lock YAMAHA MT-25 2016 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: MT-25, Model: YAMAHA MT-25 2016Pages: 96, PDF Size: 5.16 MB

Page 31 of 96

Instrument and control functions

3-16

3

EAU62622

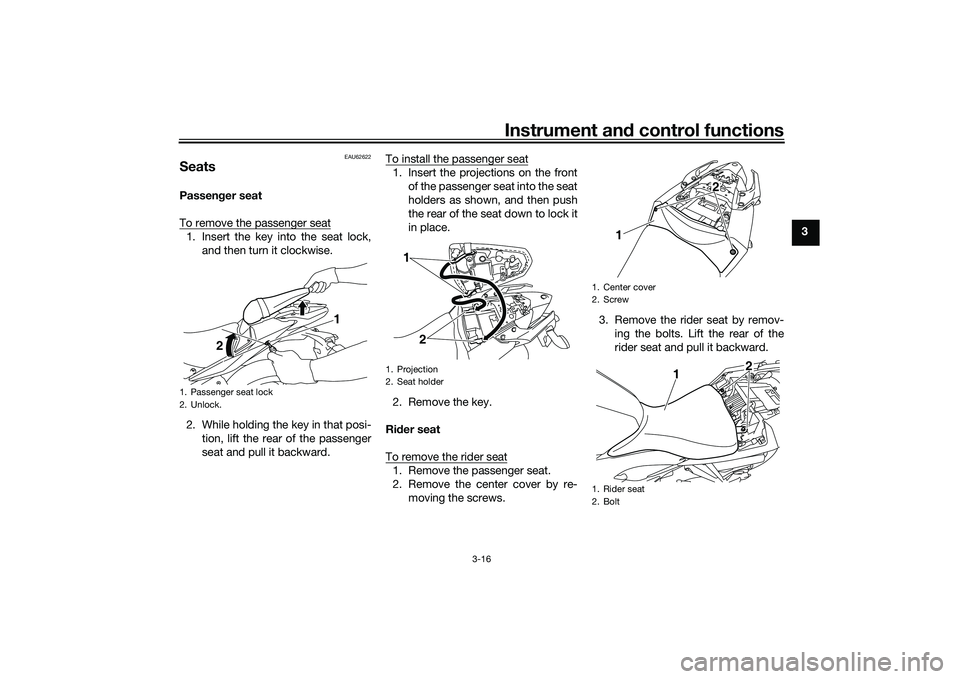

SeatsPassenger seat

To remove the passenger seat1. Insert the key into the seat lock,

and then turn it clockwise.

2. While holding the key in that posi-

tion, lift the rear of the passenger

seat and pull it backward.To install the passenger seat

1. Insert the projections on the front

of the passenger seat into the seat

holders as shown, and then push

the rear of the seat down to lock it

in place.

2. Remove the key.

Rider seat

To remove the rider seat1. Remove the passenger seat.

2. Remove the center cover by re-

moving the screws.3. Remove the rider seat by remov-

ing the bolts. Lift the rear of the

rider seat and pull it backward.

1. Passenger seat lock

2. Unlock.

1

2

1. Projection

2. Seat holder

1

2

1. Center cover

2. Screw

1. Rider seat

2. Bolt

12

12

UB04E0E0.book Page 16 Wednesday, September 2, 2015 3:51 PM

Page 60 of 96

Periodic maintenance and adjustment

6-17

6ageing. Old and aged tires shall be

checked by tire specialists to ascertain

their suitability for further use.

WARNING

EWA10462

The front and rear tires should be of

the same make and design, other-

wise the handling characteristics of

the vehicle may be different, which

could lead to an accident.After extensive tests, only the tires list-

ed below have been approved for this

model by Yamaha.

EAU21963

Cast wheelsTo maximize the performance, durabil-

ity, and safe operation of your vehicle,

note the following points regarding the

specified wheels.

The wheel rims should be

checked for cracks, bends, warp-

age or other damage before each

ride. If any damage is found, have

a Yamaha dealer replace the

wheel. Do not attempt even the

smallest repair to the wheel. A de-

formed or cracked wheel must be

replaced.

The wheel should be balanced

whenever either the tire or wheel

has been changed or replaced. An

unbalanced wheel can result in

poor performance, adverse han-

dling characteristics, and a short-

ened tire life.

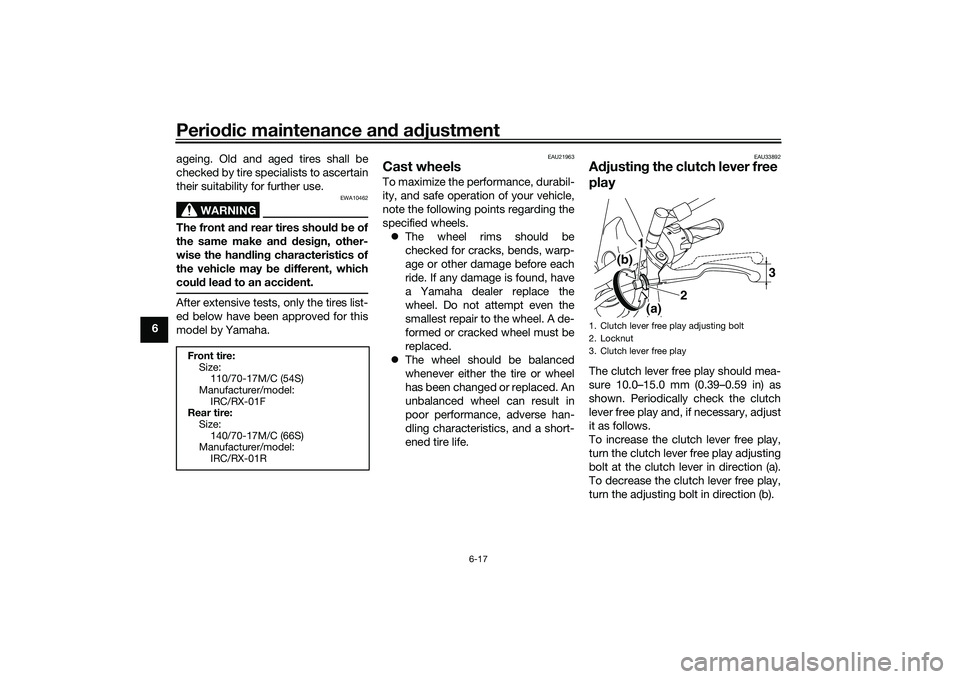

EAU33892

Adjusting the clutch lever free

playThe clutch lever free play should mea-

sure 10.0–15.0 mm (0.39–0.59 in) as

shown. Periodically check the clutch

lever free play and, if necessary, adjust

it as follows.

To increase the clutch lever free play,

turn the clutch lever free play adjusting

bolt at the clutch lever in direction (a).

To decrease the clutch lever free play,

turn the adjusting bolt in direction (b).

Front tire:

Size:

110/70-17M/C (54S)

Manufacturer/model:

IRC/RX-01F

Rear tire:

Size:

140/70-17M/C (66S)

Manufacturer/model:

IRC/RX-01R

1. Clutch lever free play adjusting bolt

2. Locknut

3. Clutch lever free play

3

(a) 1

2 (b)

UB04E0E0.book Page 17 Wednesday, September 2, 2015 3:51 PM

Page 61 of 96

Periodic maintenance and adjustment

6-18

6

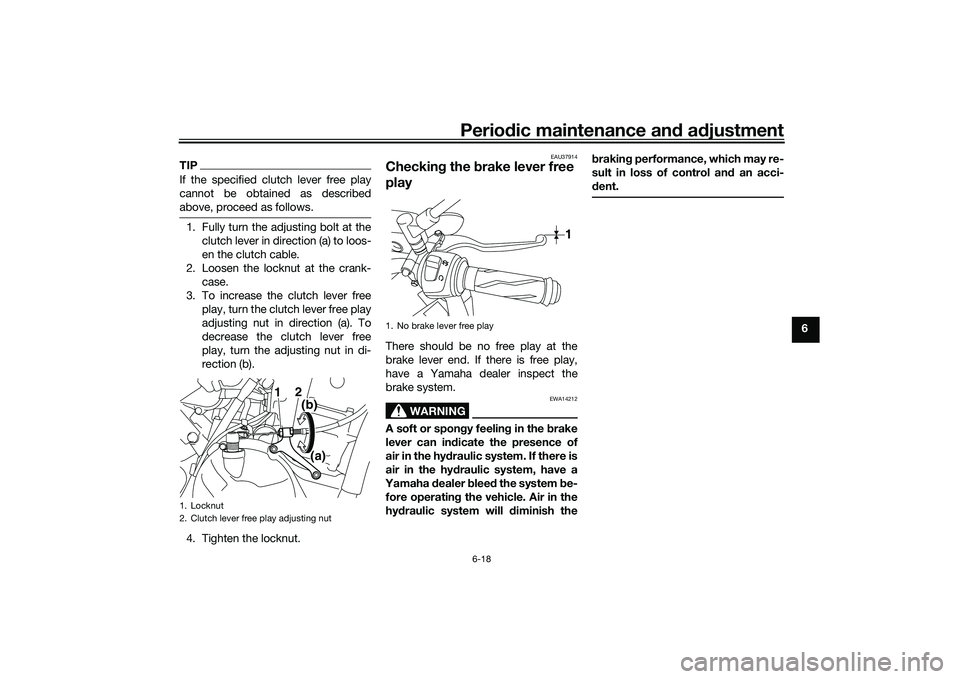

TIPIf the specified clutch lever free play

cannot be obtained as described

above, proceed as follows.1. Fully turn the adjusting bolt at the

clutch lever in direction (a) to loos-

en the clutch cable.

2. Loosen the locknut at the crank-

case.

3. To increase the clutch lever free

play, turn the clutch lever free play

adjusting nut in direction (a). To

decrease the clutch lever free

play, turn the adjusting nut in di-

rection (b).

4. Tighten the locknut.

EAU37914

Checking the brake lever free

playThere should be no free play at the

brake lever end. If there is free play,

have a Yamaha dealer inspect the

brake system.

WARNING

EWA14212

A soft or spongy feeling in the brake

lever can indicate the presence of

air in the hydraulic system. If there is

air in the hydraulic system, have a

Yamaha dealer bleed the system be-

fore operating the vehicle. Air in the

hydraulic system will diminish thebraking performance, which may re-

sult in loss of control and an acci-

dent.

1. Locknut

2. Clutch lever free play adjusting nut

2(b)(a) 1

1. No brake lever free play

1

UB04E0E0.book Page 18 Wednesday, September 2, 2015 3:51 PM

Page 63 of 96

Periodic maintenance and adjustment

6-20

6

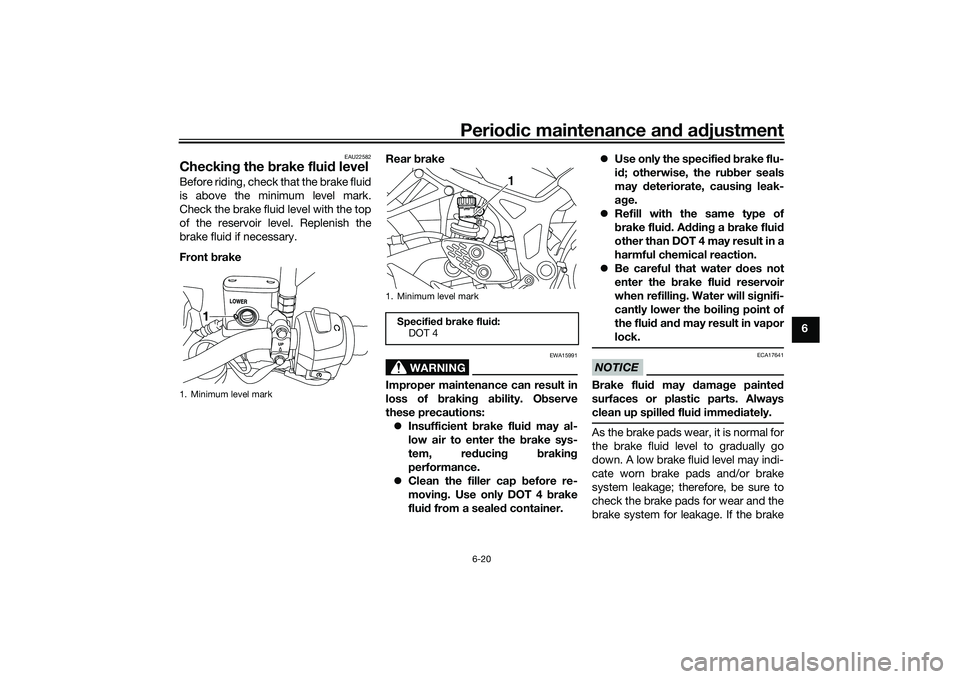

EAU22582

Checking the brake fluid levelBefore riding, check that the brake fluid

is above the minimum level mark.

Check the brake fluid level with the top

of the reservoir level. Replenish the

brake fluid if necessary.

Front brakeRear brake

WARNING

EWA15991

Improper maintenance can result in

loss of braking ability. Observe

these precautions:

Insufficient brake fluid may al-

low air to enter the brake sys-

tem, reducing braking

performance.

Clean the filler cap before re-

moving. Use only DOT 4 brake

fluid from a sealed container.Use only the specified brake flu-

id; otherwise, the rubber seals

may deteriorate, causing leak-

age.

Refill with the same type of

brake fluid. Adding a brake fluid

other than DOT 4 may result in a

harmful chemical reaction.

Be careful that water does not

enter the brake fluid reservoir

when refilling. Water will signifi-

cantly lower the boiling point of

the fluid and may result in vapor

lock.

NOTICE

ECA17641

Brake fluid may damage painted

surfaces or plastic parts. Always

clean up spilled fluid immediately.As the brake pads wear, it is normal for

the brake fluid level to gradually go

down. A low brake fluid level may indi-

cate worn brake pads and/or brake

system leakage; therefore, be sure to

check the brake pads for wear and the

brake system for leakage. If the brake

1. Minimum level mark

1

1. Minimum level mark

Specified brake fluid:

DOT 4

1

UB04E0E0.book Page 20 Wednesday, September 2, 2015 3:51 PM

Page 65 of 96

Periodic maintenance and adjustment

6-22

6 4. If the drive chain slack is incorrect,

adjust it as follows.

EAU62982

To adjust the drive chain slack

Consult a Yamaha dealer before ad-

justing the drive chain slack.

1. Remove the drive chain puller cap,

and then loosen the axle nut and

the locknut on each side of the

swingarm.

2. To tighten the drive chain, turn the

drive chain slack adjusting nut on

each side of the swingarm in di-

rection (a). To loosen the drive

chain, turn the adjusting nut on

each side of the swingarm in di-rection (b), and then push the rear

wheel forward. NOTICE: Improp-

er drive chain slack will over-

load the engine as well as other

vital parts of the motorcycle and

can lead to chain slippage or

breakage. To prevent this from

occurring, keep the drive chain

slack within the specified limits.

[ECA10572]

TIPUsing the alignment marks on each

side of the swingarm, make sure that

both drive chain pullers are in the same

position for proper wheel alignment.

1. Drive chain slack

1

1. Locknut

2. Drive chain puller cap

1. Axle nut

12

1

1. Drive chain slack adjusting nut

1

(a)(b)

UB04E0E0.book Page 22 Wednesday, September 2, 2015 3:51 PM

Page 66 of 96

Periodic maintenance and adjustment

6-23

63. Tighten the axle nut, then the lock-

nuts to their specified torques.

4. Make sure that the drive chain

pullers are in the same position,

the drive chain slack is correct,

and the drive chain moves

smoothly.

5. Install the drive chain puller caps.

EAU23026

Cleaning and lubricating the

drive chainThe drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.NOTICE

ECA10584

The drive chain must be lubricated

after washing the motorcycle, riding

in the rain or riding in wet areas.1. Clean the drive chain with kero-

sene and a small soft brush.

NOTICE: To prevent damaging

the O-rings, do not clean the

drive chain with steam cleaners,

high-pressure washers or inap-

propriate solvents.

[ECA11122]

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive

chain with a special O-ring chain

lubricant. NOTICE: Do not use

engine oil or any other lubri-

cants for the drive chain, as theymay contain substances that

could damage the O-rings.

[ECA11112]

1. Alignment marks

2. Drive chain pullerTightening torques:

Axle nut:

57 Nm (5.7 m·kgf, 41 ft·lbf)

Locknut:

16 Nm (1.6 m·kgf, 12 ft·lbf)

1 2

UB04E0E0.book Page 23 Wednesday, September 2, 2015 3:51 PM

Page 73 of 96

Periodic maintenance and adjustment

6-30

6

If a fuse is blown, replace it as follows.1. Turn the key to “ ” and turn off

the electrical circuit in question.

2. Remove the blown fuse, and then

install a new fuse of the specified

amperage. WARNING! Do not

use a fuse of a higher amperage

rating than recommended to

avoid causing extensive dam-

age to the electrical system and

possibly a fire.

[EWA15132]

3. Turn the key to “ ” and turn on

the electrical circuit in question to

check if the device operates.

4. If the fuse immediately blows

again, have a Yamaha dealer

check the electrical system.

EAU68470

Replacing the headlight bulbThis model is equipped with halogen

bulb headlight. If a headlight bulb

burns out, have a Yamaha dealer re-

place it and, if necessary, adjust the

headlight beam.NOTICE

ECA17871

Headlight lens:

Do not affix any type of tinted film or

stickers to the headlight lens.

Do not use a headlight bulb of a

wattage higher than specified.

1. Fuse box

1. Ignition fuse

2. Signaling system fuse

3. Backup fuse (for clock)

4. Headlight fuse

5. Radiator fan motor fuse

6. Spare fuse

16

12345

Specified fuses:

Main fuse:

30.0 A

Headlight fuse:

15.0 A

Signaling system fuse:

7.5 A

Ignition fuse:

15.0 A

Radiator fan motor fuse:

7.5 A

Backup fuse:

7.5 A

UB04E0E0.book Page 30 Wednesday, September 2, 2015 3:51 PM

Page 74 of 96

Periodic maintenance and adjustment

6-31

6

EAU44941

Auxiliary lightThis model is equipped with an LED-

type auxiliary light.

If the auxiliary light does not come on,

have a Yamaha dealer check it.

EAU24182

Tail/brake lightThis model is equipped with an LED-

type tail/brake light.

If the tail/brake light does not come on,

have a Yamaha dealer check it.

EAU62590

Replacing a turn signal light

bulb1. Remove the turn signal light lens

by removing the screw.

2. Remove the turn signal light bulb

socket (together with the bulb) by

turning it counterclockwise.

1. Auxiliary light

1 1

1. Turn signal light lens

2. Screw

1

2

UB04E0E0.book Page 31 Wednesday, September 2, 2015 3:51 PM

Page 75 of 96

Periodic maintenance and adjustment

6-32

6 3. Remove the burnt-out bulb by

pulling it out.

4. Insert a new bulb into the socket.

5. Install the socket (together with

the bulb) by turning it clockwise.

6. Install the turn signal light lens by

installing the screw. NOTICE: Do

not overtighten the screw, oth-

erwise the lens may break.

[ECA11192]EAU62670

Replacing the license plate

light bulb1. Remove the mudguard by remov-

ing the quick fasteners.

2. Remove the rear fender lower

panel by removing the bolts and

screws.3. Remove the license plate light

bulb socket (together with the

bulb) by pulling it out.

4. Remove the burnt-out bulb by

pulling it out.

1. Turn signal light bulb socket

1

1. Mudguard

2. Quick fastener

1

2

1. Bolt

2. Screw

3. Rear fender lower panel

1. License plate light bulb

2. License plate light bulb socket

3

2

1

2

2 121

UB04E0E0.book Page 32 Wednesday, September 2, 2015 3:51 PM

Page 78 of 96

Periodic maintenance and adjustment

6-35

6

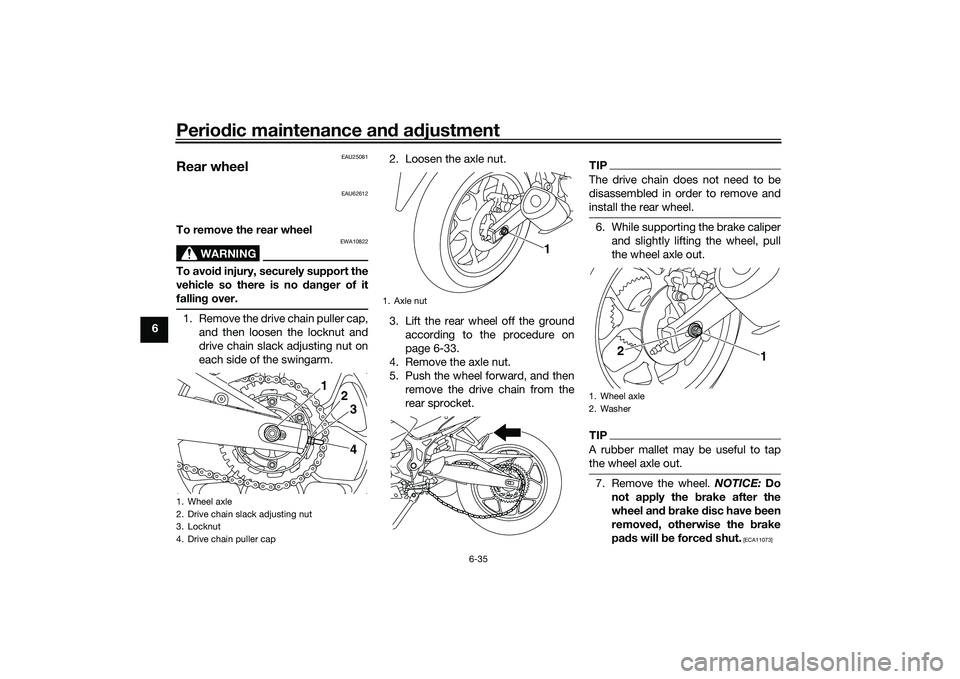

EAU25081

Rear wheel

EAU62612

To remove the rear wheel

WARNING

EWA10822

To avoid injury, securely support the

vehicle so there is no danger of it

falling over.1. Remove the drive chain puller cap,

and then loosen the locknut and

drive chain slack adjusting nut on

each side of the swingarm.2. Loosen the axle nut.

3. Lift the rear wheel off the ground

according to the procedure on

page 6-33.

4. Remove the axle nut.

5. Push the wheel forward, and then

remove the drive chain from the

rear sprocket.

TIPThe drive chain does not need to be

disassembled in order to remove and

install the rear wheel.6. While supporting the brake caliper

and slightly lifting the wheel, pull

the wheel axle out.TIPA rubber mallet may be useful to tap

the wheel axle out.7. Remove the wheel. NOTICE: Do

not apply the brake after the

wheel and brake disc have been

removed, otherwise the brake

pads will be forced shut.

[ECA11073]

1. Wheel axle

2. Drive chain slack adjusting nut

3. Locknut

4. Drive chain puller cap

342

1

1. Axle nut

1

1. Wheel axle

2. Washer

1 2

UB04E0E0.book Page 35 Wednesday, September 2, 2015 3:51 PM