engine YAMAHA FZS SVHO 2014 Workshop Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: FZS SVHO, Model: YAMAHA FZS SVHO 2014Pages: 108, PDF Size: 5.47 MB

Page 83 of 108

Operation

77

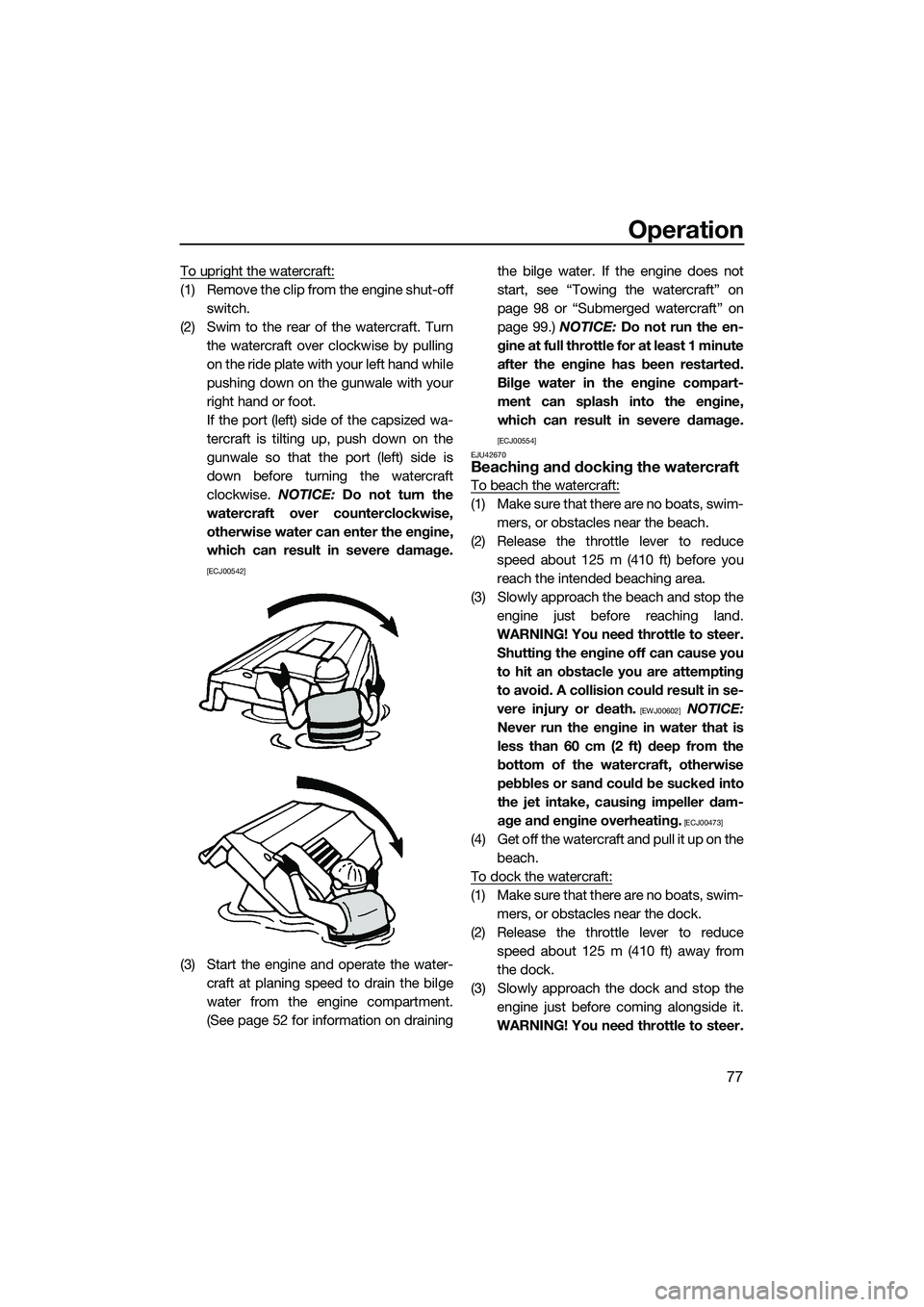

To upright the watercraft:

(1) Remove the clip from the engine shut-offswitch.

(2) Swim to the rear of the watercraft. Turn the watercraft over clockwise by pulling

on the ride plate with your left hand while

pushing down on the gunwale with your

right hand or foot.

If the port (left) side of the capsized wa-

tercraft is tilting up, push down on the

gunwale so that the port (left) side is

down before turning the watercraft

clockwise. NOTICE: Do not turn the

watercraft over counterclockwise,

otherwise water can enter the engine,

which can result in severe damage.

[ECJ00542]

(3) Start the engine and operate the water- craft at planing speed to drain the bilge

water from the engine compartment.

(See page 52 for information on draining the bilge water. If the engine does not

start, see “Towing the watercraft” on

page 98 or “Submerged watercraft” on

page 99.) NOTICE:

Do not run the en-

gine at full throttle for at least 1 minute

after the engine has been restarted.

Bilge water in the engine compart-

ment can splash into the engine,

which can result in severe damage.

[ECJ00554]

EJU42670

Beaching and docking the watercraft

To beach the watercraft:

(1) Make sure that there are no boats, swim- mers, or obstacles near the beach.

(2) Release the throttle lever to reduce speed about 125 m (410 ft) before you

reach the intended beaching area.

(3) Slowly approach the beach and stop the engine just before reaching land.

WARNING! You need throttle to steer. Shutting the engine off can cause you

to hit an obstacle you are attempting

to avoid. A collision could result in se-

vere injury or death.

[EWJ00602] NOTICE:

Never run the engine in water that is

less than 60 cm (2 ft) deep from the

bottom of the watercraft, otherwise

pebbles or sand could be sucked into

the jet intake, causing impeller dam-

age and engine overheating.

[ECJ00473]

( 4 ) G e t o f f t h e w a t e r c r a f t a n d p u l l i t u p o n t h e beach.

To dock the watercraft:

(1) Make sure that there are no boats, swim- mers, or obstacles near the dock.

(2) Release the throttle lever to reduce speed about 125 m (410 ft) away from

the dock.

(3) Slowly approach the dock and stop the engine just before coming alongside it.

WARNING! You need throttle to steer.

UF3K70E0.book Page 77 Tuesday, November 5, 2013 8:44 AM

Page 84 of 108

![YAMAHA FZS SVHO 2014 Workshop Manual Operation

78

Shutting the engine off can cause you

to hit an obstacle you are attempting

to avoid. A collision could result in se-

vere injury or death.

[EWJ00602]

(4) Come alongside the dock and get YAMAHA FZS SVHO 2014 Workshop Manual Operation

78

Shutting the engine off can cause you

to hit an obstacle you are attempting

to avoid. A collision could result in se-

vere injury or death.

[EWJ00602]

(4) Come alongside the dock and get](/img/51/50243/w960_50243-83.png)

Operation

78

Shutting the engine off can cause you

to hit an obstacle you are attempting

to avoid. A collision could result in se-

vere injury or death.

[EWJ00602]

(4) Come alongside the dock and get off thewatercraft.

EJU37194Operating in weeded areas

Always avoid using your watercraft in areas

where weed growth is thick. If operating in

weeded areas is unavoidable, alternately

squeeze the throttle lever and relax your grip

on the throttle lever to vary the engine speed.

Weeds tend to become clogged more when

operating at a steady speed and at trolling

speed. If weeds may have clogged the intake

area, clean the jet intake. (See page 94 for in-

formation on the jet intake.)

EJU40242After removing the watercraft from

the water

NOTICE

ECJ01311

Do not run the engine over 4000 r/min on

land. Also, do not run the engine for more

than 15 seconds without supplying water,

otherwise the engine could overheat.

After operating and re moving the watercraft

from the water, promptly discharge the re-

maining water from the cooling water pas-

sages.

To discharge water from the cooling water

passages:

(1) Make sure that the area around the wa- tercraft is clear, and then start the en-

gine.

(2) Discharge the remaining water out of the cooling water passages by alternately

squeezing and releasing the throttle lever

quickly for 10 to 15 seconds.

(3) Stop the engine.

UF3K70E0.book Page 78 Tuesday, November 5, 2013 8:44 AM

Page 85 of 108

Care and storage

79

EJU37146

Post-operation care

WARNING

EWJ00331

Always place the watercraft upright in a

horizontal position when storing it, other-

wise fuel could leak out into the engine or

engine compartment, which could create

a fire hazard.

After using the watercraft, always take it out

of the water, clean it, and store it. Leaving the

watercraft in the water for extended periods

will accelerate the rate of normal deteriora-

tion of the jet pump and hull. Marine organ-

isms and corrosion are some of the

conditions that can shorten the life of many

watercraft components.

EJU37564Flushing the cooling water passages

NOTICE

ECJ01880

Do not run the engine over 4000 r/min on

land. Also, do not run the engine for

more than 15 seconds without supplying

water, otherwise the engine could over-

heat.

Flush the cooling water passages to

prevent them from clogging with salt,

sand, or dirt.

(1) Place the watercraft in a horizontal posi-tion.

(2) Remove the seats and watertight stor- age compartment. (See page 41 for seat

removal and installation procedures and

page 46 for information on the watertight

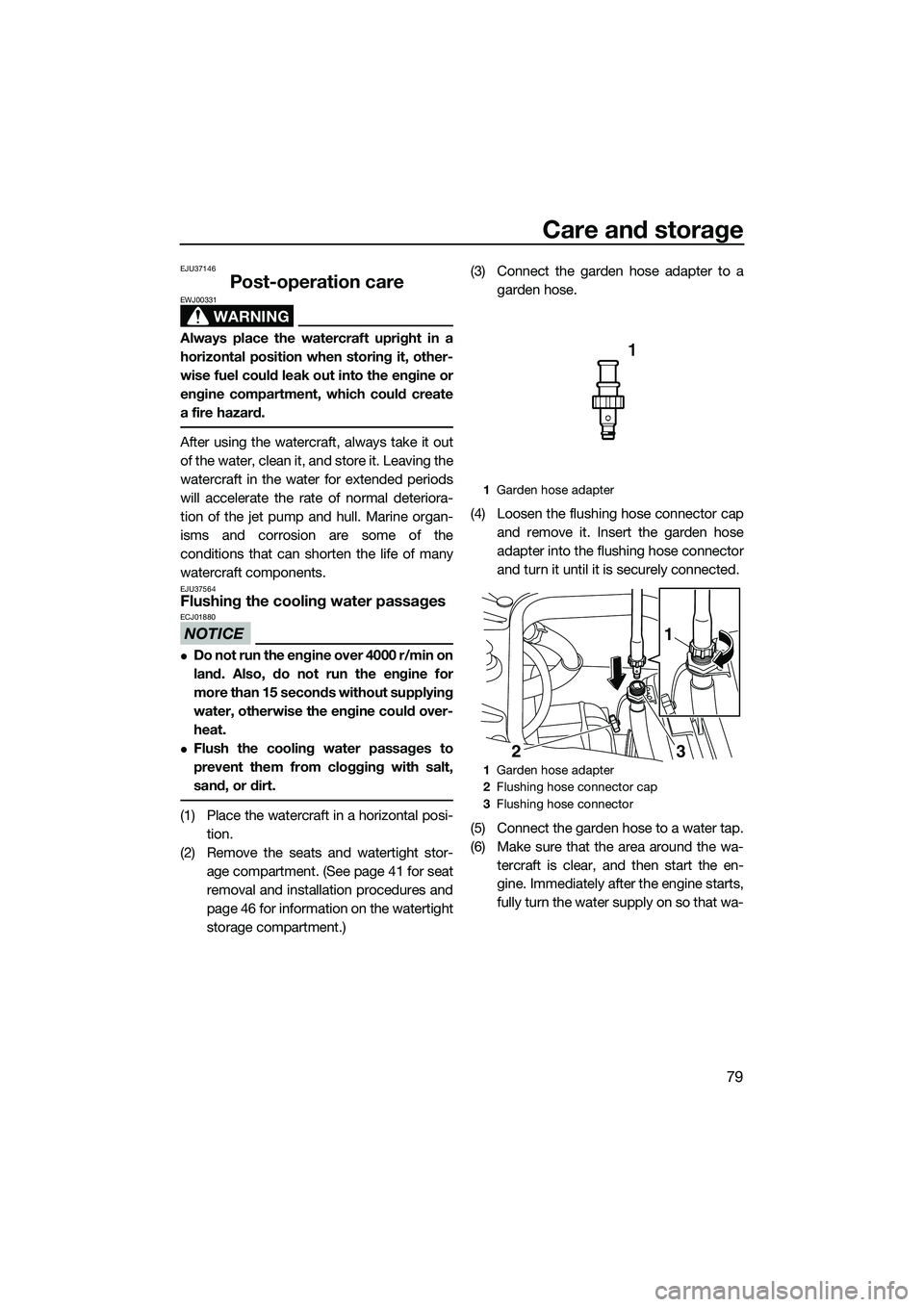

storage compartment.) (3) Connect the garden hose adapter to a

garden hose.

(4) Loosen the flushing hose connector cap and remove it. Insert the garden hose

adapter into the flushing hose connector

and turn it until it is securely connected.

(5) Connect the garden hose to a water tap.

(6) Make sure that the area around the wa- tercraft is clear, and then start the en-

gine. Immediately after the engine starts,

fully turn the water supply on so that wa-

1Garden hose adapter

1 Garden hose adapter

2 Flushing hose connector cap

3 Flushing hose connector

23 1

UF3K70E0.book Page 79 Tuesday, November 5, 2013 8:44 AM

Page 86 of 108

Care and storage

80

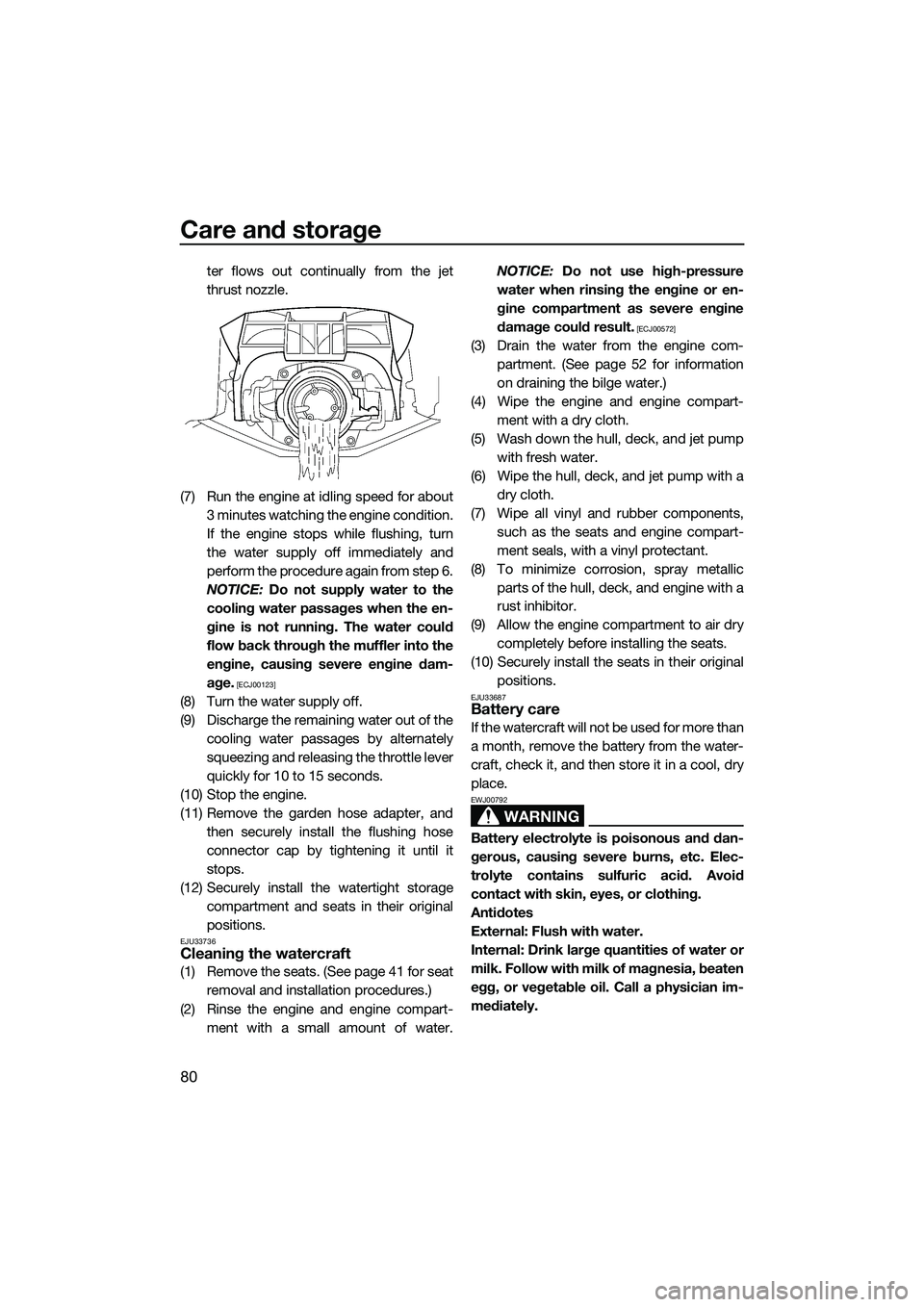

ter flows out continually from the jet

thrust nozzle.

(7) Run the engine at idling speed for about 3 minutes watching the engine condition.

If the engine stops while flushing, turn

the water supply off immediately and

perform the procedure again from step 6.

NOTICE: Do not supply water to the

cooling water passages when the en-

gine is not running. The water could

flow back through the muffler into the

engine, causing severe engine dam-

age.

[ECJ00123]

(8) Turn the water supply off.

(9) Discharge the remaining water out of the cooling water passages by alternately

squeezing and releasing the throttle lever

quickly for 10 to 15 seconds.

(10) Stop the engine.

(11) Remove the garden hose adapter, and then securely install the flushing hose

connector cap by tightening it until it

stops.

(12) Securely install the watertight storage compartment and seats in their original

positions.

EJU33736Cleaning the watercraft

(1) Remove the seats. (See page 41 for seatremoval and installation procedures.)

(2) Rinse the engine and engine compart- ment with a small amount of water. NOTICE:

Do not use high-pressure

water when rinsing the engine or en-

gine compartment as severe engine

damage could result.

[ECJ00572]

(3) Drain the water from the engine com- partment. (See page 52 for information

on draining the bilge water.)

(4) Wipe the engine and engine compart- ment with a dry cloth.

(5) Wash down the hull, deck, and jet pump with fresh water.

(6) Wipe the hull, deck, and jet pump with a dry cloth.

(7) Wipe all vinyl and rubber components, such as the seats and engine compart-

ment seals, with a vinyl protectant.

(8) To minimize corrosion, spray metallic parts of the hull, deck, and engine with a

rust inhibitor.

(9) Allow the engine compartment to air dry completely before installing the seats.

(10) Securely install the seats in their original positions.

EJU33687Battery care

If the watercraft will not be used for more than

a month, remove the battery from the water-

craft, check it, and then store it in a cool, dry

place.

WARNING

EWJ00792

Battery electrolyte is poisonous and dan-

gerous, causing severe burns, etc. Elec-

trolyte contains sulfuric acid. Avoid

contact with skin, eyes, or clothing.

Antidotes

External: Flush with water.

Internal: Drink large quantities of water or

milk. Follow with milk of magnesia, beaten

egg, or vegetable oil. Call a physician im-

mediately.

UF3K70E0.book Page 80 Tuesday, November 5, 2013 8:44 AM

Page 89 of 108

Care and storage

83

EJU33493

Long-term storage

WARNING

EWJ00331

Always place the watercraft upright in a

horizontal position when storing it, other-

wise fuel could leak out into the engine or

engine compartment, which could create

a fire hazard.

Storage for long periods of time, such as win-

ter storage, requires preventive maintenance

to ensure against deterioration. It is advisable

to have the watercraft serviced by a Yamaha

dealer prior to storage.

However, the following procedures can be

performed easily by the owner.

EJU40763Cleaning

(1) Flush the cooling water passages. (Seepage 79 for information on flushing the

cooling water passages.)

TIP:

If you will be storing the watercraft for a pro-

longed period, such as winter storage, top off

the fuel tank with fresh gasoline and add fuel

stabilizer and conditioner to the fuel tank ac-

cording to the manufacturer’s instruction be-

fore starting the engine.

(2) Clean the watercraft. (See page 80 for in-formation on cleaning the watercraft.)

Wax the hull with a non-abrasive wax.

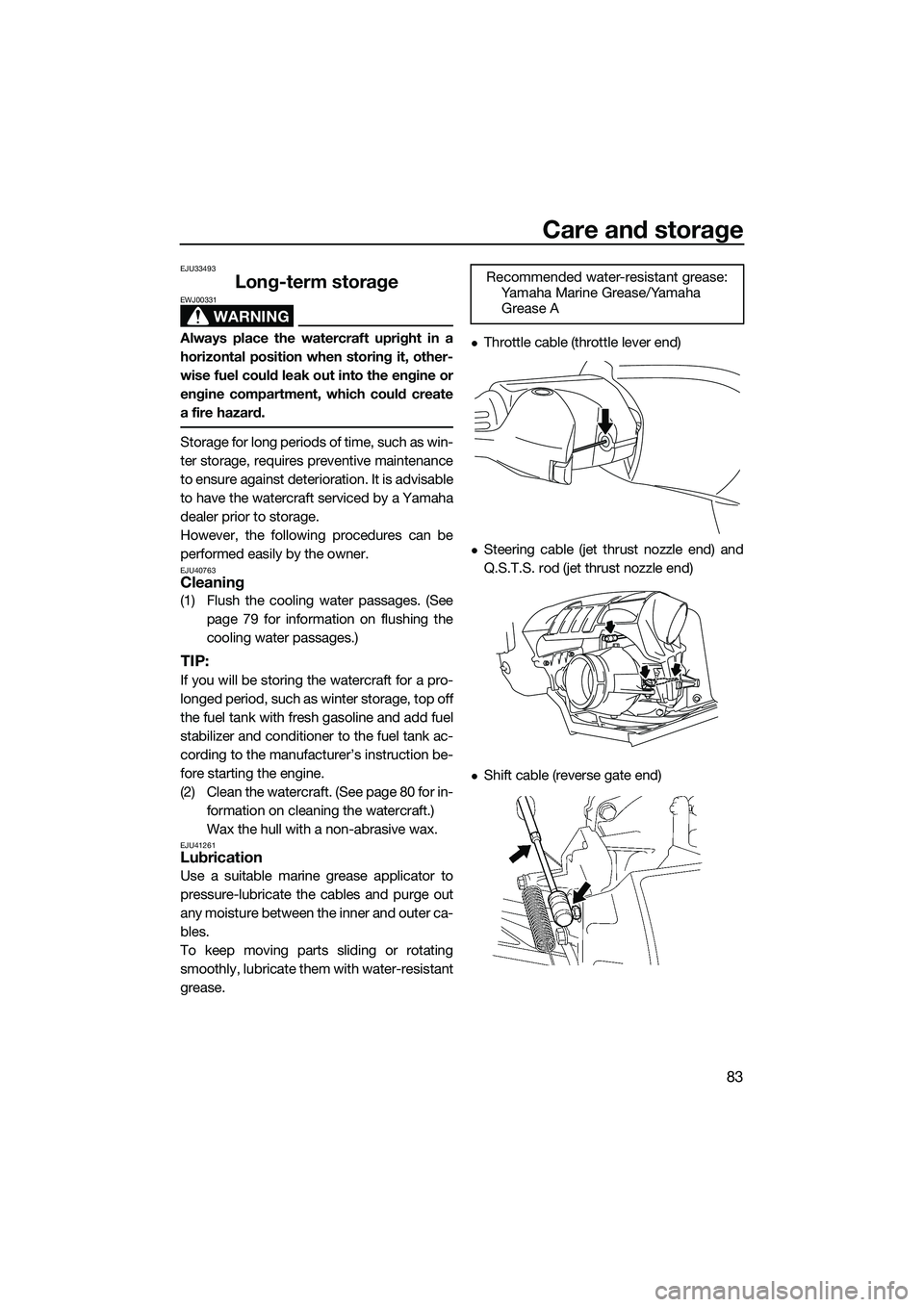

EJU41261Lubrication

Use a suitable marine grease applicator to

pressure-lubricate the cables and purge out

any moisture between the inner and outer ca-

bles.

To keep moving parts sliding or rotating

smoothly, lubricate them with water-resistant

grease.

Throttle cable (throttle lever end)

Steering cable (jet thrust nozzle end) and

Q.S.T.S. rod (jet thrust nozzle end)

Shift cable (reverse gate end)Recommended water-resistant grease:

Yamaha Marine Grease/Yamaha

Grease A

UF3K70E0.book Page 83 Tuesday, November 5, 2013 8:44 AM

Page 90 of 108

Care and storage

84

EJU40812Rustproofing

Spray metallic parts of the hull, deck, and en-

gine with a rust inhibitor.

Have a Yamaha dealer rustproof the internal

engine components.

UF3K70E0.book Page 84 Tuesday, November 5, 2013 8:44 AM

Page 91 of 108

Maintenance

85

EJU33769

Maintenance

Periodic checks and lubrication will keep

your watercraft in the safest and most effi-

cient condition possible. Therefore, make

sure to carry out the periodic maintenance.

Safety is an obligation of the watercraft own-

er. Proper maintenance must be carried out

to keep the exhaust emission and sound lev-

els within the regulated limits. The most im-

portant points of watercraft inspection and

lubrication are explained on the following

pages.

See a Yamaha dealer for genuine Yamaha re-

placement parts and optional accessories

designed for your watercraft.

Remember, failures that are the result of the

installation of parts or accessories which are

not qualitatively equivalent to genuine

Yamaha parts are not covered by the limited warranty.

Maintenance, replacement, or repair of

the emission control devices and system

may be performed by any marine SI engine

repair establishment or individual. War-

ranty repair, however, must be performed

at an authorized Yamaha marine dealer-

ship.

WARNING

EWJ00312

Be sure to turn off the engine when you

perform maintenance unless otherwise

specified. If you are not familiar with ma-

chine servicing, this work should be done

by a Yamaha dealer or other qualified me-

chanic.

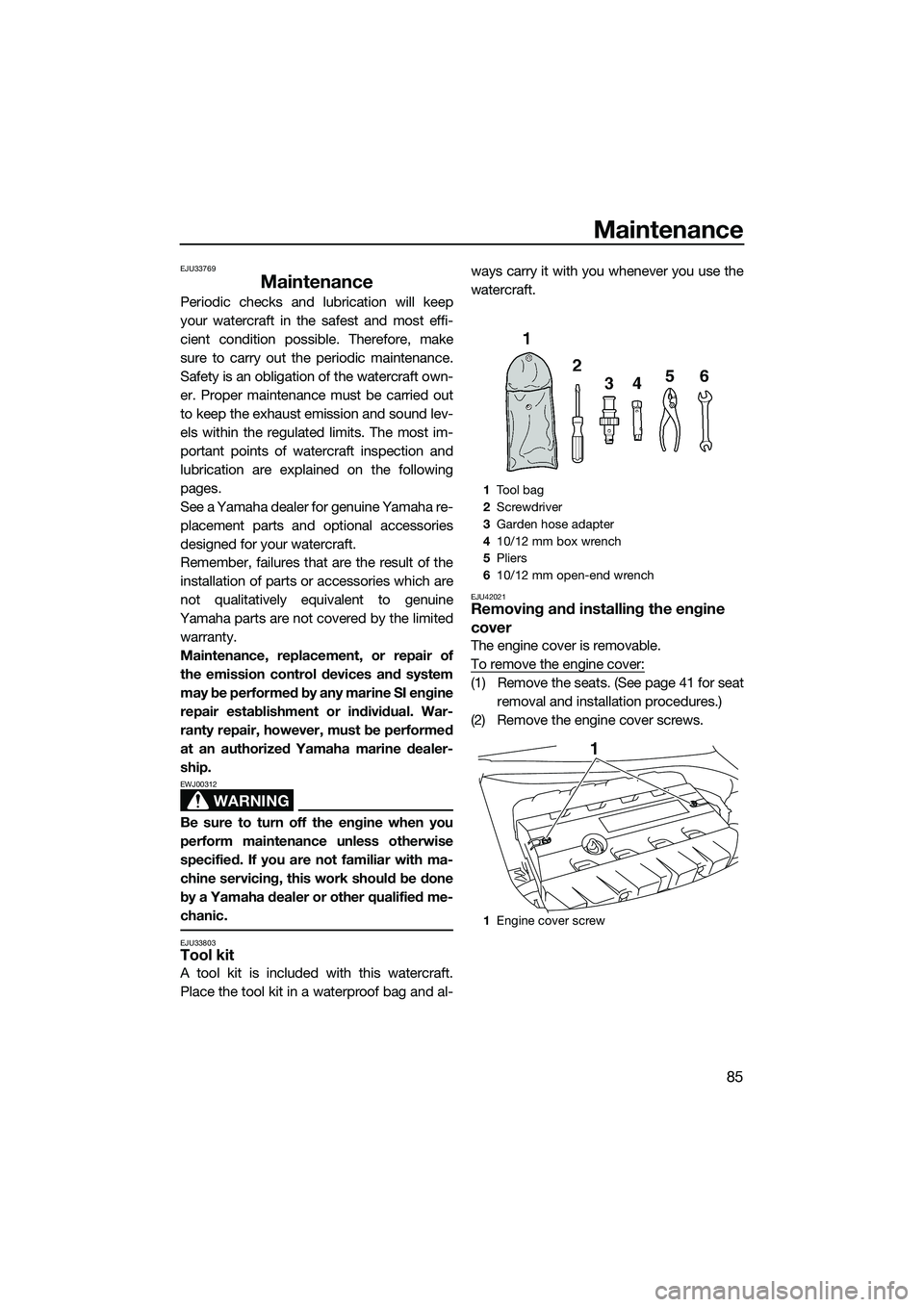

EJU33803Tool kit

A tool kit is included with this watercraft.

Place the tool kit in a waterproof bag and al- ways carry it with you whenever you use the

watercraft.

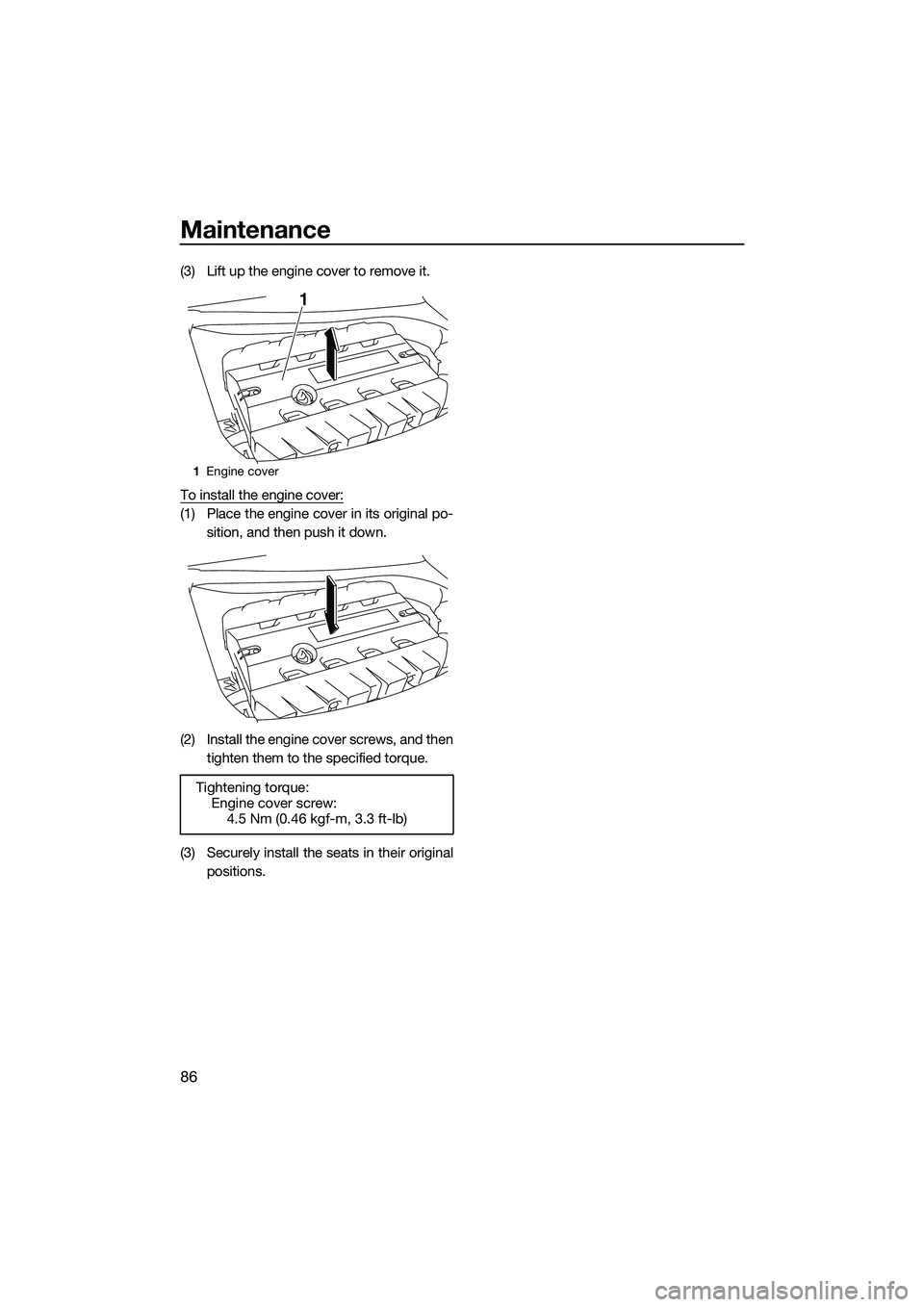

EJU42021Removing and installing the engine

cover

The engine cover is removable.

To remove the engine cover:

(1) Remove the seats. (See page 41 for seat

removal and installation procedures.)

(2) Remove the engine cover screws.

1 Tool bag

2 Screwdriver

3 Garden hose adapter

4 10/12 mm box wrench

5 Pliers

6 10/12 mm open-end wrench

1 Engine cover screw

1

UF3K70E0.book Page 85 Tuesday, November 5, 2013 8:44 AM

Page 92 of 108

Maintenance

86

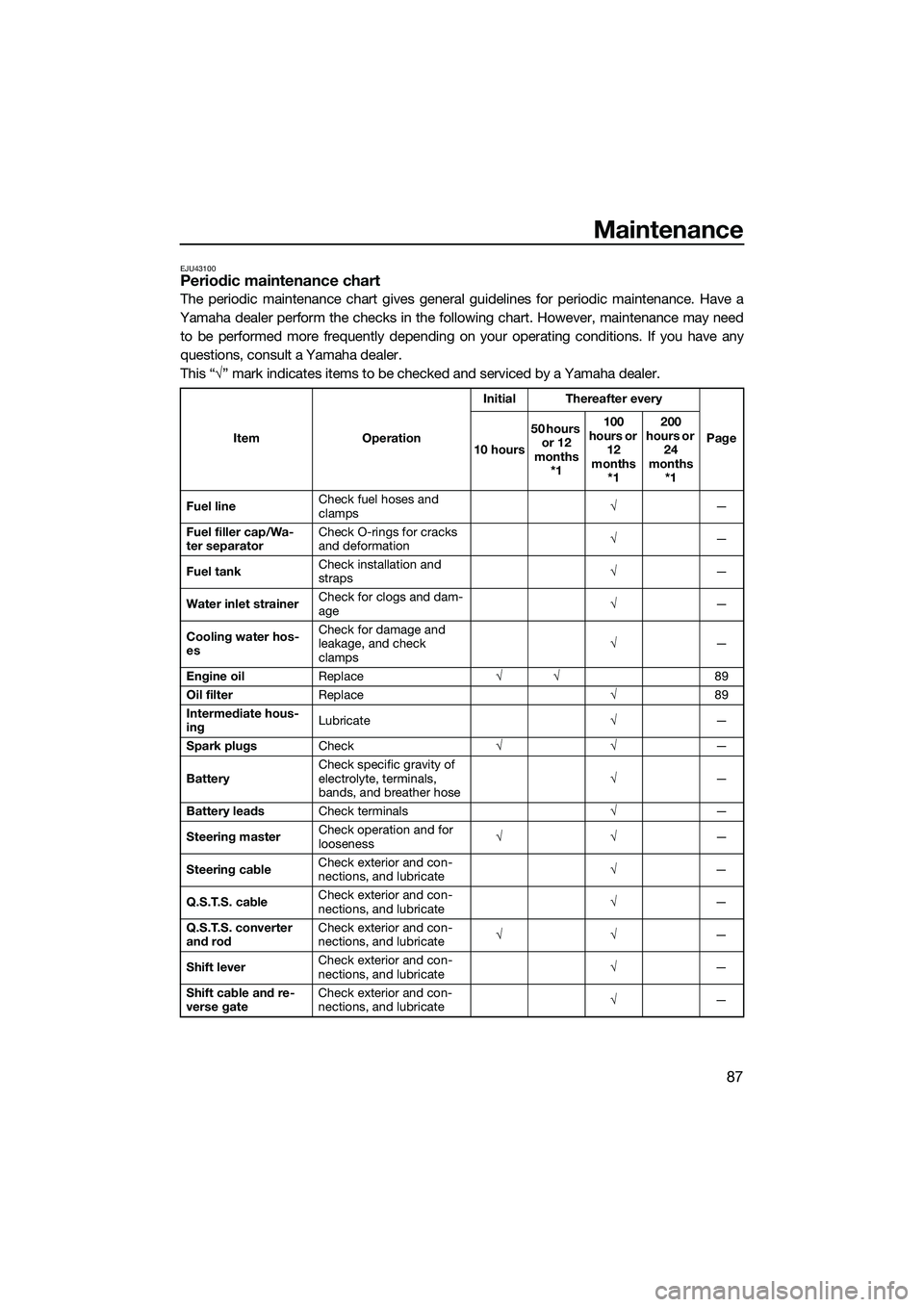

(3) Lift up the engine cover to remove it.

To install the engine cover:

(1) Place the engine cover in its original po-sition, and then push it down.

(2) Install the engine cover screws, and then tighten them to the specified torque.

(3) Securely install the seats in their original positions.

1Engine cover

Tightening torque:

Engine cover screw:

4.5 Nm (0.46 kgf-m, 3.3 ft-lb)

1

UF3K70E0.book Page 86 Tuesday, November 5, 2013 8:44 AM

Page 93 of 108

Maintenance

87

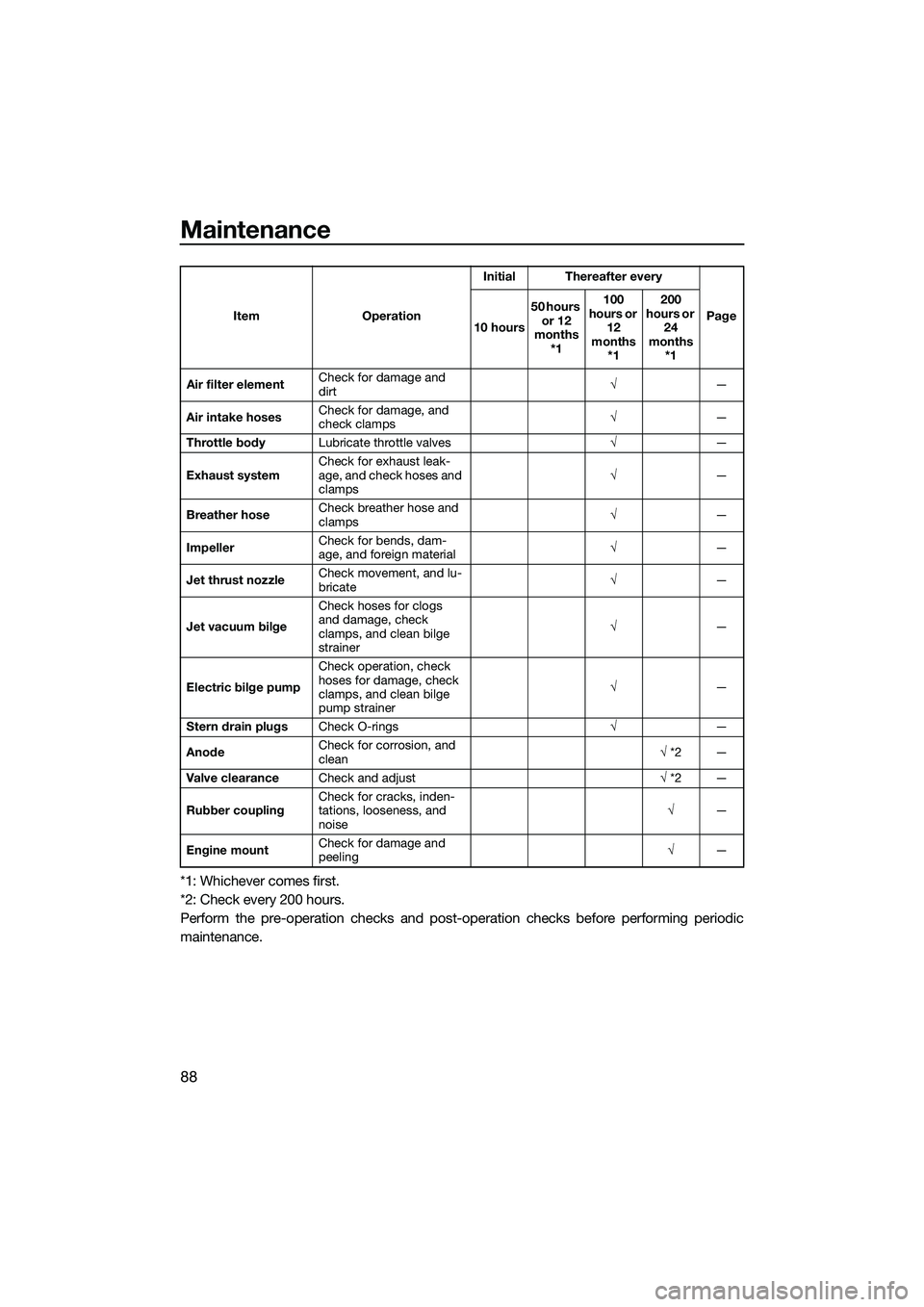

EJU43100Periodic maintenance chart

The periodic maintenance chart gives general guidelines for periodic maintenance. Have a

Yamaha dealer perform the checks in the following chart. However, maintenance may need to be performed more frequently depending on your operating conditions. If you have any

questions, consult a Yamaha dealer.

This “ √” mark indicates items to be checked and serviced by a Yamaha dealer.

Item OperationInitial Thereafter every

Page

10 hours 50 hours

or 12

months *1 100

hours or 12

months *1 200

hours or 24

months *1

Fuel line Check fuel hoses and

clamps

√

—

Fuel filler cap/Wa-

ter separator Check O-rings for cracks

and deformation

√

—

Fuel tank Check installation and

straps

√

—

Water inlet strainer Check for clogs and dam-

age

√

—

Cooling water hos-

es Check for damage and

leakage, and check

clamps

√

—

Engine oil Replace √√ 89

Oil filter Replace √89

Intermediate hous-

ing Lubricate

√—

Spark plugs Check √√ —

Battery Check specific gravity of

electrolyte, terminals,

bands, and breather hose √

—

Battery leads Check terminals √—

Steering master Check operation and for

looseness

√√

—

Steering cable Check exterior and con-

nections, and lubricate

√

—

Q.S.T.S. cable Check exterior and con-

nections, and lubricate

√

—

Q.S.T.S. converter

and rod Check exterior and con-

nections, and lubricate

√√

—

Shift lever Check exterior and con-

nections, and lubricate

√

—

Shift cable and re-

verse gate Check exterior and con-

nections, and lubricate

√

—

UF3K70E0.book Page 87 Tuesday, November 5, 2013 8:44 AM

Page 94 of 108

Maintenance

88

*1: Whichever comes first.

*2: Check every 200 hours.

Perform the pre-operation checks and post-operation checks before performing periodic

maintenance.

Air filter elementCheck for damage and

dirt

√

—

Air intake hoses Check for damage, and

check clamps

√

—

Throttle body Lubricate throttle valves √—

Exhaust system Check for exhaust leak-

age, and check hoses and

clamps √

—

Breather hose Check breather hose and

clamps

√

—

Impeller Check for bends, dam-

age, and foreign material

√

—

Jet thrust nozzle Check movement, and lu-

bricate

√

—

Jet vacuum bilge Check hoses for clogs

and damage, check

clamps, and clean bilge

strainer

√

—

Electric bilge pump Check operation, check

hoses for damage, check

clamps, and clean bilge

pump strainer

√

—

Stern drain plugs Check O-rings √—

Anode Check for corrosion, and

clean

√

*2 —

Valve clearance Check and adjust √ *2 —

Rubber coupling Check for cracks, inden-

tations, looseness, and

noise √

—

Engine mount Check for damage and

peeling

√

—

Item Operation

Initial Thereafter every

Page

10 hours 50 hours

or 12

months *1 100

hours or 12

months *1 200

hours or 24

months *1

UF3K70E0.book Page 88 Tuesday, November 5, 2013 8:44 AM