check engine YAMAHA FX SVHO 2022 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2022, Model line: FX SVHO, Model: YAMAHA FX SVHO 2022Pages: 136, PDF Size: 5.75 MB

Page 99 of 136

Pre-operation checks

90

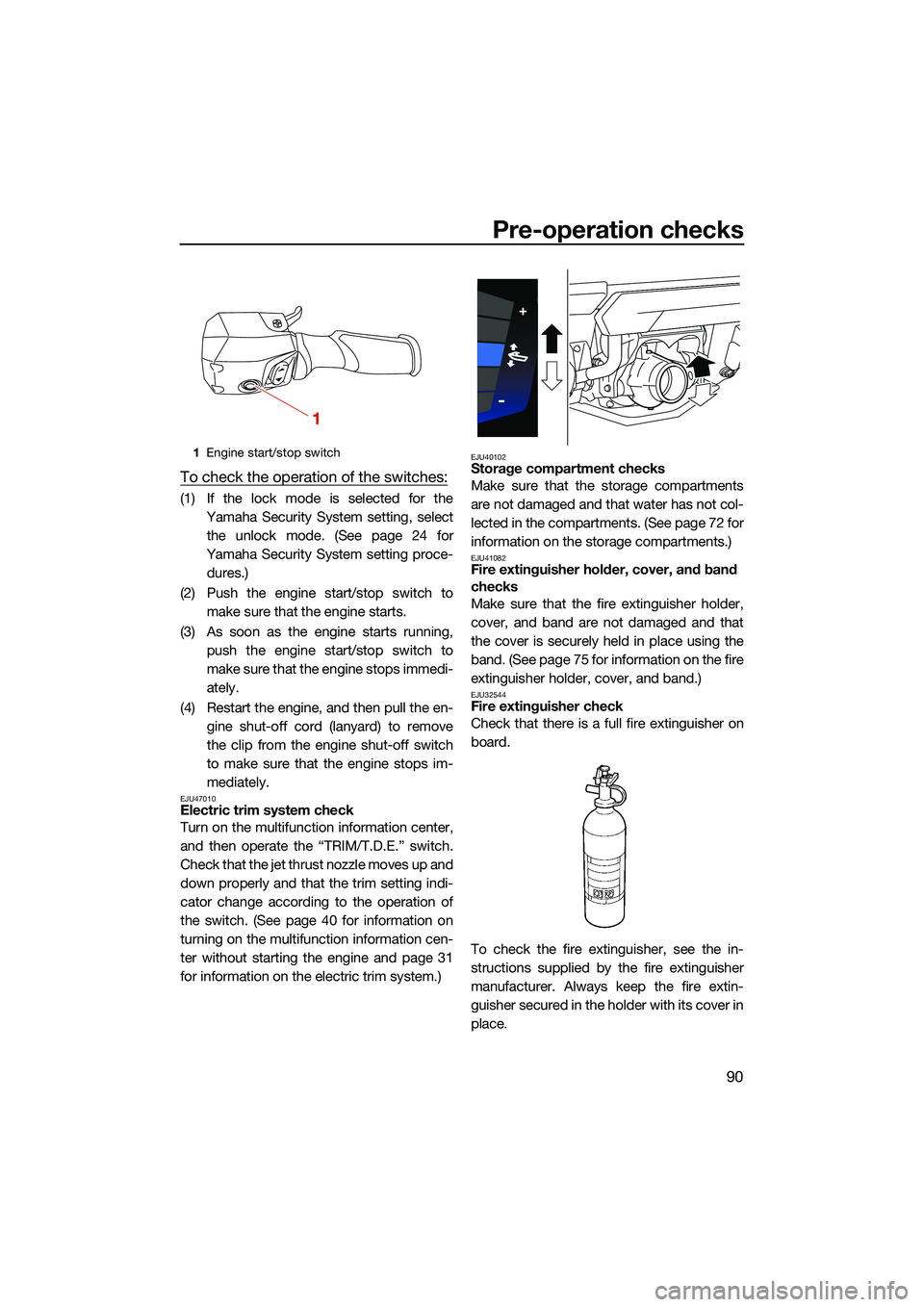

To check the operation of the switches:

(1) If the lock mode is selected for theYamaha Security System setting, selectthe unlock mode. (See page 24 for

Yamaha Security System setting proce- dures.)

(2) Push the engine start/stop switch to make sure that the engine starts.

(3) As soon as the engine starts running, push the engine start/stop switch to

make sure that the engine stops immedi-

ately.

(4) Restart the engine, and then pull the en- gine shut-off cord (lanyard) to remove

the clip from the engine shut-off switch

to make sure that the engine stops im-

mediately.

EJU47010Electric trim system check

Turn on the multifunction information center,

and then operate the “TRIM/T.D.E.” switch.

Check that the jet thrust nozzle moves up and

down properly and that the trim setting indi-

cator change according to the operation of

the switch. (See page 40 for information on

turning on the multifunction information cen-

ter without starting the engine and page 31

for information on the electric trim system.)

EJU40102Storage compartment checks

Make sure that the storage compartments

are not damaged and that water has not col-

lected in the compartments. (See page 72 for

information on the storage compartments.)

EJU41082Fire extinguisher holder, cover, and band

checks

Make sure that the fire extinguisher holder,

cover, and band are not damaged and that

the cover is securely held in place using the

band. (See page 75 for information on the fire

extinguisher holder, cover, and band.)

EJU32544Fire extinguisher check

Check that there is a full fire extinguisher on

board.

To check the fire extinguisher, see the in-

structions supplied by the fire extinguisher

manufacturer. Always keep the fire extin-

guisher secured in the holder with its cover in

place.

1 Engine start/stop switch

1

UF3X73E0.book Page 90 Wednesday, October 6, 2021 9:04 AM

Page 100 of 136

Pre-operation checks

91

Always carry a fire extinguisher on board. A

fire extinguisher is not standard equipment

with this watercraft. If you do not have one,

contact a Yamaha dealer or a fire extinguish-

er dealer to obtain one meeting the proper

specifications.

EJU40122Safety equipment check

Check that safety equipment meeting the ap-

plicable regulations is on board.

EJU32353Hull and deck check

Check the hull and deck for damage or other

problem.

EJU32657Jet intake checks

Make sure that the jet intake is not damaged

or clogged with weeds or debris. If the jet in-

take is clogged, clean it. (See page 120 for in-

formation on the jet intake.)

EJU43221Jet thrust nozzle and reverse gate check

Check the jet thrust nozzle and reverse gate

for damage or other problem.

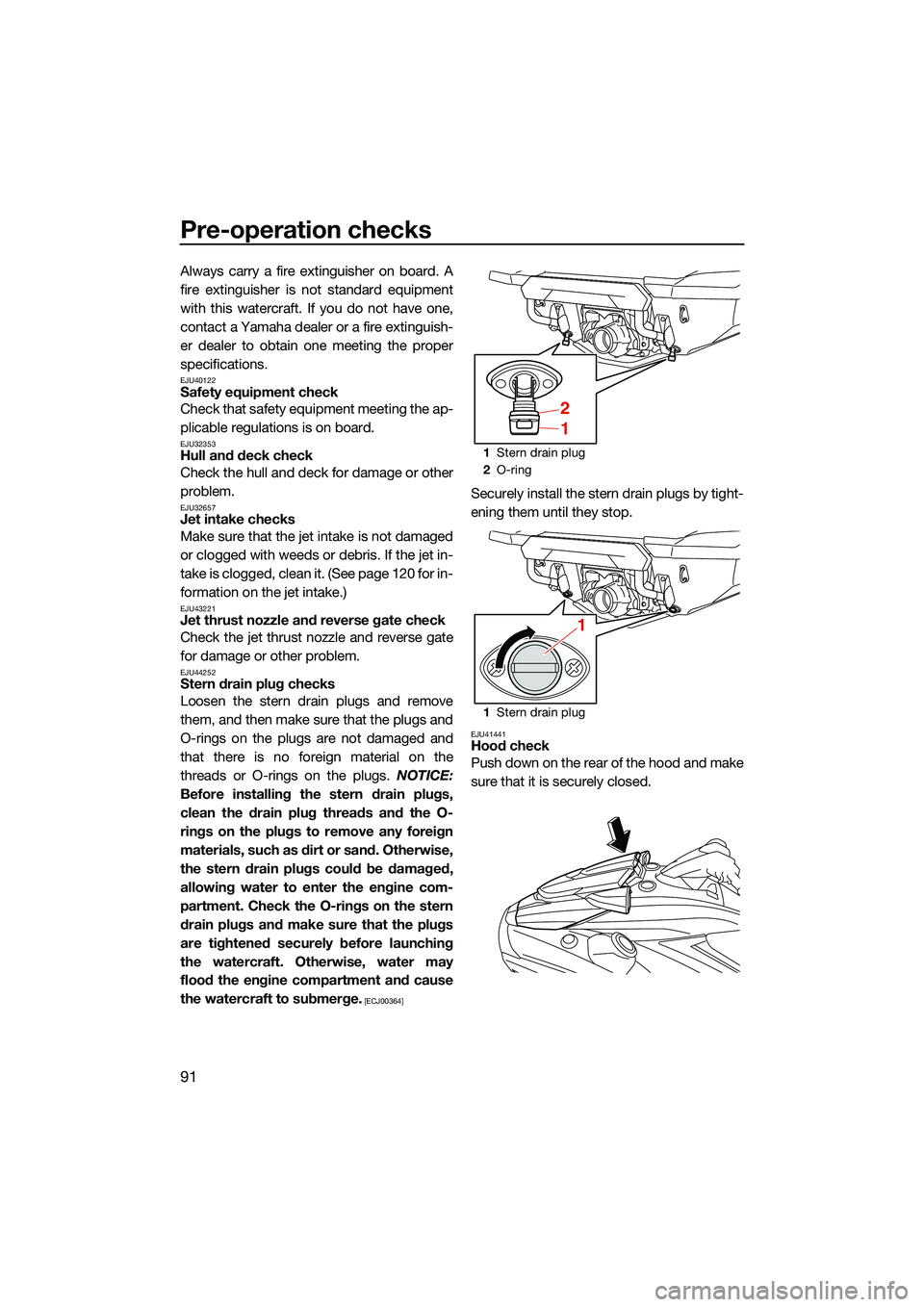

EJU44252Stern drain plug checks

Loosen the stern drain plugs and remove

them, and then make sure that the plugs and

O-rings on the plugs are not damaged and

that there is no foreign material on the

threads or O-rings on the plugs. NOTICE:

Before installing the stern drain plugs,

clean the drain plug threads and the O-

rings on the plugs to remove any foreign

materials, such as dirt or sand. Otherwise,

the stern drain plugs could be damaged,

allowing water to enter the engine com-

partment. Check the O-rings on the stern

drain plugs and make sure that the plugs

are tightened securely before launching

the watercraft. Otherwise, water may

flood the engine compartment and cause

the watercraft to submerge.

[ECJ00364]

Securely install the stern drain plugs by tight-

ening them until they stop.

EJU41441Hood check

Push down on the rear of the hood and make

sure that it is securely closed.

1 Stern drain plug

2 O-ring

1 Stern drain plug

2

1

1

UF3X73E0.book Page 91 Wednesday, October 6, 2021 9:04 AM

Page 101 of 136

Pre-operation checks

92

EJU40147Post-launch checks

Perform the post-launch checks in the pre-

operation checklist while the watercraft is in

the water and the engine is running.

To perform the post-launch checks:

(1) Launch the watercraft. (See page 94 forinformation on launching the watercraft.)

(2) Perform the checks and make sure that there are no malfunctioning items or oth-

er problems.

EJU41811Cooling water pilot outlet check

Make sure that water is discharged from the

port (left) cooling water pilot outlet while the

engine is running. (See page 27 for informa-

tion on the cooling water pilot outlets.)

EJU47000Multifunction information center check

Make sure that the multifunction information

center operates properly. (See page 40 for in-

formation on proper operation of the multi-

function information center.)

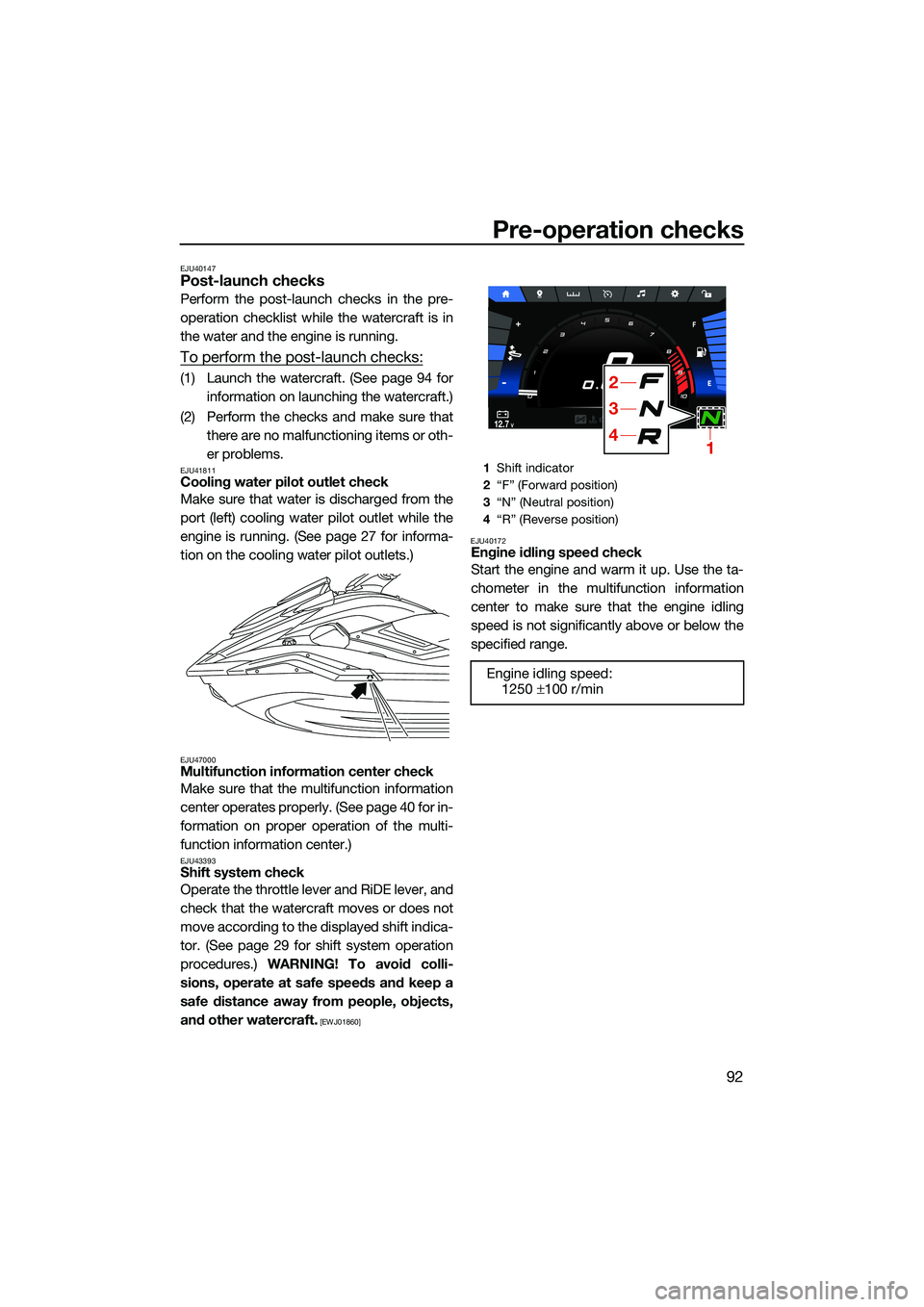

EJU43393Shift system check

Operate the throttle lever and RiDE lever, and

check that the watercraft moves or does not

move according to the displayed shift indica-

tor. (See page 29 for shift system operation

procedures.) WARNING! To avoid colli-

sions, operate at safe speeds and keep a

safe distance away from people, objects,

and other watercraft.

[EWJ01860] EJU40172

Engine idling speed check

Start the engine and warm it up. Use the ta-

chometer in the multifunction information

center to make sure that the engine idling

speed is not significantly above or below the

specified range.

1

Shift indicator

2 “F” (Forward position)

3 “N” (Neutral position)

4 “R” (Reverse position)

Engine idling speed:

1250 ±100 r/min

MPH

RPM

x1000

12.7V10 :00AM

14

3

2

UF3X73E0.book Page 92 Wednesday, October 6, 2021 9:04 AM

Page 103 of 136

Operation

94

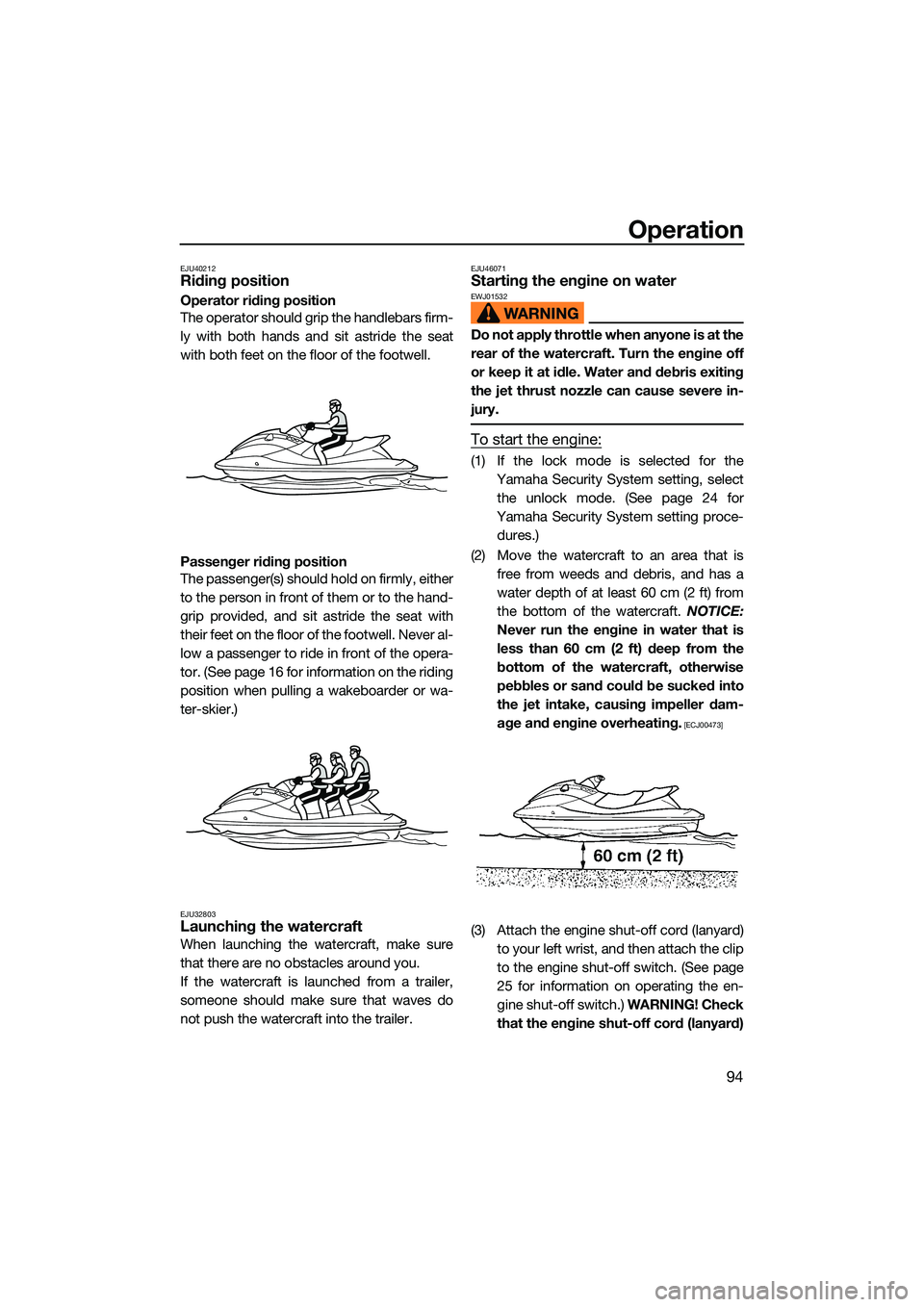

EJU40212Riding position

Operator riding position

The operator should grip the handlebars firm-

ly with both hands and sit astride the seat

with both feet on the floor of the footwell.

Passenger riding position

The passenger(s) should hold on firmly, either

to the person in front of them or to the hand-

grip provided, and sit astride the seat with

their feet on the floor of the footwell. Never al-

low a passenger to ride in front of the opera-

tor. (See page 16 for information on the riding

position when pulling a wakeboarder or wa-

ter-skier.)

EJU32803Launching the watercraft

When launching the watercraft, make sure

that there are no obstacles around you.

If the watercraft is launched from a trailer,

someone should make sure that waves do

not push the watercraft into the trailer.

EJU46071Starting the engine on waterEWJ01532

Do not apply throttle when anyone is at the

rear of the watercraft. Turn the engine off

or keep it at idle. Water and debris exiting

the jet thrust nozzle can cause severe in-

jury.

To start the engine:

(1) If the lock mode is selected for theYamaha Security System setting, selectthe unlock mode. (See page 24 for

Yamaha Security System setting proce- dures.)

(2) Move the watercraft to an area that is free from weeds and debris, and has a

water depth of at least 60 cm (2 ft) from

the bottom of the watercraft. NOTICE:

Never run the engine in water that is

less than 60 cm (2 ft) deep from the

bottom of the watercraft, otherwise

pebbles or sand could be sucked into

the jet intake, causing impeller dam-

age and engine overheating.

[ECJ00473]

(3) Attach the engine shut-off cord (lanyard) to your left wrist, and then attach the clip

to the engine shut-off switch. (See page

25 for information on operating the en-

gine shut-off switch.) WARNING! Check

that the engine shut-off cord (lanyard)

UF3X73E0.book Page 94 Wednesday, October 6, 2021 9:04 AM

Page 107 of 136

Operation

98

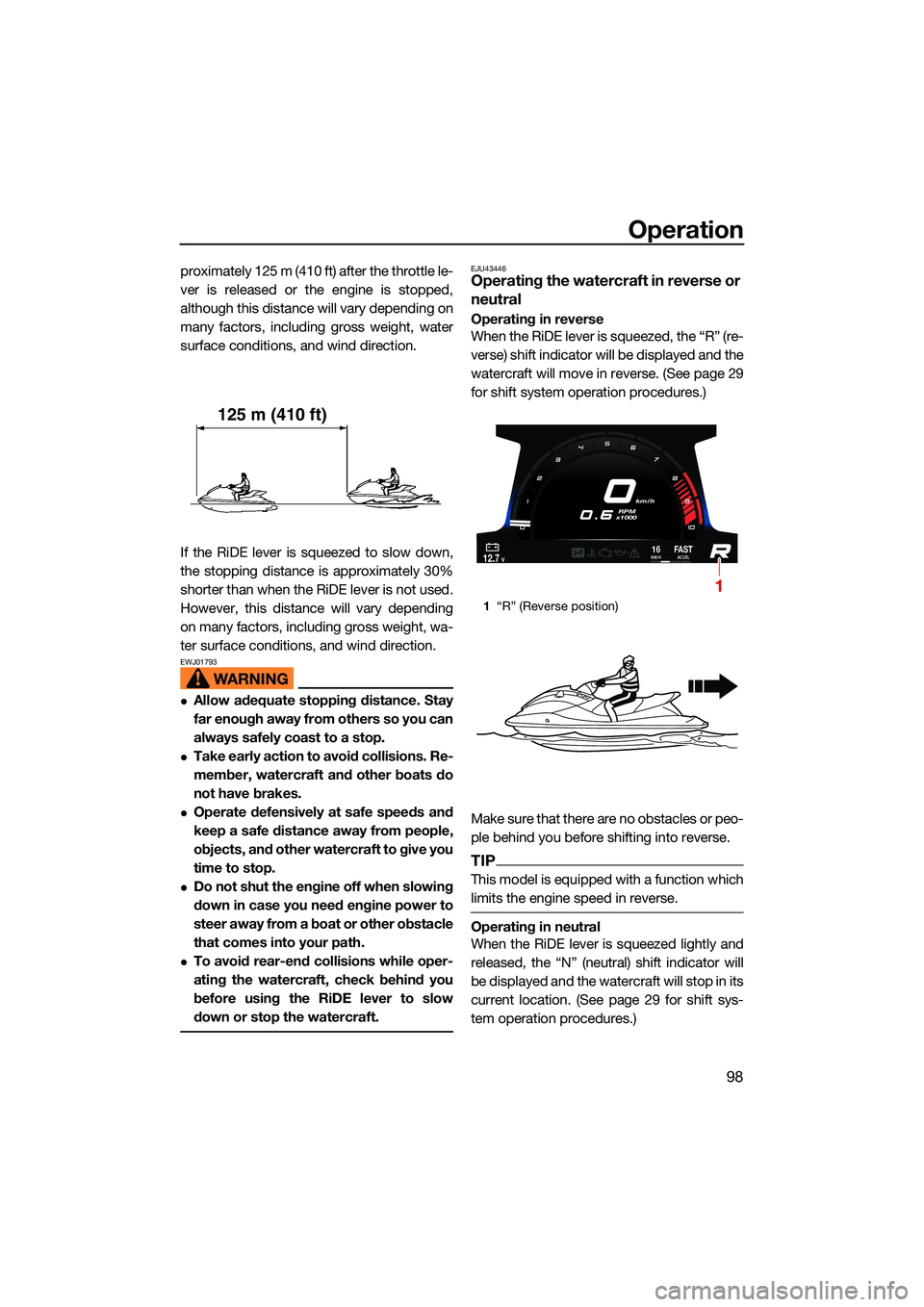

proximately 125 m (410 ft) after the throttle le-

ver is released or the engine is stopped,

although this distance will vary depending on

many factors, including gross weight, water

surface conditions, and wind direction.

If the RiDE lever is squeezed to slow down,

the stopping distance is approximately 30%

shorter than when the RiDE lever is not used.

However, this distance will vary depending

on many factors, including gross weight, wa-

ter surface conditions, and wind direction.

EWJ01793

Allow adequate stopping distance. Stay

far enough away from others so you can

always safely coast to a stop.

Take early action to avoid collisions. Re-

member, watercraft and other boats do

not have brakes.

Operate defensively at safe speeds and

keep a safe distance away from people,

objects, and other watercraft to give you

time to stop.

Do not shut the engine off when slowing

down in case you need engine power to

steer away from a boat or other obstacle

that comes into your path.

To avoid rear-end collisions while oper-

ating the watercraft, check behind you

before using the RiDE lever to slow

down or stop the watercraft.

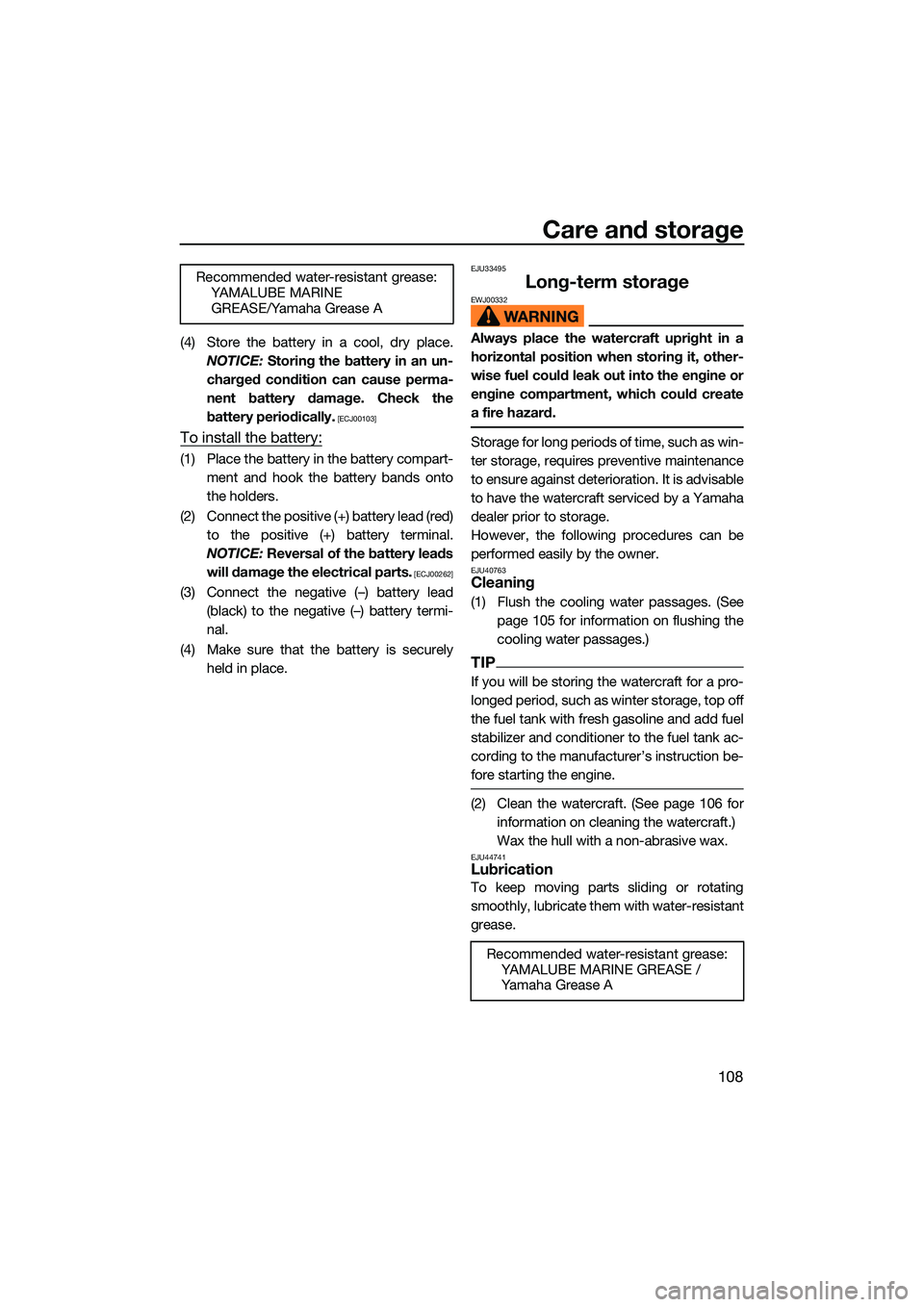

EJU43446Operating the watercraft in reverse or

neutral

Operating in reverse

When the RiDE lever is squeezed, the “R” (re-

verse) shift indicator will be displayed and the

watercraft will move in reverse. (See page 29

for shift system operation procedures.)

Make sure that there are no obstacles or peo-

ple behind you before shifting into reverse.

TIP

This model is equipped with a function which

limits the engine speed in reverse.

Operating in neutral

When the RiDE lever is squeezed lightly and

released, the “N” (neutral) shift indicator will

be displayed and the watercraft will stop in its

current location. (See page 29 for shift sys-

tem operation procedures.)

125 m (410 ft)

1“R” (Reverse position)

km/h

RPM

x1000

12.7V16KM/HFA S TACCEL

1

UF3X73E0.book Page 98 Wednesday, October 6, 2021 9:04 AM

Page 115 of 136

Care and storage

106

(8) Run the engine at idling speed for about3 minutes watching the engine condition.

If the engine stops while flushing, turn

the water supply off immediately and

perform the procedure again from step 7.

NOTICE: Do not supply water to the

cooling water passages when the en-

gine is not running. The water could

flow back through the muffler into the

engine, causing severe engine dam-

age.

[ECJ00123]

(9) Turn the water supply off.

(10) Discharge the remaining water out of the cooling water passages by alternately

squeezing and releasing the throttle lever

quickly for 10 to 15 seconds.

(11) Stop the engine.

(12) Remove the garden hose adapter, and then securely install the flushing hose

connector cap by tightening it until it

stops.

(13) Securely close the stern storage com- partment.

(14) Securely install the removable watertight storage compartment and seats in their

original positions.

EJU33736Cleaning the watercraft

(1) Remove the seats. (See page 69 for seatremoval and installation procedures.) (2) Rinse the engine and engine compart-

ment with a small amount of water.

NOTICE: Do not use high-pressure

water when rinsing the engine or en-

gine compartment as severe engine

damage could result.

[ECJ00572]

(3) Drain the water from the engine com- partment. (See page 81 for information

on draining the bilge water.)

(4) Wipe the engine and engine compart- ment with a dry cloth.

(5) Wash down the hull, deck, and jet pump with fresh water.

(6) Wipe the hull, deck, and jet pump with a dry cloth.

(7) Wipe all vinyl and rubber components, such as the seats and engine compart-

ment seals, with a vinyl protectant.

(8) To minimize corrosion, spray metallic parts of the hull, deck, and engine with a

rust inhibitor.

(9) Allow the engine compartment to air dry completely before installing the seats.

(10) Securely install the seats in their original positions.

EJU3368DBattery care

If the watercraft will not be used for more than

a month, remove the battery from the water-

craft, check it, and then store it in a cool, dry

place.

EWJ00794

Battery electrolyte is poisonous and dan-

gerous, causing severe burns, etc. Elec-

trolyte contains sulfuric acid. Avoid

contact with skin, eyes, or clothing.

Batteries produce explosive gases. Keep

sparks, flames, cigarettes, etc., well away.

If using or charging the battery in an en-

closed space, make sure that it is well

UF3X73E0.book Page 106 Wednesday, October 6, 2021 9:04 AM

Page 117 of 136

Care and storage

108

(4) Store the battery in a cool, dry place.NOTICE: Storing the battery in an un-

charged condition can cause perma-

nent battery damage. Check the

battery periodically.

[ECJ00103]

To install the battery:

(1) Place the battery in the battery compart- ment and hook the battery bands onto

the holders.

(2) Connect the positive (+) battery lead (red) to the positive (+) battery terminal.

NOTICE: Reversal of the battery leads

will damage the electrical parts.

[ECJ00262]

(3) Connect the negative (–) battery lead (black) to the negative (–) battery termi-

nal.

(4) Make sure that the battery is securely held in place.

EJU33495

Long-term storageEWJ00332

Always place the watercraft upright in a

horizontal position when storing it, other-

wise fuel could leak out into the engine or

engine compartment, which could create

a fire hazard.

Storage for long periods of time, such as win-

ter storage, requires preventive maintenance

to ensure against deterioration. It is advisable

to have the watercraft serviced by a Yamaha

dealer prior to storage.

However, the following procedures can be

performed easily by the owner.

EJU40763Cleaning

(1) Flush the cooling water passages. (Seepage 105 for information on flushing the

cooling water passages.)

TIP

If you will be storing the watercraft for a pro-

longed period, such as winter storage, top off

the fuel tank with fresh gasoline and add fuel

stabilizer and conditioner to the fuel tank ac-

cording to the manufacturer’s instruction be-

fore starting the engine.

(2) Clean the watercraft. (See page 106 forinformation on cleaning the watercraft.)

Wax the hull with a non-abrasive wax.

EJU44741Lubrication

To keep moving parts sliding or rotating

smoothly, lubricate them with water-resistant

grease.

Recommended water-resistant grease:

YAMALUBE MARINE

GREASE/Yamaha Grease A

Recommended water-resistant grease:

YAMALUBE MARINE GREASE /

Ya m a h a G r e a s e A

UF3X73E0.book Page 108 Wednesday, October 6, 2021 9:04 AM

Page 119 of 136

Maintenance

110

EJU3376A

Maintenance

Periodic checks and lubrication will keep

your watercraft in the safest and most effi-

cient condition possible. Therefore, make

sure to carry out the periodic maintenance.

Safety is an obligation of the watercraft own-

er. Proper maintenance must be carried out

to keep the exhaust emission and sound lev-

els within the regulated limits. The most im-

portant points of watercraft inspection and

lubrication are explained on the following pa-

ges.

See a Yamaha dealer for genuine Yamaha re-

placement parts and optional accessories

designed for your watercraft.

Remember, failures that are the result of the

installation of parts or accessories which are

not qualitatively equivalent to genuine

Yamaha parts are not covered by the limited warranty.

Maintenance, replacement, or repair of

the emission control devices and system

may be performed by any marine SI engine

repair establishment or individual. War-

ranty repair, however, must be performed

at an authorized Yamaha marine dealer-

ship.

EWJ00312

Be sure to turn off the engine when you

perform maintenance unless otherwise

specified. If you are not familiar with ma-

chine servicing, this work should be done

by a Yamaha dealer or other qualified me-

chanic.

EJU42023Removing and installing the engine

cover

The engine cover is removable.

To remove the engine cover:

(1) Remove the seats. (See page 69 for seat removal and installation procedures.)

(2) Remove the engine cover screws.

(3) Lift up the engine cover to remove it.

To install the engine cover:

(1) Place the engine cover in its original po- sition, and then push it down.

(2) Install the engine cover screws.

1 Engine cover screw

1 Engine cover

1

1

UF3X73E0.book Page 110 Wednesday, October 6, 2021 9:04 AM

Page 121 of 136

Maintenance

112

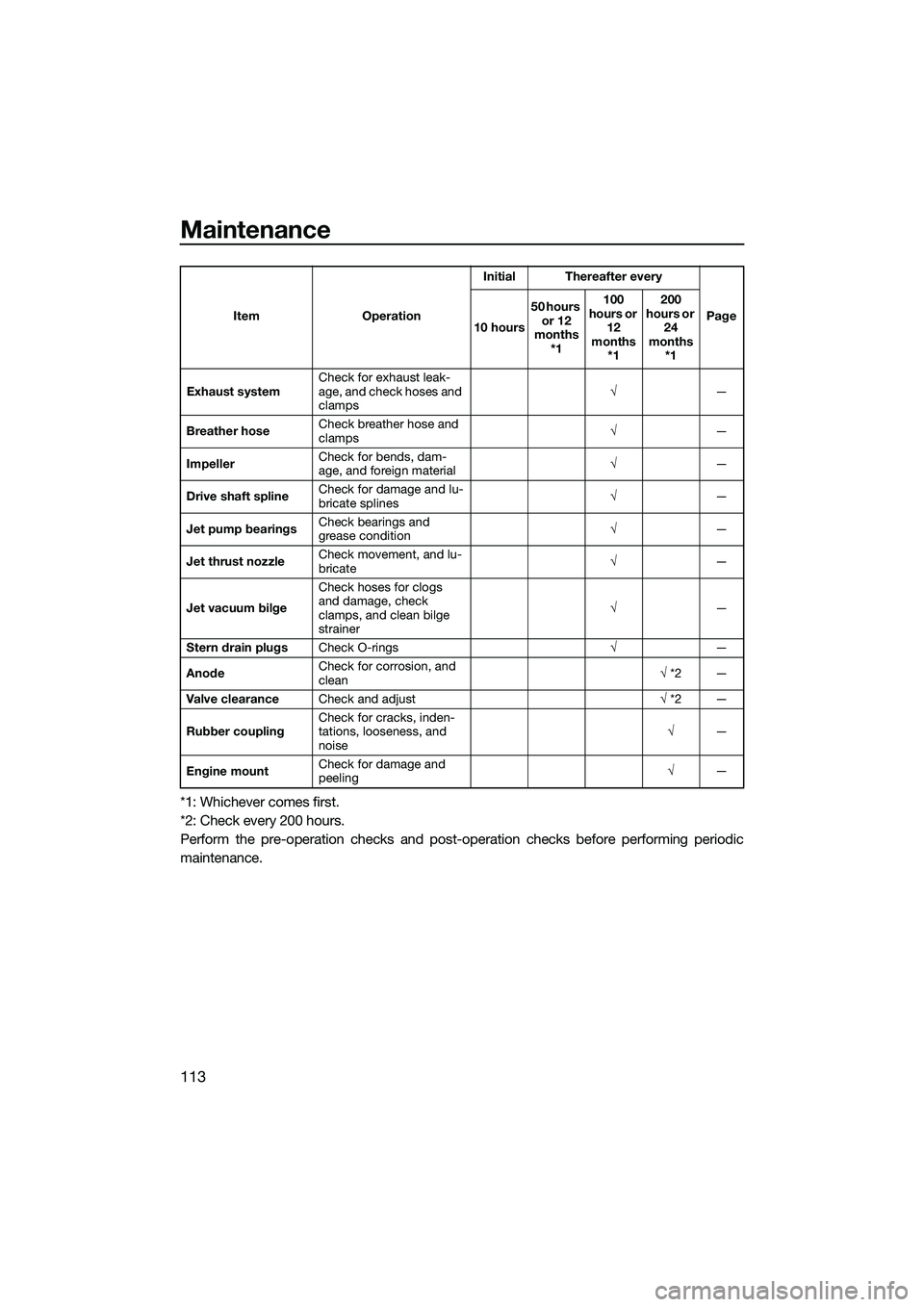

EJU43103Periodic maintenance chart

The periodic maintenance chart gives general guidelines for periodic maintenance. Have a

Yamaha dealer perform the checks in the following chart. However, maintenance may need to be performed more frequently depending on your operating conditions. If you have any

questions, consult a Yamaha dealer.

This “ √” mark indicates items to be checked and serviced by a Yamaha dealer.

Item OperationInitial Thereafter every

Page

10 hours 50 hours

or 12

months *1 100

hours or 12

months *1 200

hours or 24

months *1

Fuel line Check fuel hoses and

clamps

√

—

Fuel filler cap/Wa-

ter separator Check O-rings for cracks

and deformation

√

—

Fuel tank Check installation and

straps

√

—

Water inlet strainer Check for clogs and dam-

age

√

—

Cooling water hos-

es Check for damage and

leakage, and check

clamps

√

—

Engine oil Replace √√ 114

Oil filter Replace √114

Intermediate hous-

ing Lubricate

√—

Spark plugs Check √√ —

Battery Check state of charge,

terminals and bands

√

—

Battery leads Check terminals √—

Steering master Check operation and for

looseness

√√

—

Steering cable Check exterior and con-

nections, and lubricate

√

—

Electric trim rod Check exterior and con-

nections, and lubricate

√

—

Shift rod and re-

verse gate Check exterior and con-

nections, and lubricate

√

—

Air filter element Check for damage and

dirt

√

—

Air intake hoses Check for damage, and

check clamps

√

—

Thr

ottle body Lubricate throttle valve √—

UF3X73E0.book Page 112 Wednesday, October 6, 2021 9:04 AM

Page 122 of 136

Maintenance

113

*1: Whichever comes first.

*2: Check every 200 hours.

Perform the pre-operation checks and post-operation checks before performing periodic

maintenance.

Exhaust systemCheck for exhaust leak-

age, and check hoses and

clamps √

—

Breather hose Check breather hose and

clamps

√

—

Impeller Check for bends, dam-

age, and foreign material

√

—

Drive shaft spline Check for damage and lu-

bricate splines

√

—

Jet pump bearings Check bearings and

grease condition

√

—

Jet thrust nozzle Check movement, and lu-

bricate

√

—

Jet vacuum bilge Check hoses for clogs

and damage, check

clamps, and clean bilge

strainer

√

—

Stern drain plugs Check O-rings √—

Anode Check for corrosion, and

clean

√

*2 —

Valve clearance Check and adjust √ *2 —

Rubber coupling Check for cracks, inden-

tations, looseness, and

noise √

—

Engine mount Check for damage and

peeling

√

—

Item Operation

Initial Thereafter every

Page

10 hours 50 hours

or 12

months *1 100

hours or 12

months *1 200

hours or 24

months *1

UF3X73E0.book Page 113 Wednesday, October 6, 2021 9:04 AM