Trouble recovery

105

(2) Remove any weeds or debris fromaround the jet intake, drive shaft, impel-

ler, jet pump housing, and jet thrust noz-

zle.

If debris is difficult to remove, consult a

Yamaha dealer.

EJU34642Jumping the battery

If the watercraft battery has run down, the en-

gine can be started using a 12-volt booster

battery and jumper cables.

EJU34664Connecting the jumper cables

WARNING

EWJ01251

To avoid battery explosion and serious

damage to the electrical system:

Do not reverse the polarity of the jumper

cables when connecting to the batter-

ies.

Do not connect the negative (–) jumper

cable to the negative (–) terminal of the

watercraft battery.

Do not touch the positive (+) jumper ca-

ble to the negative (–) jumper cable.

(1) Connect the positive (+) jumper cable to the positive (+) battery terminals of both

batteries.

(2) Connect one end of the negative (–) jumper cable to the negative (–) battery

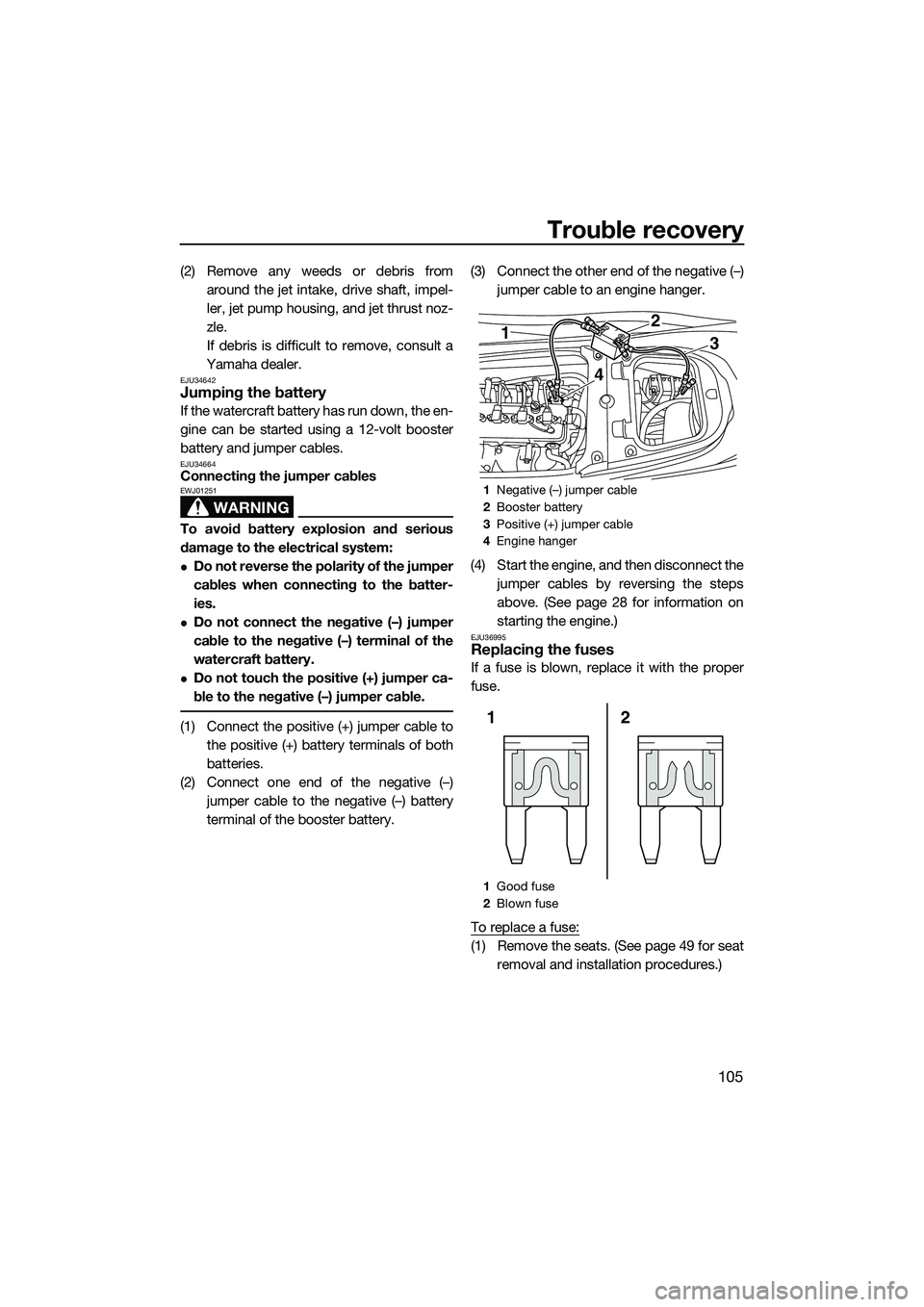

terminal of the booster battery. (3) Connect the other end of the negative (–)

jumper cable to an engine hanger.

(4) Start the engine, and then disconnect the jumper cables by reversing the steps

above. (See page 28 for information on

starting the engine.)

EJU36995Replacing the fuses

If a fuse is blown, replace it with the proper

fuse.

To replace a fuse:

(1) Remove the seats. (See page 49 for seatremoval and installation procedures.)

1Negative (–) jumper cable

2 Booster battery

3 Positive (+) jumper cable

4 Engine hanger

1 Good fuse

2 Blown fuse

1

4

3

2

2

1

UF3J70E0.book Page 105 Wednesd ay, October 9, 2013 2:07 PM

Trouble recovery

107

(7) Securely install the seats in their originalpositions.

If the fuse immediately blows again, the elec-

trical system may be defective. If this occurs,

have a Yamaha dealer service the watercraft.

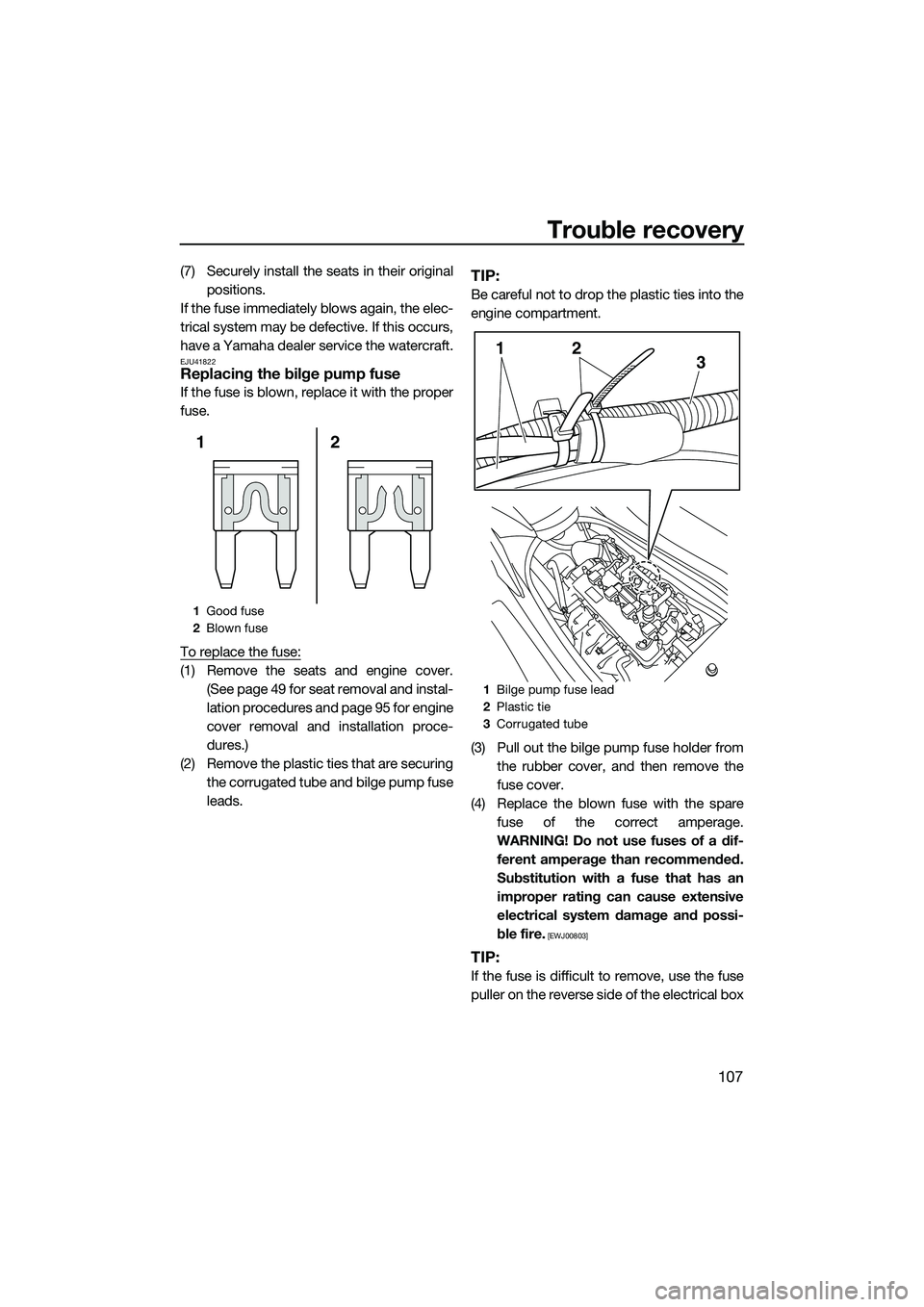

EJU41822Replacing the bilge pump fuse

If the fuse is blown, replace it with the proper

fuse.

To replace the fuse:

(1) Remove the seats and engine cover. (See page 49 for seat removal and instal-

lation procedures and page 95 for engine

cover removal and installation proce-

dures.)

(2) Remove the plastic ties that are securing the corrugated tube and bilge pump fuse

leads.

TIP:

Be careful not to drop the plastic ties into the

engine compartment.

(3) Pull out the bilge pump fuse holder fromthe rubber cover, and then remove the

fuse cover.

(4) Replace the blown fuse with the spare fuse of the correct amperage.

WARNING! Do not use fuses of a dif- ferent amperage than recommended.

Substitution with a fuse that has an

improper rating can cause extensive

electrical system damage and possi-

ble fire.

[EWJ00803]

TIP:

If the fuse is difficult to remove, use the fuse

puller on the reverse side of the electrical box

1 Good fuse

2 Blown fuse

2

1

1 Bilge pump fuse lead

2 Plastic tie

3 Corrugated tube

213

UF3J70E0.book Page 107 Wednesd ay, October 9, 2013 2:07 PM