torque YAMAHA MT-09 2016 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: MT-09, Model: YAMAHA MT-09 2016Pages: 114, PDF Size: 4.24 MB

Page 57 of 114

Periodic maintenance and adjustment

6-2

1

2

3

4

567

8

9

10

11

12

EAU39692

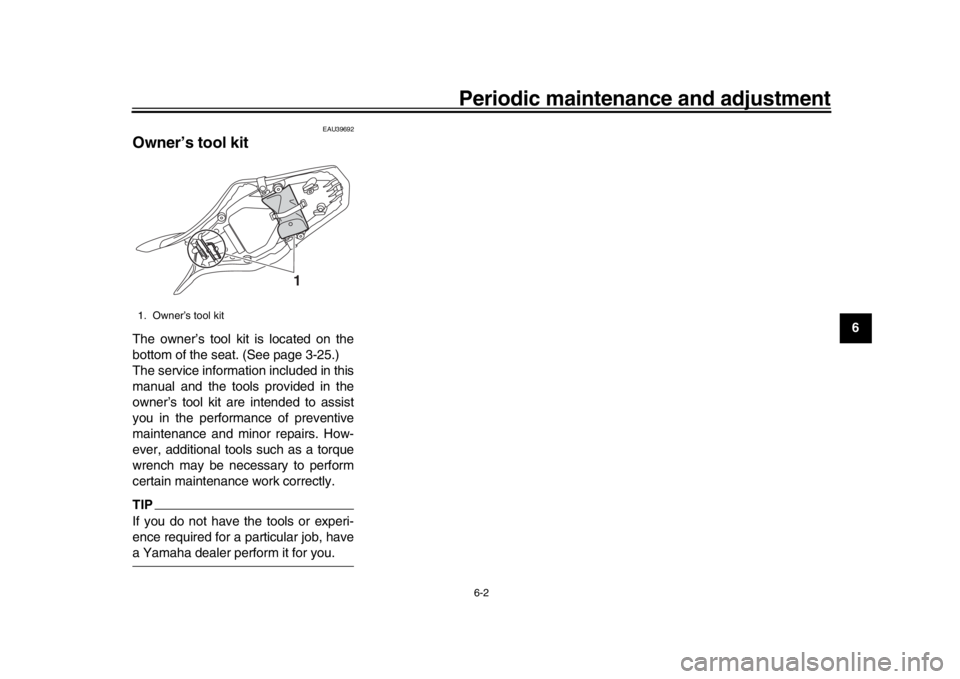

Owner’s tool kitThe owner’s tool kit is located on the

bottom of the seat. (See page 3-25.)

The service information included in this

manual and the tools provided in the

owner’s tool kit are intended to assist

you in the performance of preventive

maintenance and minor repairs. How-

ever, additional tools such as a torque

wrench may be necessary to perform

certain maintenance work correctly.TIPIf you do not have the tools or experi-

ence required for a particular job, havea Yamaha dealer perform it for you.1. Owner’s tool kit

1

B87-9-E0_1.book 2 ページ 2015年12月16日 水曜日 午前10時21分

Page 63 of 114

Periodic maintenance and adjustment

6-8

1

2

3

4

567

8

9

10

11

12

EAU19653

Checking the spark plugsThe spark plugs are important engine

components, which should be checked

periodically, preferably by a Yamaha

dealer. Since heat and deposits will

cause any spark plug to slowly erode,

they should be removed and checked

in accordance with the periodic mainte-

nance and lubrication chart. In addition,

the condition of the spark plugs can re-

veal the condition of the engine.

The porcelain insulator around the cen-

ter electrode of each spark plug should

be a medium-to-light tan (the ideal color

when the vehicle is ridden normally),

and all spark plugs installed in the en-

gine should have the same color. If any

spark plug shows a distinctly different

color, the engine could be operating im-

properly. Do not attempt to diagnose

such problems yourself. Instead, have

a Yamaha dealer check the vehicle.

If a spark plug shows signs of electrode

erosion and excessive carbon or other

deposits, it should be replaced. Before installing a spark plug, the spark

plug gap should be measured with a

wire thickness gauge and, if necessary,

adjusted to specification.

Clean the surface of the spark plug

gasket and its mating surface, and then

wipe off any grime from the spark plug

threads.

TIPIf a torque wrench is not available wheninstalling a spark plug, a good estimate

of the correct torque is 1/4–1/2 turn

past finger tight. However, the spark

plug should be tightened to the speci-

fied torque as soon as possible.NOTICE

ECA10841

Do not use any tools to remove or in-

stall the spark plug cap, otherwise

the ignition coil coupler may get

damaged. The spark plug cap may

be difficult to remove because the

rubber seal on the end of the cap fits

tightly. To remove the spark plug

cap, simply twist it back and forth

while pulling it out; to install it, twistit back and forth while pushing it in.

Specified spark plug:

NGK/CPR9EA9

1. Spark plug gapSpark plug gap:0.8–0.9 mm (0.031–0.035 in)

Tightening torque: Spark plug:13 Nm (1.3 m·kgf, 9.4 ft·lbf)

B87-9-E0_1.book 8 ページ 2015年12月16日 水曜日 午前10時21分

Page 65 of 114

Periodic maintenance and adjustment6-10

1

2

3

4

567

8

9

10

11

12

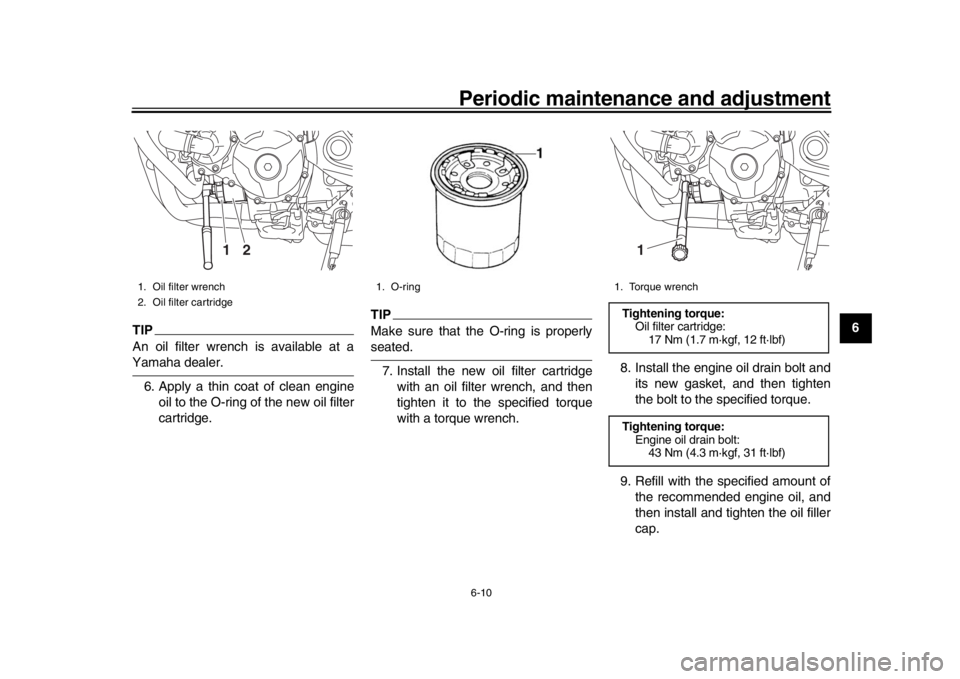

TIPAn oil filter wrench is available at aYamaha dealer. 6. Apply a thin coat of clean engine oil to the O-ring of the new oil filter

cartridge.

TIPMake sure that the O-ring is properlyseated.

7. Install the new oil filter cartridge with an oil filter wrench, and then

tighten it to the specified torque

with a torque wrench. 8. Install the engine oil drain bolt and

its new gasket, and then tighten

the bolt to the specified torque.

9. Refill with the specified amount of the recommended engine oil, and

then install and tighten the oil filler

cap.

1. Oil filter wrench

2. Oil filter cartridge

2

1

1. O-ring

1. Torque wrenchTightening torque:Oil filter cartridge:

17 Nm (1.7 m·kgf, 12 ft·lbf)

Tightening torque: Engine oil drain bolt:43 Nm (4.3 m·kgf, 31 ft·lbf)

1

B87-9-E0_1.book 10 ページ 2015年12月16日 水曜日 午前10時21分

Page 68 of 114

Periodic maintenance and adjustment

6-13

1

2

3

4

56

7

8

9

10

11

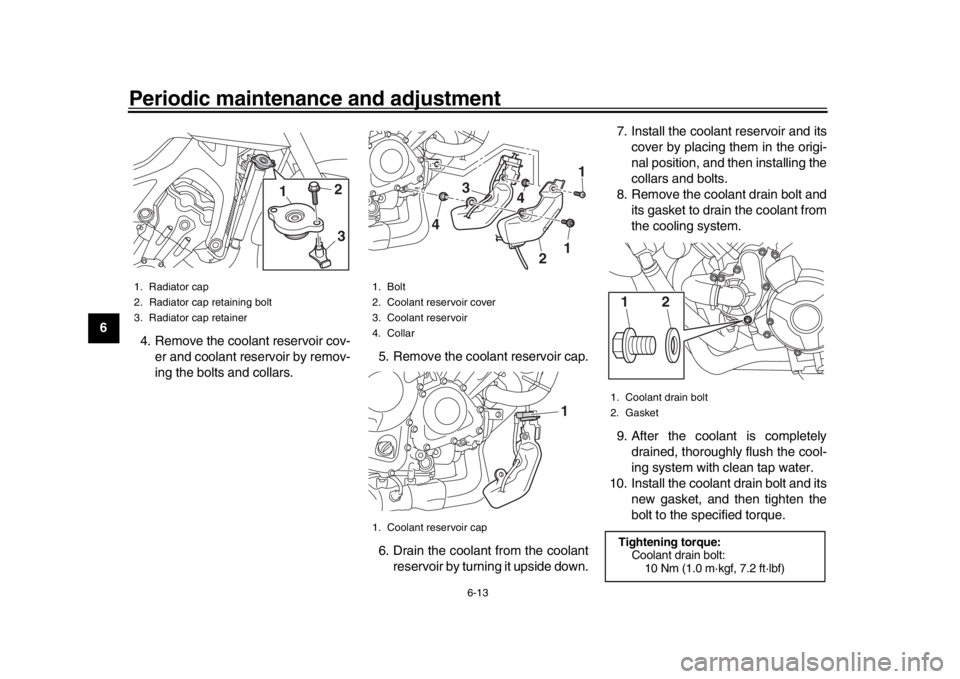

12 4. Remove the coolant reservoir cov-

er and coolant reservoir by remov-

ing the bolts and collars. 5. Remove the coolant reservoir cap.

6. Drain the coolant from the coolant

reservoir by turning it upside down. 7. Install the coolant reservoir and its

cover by placing them in the origi-

nal position, and then installing the

collars and bolts.

8. Remove the coolant drain bolt and its gasket to drain the coolant from

the cooling system.

9. After the coolant is completely drained, thoroughly flush the cool-

ing system with clean tap water.

10. Install the coolant drain bolt and its new gasket, and then tighten the

bolt to the specified torque.

1. Radiator cap

2. Radiator cap retaining bolt

3. Radiator cap retainer

2

1

3

1. Bolt

2. Coolant reservoir cover

3. Coolant reservoir

4. Collar

1. Coolant reservoir cap

1

1

2

4

3

4

1

1. Coolant drain bolt

2. GasketTightening torque:Coolant drain bolt:

10 Nm (1.0 m·kgf, 7.2 ft·lbf)1

2

B87-9-E0_1.book 13 ページ 2015年12月16日 水曜日 午前10時21分

Page 79 of 114

Periodic maintenance and adjustment6-24

1

2

3

4

567

8

9

10

11

12

EAU57971

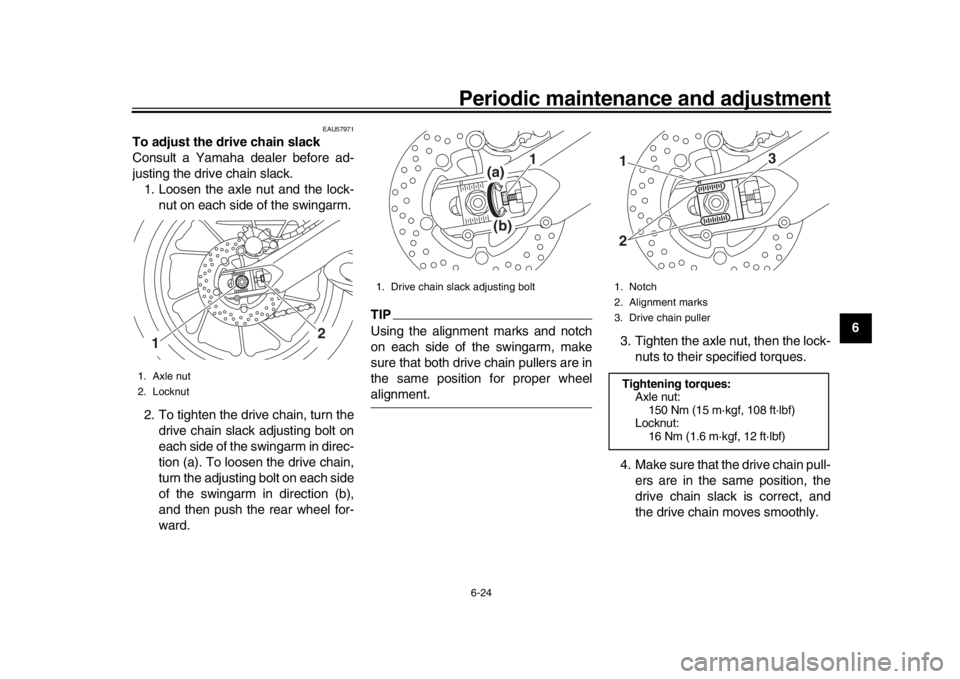

To adjust the drive chain slack

Consult a Yamaha dealer before ad-

justing the drive chain slack. 1. Loosen the axle nut and the lock- nut on each side of the swingarm.

2. To tighten the drive chain, turn the drive chain slack adjusting bolt on

each side of the swingarm in direc-

tion (a). To loosen the drive chain,

turn the adjusting bolt on each side

of the swingarm in direction (b),

and then push the rear wheel for-

ward.

TIPUsing the alignment marks and notch

on each side of the swingarm, make

sure that both drive chain pullers are in

the same position for proper wheelalignment. 3. Tighten the axle nut, then the lock-

nuts to their specified torques.

4. Make sure that the drive chain pull- ers are in the same position, the

drive chain slack is correct, and

the drive chain moves smoothly.

1. Axle nut

2. Locknut

2

1

1. Drive chain slack adjusting bolt

(a)(b)

1

1. Notch

2. Alignment marks

3. Drive chain pullerTightening torques:Axle nut:150 Nm (15 m·kgf, 108 ft·lbf)

Locknut:

16 Nm (1.6 m·kgf, 12 ft·lbf)

3

12

B87-9-E0_1.book 24 ページ 2015年12月16日 水曜日 午前10時21分

Page 95 of 114

Periodic maintenance and adjustment6-40

1

2

3

4

567

8

9

10

11

12

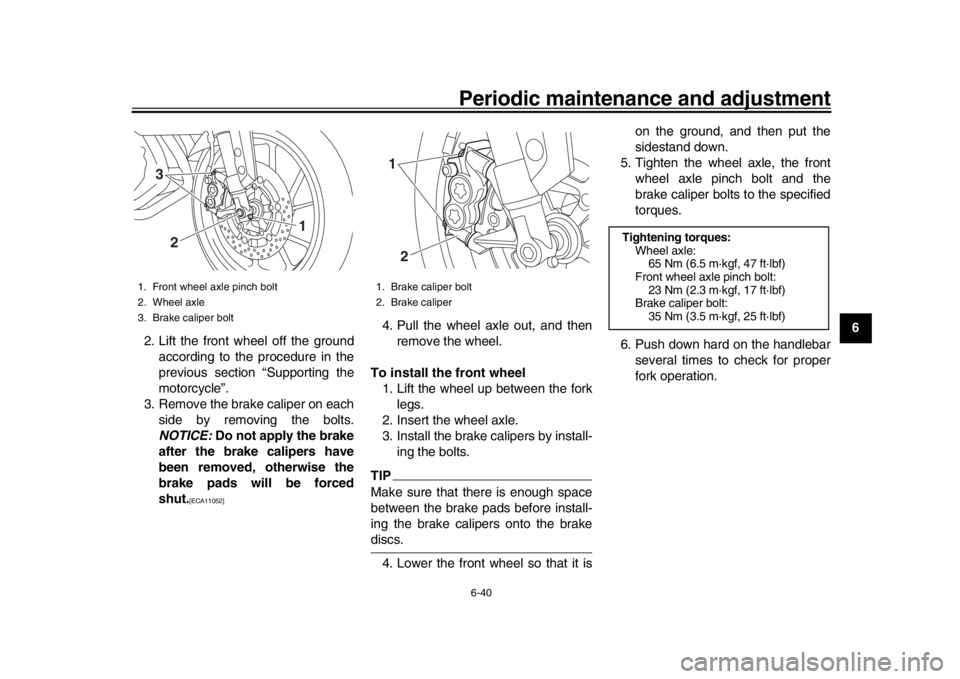

2. Lift the front wheel off the ground

according to the procedure in the

previous section “Supporting the

motorcycle”.

3. Remove the brake caliper on each side by removing the bolts.

NOTICE: Do not apply the brake

after the brake calipers have

been removed, otherwise the

brake pads will be forced

shut.

[ECA11052]

4. Pull the wheel axle out, and then remove the wheel.

To install the front wheel 1. Lift the wheel up between the fork legs.

2. Insert the wheel axle.

3. Install the brake calipers by install- ing the bolts.TIPMake sure that there is enough space

between the brake pads before install-

ing the brake calipers onto the brakediscs.

4. Lower the front wheel so that it is on the ground, and then put the

sidestand down.

5. Tighten the wheel axle, the front wheel axle pinch bolt and the

brake caliper bolts to the specified

torques.

6. Push down hard on the handlebar several times to check for proper

fork operation.

1. Front wheel axle pinch bolt

2. Wheel axle

3. Brake caliper bolt

3

2

1

1. Brake caliper bolt

2. Brake caliper12

Tightening torques:Wheel axle:65 Nm (6.5 m·kgf, 47 ft·lbf)

Front wheel axle pinch bolt: 23 Nm (2.3 m·kgf, 17 ft·lbf)

Brake caliper bolt:

35 Nm (3.5 m·kgf, 25 ft·lbf)

B87-9-E0_1.book 40 ページ 2015年12月16日 水曜日 午前10時21分

Page 97 of 114

![YAMAHA MT-09 2016 Owners Manual Periodic maintenance and adjustment6-42

1

2

3

4

567

8

9

10

11

12

have been removed, otherwise

the brake pads will be forced

shut.

[ECA11073]

To install the rear wheel

1. Install the wheel and the brak YAMAHA MT-09 2016 Owners Manual Periodic maintenance and adjustment6-42

1

2

3

4

567

8

9

10

11

12

have been removed, otherwise

the brake pads will be forced

shut.

[ECA11073]

To install the rear wheel

1. Install the wheel and the brak](/img/51/50880/w960_50880-96.png)

Periodic maintenance and adjustment6-42

1

2

3

4

567

8

9

10

11

12

have been removed, otherwise

the brake pads will be forced

shut.

[ECA11073]

To install the rear wheel

1. Install the wheel and the brake cal- iper bracket by inserting the wheel

axle from the left-hand side.TIP

Make sure that the slot in the brake

caliper bracket is fit over the retain-

er on the swingarm.

Make sure that there is enough

space between the brake pads be-fore installing the wheel. 2. Install the drive chain onto the rear

sprocket.

3. Install the axle nut.

4. Lower the rear wheel so that it is on the ground, and then put the

sidestand down.

5. Adjust the drive chain slack. (See page 6-23.)

6. Tighten the axle nut, and then tighten the locknuts to the speci-

fied torques.

EAU25872

TroubleshootingAlthough Yamaha motorcycles receive

a thorough inspection before shipment

from the factory, trouble may occur dur-

ing operation. Any problem in the fuel,

compression, or ignition systems, for

example, can cause poor starting and

loss of power.

The following troubleshooting charts

represent quick and easy procedures

for checking these vital systems your-

self. However, should your motorcycle

require any repair, take it to a Yamaha

dealer, whose skilled technicians have

the necessary tools, experience, and

know-how to service the motorcycle

properly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look like

Yamaha parts, but they are often inferi-

or, have a shorter service life and can

lead to expensive repair bills.

WARNING

EWA15142

When checking the fuel system, do

not smoke, and make sure there are

no open flames or sparks in the ar-

ea, including pilot lights from water

1. Wheel axle

1

1. Slot

2. RetainerTightening torques:Axle nut:

150 Nm (15 m·kgf, 108 ft·lbf)

Locknut: 16 Nm (1.6 m·kgf, 12 ft·lbf)

2

1

B87-9-E0_1.book 42 ページ 2015年12月16日 水曜日 午前10時21分