YAMAHA MT-09 2014 Owner's Guide

Manufacturer: YAMAHA, Model Year: 2014, Model line: MT-09, Model: YAMAHA MT-09 2014Pages: 110, PDF Size: 3.21 MB

Page 31 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-16

3

EAU12821

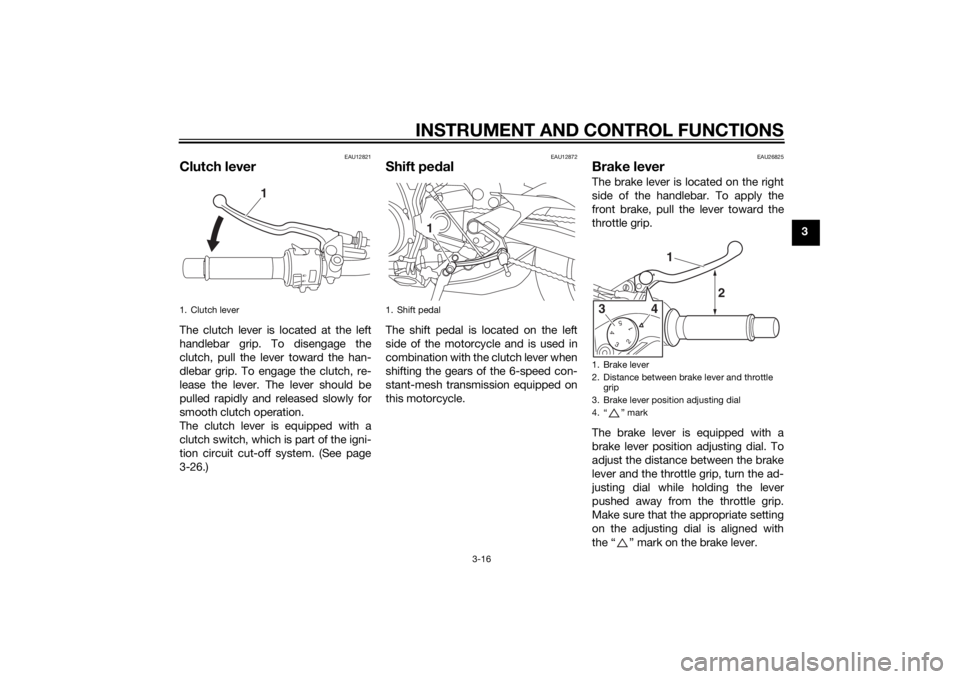

Clutch leverThe clutch lever is located at the left

handlebar grip. To disengage the

clutch, pull the lever toward the han-

dlebar grip. To engage the clutch, re-

lease the lever. The lever should be

pulled rapidly and released slowly for

smooth clutch operation.

The clutch lever is equipped with a

clutch switch, which is part of the igni-

tion circuit cut-off system. (See page

3-26.)

EAU12872

Shift pedalThe shift pedal is located on the left

side of the motorcycle and is used in

combination with the clutch lever when

shifting the gears of the 6-speed con-

stant-mesh transmission equipped on

this motorcycle.

EAU26825

Brake leverThe brake lever is located on the right

side of the handlebar. To apply the

front brake, pull the lever toward the

throttle grip.

The brake lever is equipped with a

brake lever position adjusting dial. To

adjust the distance between the brake

lever and the throttle grip, turn the ad-

justing dial while holding the lever

pushed away from the throttle grip.

Make sure that the appropriate setting

on the adjusting dial is aligned with

the “ ” mark on the brake lever.

1. Clutch lever

1

1. Shift pedal

1

1. Brake lever

2. Distance between brake lever and throttle

grip

3. Brake lever position adjusting dial

4. “ ” mark

543

21

1

2

43

U1RCELE0.book Page 16 Monday, May 12, 2014 8:51 AM

Page 32 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-17

3

EAU12944

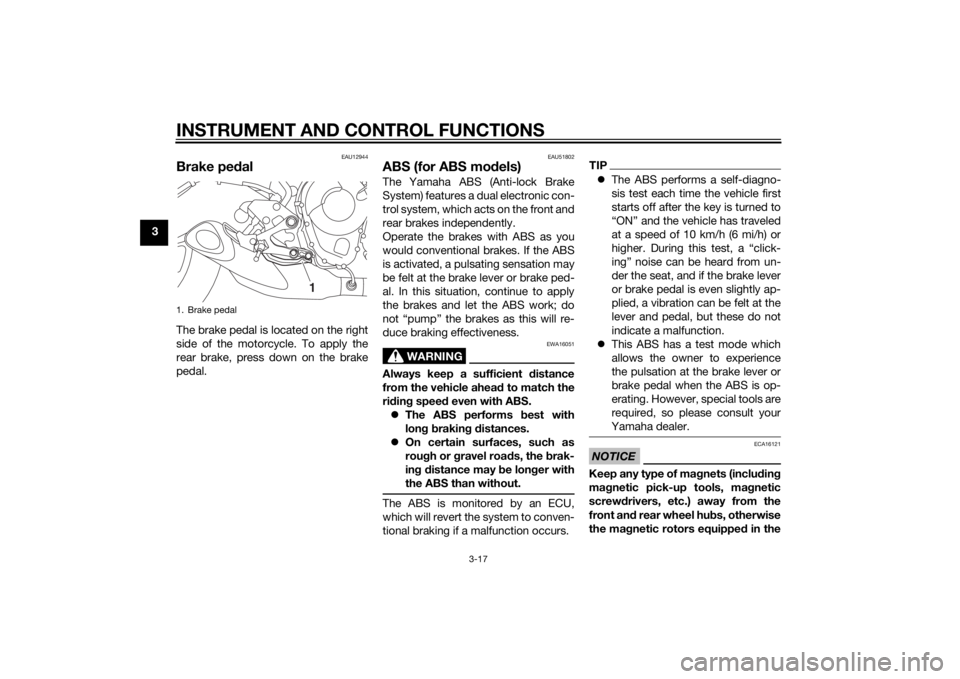

Brake pedalThe brake pedal is located on the right

side of the motorcycle. To apply the

rear brake, press down on the brake

pedal.

EAU51802

ABS (for ABS mo dels)The Yamaha ABS (Anti-lock Brake

System) features a dual electronic con-

trol system, which acts on the front and

rear brakes independently.

Operate the brakes with ABS as you

would conventional brakes. If the ABS

is activated, a pulsating sensation may

be felt at the brake lever or brake ped-

al. In this situation, continue to apply

the brakes and let the ABS work; do

not “pump” the brakes as this will re-

duce braking effectiveness.

WARNING

EWA16051

Always keep a sufficient distance

from the vehicle ahea d to match the

ri din g spee d even with ABS.

The ABS performs best with

lon g b rakin g d istances.

On certain surfaces, such as

rou gh or g ravel roa ds, the b rak-

in g d istance may b e longer with

the ABS than without.The ABS is monitored by an ECU,

which will revert the system to conven-

tional braking if a malfunction occurs.

TIP The ABS performs a self-diagno-

sis test each time the vehicle first

starts off after the key is turned to

“ON” and the vehicle has traveled

at a speed of 10 km/h (6 mi/h) or

higher. During this test, a “click-

ing” noise can be heard from un-

der the seat, and if the brake lever

or brake pedal is even slightly ap-

plied, a vibration can be felt at the

lever and pedal, but these do not

indicate a malfunction.

This ABS has a test mode which

allows the owner to experience

the pulsation at the brake lever or

brake pedal when the ABS is op-

erating. However, special tools are

required, so please consult your

Yamaha dealer.NOTICE

ECA16121

Keep any type of ma gnets (inclu din g

ma gnetic pick-up tools, mag netic

screwd rivers, etc.) away from the

front an d rear wheel hu bs, otherwise

the ma gnetic rotors equippe d in the

1. Brake pedal

1

U1RCELE0.book Page 17 Monday, May 12, 2014 8:51 AM

Page 33 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-18

3

wheel hu

bs may be damag ed , re-

sultin g in improper performance of

the ABS system.

EAU13075

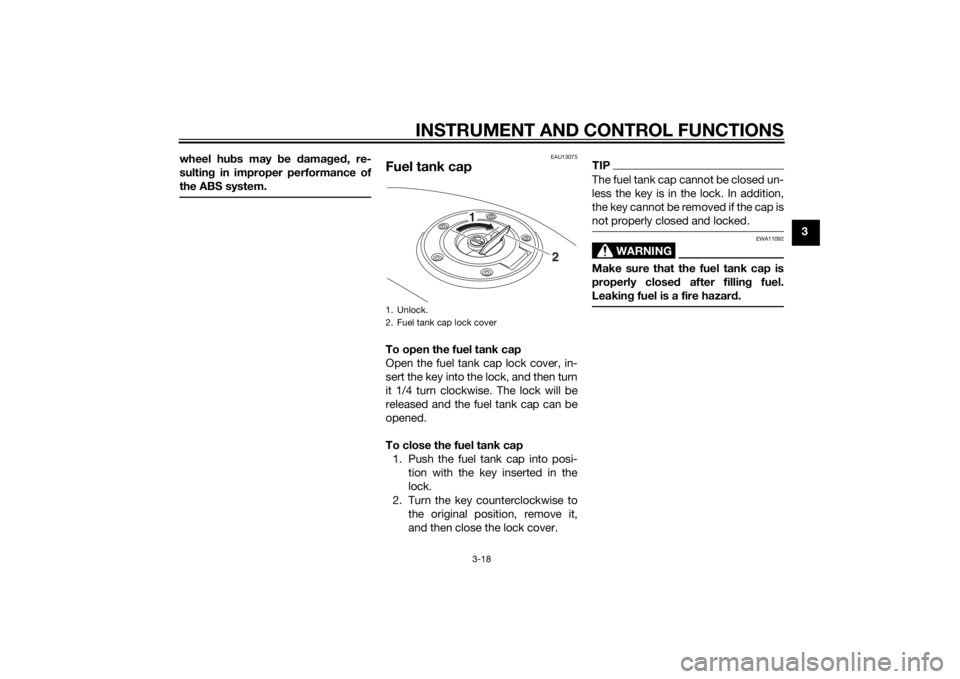

Fuel tank capTo open the fuel tank cap

Open the fuel tank cap lock cover, in-

sert the key into the lock, and then turn

it 1/4 turn clockwise. The lock will be

released and the fuel tank cap can be

opened.

To close the fuel tank cap 1. Push the fuel tank cap into posi- tion with the key inserted in the

lock.

2. Turn the key counterclockwise to the original position, remove it,

and then close the lock cover.

TIPThe fuel tank cap cannot be closed un-

less the key is in the lock. In addition,

the key cannot be removed if the cap is

not properly closed and locked.

WARNING

EWA11092

Make sure that the fuel tank cap is

properly close d after fillin g fuel.

Leakin g fuel is a fire hazar d.

1. Unlock.

2. Fuel tank cap lock cover

2

1

U1RCELE0.book Page 18 Monday, May 12, 2014 8:51 AM

Page 34 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-19

3

EAU13222

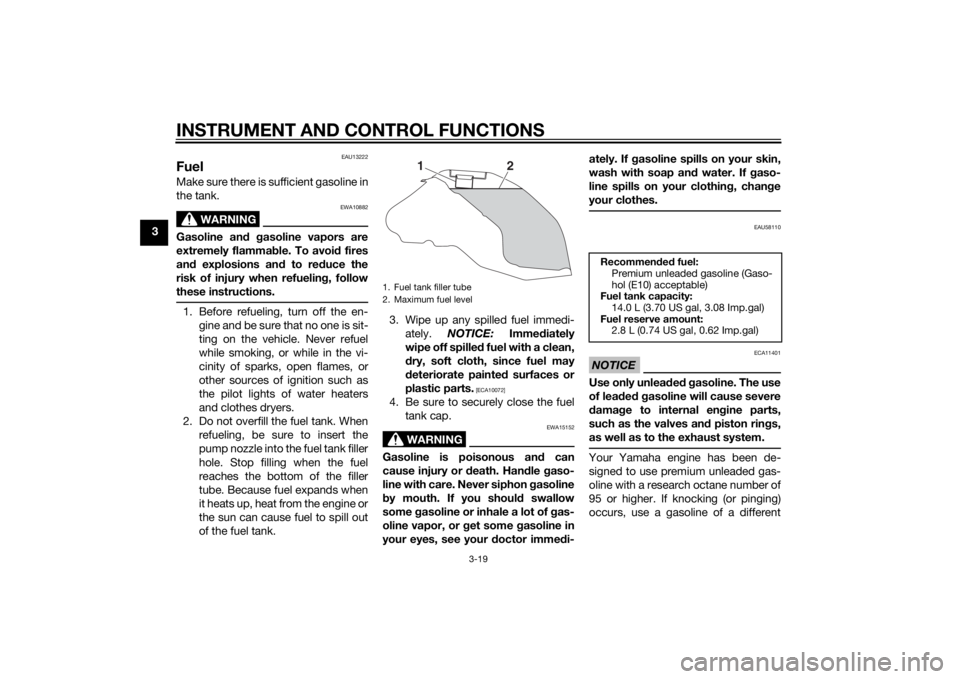

FuelMake sure there is sufficient gasoline in

the tank.

WARNING

EWA10882

Gasoline and g asoline vapors are

extremely flamma ble. To avoi d fires

an d explosions an d to re duce the

risk of injury when refuelin g, follow

these instructions.1. Before refueling, turn off the en- gine and be sure that no one is sit-

ting on the vehicle. Never refuel

while smoking, or while in the vi-

cinity of sparks, open flames, or

other sources of ignition such as

the pilot lights of water heaters

and clothes dryers.

2. Do not overfill the fuel tank. When refueling, be sure to insert the

pump nozzle into the fuel tank filler

hole. Stop filling when the fuel

reaches the bottom of the filler

tube. Because fuel expands when

it heats up, heat from the engine or

the sun can cause fuel to spill out

of the fuel tank. 3. Wipe up any spilled fuel immedi-

ately. NOTICE: Immediately

wipe off spille d fuel with a clean,

d ry, soft cloth, since fuel may

d eteriorate painted surfaces or

plastic parts.

[ECA10072]

4. Be sure to securely close the fuel tank cap.

WARNING

EWA15152

Gasoline is poisonous an d can

cause injury or death. Han dle gaso-

line with care. Never siphon gasoline

b y mouth. If you shoul d swallow

some gasoline or inhale a lot of gas-

oline vapor, or g et some gasoline in

your eyes, see your doctor imme di- ately. If g

asoline spills on your skin,

wash with soap an d water. If gaso-

line spills on your clothin g, chan ge

your clothes.

EAU58110

NOTICE

ECA11401

Use only unlea ded g asoline. The use

of lea ded g asoline will cause severe

d amag e to internal en gine parts,

such as the valves an d piston rin gs,

as well as to the exhaust system.Your Yamaha engine has been de-

signed to use premium unleaded gas-

oline with a research octane number of

95 or higher. If knocking (or pinging)

occurs, use a gasoline of a different

1. Fuel tank filler tube

2. Maximum fuel level

1

2

Recommen ded fuel:

Premium unleaded gasoline (Gaso-

hol (E10) acceptable)

Fuel tank capacity:

14.0 L (3.70 US gal, 3.08 Imp.gal)

Fuel reserve amount: 2.8 L (0.74 US gal, 0.62 Imp.gal)

U1RCELE0.book Page 19 Monday, May 12, 2014 8:51 AM

Page 35 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-20

3

brand. Use of unleaded fuel will extend

spark plug life and reduce mainte-

nance costs.

Gasohol

There are two types of gasohol: gaso-

hol containing ethanol and that con-

taining methanol. Gasohol containing

ethanol can be used if the ethanol con-

tent does not exceed 10% (E10). Gas-

ohol containing methanol is not

recommended by Yamaha because it

can cause damage to the fuel system

or vehicle performance problems.

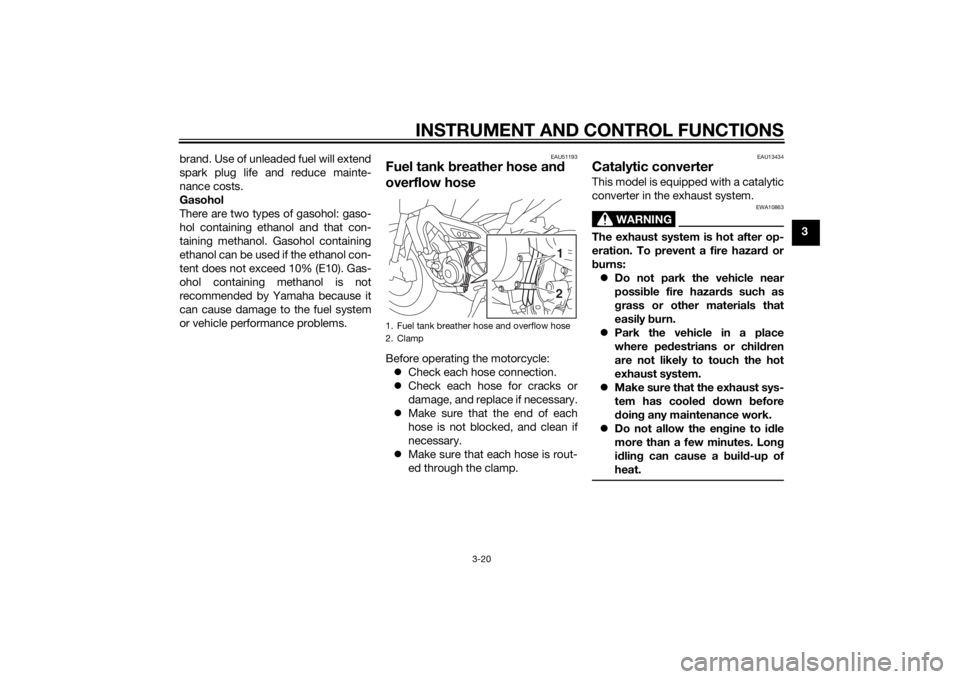

EAU51193

Fuel tank

breather hose an d

overflow hoseBefore operating the motorcycle:

Check each hose connection.

Check each hose for cracks or

damage, and replace if necessary.

Make sure that the end of each

hose is not blocked, and clean if

necessary.

Make sure that each hose is rout-

ed through the clamp.

EAU13434

Catalytic converterThis model is equipped with a catalytic

converter in the exhaust system.

WARNING

EWA10863

The exhaust system is hot after op-

eration. To prevent a fire hazar d or

b urns:

Do not park the vehicle near

possi ble fire hazar ds such as

g rass or other materials that

easily burn.

Park the vehicle in a place

where pe destrians or chil dren

are not likely to touch the hot

exhaust system.

Make sure that the exhaust sys-

tem has coole d down before

d oin g any maintenance work.

Do not allow the en gine to i dle

more than a few minutes. Lon g

i d lin g can cause a b uild-up of

heat.

1. Fuel tank breather hose and overflow hose

2. Clamp

21

U1RCELE0.book Page 20 Monday, May 12, 2014 8:51 AM

Page 36 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-21

3

NOTICE

ECA10702

Use only unleaded g asoline. The use

of lead ed g asoline will cause unre-

pairab le damag e to the catalytic

converter.

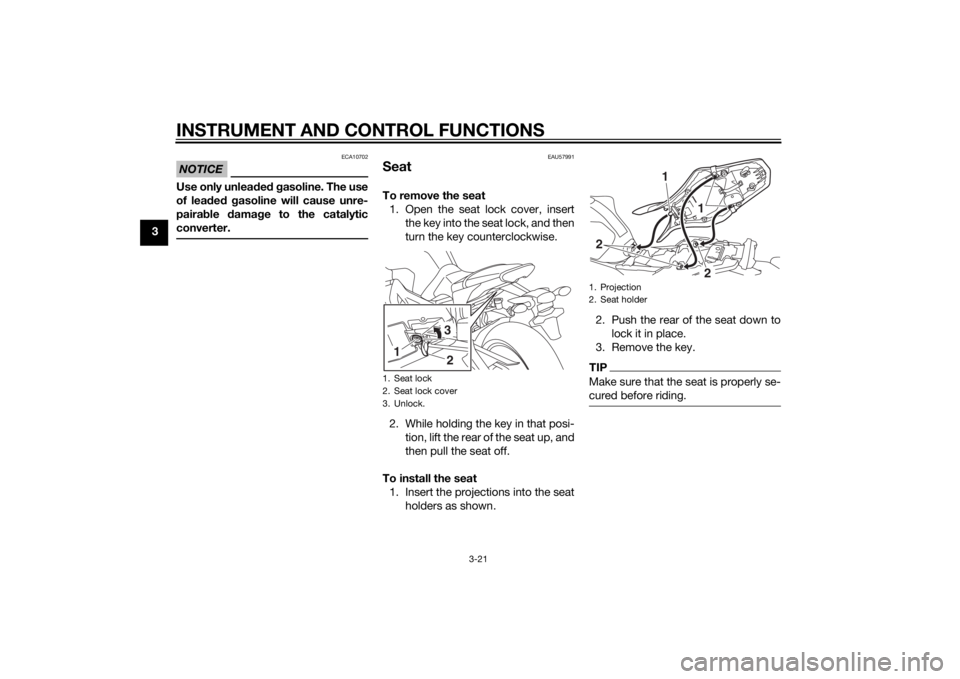

EAU57991

SeatTo remove the seat 1. Open the seat lock cover, insert the key into the seat lock, and then

turn the key counterclockwise.

2. While holding the key in that posi- tion, lift the rear of the seat up, and

then pull the seat off.

To install the seat 1. Insert the projections into the seat holders as shown. 2. Push the rear of the seat down to

lock it in place.

3. Remove the key.

TIPMake sure that the seat is properly se-

cured before riding.

1. Seat lock

2. Seat lock cover

3. Unlock.1

32

1. Projection

2. Seat holder

1

2

21

U1RCELE0.book Page 21 Monday, May 12, 2014 8:51 AM

Page 37 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-22

3

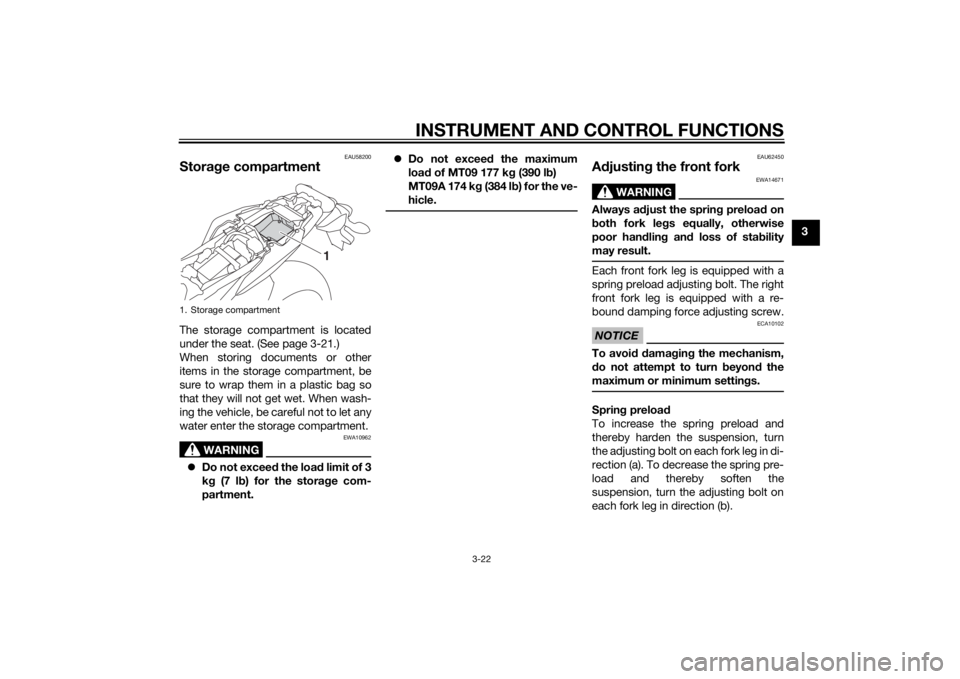

EAU58200

Storage compartmentThe storage compartment is located

under the seat. (See page 3-21.)

When storing documents or other

items in the storage compartment, be

sure to wrap them in a plastic bag so

that they will not get wet. When wash-

ing the vehicle, be careful not to let any

water enter the storage compartment.

WARNING

EWA10962

Do not exceed the load limit of 3

k g (7 l b) for the stora ge com-

partment.

Do not exceed the maximum

loa d of MT09 177 k g (390 l b)

MT09A 174 k g (384 l b) for the ve-

hicle.

EAU62450

A djustin g the front fork

WARNING

EWA14671

Always a djust the sprin g preloa d on

b oth fork le gs equally, otherwise

poor han dlin g an d loss of sta bility

may result.Each front fork leg is equipped with a

spring preload adjusting bolt. The right

front fork leg is equipped with a re-

bound damping force adjusting screw.NOTICE

ECA10102

To avoi d d amag ing the mechanism,

d o not attempt to turn beyon d the

maximum or minimum settin gs.Sprin g preloa d

To increase the spring preload and

thereby harden the suspension, turn

the adjusting bolt on each fork leg in di-

rection (a). To decrease the spring pre-

load and thereby soften the

suspension, turn the adjusting bolt on

each fork leg in direction (b).

1. Storage compartment

1

U1RCELE0.book Page 22 Monday, May 12, 2014 8:51 AM

Page 38 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-23

3The spring preload setting is deter-

mined by measuring distance A,

shown in the illustration. The shorter

distance A is, the higher the spring pre-

load; the longer distance A is, the lower

the spring preload. Re

boun d d ampin g force

The rebound damping force is adjust-

ed on the right front fork leg only.

To increase the rebound damping

force and thereby harden the rebound

damping, turn the adjusting screw in

direction (a). To decrease the rebound

damping force and thereby soften the

rebound damping, turn the adjusting

screw in direction (b).

TIPAlthough the total number of clicks of a

damping force adjusting mechanism

may not exactly match the above

specifications due to small differences

in production, the actual number of

clicks always represents the entire ad-

justing range. To obtain a precise ad-

justment, it would be advisable to

check the number of clicks of each

damping force adjusting mechanism

and to modify the specifications as

necessary.

1. Spring preload adjusting bolt

1. Distance A

1

1

(a)

(b)

(a)

(b)

1

Sprin g preloa d setting :

Minimum (soft):

Distance A = 19.0 mm (0.75 in)

Standard:

Distance A = 16.0 mm (0.63 in)

Maximum (hard): Distance A = 4.0 mm (0.16 in)1. Rebound damping force adjusting screw

1

(a)

(b)

Re boun d d ampin g setting :

Minimum (soft):

11 click(s) in direction (b)*

Standard:

8 click(s) in direction (b)*

Maximum (hard): 1 click(s) in direction (b)*

* With the adjusting screw fully turned in direction (a)

U1RCELE0.book Page 23 Monday, May 12, 2014 8:51 AM

Page 39 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-24

3

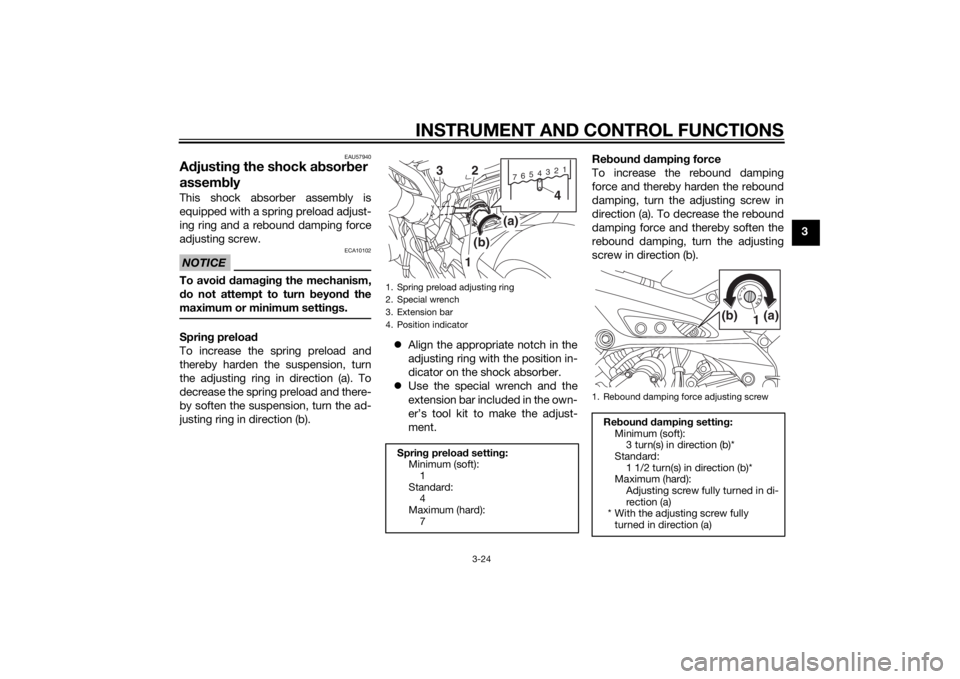

EAU57940

Adjustin g the shock a bsor ber

assem blyThis shock absorber assembly is

equipped with a spring preload adjust-

ing ring and a rebound damping force

adjusting screw.NOTICE

ECA10102

To avoi d d amag ing the mechanism,

d o not attempt to turn b eyond the

maximum or minimum settin gs.Sprin g preloa d

To increase the spring preload and

thereby harden the suspension, turn

the adjusting ring in direction (a). To

decrease the spring preload and there-

by soften the suspension, turn the ad-

justing ring in direction (b).

Align the appropriate notch in the

adjusting ring with the position in-

dicator on the shock absorber.

Use the special wrench and the

extension bar included in the own-

er’s tool kit to make the adjust-

ment. Re

boun d d ampin g force

To increase the rebound damping

force and thereby harden the rebound

damping, turn the adjusting screw in

direction (a). To decrease the rebound

damping force and thereby soften the

rebound damping, turn the adjusting

screw in direction (b).

1. Spring preload adjusting ring

2. Special wrench

3. Extension bar

4. Position indicator

Sprin g preloa d settin g:

Minimum (soft): 1

Standard: 4

Maximum (hard):

7

7654321

1(b) (a)

4

2

3

1. Rebound damping force adjusting screw

Re

boun d d ampin g settin g:

Minimum (soft): 3 turn(s) in direction (b)*

Standard: 1 1/2 turn(s) in direction (b)*

Maximum (hard):

Adjusting screw fully turned in di-

rection (a)

* With the adjusting screw fully

turned in direction (a)

1 (a)(b)

U1RCELE0.book Page 24 Monday, May 12, 2014 8:51 AM

Page 40 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-25

3

TIPTo obtain a precise adjustment, it is

advisable to check the actual total

number of turns of the damping force

adjusting mechanism. This adjustment

range may not exactly match the spec-

ifications listed due to small differenc-

es in production.

WARNING

EWA10222

This shock absor ber assem bly con-

tains hi ghly pressurize d nitro gen

g as. Rea d an d un derstan d the fol-

lowin g information before han dlin g

the shock a bsor ber assem bly.

Do not tamper with or attempt

to open the cylind er assembly.

Do not su bject the shock a b-

sor ber assem bly to an open

flame or other hi gh heat source.

This may cause the unit to ex-

plo de due to excessive gas

pressure.

Do not d eform or d amage the

cylin der in any way. Cylin der

d amag e will result in poor

d ampin g performance.

Do not dispose of a damag ed or

worn-out shock a bsor ber as-

sem bl

y yourself. Take the shock

a b sor ber assem bly to a Yamaha

d ealer for any service.

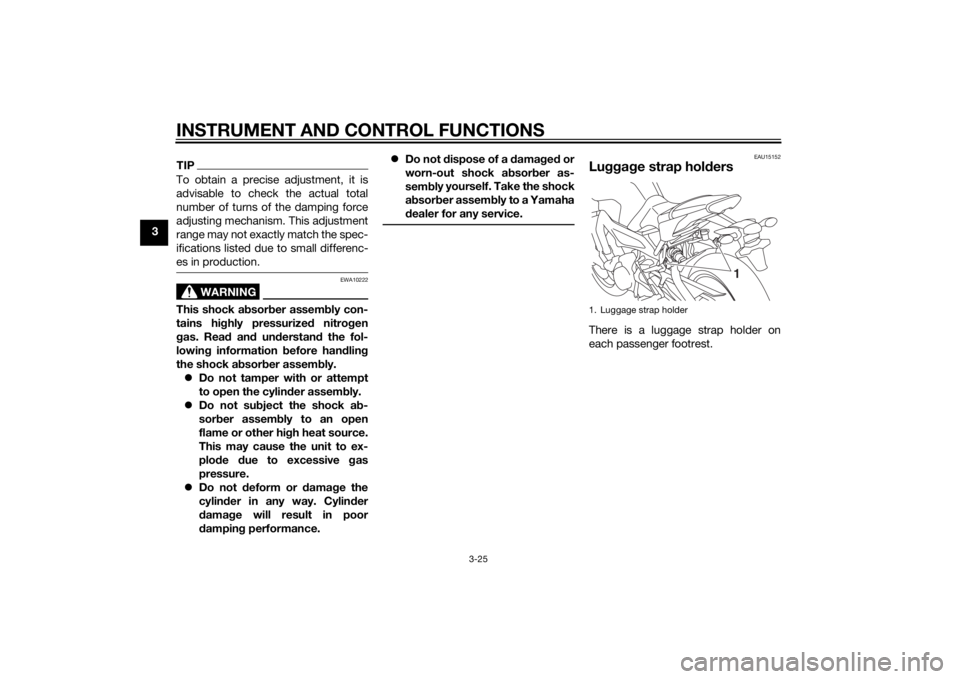

EAU15152

Lugga ge strap hol dersThere is a luggage strap holder on

each passenger footrest.1. Luggage strap holder

1

U1RCELE0.book Page 25 Monday, May 12, 2014 8:51 AM