light YAMAHA NMAX 150 2017 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2017, Model line: NMAX 150, Model: YAMAHA NMAX 150 2017Pages: 94, PDF Size: 3.7 MB

Page 39 of 94

Operation and important ri din g points

5-4

5

EAU16821

Tips for re ducin g fuel con-

sumption

Fuel consumption depends largely on

your riding style. Consider the follow-

ing tips to reduce fuel consumption:

Avoid high engine speeds during

acceleration.

Avoid high engine speeds with no

load on the engine.

Turn the engine off instead of let-

ting it idle for an extended length

of time (e.g., in traffic jams, at traf-

fic lights or at railroad crossings).

EAU16842

Engine break-in

There is never a more important period

in the life of your engine than the period

between 0 and 1600 km (1000 mi). For

this reason, you should read the fol-

lowing material carefully.

Since the engine is brand new, do not

put an excessive load on it for the first

1600 km (1000 mi). The various parts in

the engine wear and polish themselves

to the correct operating clearances.

During this period, prolonged full-throt-

tle operation or any condition that

might result in engine overheating

must be avoided.

EAUM2012

0–1000 km (0–600 mi)

Avoid prolonged operation above 1/3

throttle. NOTICE: After 1000 km (600

mi) of operation, be sure to replace

the en gine oil an d final transmission

oil.

[ECA11662]

1000–1600 km (600–1000 mi)

Avoid prolonged operation above 1/2

throttle.

1600 km (1000 mi) an d b eyon d

The vehicle can now be operated nor-

mally.

NOTICE

ECA10271

If any en gine trou ble shoul d occur

d urin g the en gine break-in perio d,

imme diately have a Yamaha dealer

check the vehicle.

UBV3E0E0.book Page 4 Monday, September 26, 2016 3:42 PM

Page 46 of 94

Periodic maintenance an d a djustment

6-6

6

EAU72790

TIP

Engine air filter and V-belt air filter

• This model’s engine air filter is equipped with a disposable oil-coated pa- per element, which must not be cleaned with compressed air to avoid

damaging it.

• The engine air filter element needs to be replaced and the V-belt air filter element needs to be serviced more frequently when riding in unusually wet

or dusty areas.

Hydraulic brake service

• After disassembling the brake master cylinders and calipers, always change the fluid. Regularly check the brake fluid levels and fill the reser-

voirs as required.

• Every two years replace the internal components of the brake master cyl- inders and calipers, and change the brake fluid.

• Replace the brake hoses every four years and if cracked or damaged.

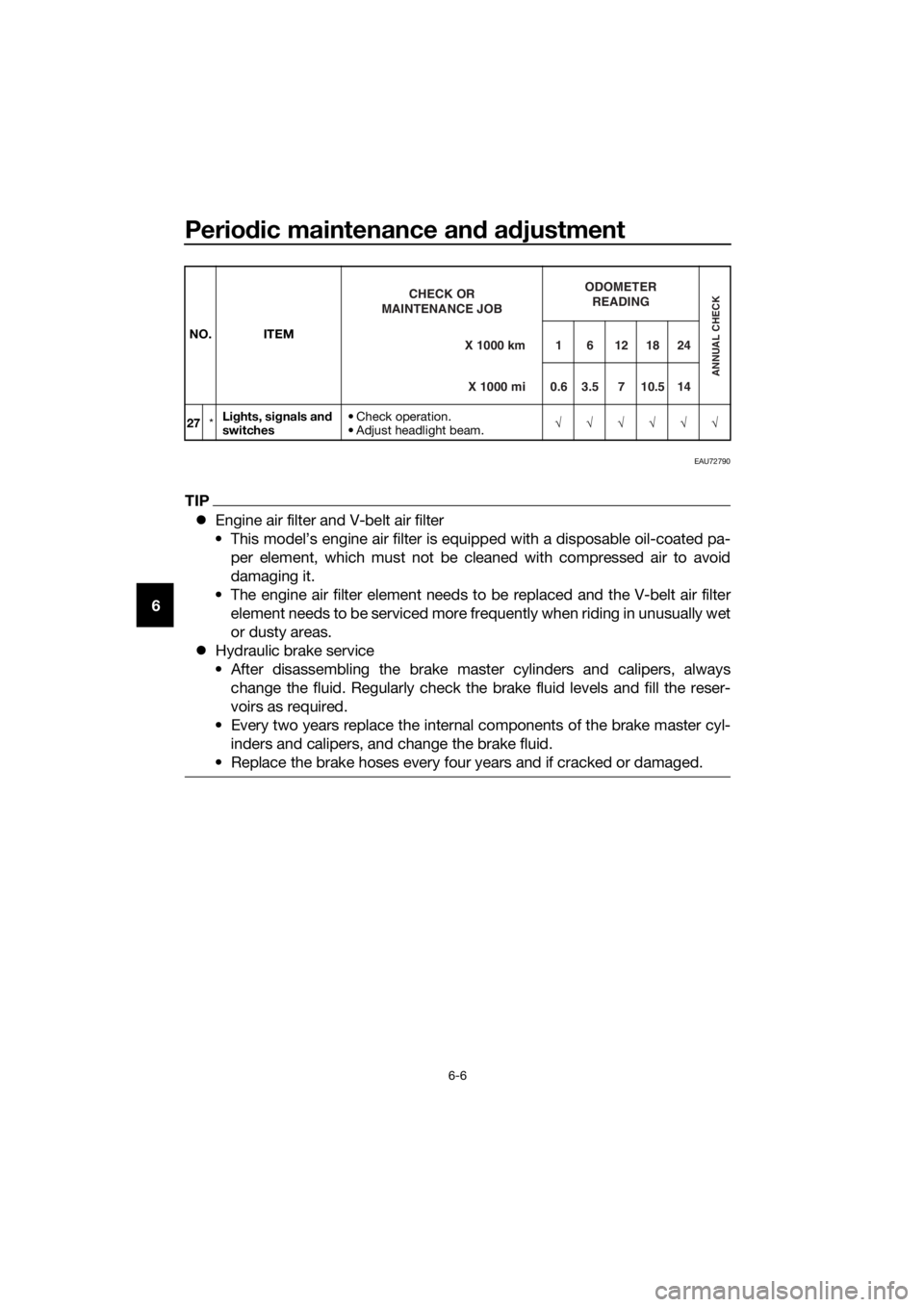

27 *Li

ghts, si gnals an d

switches • Check operation.

• Adjust headlight beam.

√√√√√√

NO. ITEM

X 1000 km

CHECK OR

MAINTENANCE JOB

X 1000 mi ODOMETER

READING

ANNUAL CHECK

16121824

0.6 3.5 7 10.5 14

UBV3E0E0.book Page 6 Monday, September 26, 2016 3:42 PM

Page 49 of 94

Periodic maintenance an d a djustment

6-9

6

EAU67161

Checkin g the spark plu g

The spark plug is an important engine

component, which is easy to check.

Since heat and deposits will cause any

spark plug to slowly erode, the spark

plug should be removed and checked

in accordance with the periodic main-

tenance and lubrication chart. In addi-

tion, the condition of the spark plug

can reveal the condition of the engine.

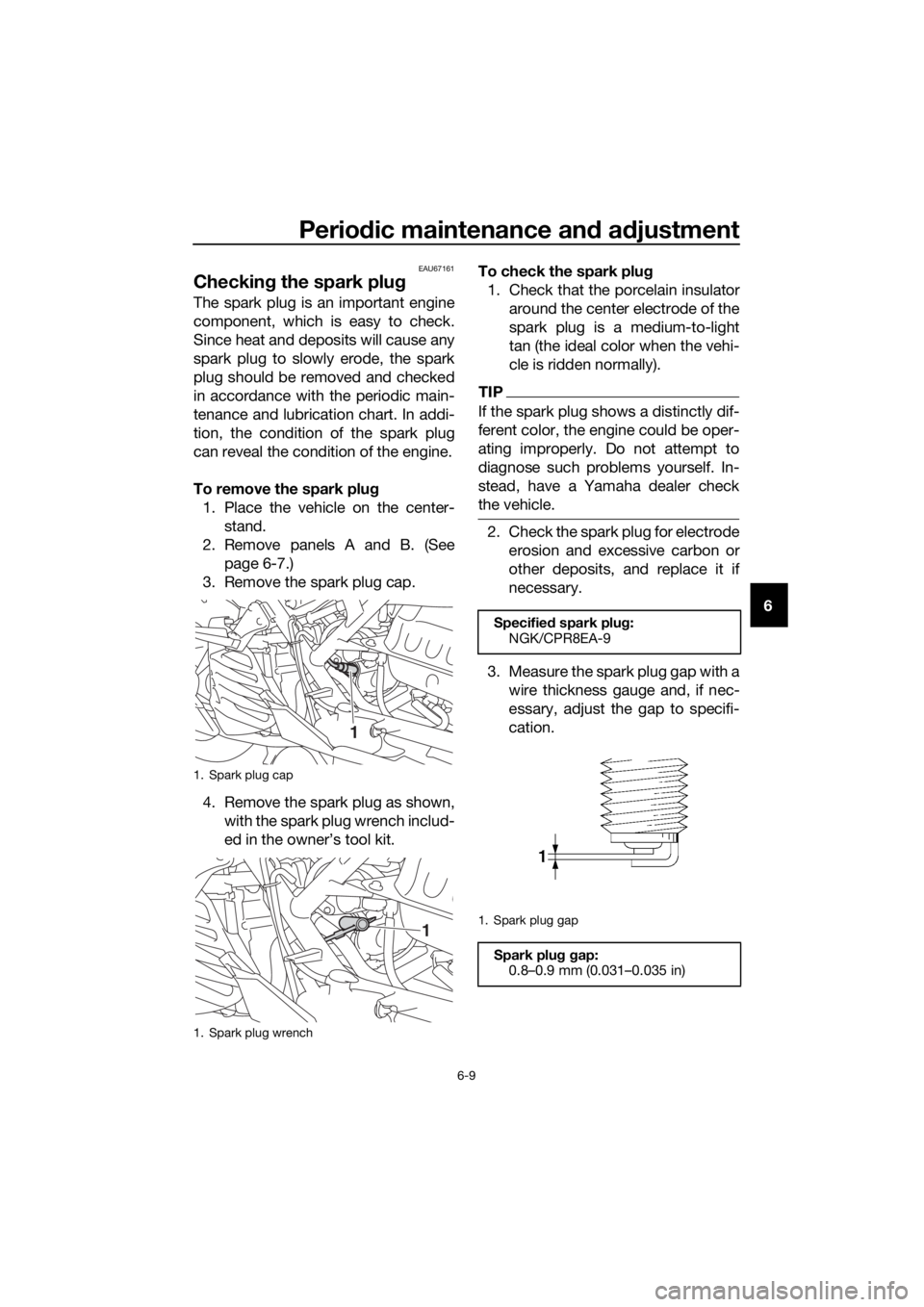

To remove the spark plu g

1. Place the vehicle on the center- stand.

2. Remove panels A and B. (See page 6-7.)

3. Remove the spark plug cap.

4. Remove the spark plug as shown, with the spark plug wrench includ-

ed in the owner’s tool kit. To check the spark plu

g

1. Check that the porcelain insulator around the center electrode of the

spark plug is a medium-to-light

tan (the ideal color when the vehi-

cle is ridden normally).

TIP

If the spark plug shows a distinctly dif-

ferent color, the engine could be oper-

ating improperly. Do not attempt to

diagnose such problems yourself. In-

stead, have a Yamaha dealer check

the vehicle.

2. Check the spark plug for electrodeerosion and excessive carbon or

other deposits, and replace it if

necessary.

3. Measure the spark plug gap with a wire thickness gauge and, if nec-

essary, adjust the gap to specifi-

cation.

1. Spark plug cap

1. Spark plug wrench

1

1

Specified spark plu g:

NGK/CPR8EA-9

1. Spark plug gap

Spark plu g g ap:

0.8–0.9 mm (0.031–0.035 in)

UBV3E0E0.book Page 9 Monday, September 26, 2016 3:42 PM

Page 50 of 94

Periodic maintenance an d a djustment

6-10

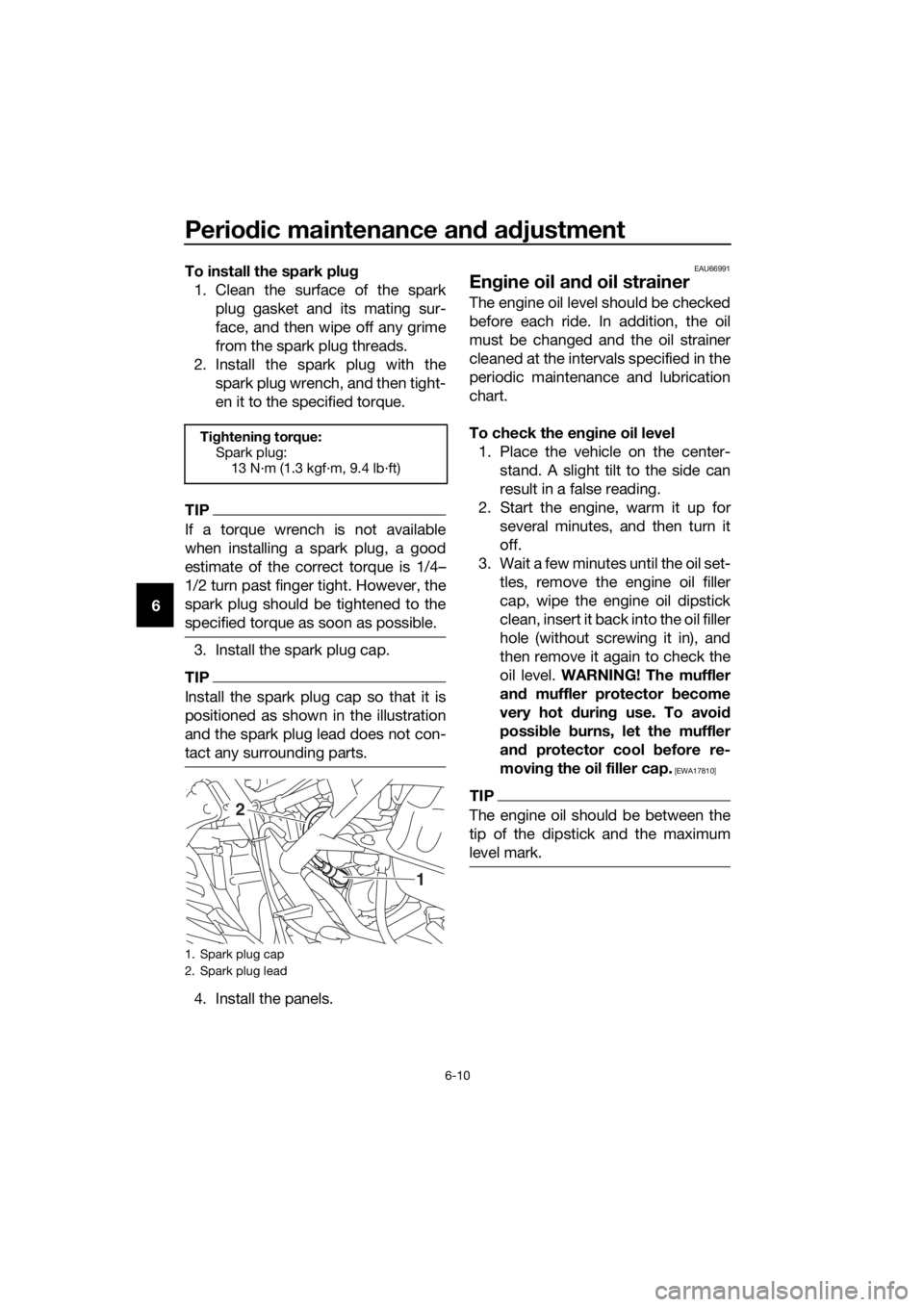

6 To install the spark plu

g

1. Clean the surface of the spark plug gasket and its mating sur-

face, and then wipe off any grime

from the spark plug threads.

2. Install the spark plug with the spark plug wrench, and then tight-

en it to the specified torque.

TIP

If a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4–

1/2 turn past finger tight. However, the

spark plug should be tightened to the

specified torque as soon as possible.

3. Install the spark plug cap.

TIP

Install the spark plug cap so that it is

positioned as shown in the illustration

and the spark plug lead does not con-

tact any surrounding parts.

4. Install the panels.

EAU66991

Engine oil an d oil strainer

The engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil strainer

cleaned at the intervals specified in the

periodic maintenance and lubrication

chart.

To check the en gine oil level

1. Place the vehicle on the center- stand. A slight tilt to the side can

result in a false reading.

2. Start the engine, warm it up for several minutes, and then turn it

off.

3. Wait a few minutes until the oil set- tles, remove the engine oil filler

cap, wipe the engine oil dipstick

clean, insert it back into the oil filler

hole (without screwing it in), and

then remove it again to check the

oil level. WARNING! The muffler

an d muffler protector become

very hot d uring use. To avoi d

possi ble burns, let the muffler

an d protector cool b efore re-

moving the oil filler cap.

[EWA17810]

TIP

The engine oil should be between the

tip of the dipstick and the maximum

level mark.

Tightenin g torque:

Spark plug: 13 N·m (1.3 kgf·m, 9.4 lb·ft)

1. Spark plug cap

2. Spark plug lead

1

2

UBV3E0E0.book Page 10 Monday, September 26, 2016 3:42 PM

Page 53 of 94

Periodic maintenance an d a djustment

6-13

6

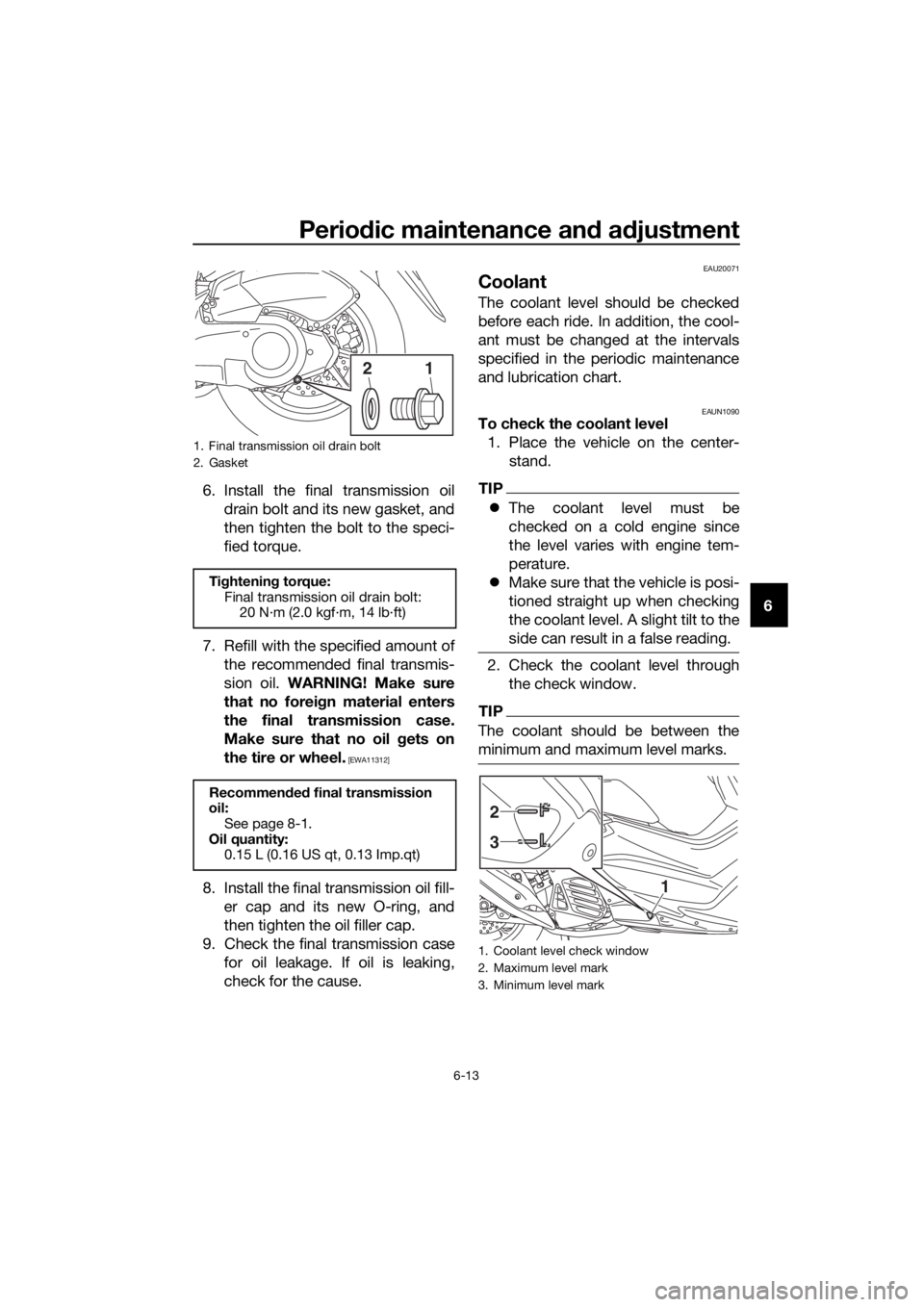

6. Install the final transmission oil

drain bolt and its new gasket, and

then tighten the bolt to the speci-

fied torque.

7. Refill with the specified amount of the recommended final transmis-

sion oil. WARNING! Make sure

that no forei gn material enters

the final transmission case.

Make sure that no oil gets on

the tire or wheel.

[EWA11312]

8. Install the final transmission oil fill- er cap and its new O-ring, and

then tighten the oil filler cap.

9. Check the final transmission case for oil leakage. If oil is leaking,

check for the cause.

EAU20071

Coolant

The coolant level should be checked

before each ride. In addition, the cool-

ant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

EAUN1090To check the coolant level1. Place the vehicle on the center- stand.

TIP

The coolant level must be

checked on a cold engine since

the level varies with engine tem-

perature.

Make sure that the vehicle is posi-

tioned straight up when checking

the coolant level. A slight tilt to the

side can result in a false reading.

2. Check the coolant level through

the check window.

TIP

The coolant should be between the

minimum and maximum level marks.

1. Final transmission oil drain bolt

2. Gasket

Tightening torque:

Final transmission oil drain bolt: 20 N·m (2.0 kgf·m, 14 lb·ft)

Recommen ded final transmission

oil: See page 8-1.

Oil quantity: 0.15 L (0.16 US qt, 0.13 Imp.qt)

12

1. Coolant level check window

2. Maximum level mark

3. Minimum level mark

1

2

3

UBV3E0E0.book Page 13 Monday, September 26, 2016 3:42 PM

Page 72 of 94

Periodic maintenance an d a djustment

6-32

6

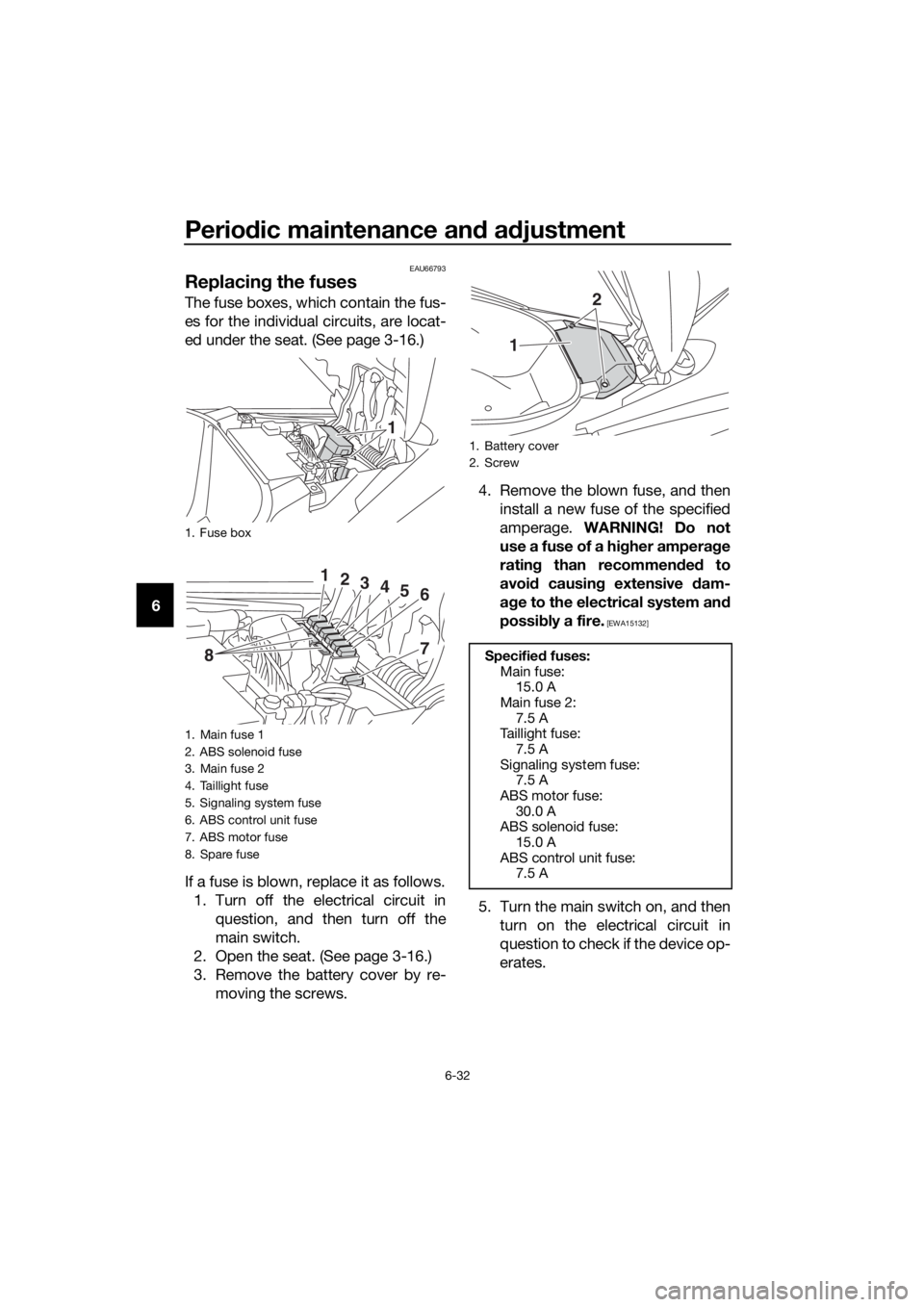

EAU66793

Replacin g the fuses

The fuse boxes, which contain the fus-

es for the individual circuits, are locat-

ed under the seat. (See page 3-16.)

If a fuse is blown, replace it as follows.

1. Turn off the electrical circuit in question, and then turn off the

main switch.

2. Open the seat. (See page 3-16.)

3. Remove the battery cover by re- moving the screws. 4. Remove the blown fuse, and then

install a new fuse of the specified

amperage. WARNING! Do not

use a fuse of a hi gher ampera ge

ratin g than recommen ded to

avoi d causin g extensive dam-

a g e to the electrical system an d

possi bly a fire.

[EWA15132]

5. Turn the main switch on, and then

turn on the electrical circuit in

question to check if the device op-

erates.

1. Fuse box

1. Main fuse 1

2. ABS solenoid fuse

3. Main fuse 2

4. Taillight fuse

5. Signaling system fuse

6. ABS control unit fuse

7. ABS motor fuse

8. Spare fuse

1

123456

78

1. Battery cover

2. Screw

Specified fuses:

Main fuse: 15.0 A

Main fuse 2:

7.5 A

Taillight fuse: 7.5 A

Signaling system fuse: 7.5 A

ABS motor fuse:

30.0 A

ABS solenoid fuse: 15.0 A

ABS control unit fuse: 7.5 A

1

2

UBV3E0E0.book Page 32 Monday, September 26, 2016 3:42 PM

Page 73 of 94

Periodic maintenance an d a djustment

6-33

6

TIP

If the fuse immediately blows again,

have a Yamaha dealer check the elec-

trical system.

6. Install the battery cover by install-

ing the screws.

7. Close the seat.

EAU62850

Hea dlig ht

This model is equipped with an LED-

type headlight.

If a headlight does not come on, have

a Yamaha dealer check its electrical

circuit.

NOTICE

ECA16581

Do not affix any type of tinted film or

stickers to the head lig ht lens.

UBV3E0E0.book Page 33 Monday, September 26, 2016 3:42 PM

Page 74 of 94

Periodic maintenance an d a djustment

6-34

6

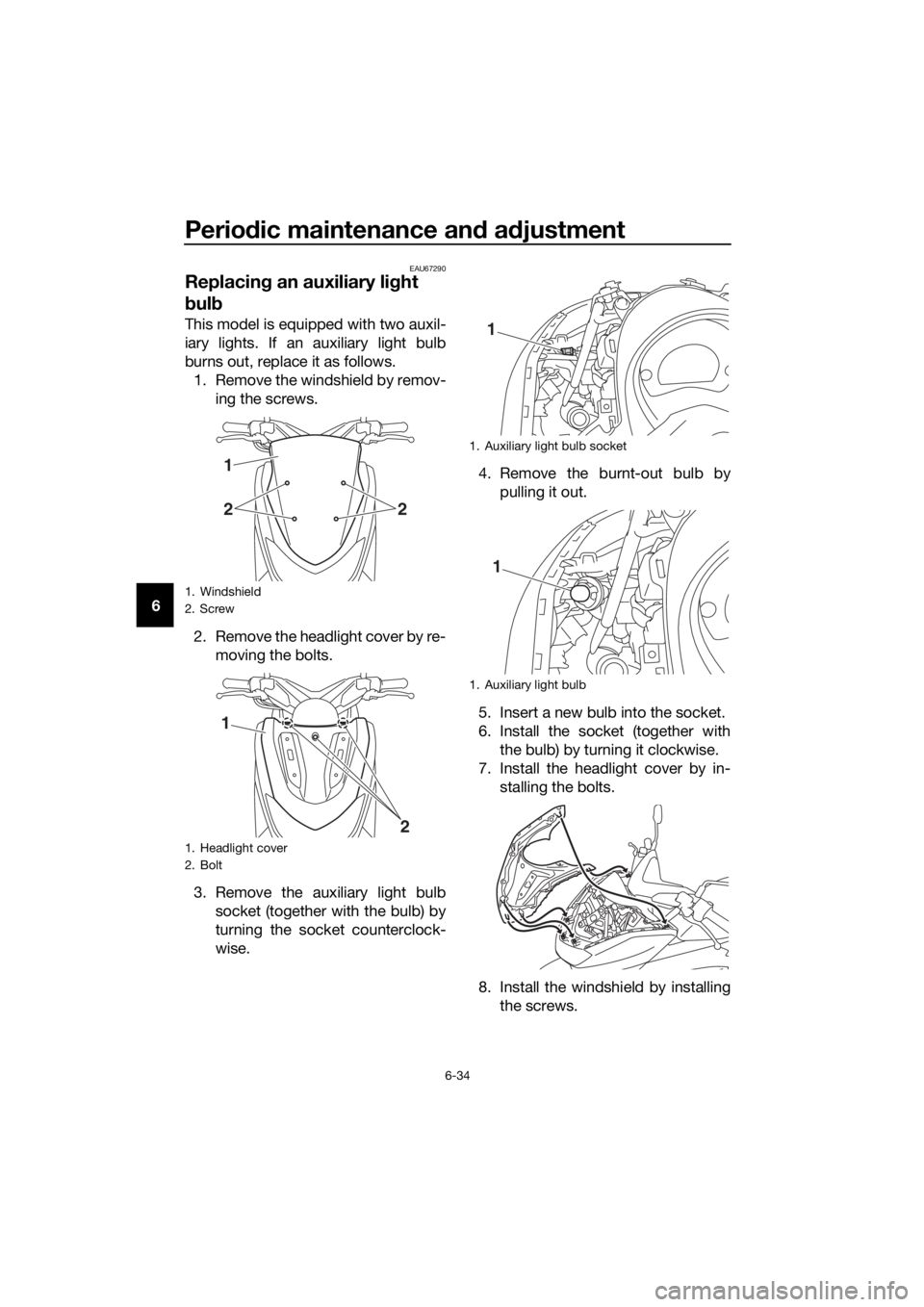

EAU67290

Replacin g an auxiliary lig ht

b ul b

This model is equipped with two auxil-

iary lights. If an auxiliary light bulb

burns out, replace it as follows.

1. Remove the windshield by remov- ing the screws.

2. Remove the headlight cover by re- moving the bolts.

3. Remove the auxiliary light bulb socket (together with the bulb) by

turning the socket counterclock-

wise. 4. Remove the burnt-out bulb by

pulling it out.

5. Insert a new bulb into the socket.

6. Install the socket (together with the bulb) by turning it clockwise.

7. Install the headlight cover by in- stalling the bolts.

8. Install the windshield by installing the screws.

1. Windshield

2. Screw

1. Headlight cover

2. Bolt

22

1

2

1

1. Auxiliary light bulb socket

1. Auxiliary light bulb

1

1

UBV3E0E0.book Page 34 Monday, September 26, 2016 3:42 PM

Page 75 of 94

Periodic maintenance an d a djustment

6-35

6

EAU67300

Brake li ght

This model is equipped with an LED-

type brake light.

If the brake light does not come on,

have a Yamaha dealer check it.

EAU67310

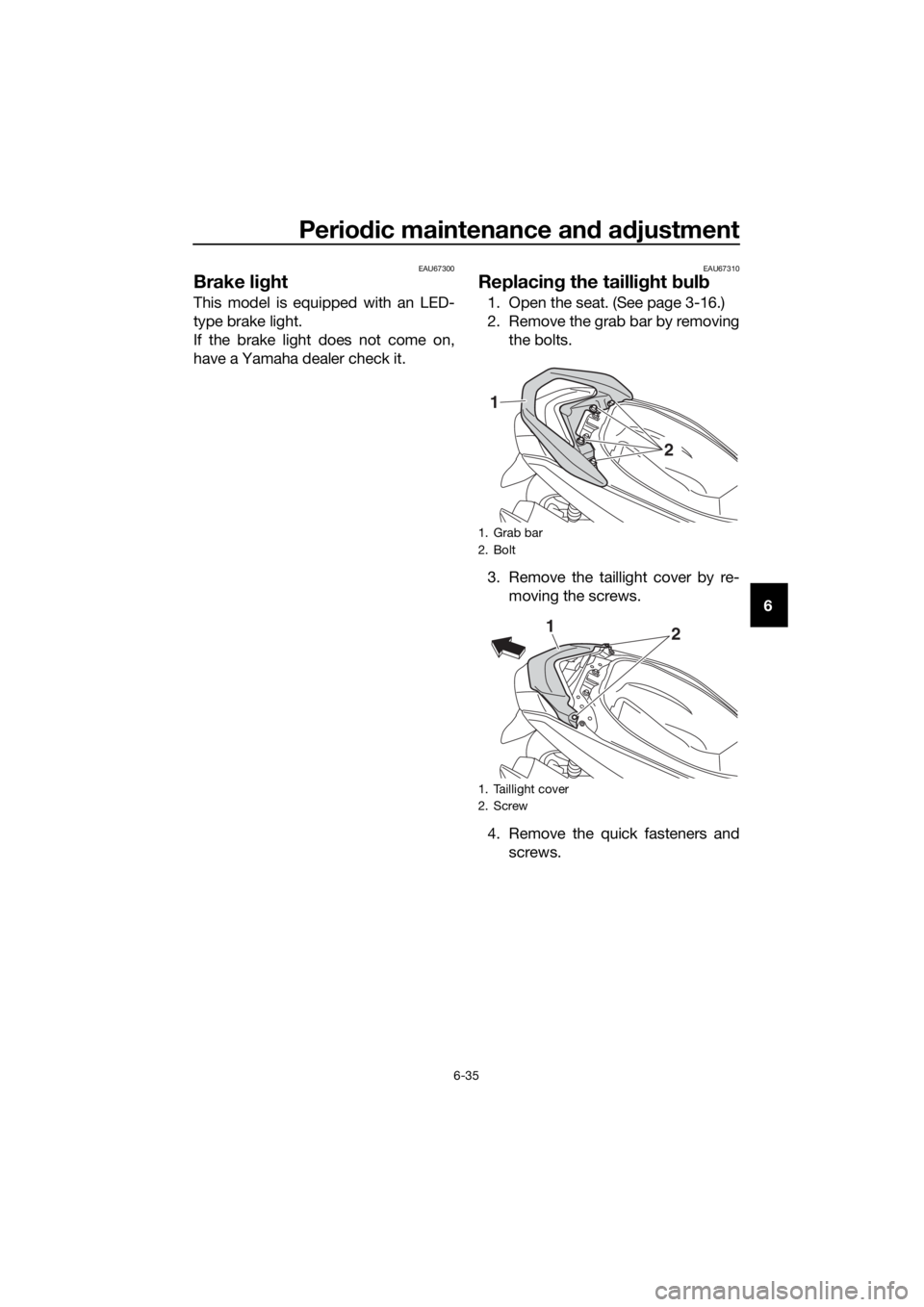

Replacin g the tailli ght bul b

1. Open the seat. (See page 3-16.)

2. Remove the grab bar by removing

the bolts.

3. Remove the taillight cover by re- moving the screws.

4. Remove the quick fasteners and screws.

1. Grab bar

2. Bolt

1. Taillight cover

2. Screw

1

2

12

UBV3E0E0.book Page 35 Monday, September 26, 2016 3:42 PM

Page 76 of 94

Periodic maintenance an d a djustment

6-36

6

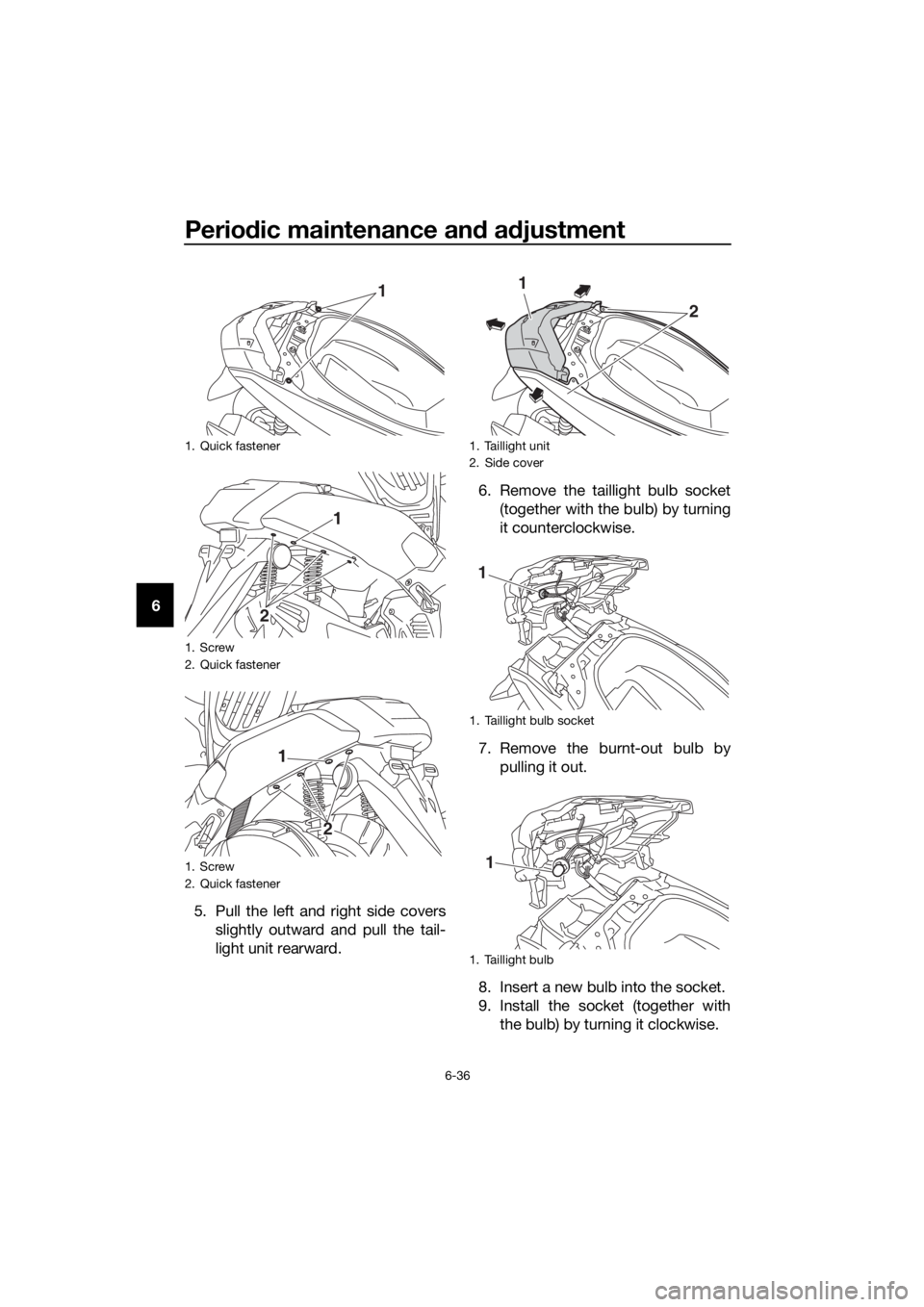

5. Pull the left and right side coversslightly outward and pull the tail-

light unit rearward. 6. Remove the taillight bulb socket

(together with the bulb) by turning

it counterclockwise.

7. Remove the burnt-out bulb by pulling it out.

8. Insert a new bulb into the socket.

9. Install the socket (together with the bulb) by turning it clockwise.

1. Quick fastener

1. Screw

2. Quick fastener

1. Screw

2. Quick fastener

1

2 1

1

2

1. Taillight unit

2. Side cover

1. Taillight bulb socket

1. Taillight bulb

1

2

1

1

UBV3E0E0.book Page 36 Monday, September 26, 2016 3:42 PM