engine YAMAHA JOG50R 2012 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2012, Model line: JOG50R, Model: YAMAHA JOG50R 2012Pages: 76, PDF Size: 1.51 MB

Page 45 of 76

6. Refill with the specified amount

of the recommended final trans-

mission oil, and then install and

tighten the oil filler cap. WAR-

NING! Make sure that no

foreign material enters the final

transmission case. Make sure

that no oil gets on the tire or

wheel.

[EWA11311]

7. Check the final transmission case

for oil leakage. If oil is leaking,

check for the cause.

EAUS1200

Coolant (CS50Z)

The coolant level should be checked

before each ride. In addition, the coo-

lant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

EAUM2102

To check the coolant level

1. Place the vehicle on a level surfa-

ce and hold it in an upright posi-

tion.

TIP

●The coolant level must be chec-

ked on a cold engine since the

level varies with engine tempera-

ture.

●Make sure that the vehicle is

positioned straight up when

checking the coolant level. A

slight tilt to the side can result in

a false reading.

2. Check the coolant level through

the check window.

TIP

The coolant should be between the

minimum and maximum level marks.

1. Coolant level check window

2. Maximum level mark

3. Minimum level mark

3. If the coolant is at or below the

minimum level mark, remove the

cowling A. (See page 6-5).

4. Open the reservoir cap, and then

add coolant to the maximum

level mark. WARNING! Remove

only the coolant reservoir cap.

Never attempt to remove the

radiator cap when the engine is

hot.

[EWA15161]. NOTICE: If coolant

is not available, use distilled

MAX

MIN2

3

1

Recommended final transmission

oil:

See page 8-1

Oil quantity:

0.11 L (0.12 US qt, 0.10 Imp.qt)

Tightening torque:

Final transmission oil drain bolt:

18 Nm (1.8 m•kgf, 13.0 ft•lbf)

PERIODIC MAINTENANCE AND ADJUSTMENT

6-8

6

Page 46 of 76

water or soft tap water instead.

Do not use hard water or salt

water since it is harmful to the

engine. If water has been used

instead of coolant, replace it

with coolant as soon as possi-

ble, otherwise the cooling sys-

tem will not be protected

against frost and corrosion. If

water has been added to the

coolant, have a Yamaha dealer

check the antifreeze content of

the coolant as soon as possi-

ble, otherwise the effective-

ness of the coolant will be

reduced.

[ECA10472]

1. Coolant reservoir cap

2. Maximum level mark

3. Minimum level mark

5. Close the reservoir cap, and then

install the cowling.

EAU33031

Changing the coolant

The coolant must be changed at the

intervals specified in the periodic

maintenance and lubrication chart.

Have a Yamaha dealer change the

coolant. WARNING! Never attempt

to remove the radiator cap when

the engine is hot.

[EWA10381]EAU40370

Air filter element

The air filter element must be cleaned

and replaced at the intervals specified

in the periodic maintenance and lubri-

cation chart. Have a Yamaha dealer

clean and replace the air filter ele-

ment.

Coolant reservoir capacity:

0.25 L (0.26 US qt, 0.22 Imp.qt)

1

2

3FULL

LOW

PERIODIC MAINTENANCE AND ADJUSTMENT

6-9

6

Page 47 of 76

EAU21300

Adjusting the carburetor

The carburetor is an important part of

the engine and requires very sophisti-

cated adjustment. Therefore, all car-

buretor adjustments should be left to

a Yamaha dealer, who has the neces-

sary professional knowledge and

experience.

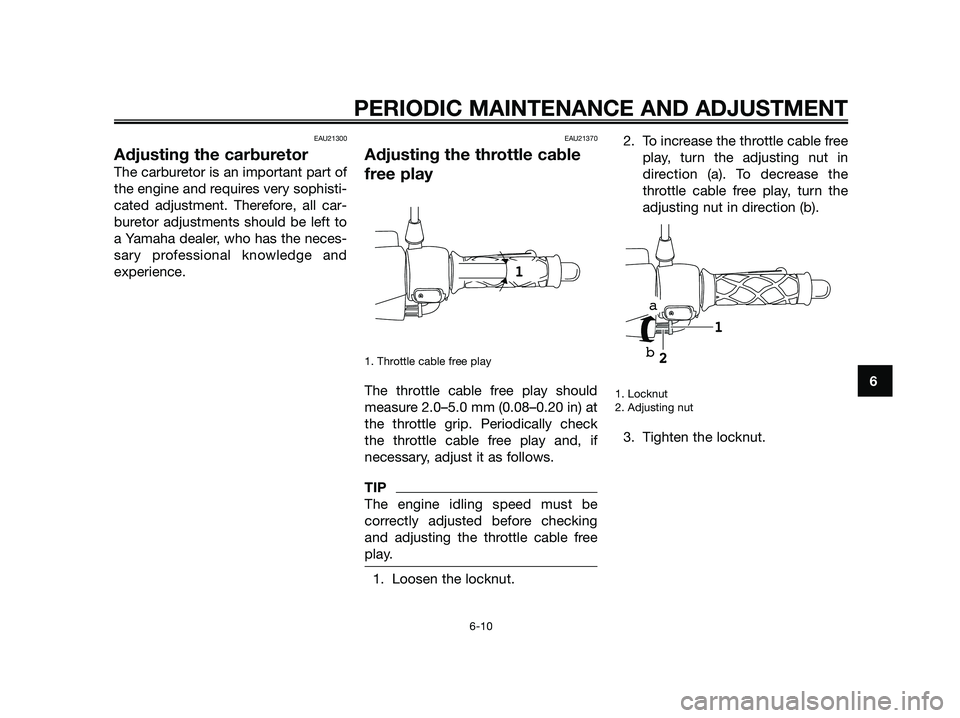

EAU21370

Adjusting the throttle cable

free play

1. Throttle cable free play

The throttle cable free play should

measure 2.0–5.0 mm (0.08–0.20 in) at

the throttle grip. Periodically check

the throttle cable free play and, if

necessary, adjust it as follows.

TIP

The engine idling speed must be

correctly adjusted before checking

and adjusting the throttle cable free

play.

1. Loosen the locknut.2. To increase the throttle cable free

play, turn the adjusting nut in

direction (a). To decrease the

throttle cable free play, turn the

adjusting nut in direction (b).

1. Locknut

2. Adjusting nut

3. Tighten the locknut.

1

2

a

b

1

PERIODIC MAINTENANCE AND ADJUSTMENT

6-10

6

Page 63 of 76

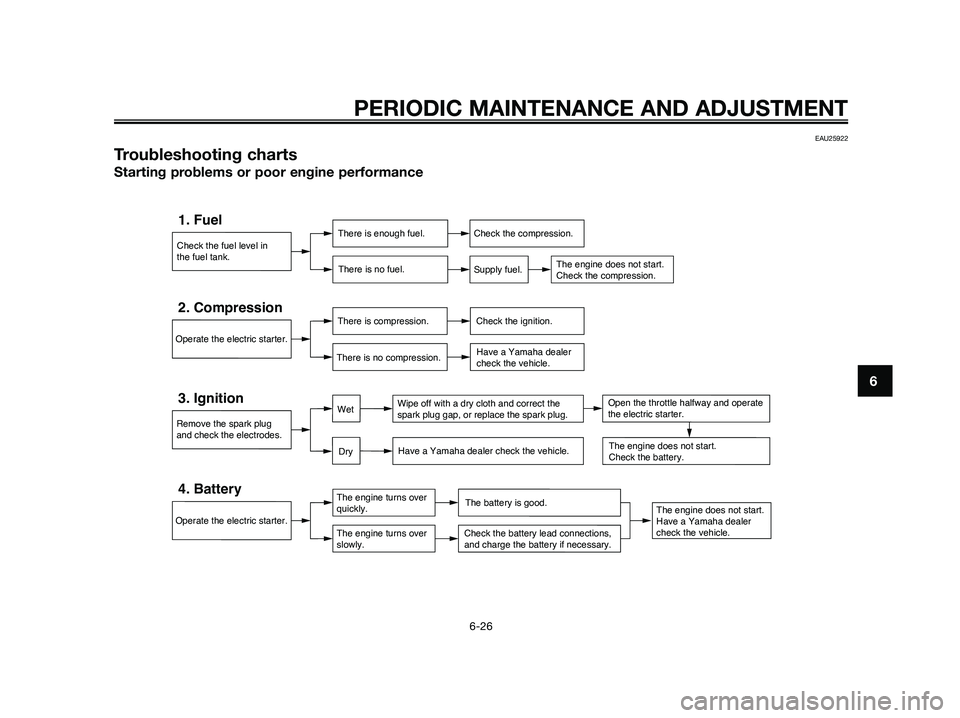

EAU25922

Troubleshooting charts

Starting problems or poor engine performance

Check the fuel level in

the fuel tank.

1. FuelThere is enough fuel.

There is no fuel.Check the compression.

Supply fuel.

The engine does not start.

Check the compression.

Operate the electric starter.

2. CompressionThere is compression.

There is no compression.Check the ignition.

Have a Yamaha dealer

check the vehicle.

Remove the spark plug

and check the electrodes.

3. IgnitionWipe off with a dry cloth and correct the

spark plug gap, or replace the spark plug.

Have a Yamaha dealer check the vehicle.

The engine does not start.

Have a Yamaha dealer

check the vehicle.

The engine does not start.

Check the battery.

Operate the electric starter.

4. BatteryThe engine turns over

quickly.

The engine turns over

slowly.The battery is good.

Check the battery lead connections,

and charge the battery if necessary.

Dry

WetOpen the throttle halfway and operate

the electric starter.

PERIODIC MAINTENANCE AND ADJUSTMENT

6-26

6

Page 64 of 76

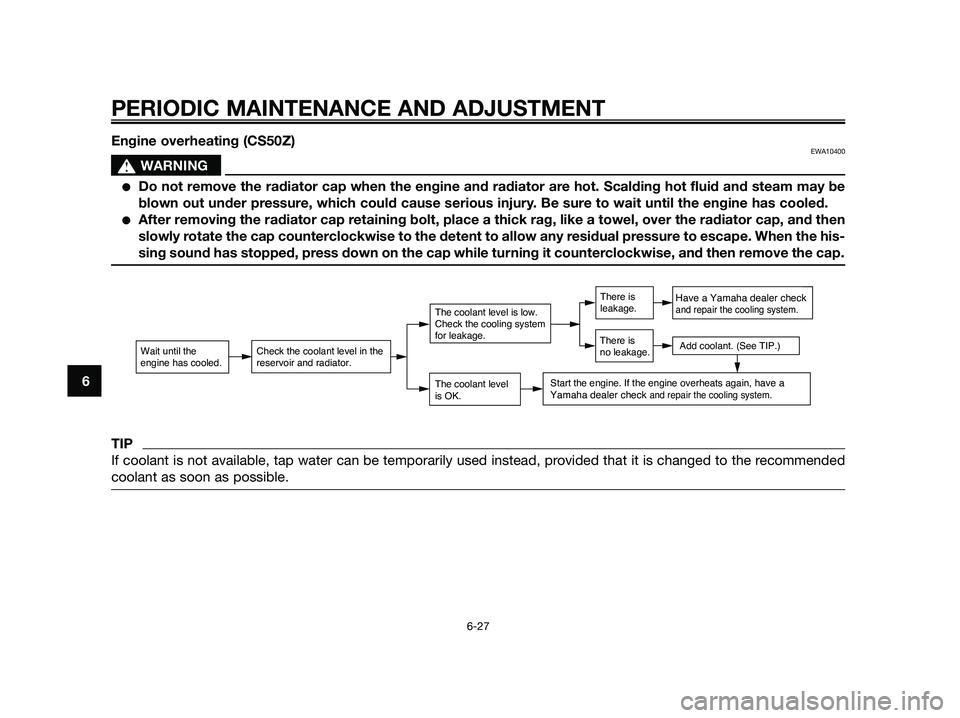

Engine overheating (CS50Z)EWA10400

sWARNING

●Do not remove the radiator cap when the engine and radiator are hot. Scalding hot fluid and steam may be

blown out under pressure, which could cause serious injury. Be sure to wait until the engine has cooled.

●After removing the radiator cap retaining bolt, place a thick rag, like a towel, over the radiator cap, and then

slowly rotate the cap counterclockwise to the detent to allow any residual pressure to escape. When the his-

sing sound has stopped, press down on the cap while turning it counterclockwise, and then remove the cap.

TIP

If coolant is not available, tap water can be temporarily used instead, provided that it is changed to the recommended

coolant as soon as possible.

Wait until the

engine has cooled.Check the coolant level in the

reservoir and radiator.

The coolant level

is OK.

The coolant level is low.

Check the cooling system

for leakage.

Have a Yamaha dealer checkand repair the cooling system.

Add coolant. (See TIP.)

Start the engine. If the engine overheats again, have a

Yamaha dealer check and repair the cooling system.

There is

leakage.

There is

no leakage.

PERIODIC MAINTENANCE AND ADJUSTMENT

6-27

6

Page 65 of 76

EAU37833

Matte color cautionECA15192

NOTICE

Some models are equipped with

matte colored finished parts. Be

sure to consult a Yamaha dealer for

advice on what products to use

before cleaning the vehicle.

Using a brush, harsh chemical pro-

ducts or cleaning compounds

when cleaning these parts will

scratch or damage their surface.

Wax also should not be applied to

any matte colored finished parts.

EAU26092

Care

While the open design of a scooter

reveals the attractiveness of the tech-

nology, it also makes it more vulnera-

ble. Rust and corrosion can develop

even if high-quality components are

used. A rusty exhaust pipe may go

unnoticed on a car, however, it

detracts from the overall appearance

of a scooter. Frequent and proper

care does not only comply with the

terms of the warranty, but it will also

keep your scooter looking good,

extend its life and optimize its perfor-

mance.

Before cleaning

1. Cover the muffler outlet with a

plastic bag after the engine has

cooled down.

2. Make sure that all caps and

covers as well as all electrical

couplers and connectors, inclu-

ding the spark plug cap, are

tightly installed.

3. Remove extremely stubborn dirt,

like oil burnt onto the crankcase,

with a degreasing agent and a

brush, but never apply such pro-ducts onto seals, gaskets and

wheel axles. Always rinse the dirt

and degreaser off with water.

Cleaning

ECA10781

NOTICE

●Avoid using strong acidic whe-

el cleaners, especially on spo-

ked wheels. If such products

are used on hard-to-remove

dirt, do not leave the cleaner on

the affected area any longer

than instructed. Also, tho-

roughly rinse the area off with

water, immediately dry it, and

then apply a corrosion protec-

tion spray.

●Improper cleaning can damage

plastic parts such as cowlings,

panels, windshields, headlight

lenses, meter lenses, etc. Use

only a soft, clean cloth or spon-

ge with mild detergent and

water to clean plastic.

●Do not use any harsh chemical

products on plastic parts. Be

sure to avoid using cloths or

sponges which have been in

contact with strong or abrasive

SCOOTER CARE AND STORAGE

7-1

7

Page 66 of 76

cleaning products, solvent or

thinner, fuel (gasoline), rust

removers or inhibitors, brake

fluid, antifreeze or electrolyte.

●Do not use high-pressure was-

hers or steam-jet cleaners sin-

ce they cause water seepage

and deterioration in the follo-

wing areas: seals (of wheel and

swingarm bearings, fork and

brakes), electric components

(couplers, connectors, instru-

ments, switches and lights),

breather hoses and vents.

●For scooters equipped with a

windshield: Do not use strong

cleaners or hard sponges as

they will cause dulling or scrat-

ching. Some cleaning com-

pounds for plastic may leave

scratches on the windshield.

Test the product on a small hid-

den part of the windshield to

make sure that it does not lea-

ve any marks. If the windshield

is scratched, use a quality

plastic polishing compound

after washing.

After normal use

1. Remove dirt with warm water, a

mild detergent, and a soft, clean

sponge, and then rinse tho-

roughly with clean water. Use a

toothbrush or bottlebrush for

hard-to-reach areas. Stubborn

dirt and insects will come off

more easily if the area is covered

with a wet cloth for a few minutes

before cleaning.

After riding in the rain, near the sea or

on salt-sprayed roads

1. Since sea salt or salt sprayed on

the roads during winter are extre-

mely corrosive in combination

with water, carry out the following

steps after each ride in the rain,

near the sea or on salt-sprayed

roads.

TIP

Salt sprayed on roads in the winter

may remain well into spring.

1. Clean the scooter with cold water

and a mild detergent after the

engine has cooled down. NOTI-

CE:Do not use warm watersince it increases the corrosive

action of the salt.

[ECA10791]

2. Apply a corrosion protection

spray on all metal, including

chrome- and nickel-plated, surfa-

ces to prevent corrosion.

After cleaning

1. Dry the scooter with a chamois or

an absorbing cloth.

2. Use a chrome polish to shine

chrome, aluminum and stainless-

steel parts, including the exhaust

system. (Even the thermally indu-

ced discoloring of stainless-steel

exhaust systems can be removed

through polishing.)

3. To prevent corrosion, it is recom-

mended to apply a corrosion pro-

tection spray on all metal, inclu-

ding chrome- and nickel-plated,

surfaces.

4. Use spray oil as a universal clea-

ner to remove any remaining dirt.

5. Touch up minor paint damage

caused by stones, etc.

6. Wax all painted surfaces.

7. Let the scooter dry completely

before storing or covering it.

SCOOTER CARE AND STORAGE

7-2

7

Page 68 of 76

3. Fill up the fuel tank and add fuel

stabilizer (if available) to prevent

the fuel tank from rusting and the

fuel from deteriorating.

4. Perform the following steps to

protect the cylinder, piston rings,

etc. from corrosion.

a. Remove the spark plug cap

and spark plug.

b. Pour a teaspoonful of engine

oil into the spark plug bore.

c. Install the spark plug cap

onto the spark plug, and then

place the spark plug on the

cylinder head so that the

electrodes are grounded.

(This will limit sparking during

the next step.)

d. Turn the engine over several

times with the starter. (This

will coat the cylinder wall with

oil.) WARNING! To prevent

damage or injury from spar-

king, make sure to ground

the spark plug electrodes

while turning the engine

over. e. Remove the spark plug cap

from the spark plug, and then

install the spark plug and the

spark plug cap.

5. Lubricate all control cables and

the pivoting points of all levers

and pedals as well as of the

sidestand/centerstand.

6. Check and, if necessary, correct

the tire air pressure, and then lift

the scooter so that both of its

wheels are off the ground. Alter-

natively, turn the wheels a little

every month in order to prevent

the tires from becoming degra-

ded in one spot.

7. Cover the muffler outlet with a

plastic bag to prevent moisture

from entering it.

8. Remove the battery and fully

charge it. Store it in a cool, dry

place and charge it once a

month. Do not store the battery in

an excessively cold or warm pla-

ce [less than 0 °C (30 °F) or more

than 30 °C (90 °F)]. For more

information on storing the bat-

tery, see page 6-19.TIP

Make any necessary repairs before

storing the scooter.

SCOOTER CARE AND STORAGE

7-4

7

Page 69 of 76

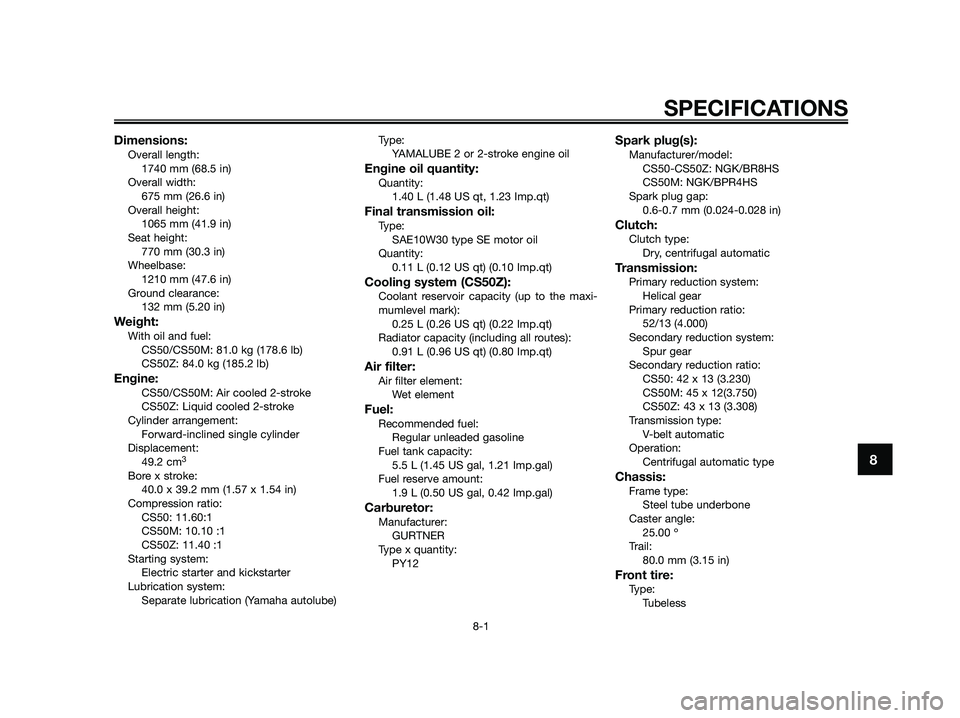

Dimensions:Overall length:

1740 mm (68.5 in)

Overall width:

675 mm (26.6 in)

Overall height:

1065 mm (41.9 in)

Seat height:

770 mm (30.3 in)

Wheelbase:

1210 mm (47.6 in)

Ground clearance:

132 mm (5.20 in)

Weight:With oil and fuel:

CS50/CS50M: 81.0 kg (178.6 lb)

CS50Z: 84.0 kg (185.2 lb)

Engine:CS50/CS50M: Air cooled 2-stroke

CS50Z: Liquid cooled 2-stroke

Cylinder arrangement:

Forward-inclined single cylinder

Displacement:

49.2 cm

3

Bore x stroke:

40.0 x 39.2 mm (1.57 x 1.54 in)

Compression ratio:

CS50: 11.60:1

CS50M: 10.10 :1

CS50Z: 11.40 :1

Starting system:

Electric starter and kickstarter

Lubrication system:

Separate lubrication (Yamaha autolube)Type:

YAMALUBE 2 or 2-stroke engine oil

Engine oil quantity:Quantity:

1.40 L (1.48 US qt, 1.23 Imp.qt)

Final transmission oil:Type:

SAE10W30 type SE motor oil

Quantity:

0.11 L (0.12 US qt) (0.10 Imp.qt)

Cooling system (CS50Z):Coolant reservoir capacity (up to the maxi-

mumlevel mark):

0.25 L (0.26 US qt) (0.22 Imp.qt)

Radiator capacity (including all routes):

0.91 L (0.96 US qt) (0.80 Imp.qt)

Air filter:Air filter element:

Wet element

Fuel:Recommended fuel:

Regular unleaded gasoline

Fuel tank capacity:

5.5 L (1.45 US gal, 1.21 Imp.gal)

Fuel reserve amount:

1.9 L (0.50 US gal, 0.42 Imp.gal)

Carburetor:Manufacturer:

GURTNER

Type x quantity:

PY12

Spark plug(s):Manufacturer/model:

CS50-CS50Z: NGK/BR8HS

CS50M: NGK/BPR4HS

Spark plug gap:

0.6-0.7 mm (0.024-0.028 in)

Clutch:Clutch type:

Dry, centrifugal automatic

Transmission:Primary reduction system:

Helical gear

Primary reduction ratio:

52/13 (4.000)

Secondary reduction system:

Spur gear

Secondary reduction ratio:

CS50: 42 x 13 (3.230)

CS50M: 45 x 12(3.750)

CS50Z: 43 x 13 (3.308)

Transmission type:

V-belt automatic

Operation:

Centrifugal automatic type

Chassis:Frame type:

Steel tube underbone

Caster angle:

25.00 º

Trail:

80.0 mm (3.15 in)

Front tire:Type:

Tubeless

SPECIFICATIONS

8-1

8

Page 74 of 76

2-stroke engine oil ...................................3-10

AAcceleration and deceleration ...................5-2

Air filter element .........................................6-9

Auxiliary light bulb, replacing ...................6-24

BBattery......................................................6-19

Brake fluid level, checking .......................6-15

Brake fluid, changing ...............................6-16

Brake lever, front ........................................3-6

Brake lever, rear .........................................3-7

Brake levers, lubricating ..........................6-16

Brake pads and shoes, checking ............6-14

Braking .......................................................5-3

CCarburetor,adjusting.................................6-10

Care............................................................7-1

Catalytic converter .....................................3-9

Centerstand, checking and lubricating ....6-17

Coolant.......................................................6-8

Cowling and panel, removing

and installing............................................6-5

DDimmer switch ...........................................3-6

EEngine break-in ..........................................5-4

FFinal transmission oil .................................6-7

Front brake lever free play, checking.......6-13

Front fork, checking .................................6-18

Fuel ............................................................3-8

Fuel and 2-stroke engine oil tank caps .....3-7

Fuel consumption, tips for reducing ..........5-3

Fuse, replacing.........................................6-20

HHandlebar switches ...................................3-6

Headlight and front turn signal light

bulb, replacing .......................................6-21

High beam indicator light...........................3-2

Horn switch ................................................3-6

IIdentification numbers ...............................9-1

Indicator and warning lights ......................3-2

KKey identification number ..........................9-1

Kickstarter ................................................3-10

LLicense plate light bulb, replacing ...........6-24

Luggage hook ..........................................3-13

M

Main switch/steering lock ..........................3-1

Matte color, caution ...................................7-1

Model label ................................................9-2

Multi-function display ................................3-4

OOil level warning light .................................3-3

PParking .......................................................5-4

Part locations .............................................1-5

Periodic maintenance and lubrication

chart .........................................................6-2

Pre-operation check list .............................4-2

RRear brake lever free play, adjusting .......6-13

Rider seat .................................................3-11

SSafe-riding points.......................................1-5

Safety information ......................................1-1Shock absorber assembly, adjusting.......3-12

Spark plug, checking .................................6-6

Specifications.............................................7-3

Speedometer .............................................3-3

Start switch ................................................3-6

Starting a cold engine ................................5-1

Starting off .................................................5-2

Steering, checking ...................................6-18

Storage.......................................................7-3

Storage compartment ..............................3-11

TTail/brake light bulb or rear turn signal

light bulb, replacing ...............................6-23

Throttle cable free play, adjusting ............6-10

Throttle grip and cable, checking and

lubricating ..............................................6-16

Tires .........................................................6-11

Troubleshooting .......................................6-25

Troubleshooting charts ............................6-26

Turn signal indicator lights .........................3-2

Turn signal switch ......................................3-6

VVehicle identification number .....................9-1

WWheel bearings, checking........................6-19

Wheels .....................................................6-12

INDEX