wheel YAMAHA MT-09 2022 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2022, Model line: MT-09, Model: YAMAHA MT-09 2022Pages: 110, PDF Size: 3.8 MB

Page 42 of 110

Instrument and control functions

4-21

4

EAU13077

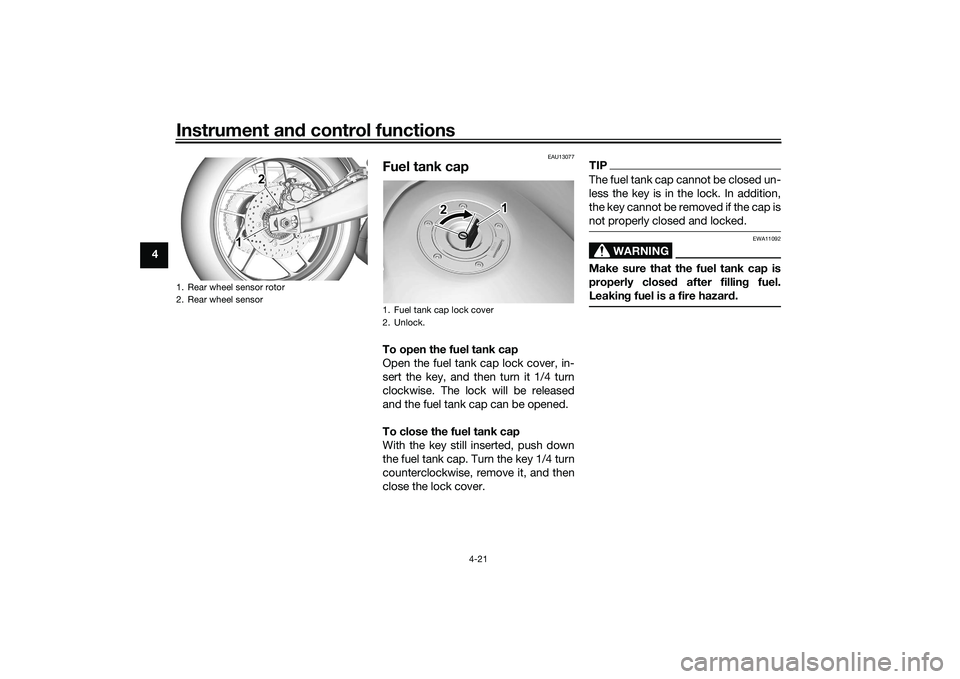

Fuel tank capTo open the fuel tank cap

Open the fuel tank cap lock cover, in-

sert the key, and then turn it 1/4 turn

clockwise. The lock will be released

and the fuel tank cap can be opened.

To close the fuel tank cap

With the key still inserted, push down

the fuel tank cap. Turn the key 1/4 turn

counterclockwise, remove it, and then

close the lock cover.

TIPThe fuel tank cap cannot be closed un-

less the key is in the lock. In addition,

the key cannot be removed if the cap is

not properly closed and locked.

WARNING

EWA11092

Make sure that the fuel tank cap is

properly close d after fillin g fuel.

Leakin g fuel is a fire hazar d.

1. Rear wheel sensor rotor

2. Rear wheel sensor

1 1 1 2 2

1. Fuel tank cap lock cover

2. UnlockK

1

2

UB7NE1E0.book Page 21 Friday, September 3, 2021 11:25 AM

Page 55 of 110

For your safety – pre-operation checks

5-2

5

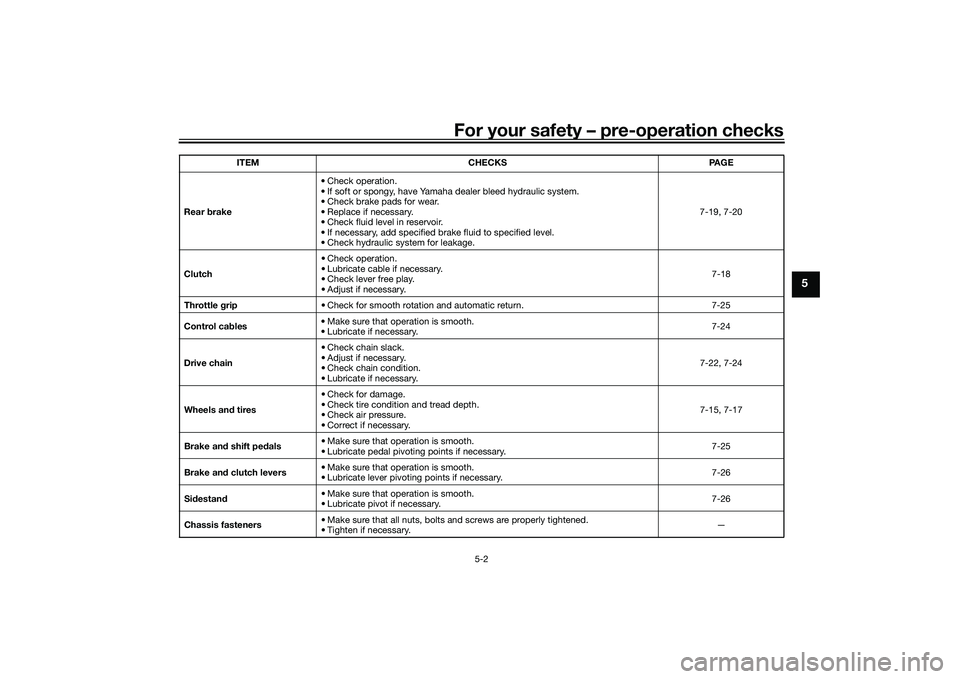

Rear brake • Check operation.

• If soft or spongy, have Yamaha dealer bleed hydraulic system.

• Check brake pads for wear.

• Replace if necessary.

• Check fluid level in reservoir.

• If necessary, add specified brake fluid to specified level.

• Check hydraulic system for leakage. 7-19, 7-20

Clutch • Check operation.

• Lubricate cable if necessary.

• Check lever free play.

• Adjust if necessary.

7-18

Throttle grip • Check for smooth rotation and automatic return. 7-25

Control ca bles • Make sure that operation is smooth.

• Lubricate if necessary. 7-24

Drive chain • Check chain slack.

• Adjust if necessary.

• Check chain condition.

• Lubricate if necessary.

7-22, 7-24

Wheels an d tires • Check for damage.

• Check tire condition and tread depth.

• Check air pressure.

• Correct if necessary.

7-15, 7-17

Brake an d shift pe dals • Make sure that operation is smooth.

• Lubricate pedal pivoting points if necessary. 7-25

Brake an d clutch levers • Make sure that operation is smooth.

• Lubricate lever pivoting points if necessary.

7-26

Si destan d • Make sure that operation is smooth.

• Lubricate pivot if necessary.

7-26

Chassis fasteners • Make sure that all nuts, bolts and screws are properly tightened.

• Tighten if necessary. —

ITEM CHECKS PAGE

UB7NE1E0.book Page 2 Friday, September 3, 2021 11:25 AM

Page 60 of 110

Operation and important rid ing points

6-4

6 3. Open the throttle gradually, and at

the same time, release the clutch

lever slowly.

4. After starting out, close the throt- tle, and at the same time, quickly

pull the clutch lever in.

5. Shift the transmission into second gear. (Make sure not to shift the

transmission into the neutral posi-

tion.)

6. Open the throttle part way and gradually release the clutch lever.

7. Follow the same procedure when shifting to the next higher gear.

EAU85380

To decelerate

1. Release the throttle and apply both the front and the rear brakes

smoothly to slow the motorcycle.

2. As the vehicle decelerates, shift to a lower gear.

3. When the engine is about to stall or runs roughly, pull the clutch le-

ver in, use the brakes to slow the

motorcycle, and continue to

downshift as necessary. 4. Once the motorcycle has

stopped, the transmission can be

shifted into the neutral position.

The neutral indicator light should

come on and then the clutch lever

can be released.

WARNING

EWA17380

Improper brakin g can cause

loss of control or traction. Al-

ways use b oth brakes an d apply

them smoothly.

Make sure that the motorcycle

and the en gine have sufficiently

slowe d b efore shiftin g to a low-

er gear. En gag in g a lower gear

when the vehicle or en gine

speed is too hi gh coul d make

the rear wheel lose traction or

the en gine to over-rev. This

coul d cause loss of control, an

acci dent an d injury. It coul d also

cause en gine or drive train dam-

a g e.

EAU16811

Tips for re ducin g fuel con-

sumptionFuel consumption depends largely on

your riding style. Consider the follow-

ing tips to reduce fuel consumption:

Shift up swiftly, and avoid high en-

gine speeds during acceleration.

Do not rev the engine while shift-

ing down, and avoid high engine

speeds with no load on the en-

gine.

Turn the engine off instead of let-

ting it idle for an extended length

of time (e.g., in traffic jams, at traf-

fic lights or at railroad crossings).

UB7NE1E0.book Page 4 Friday, September 3, 2021 11:25 AM

Page 66 of 110

Periodic maintenance an d a djustment

7-5

7

EAU71353

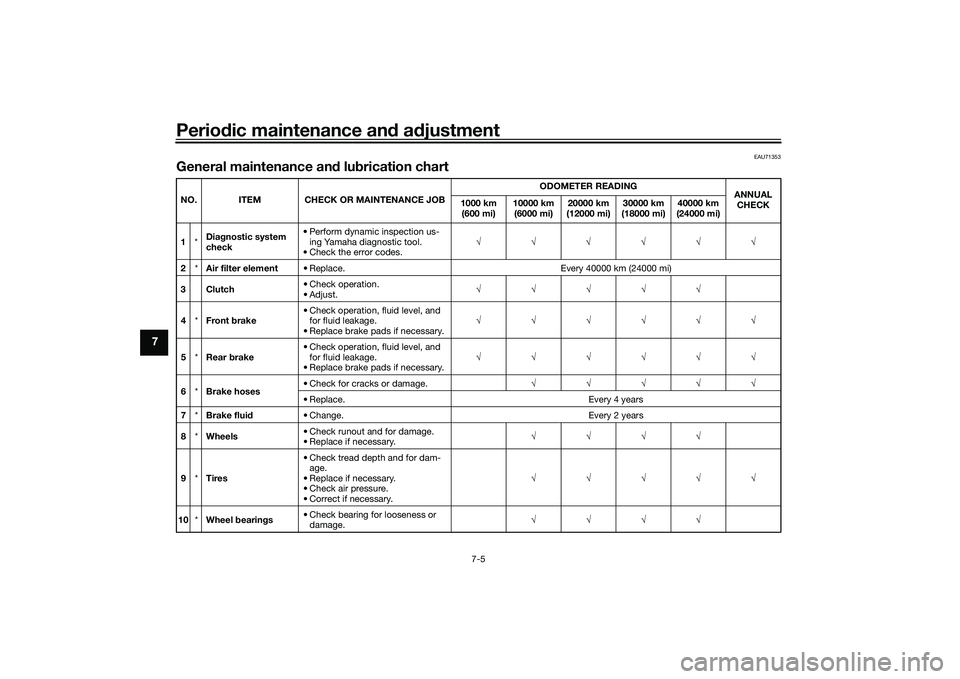

General maintenance an d lu brication chartNO. ITEM CHECK OR MAINTENANCE JOB ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)

1 *Dia

gnostic system

check • Perform dynamic inspection us-

ing Yamaha diagnostic tool.

• Check the error codes. √√√√√√

2 *Air filter element • Replace. Every 40000 km (24000 mi)

3Clutch • Check operation.

•Adjust. √√√√√

4 *Front brake • Check operation, fluid level, and

for fluid leakage.

• Replace brake pads if necessary. √√√√√√

5 *Rear brake • Check operation, fluid level, and

for fluid leakage.

• Replace brake pads if necessary. √√√√√√

6 *Brake hoses • Check for cracks or damage.

√√√√√

• Replace. Every 4 years

7 *Brake flui d • Change. Every 2 years

8 *Wheels • Check runout and for damage.

• Replace if necessary. √√√√

9 *Tires • Check tread depth and for dam-

age.

• Replace if necessary.

• Check air pressure.

• Correct if necessary. √√√√√

10 *Wheel bearin gs • Check bearing for looseness or

damage. √√√√

UB7NE1E0.book Page 5 Friday, September 3, 2021 11:25 AM

Page 77 of 110

Periodic maintenance an d a djustment

7-16

7

Tire inspection

The tires must be checked before each

ride. If the center tread depth reaches

the specified limit, if the tire has a nail

or glass fragments in it, or if the side-

wall is cracked, have a Yamaha dealer

replace the tire immediately.

TIPThe tire tread depth limits may differ

from country to country. Always com-

ply with the local regulations.

WARNING

EWA10472

Have a Yamaha d ealer replace

excessively worn tires. Besi des

b ein g ille gal, operatin g the vehi-

cle with excessively worn tires

d ecreases ri din g sta bility an d

can lea d to loss of control.

The replacement of all wheel

and b rake-relate d parts, inclu d-

in g the tires, shoul d b e left to a

Yamaha dealer, who has the

necessary professional knowl-

e dg e an d experience to do so.

Ride at mo derate spee ds after

chan gin g a tire since the tire

surface must first be “ broken

in” for it to d evelop its optimal

characteristics.

Tire information

This model is equipped with tubeless

tires and tire air valves.

Tires age, even if they have not been

used or have only been used occasion-

ally. Cracking of the tread and sidewall

rubber, sometimes accompanied by

carcass deformation, is an evidence of

ageing. Old and aged tires shall be

checked by tire specialists to ascertain

their suitability for further use.

WARNING

EWA10902

The front an d rear tires shoul d

b e of the same make an d d e-

si gn, otherwise the han dlin g

1. Tire sidewall

2. Tire tread depthMinimum tire trea d d epth (front an d

rear): 1.6 mm (0.06 in)

1. Tire air valve

2. Tire air valve core

3. Tire air valve cap with seal

UB7NE1E0.book Page 16 Friday, September 3, 2021 11:25 AM

Page 78 of 110

Periodic maintenance an d a djustment

7-17

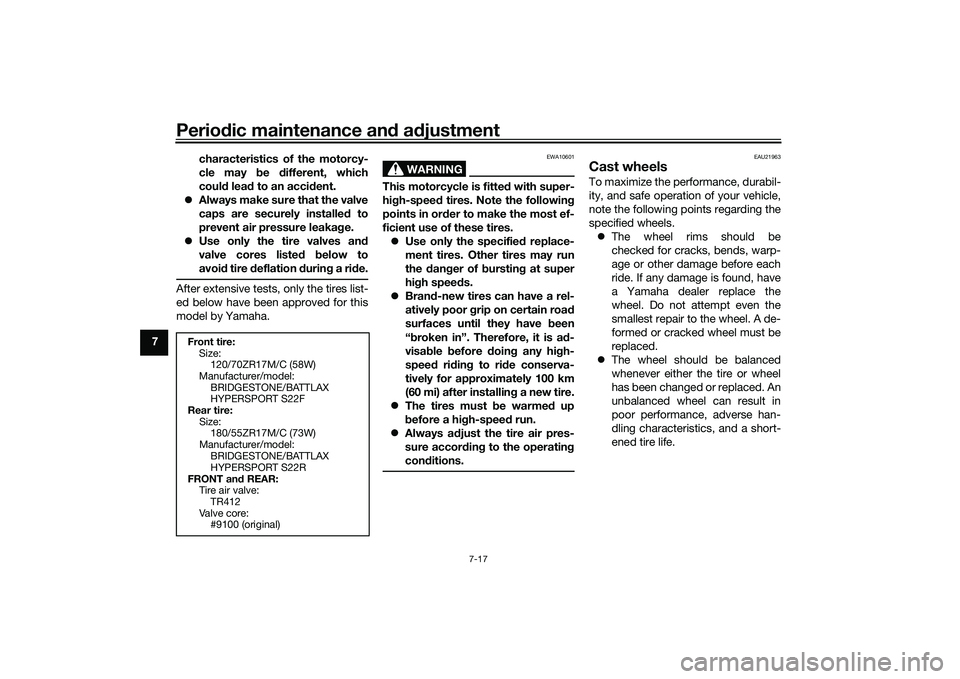

7 characteristics of the motorcy-

cle may

be different, which

coul d lea d to an acci dent.

Always make sure that the valve

caps are securely installed to

prevent air pressure leakag e.

Use only the tire valves an d

valve cores listed below to

avoi d tire d eflation durin g a ri de.

After extensive tests, only the tires list-

ed below have been approved for this

model by Yamaha.

WARNING

EWA10601

This motorcycle is fitte d with super-

hi gh-spee d tires. Note the following

points in or der to make the most ef-

ficient use of these tires. Use only the specified replace-

ment tires. Other tires may run

the dan ger of burstin g at super

hi gh spee ds.

Bran d-new tires can have a rel-

atively poor g rip on certain roa d

surfaces until they have been

“ b roken in”. Therefore, it is a d-

visa ble before doin g any hi gh-

speed ridin g to ri de conserva-

tively for approximately 100 km

(60 mi) after installin g a new tire.

The tires must be warme d up

b efore a hi gh-spee d run.

Always a djust the tire air pres-

sure accor din g to the operating

con ditions.

EAU21963

Cast wheelsTo maximize the performance, durabil-

ity, and safe operation of your vehicle,

note the following points regarding the

specified wheels.

The wheel rims should be

checked for cracks, bends, warp-

age or other damage before each

ride. If any damage is found, have

a Yamaha dealer replace the

wheel. Do not attempt even the

smallest repair to the wheel. A de-

formed or cracked wheel must be

replaced.

The wheel should be balanced

whenever either the tire or wheel

has been changed or replaced. An

unbalanced wheel can result in

poor performance, adverse han-

dling characteristics, and a short-

ened tire life.

Front tire:

Size:120/70ZR17M/C (58W)

Manufacturer/model: BRIDGESTONE/BATTLAX

HYPERSPORT S22F

Rear tire: Size:180/55ZR17M/C (73W)

Manufacturer/model: BRIDGESTONE/BATTLAX

HYPERSPORT S22R

FRONT an d REAR:

Tire air valve: TR412

Valve core: #9100 (original)

UB7NE1E0.book Page 17 Friday, September 3, 2021 11:25 AM

Page 84 of 110

Periodic maintenance an d a djustment

7-23

7

2. To tighten the drive chain, turn thedrive chain slack adjusting bolt on

each side of the swingarm in di-

rection (a). To loosen the drive

chain, turn the adjusting bolt on

each side of the swingarm in di-

rection (b), and then push the rear

wheel forward.

TIPUsing the alignment marks on each

side of the swingarm, make sure that

both drive chain pullers are in the same

position for proper wheel alignment.3. Tighten the axle nut, then the lock-nuts to their specified torques. 4. Make sure that the drive chain

pullers are in the same position,

the drive chain slack is correct,

and the drive chain moves

smoothly.

1. Drive chain puller

2. Axle nut

3. Drive chain slack adjusting bolt

4. Locknut

5. Alignment marks

5 3

1 2

4

1. Drive chain slack adjusting bolt

2. LocknutTightenin g torques:

Axle nut: 105 N·m (10.5 kgf·m, 77 lb·ft)

Locknut:

16 N·m (1.6 kgf·m, 12 lb·ft)

(a) 1

2

(b)

UB7NE1E0.book Page 23 Friday, September 3, 2021 11:25 AM

Page 89 of 110

Periodic maintenance an d a djustment

7-28

7

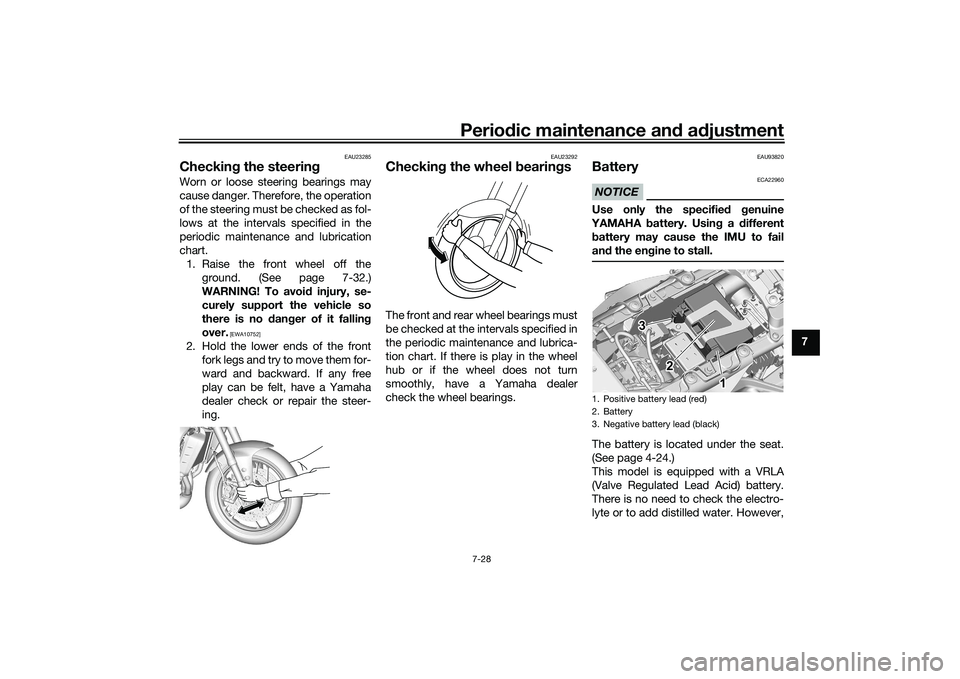

EAU23285

Checkin g the steerin gWorn or loose steering bearings may

cause danger. Therefore, the operation

of the steering must be checked as fol-

lows at the intervals specified in the

periodic maintenance and lubrication

chart.

1. Raise the front wheel off the ground. (See page 7-32.)

WARNING! To avoi d injury, se-

curely support the vehicle so

there is no dan ger of it fallin g

over.

[EWA10752]

2. Hold the lower ends of the front fork legs and try to move them for-

ward and backward. If any free

play can be felt, have a Yamaha

dealer check or repair the steer-

ing.

EAU23292

Checkin g the wheel bearin gsThe front and rear wheel bearings must

be checked at the intervals specified in

the periodic maintenance and lubrica-

tion chart. If there is play in the wheel

hub or if the wheel does not turn

smoothly, have a Yamaha dealer

check the wheel bearings.

EAU93820

BatteryNOTICE

ECA22960

Use only the specifie d genuine

YAMAHA battery. Usin g a d ifferent

b attery may cause the IMU to fail

an d the en gine to stall. The battery is located under the seat.

(See page 4-24.)

This model is equipped with a VRLA

(Valve Regulated Lead Acid) battery.

There is no need to check the electro-

lyte or to add distilled water. However,1. Positive battery lead (red)

2. Battery

3. Negative battery lead (black)

3 3

2 1

3

2 1

UB7NE1E0.book Page 28 Friday, September 3, 2021 11:25 AM

Page 93 of 110

Periodic maintenance an d a djustment

7-32

7

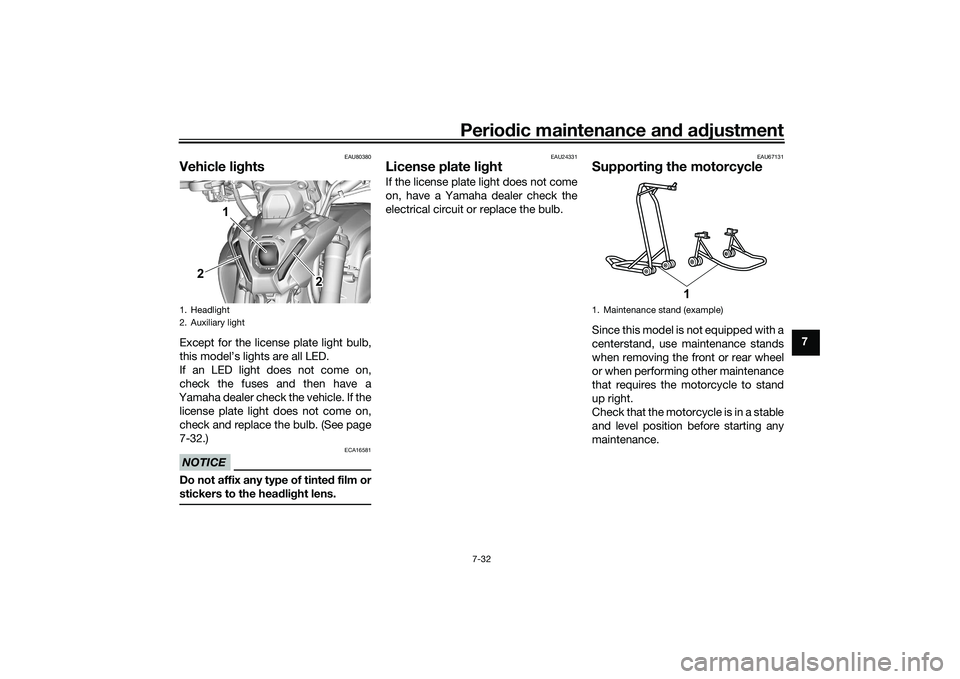

EAU80380

Vehicle li ghtsExcept for the license plate light bulb,

this model’s lights are all LED.

If an LED light does not come on,

check the fuses and then have a

Yamaha dealer check the vehicle. If the license plate light does not come on,

check and replace the bulb. (See page

7-32.)NOTICE

ECA16581

Do not affix any type of tinte d film or

stickers to the head lig ht lens.

EAU24331

License plate li ghtIf the license plate light does not come

on, have a Yamaha dealer check the

electrical circuit or replace the bulb.

EAU67131

Supportin g the motorcycleSince this model is not equipped with a

centerstand, use maintenance stands

when removing the front or rear wheel

or when performing other maintenance

that requires the motorcycle to stand

up right.

Check that the motorcycle is in a stable

and level position before starting any

maintenance.

1. Headlight

2. Auxiliary light

2 2 2

2 1

1. Maintenance stand (exampleF

1

UB7NE1E0.book Page 32 Friday, September 3, 2021 11:25 AM

Page 97 of 110

Motorcycle care and stora ge

8-1

8

EAU37834

Matte color cautionNOTICE

ECA15193

Some mo dels are equipped with

matte colored finished parts. Be

sure to consult a Yamaha dealer for

a d vice on what prod ucts to use be-

fore cleanin g the vehicle. Usin g a

b rush, harsh chemical pro ducts or

cleanin g compoun ds when cleanin g

these parts will scratch or damag e

their surface. Wax also shoul d not

b e applie d to any matte colored fin-

ishe d parts.

EAU83443

CareFrequent, thorough cleaning of the ve-

hicle will not only enhance its appear-

ance but also will improve its general

performance and extend the useful life

of many components. Washing, clean-

ing, and polishing will also give you a

chance to inspect the condition of the

vehicle more frequently. Be sure to

wash the vehicle after riding in the rain

or near the sea, because salt is corro-

sive to metals.TIP The roads of heavy snowfall areas

may be sprayed with salt as a de-

icing method. This salt can stay on

the roads well into spring, so be

sure to wash the underside and

chassis parts after riding in such

areas.

Genuine Yamaha care and main-

tenance products are sold under

the YAMALUBE brand in many

markets worldwide.

See your Yamaha dealer for addi-

tional cleaning tips.

NOTICE

ECA26280

Improper cleanin g can cause cos-

metic an d mechanical damag e. Do

not use: high-pressure washers or

steam-jet cleaners. Excessive

water pressure may cause wa-

ter seepag e and d eterioration of

wheel bearin gs, brakes, trans-

mission seals an d electrical de-

vices. Avoi d hi gh-pressure

d eter gent applications such as

those availab le in coin-operate d

car washers.

harsh chemicals, inclu din g

stron g aci dic wheel cleaners,

especially on spoke or ma gne-

sium wheels.

harsh chemicals, a brasive

cleanin g compoun ds, or wax on

matte-finishe d parts. Brushes

can scratch an d damag e the

matte-finish, use soft spon ge or

towel only.

towels, spon ges, or brushes

contaminate d with a brasive

cleanin g prod ucts or stron g

UB7NE1E0.book Page 1 Friday, September 3, 2021 11:25 AM