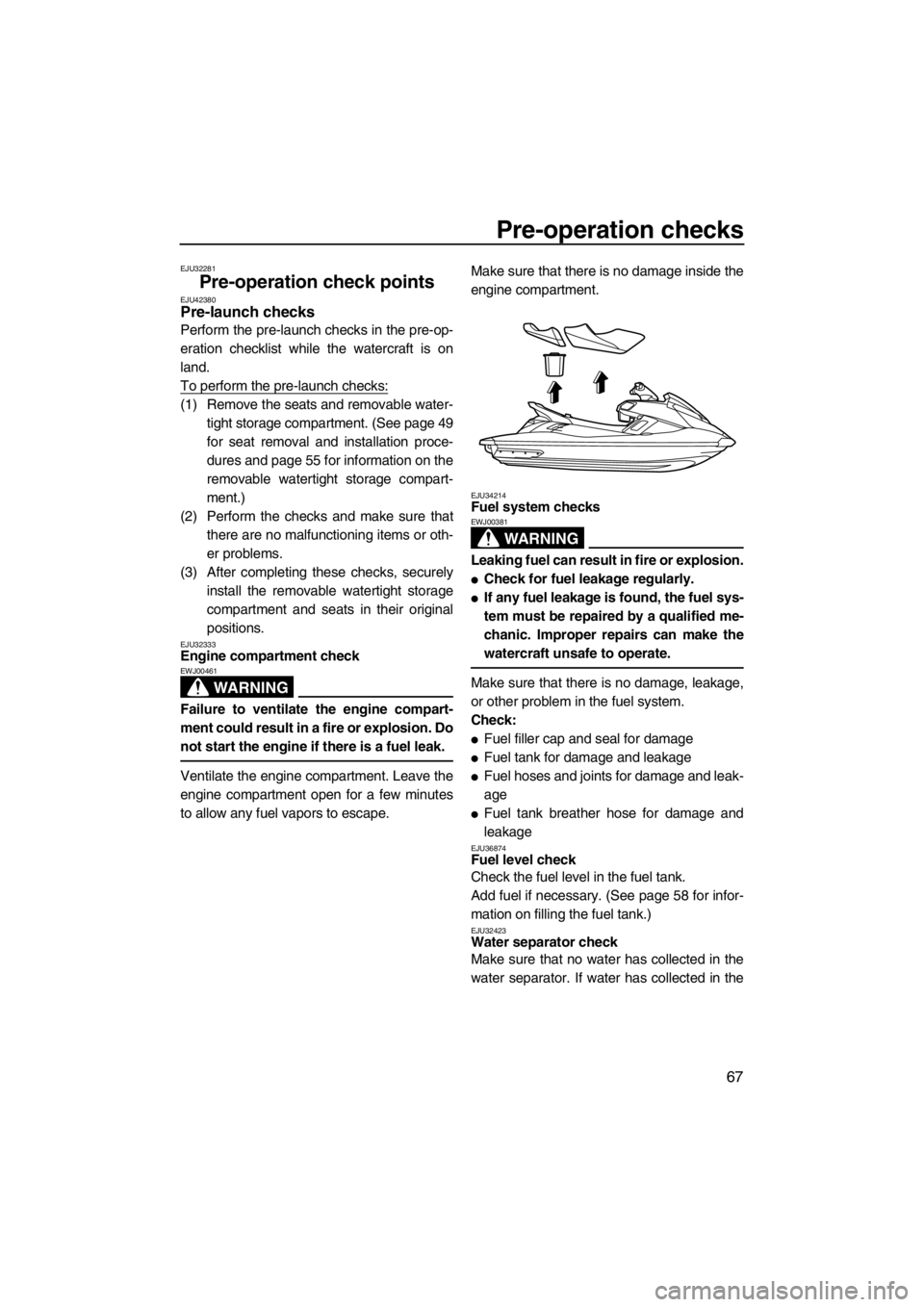

EJU32423Water separator check

Make sure that no water has collected in the

water separator. If water has collected in the

UF2S70E0.book Page 67 Wednesday, December 7, 2011 3:56 PM

Page 74 of 116

Pre-operation checks

68

water separator, drain it. (See page 31 for in-

formation on draining the water separator.)

EJU40181Engine unit check

Check the exterior of the engine unit for dam-

age or other problem.

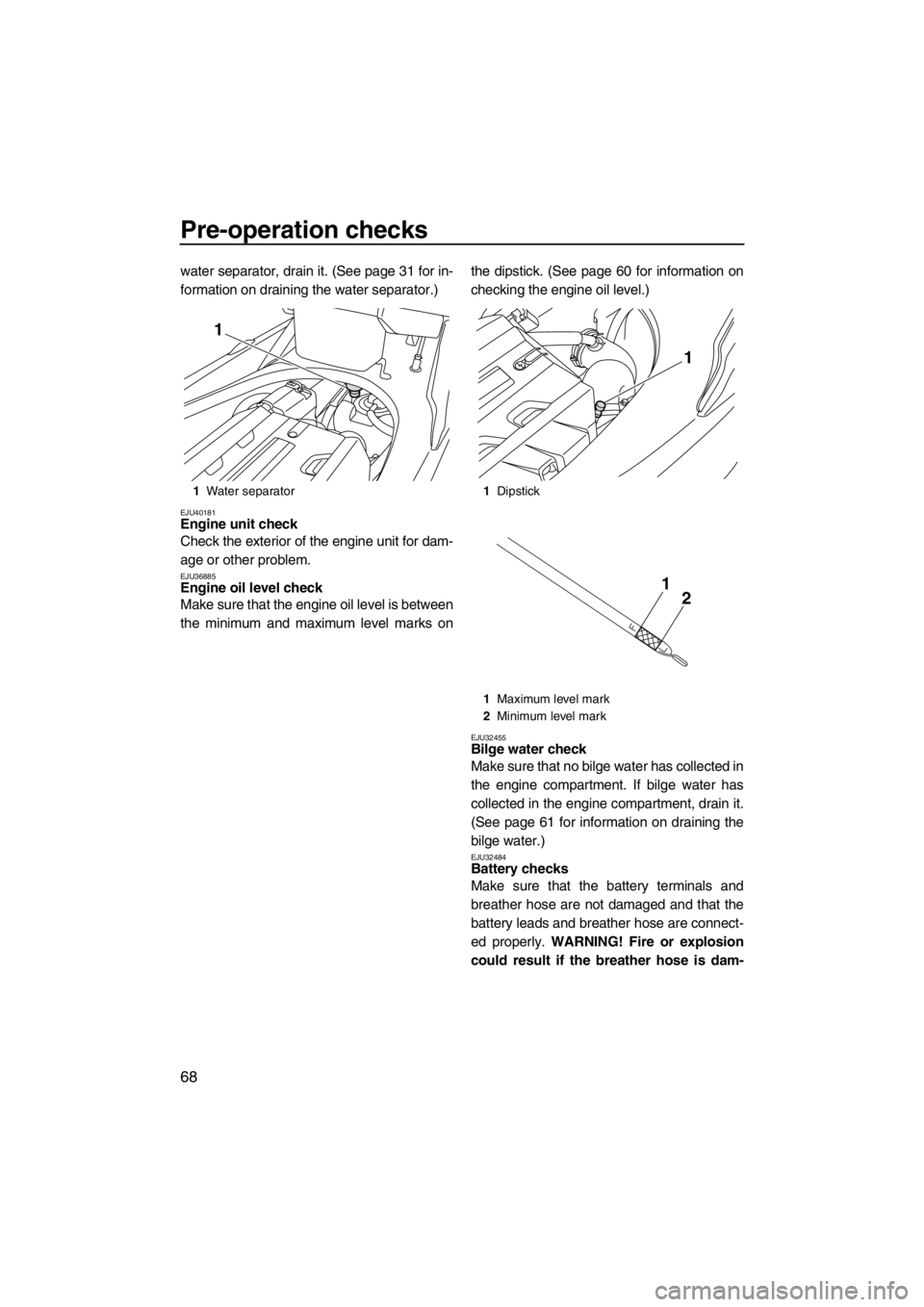

EJU36885Engine oil level check

Make sure that the engine oil level is between

the minimum and maximum level marks onthe dipstick. (See page 60 for information on

checking the engine oil level.)

EJU32455Bilge water check

Make sure that no bilge water has collected in

the engine compartment. If bilge water has

collected in the engine compartment, drain it.

(See page 61 for information on draining the

bilge water.)

EJU32484Battery checks

Make sure that the battery terminals and

breather hose are not damaged and that the

battery leads and breather hose are connect-

ed properly. WARNING! Fire or explosion

could result if the breather hose is dam-

1Water separator

1

1Dipstick

1Maximum level mark

2Minimum level mark

1

21

UF2S70E0.book Page 68 Wednesday, December 7, 2011 3:56 PM

Page 75 of 116

![YAMAHA FX SHO 2012 Manual PDF Pre-operation checks

69

aged, obstructed, or not connected prop-

erly.

[EWJ00451]

Make sure that the electrolyte level is be-

tween the minimum and maximum level

marks. WARNING! Never operate the wa- YAMAHA FX SHO 2012 Manual PDF Pre-operation checks

69

aged, obstructed, or not connected prop-

erly.

[EWJ00451]

Make sure that the electrolyte level is be-

tween the minimum and maximum level

marks. WARNING! Never operate the wa-](/img/51/49838/w960_49838-74.png)

Pre-operation checks

69

aged, obstructed, or not connected prop-

erly.

[EWJ00451]

Make sure that the electrolyte level is be-

tween the minimum and maximum level

marks. WARNING! Never operate the wa-

tercraft if the battery does not have suffi-

cient power to start the engine or if it

shows any other signs of decreased pow-

er. Loss of battery power may leave you

stranded.

[EWJ01240]

Make sure that the battery is securely held in

place.

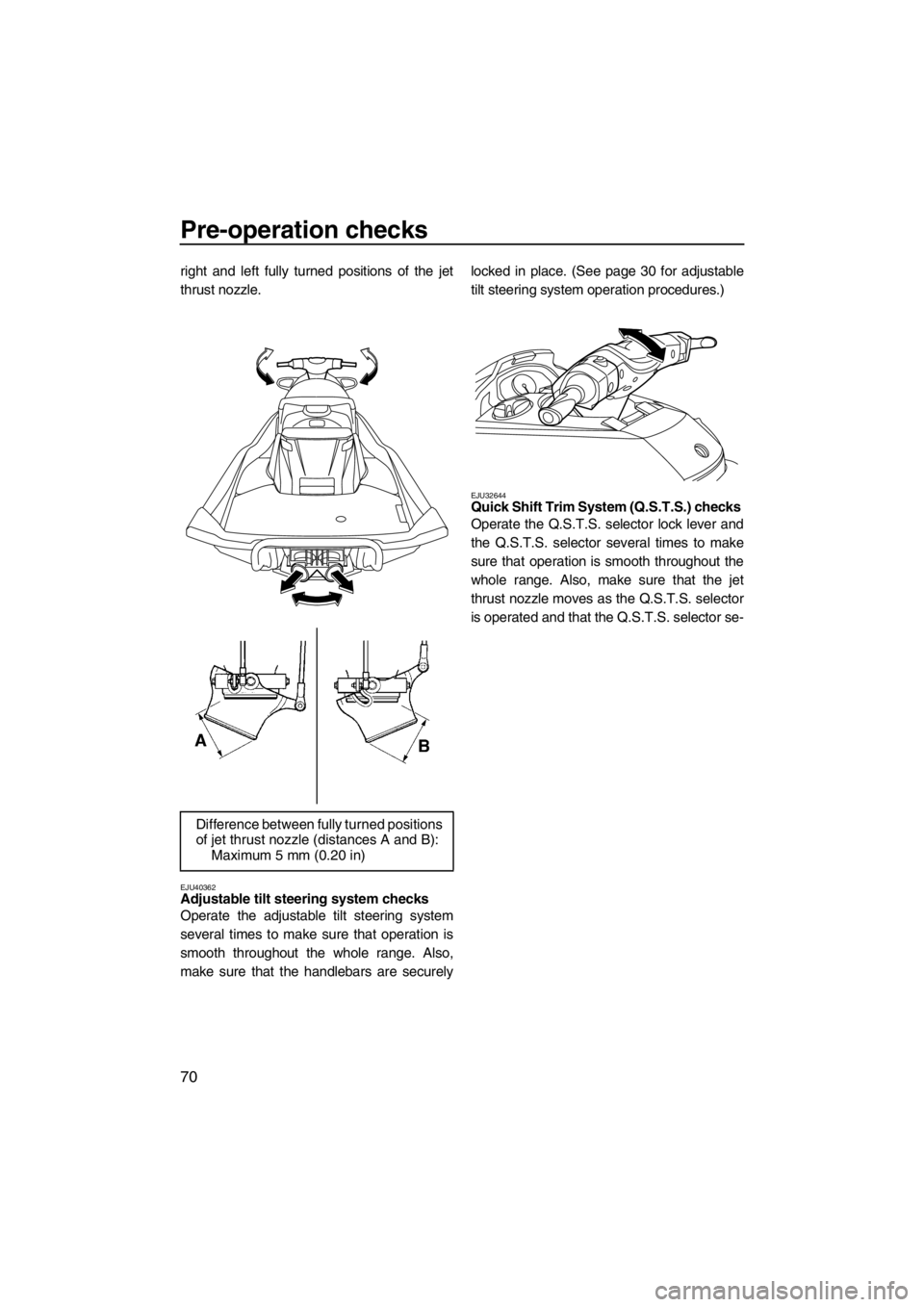

EJU32613Steering system checks

Turn the handlebars to the right and left sev-

eral times to make sure that operation is

smooth and unrestricted throughout thewhole range, and that the free play is not ex-

cessive.

Turn the handlebars as far as possible to the

right and left to make sure that the jet thrust

nozzle moves as the handlebars are turned,

and that there is no difference between the

1Breather hose

2Negative (–) battery terminal: Black lead

3Positive (+) battery terminal: Red lead

1Maximum level mark

2Minimum level mark

23

1

UF2S70E0.book Page 69 Wednesday, December 7, 2011 3:56 PM

Page 76 of 116

Pre-operation checks

70

right and left fully turned positions of the jet

thrust nozzle.

EJU40362Adjustable tilt steering system checks

Operate the adjustable tilt steering system

several times to make sure that operation is

smooth throughout the whole range. Also,

make sure that the handlebars are securelylocked in place. (See page 30 for adjustable

tilt steering system operation procedures.)

EJU32644Quick Shift Trim System (Q.S.T.S.) checks

Operate the Q.S.T.S. selector lock lever and

the Q.S.T.S. selector several times to make

sure that operation is smooth throughout the

whole range. Also, make sure that the jet

thrust nozzle moves as the Q.S.T.S. selector

is operated and that the Q.S.T.S. selector se-

Difference between fully turned positions

of jet thrust nozzle (distances A and B):

Maximum 5 mm (0.20 in)

UF2S70E0.book Page 70 Wednesday, December 7, 2011 3:56 PM

Page 77 of 116

Pre-operation checks

71

curely locks in place. (See page 33 for

Q.S.T.S. operation procedures.)

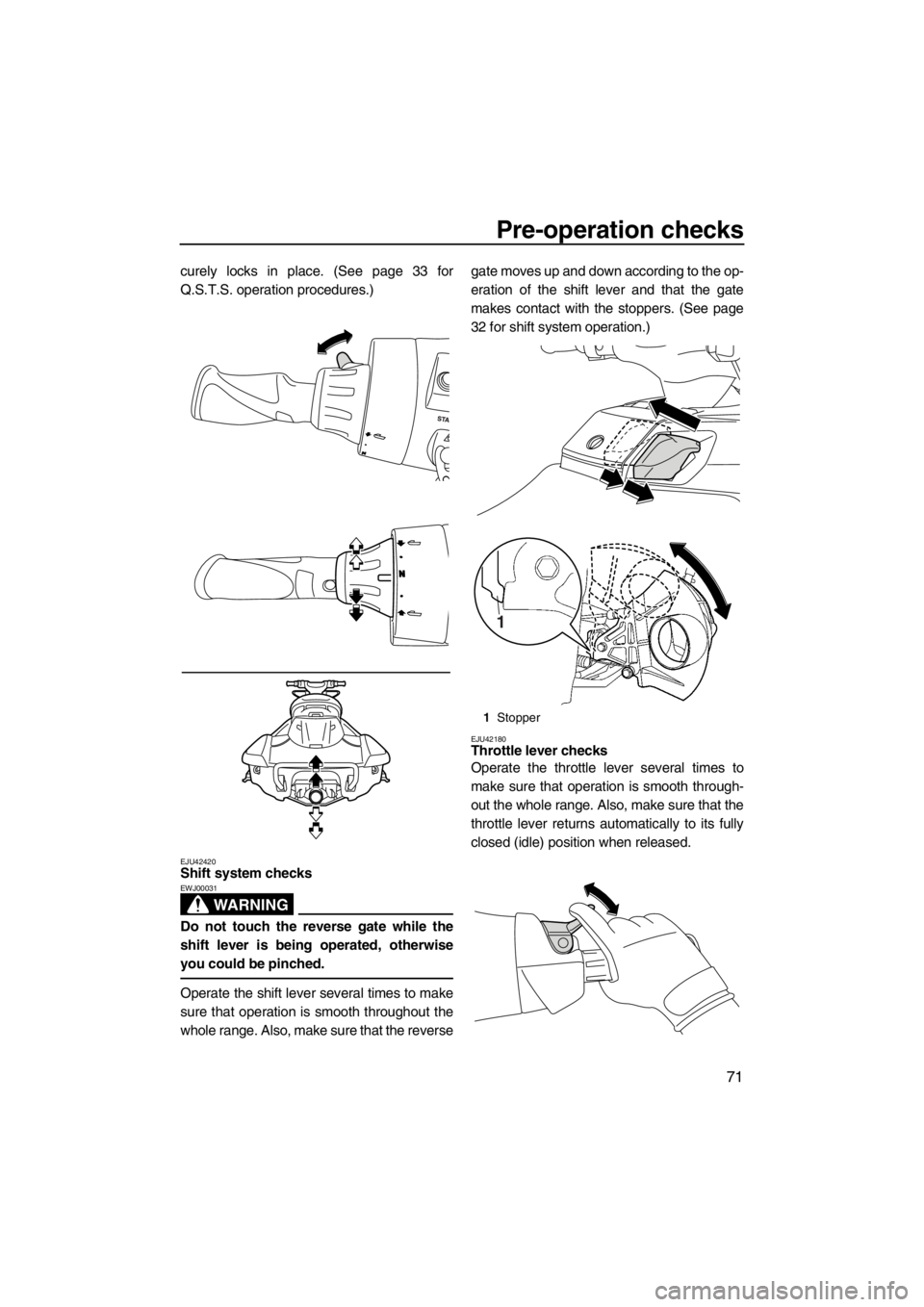

EJU42420Shift system checks

WARNING

EWJ00031

Do not touch the reverse gate while the

shift lever is being operated, otherwise

you could be pinched.

Operate the shift lever several times to make

sure that operation is smooth throughout the

whole range. Also, make sure that the reversegate moves up and down according to the op-

eration of the shift lever and that the gate

makes contact with the stoppers. (See page

32 for shift system operation.)

EJU42180Throttle lever checks

Operate the throttle lever several times to

make sure that operation is smooth through-

out the whole range. Also, make sure that the

throttle lever returns automatically to its fully

closed (idle) position when released.

1Stopper

1

UF2S70E0.book Page 71 Wednesday, December 7, 2011 3:56 PM

Page 78 of 116

Pre-operation checks

72

EJU40112Remote control transmitter check

Make sure that the remote control transmitter

operates properly. (See page 27 for Yamaha

Security System setting procedures and page

35 for Low RPM Mode activation procedures.)

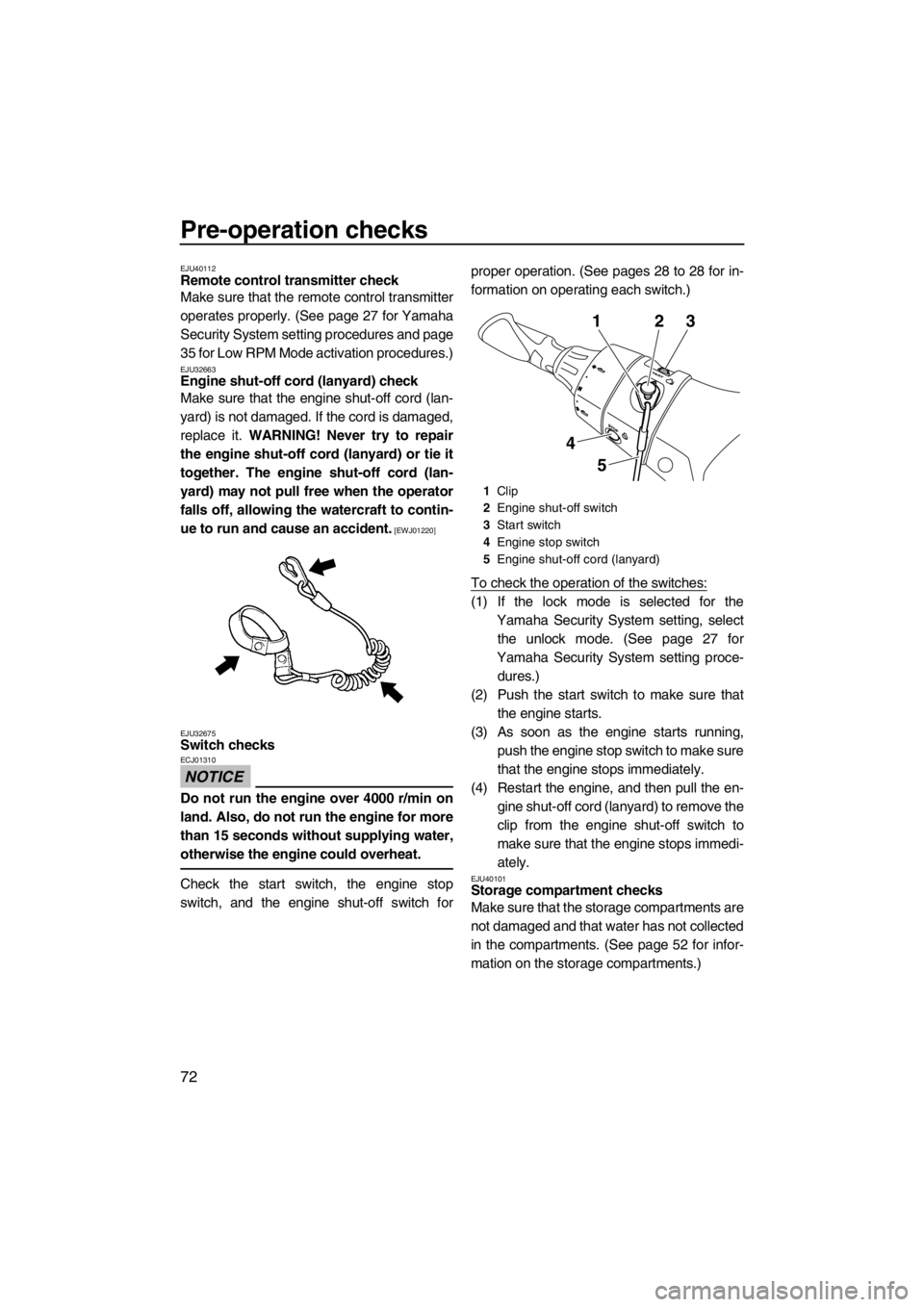

EJU32663Engine shut-off cord (lanyard) check

Make sure that the engine shut-off cord (lan-

yard) is not damaged. If the cord is damaged,

replace it. WARNING! Never try to repair

the engine shut-off cord (lanyard) or tie it

together. The engine shut-off cord (lan-

yard) may not pull free when the operator

falls off, allowing the watercraft to contin-

ue to run and cause an accident.

[EWJ01220]

EJU32675

Switch checks

NOTICE

ECJ01310

Do not run the engine over 4000 r/min on

land. Also, do not run the engine for more

than 15 seconds without supplying water,

otherwise the engine could overheat.

Check the start switch, the engine stop

switch, and the engine shut-off switch forproper operation. (See pages 28 to 28 for in-

formation on operating each switch.)

To check the operation of the switches:

(1) If the lock mode is selected for the

Yamaha Security System setting, select

the unlock mode. (See page 27 for

Yamaha Security System setting proce-

dures.)

(2) Push the start switch to make sure that

the engine starts.

(3) As soon as the engine starts running,

push the engine stop switch to make sure

that the engine stops immediately.

(4) Restart the engine, and then pull the en-

gine shut-off cord (lanyard) to remove the

clip from the engine shut-off switch to

make sure that the engine stops immedi-

ately.

EJU40101Storage compartment checks

Make sure that the storage compartments are

not damaged and that water has not collected

in the compartments. (See page 52 for infor-

mation on the storage compartments.)

1Clip

2Engine shut-off switch

3Start switch

4Engine stop switch

5Engine shut-off cord (lanyard)

132

5

4

UF2S70E0.book Page 72 Wednesday, December 7, 2011 3:56 PM

Page 79 of 116

Pre-operation checks

73

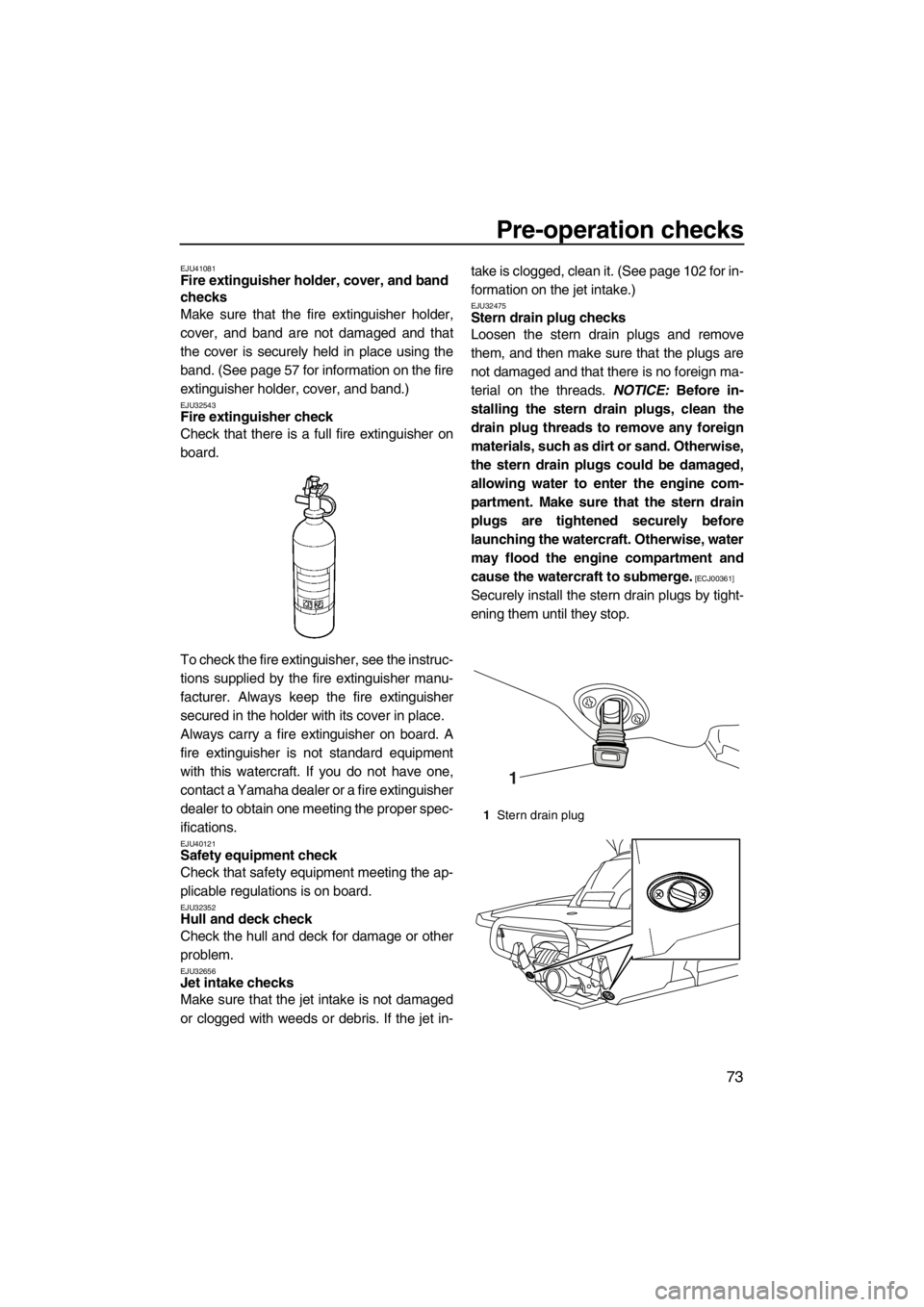

EJU41081Fire extinguisher holder, cover, and band

checks

Make sure that the fire extinguisher holder,

cover, and band are not damaged and that

the cover is securely held in place using the

band. (See page 57 for information on the fire

extinguisher holder, cover, and band.)

EJU32543Fire extinguisher check

Check that there is a full fire extinguisher on

board.

To check the fire extinguisher, see the instruc-

tions supplied by the fire extinguisher manu-

facturer. Always keep the fire extinguisher

secured in the holder with its cover in place.

Always carry a fire extinguisher on board. A

fire extinguisher is not standard equipment

with this watercraft. If you do not have one,

contact a Yamaha dealer or a fire extinguisher

dealer to obtain one meeting the proper spec-

ifications.

EJU40121Safety equipment check

Check that safety equipment meeting the ap-

plicable regulations is on board.

EJU32352Hull and deck check

Check the hull and deck for damage or other

problem.

EJU32656Jet intake checks

Make sure that the jet intake is not damaged

or clogged with weeds or debris. If the jet in-take is clogged, clean it. (See page 102 for in-

formation on the jet intake.)

EJU32475Stern drain plug checks

Loosen the stern drain plugs and remove

them, and then make sure that the plugs are

not damaged and that there is no foreign ma-

terial on the threads. NOTICE: Before in-

stalling the stern drain plugs, clean the

drain plug threads to remove any foreign

materials, such as dirt or sand. Otherwise,

the stern drain plugs could be damaged,

allowing water to enter the engine com-

partment. Make sure that the stern drain

plugs are tightened securely before

launching the watercraft. Otherwise, water

may flood the engine compartment and

cause the watercraft to submerge.

[ECJ00361]

Securely install the stern drain plugs by tight-

ening them until they stop.

1Stern drain plug

1

UF2S70E0.book Page 73 Wednesday, December 7, 2011 3:56 PM

Page 80 of 116

Pre-operation checks

74

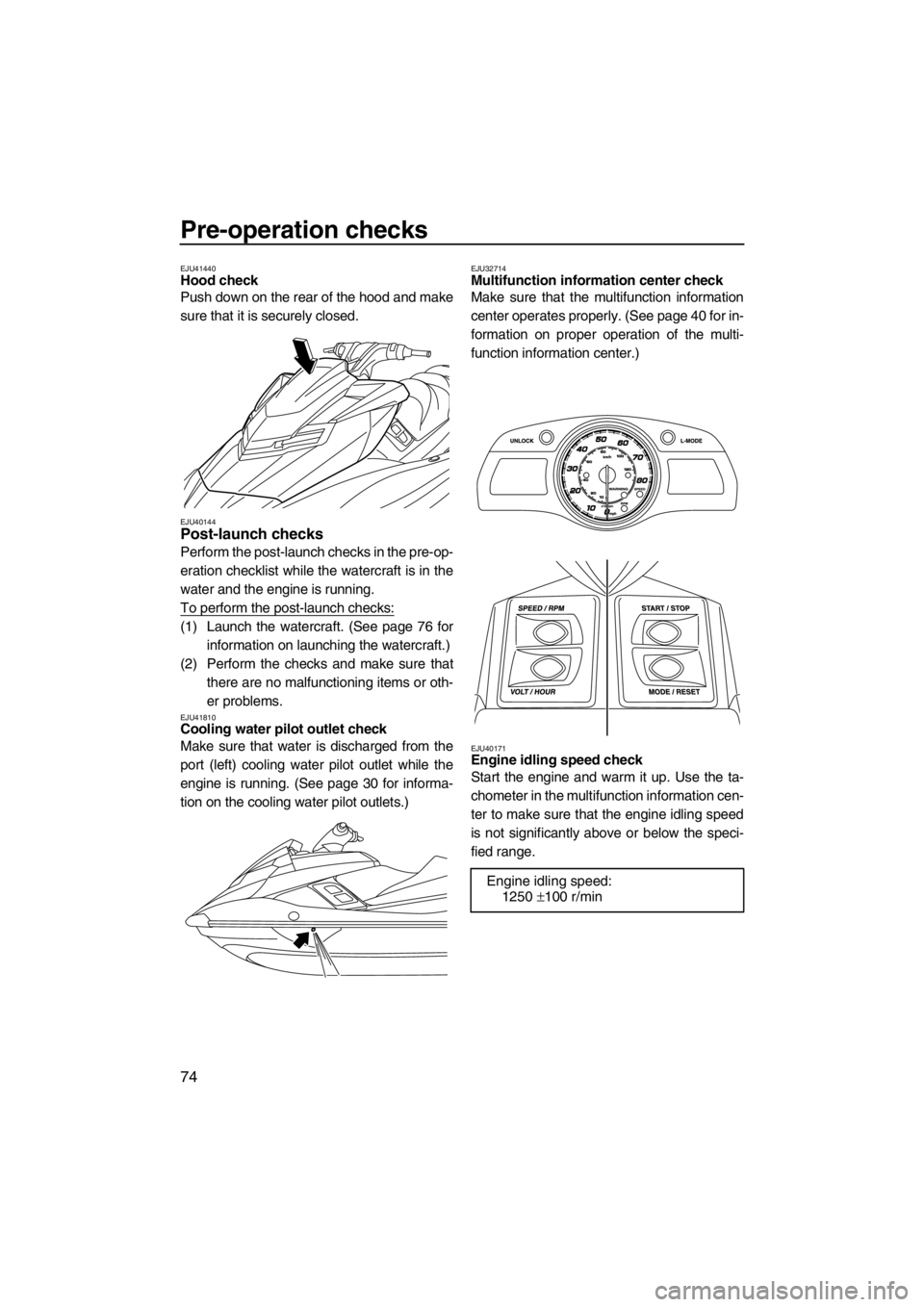

EJU41440Hood check

Push down on the rear of the hood and make

sure that it is securely closed.

EJU40144Post-launch checks

Perform the post-launch checks in the pre-op-

eration checklist while the watercraft is in the

water and the engine is running.

To perform the post-launch checks:

(1) Launch the watercraft. (See page 76 for

information on launching the watercraft.)

(2) Perform the checks and make sure that

there are no malfunctioning items or oth-

er problems.

EJU41810Cooling water pilot outlet check

Make sure that water is discharged from the

port (left) cooling water pilot outlet while the

engine is running. (See page 30 for informa-

tion on the cooling water pilot outlets.)

EJU32714Multifunction information center check

Make sure that the multifunction information

center operates properly. (See page 40 for in-

formation on proper operation of the multi-

function information center.)

EJU40171Engine idling speed check

Start the engine and warm it up. Use the ta-

chometer in the multifunction information cen-

ter to make sure that the engine idling speed

is not significantly above or below the speci-

fied range.

Engine idling speed:

1250 ±100 r/min

UF2S70E0.book Page 74 Wednesday, December 7, 2011 3:56 PM