YAMAHA PW50 2010 Workshop Manual

Manufacturer: YAMAHA, Model Year: 2010, Model line: PW50, Model: YAMAHA PW50 2010Pages: 70, PDF Size: 1.44 MB

Page 51 of 70

PERIODIC MAINTENANCE AND ADJUSTMENT

7-15

2

3

4

5

6

78

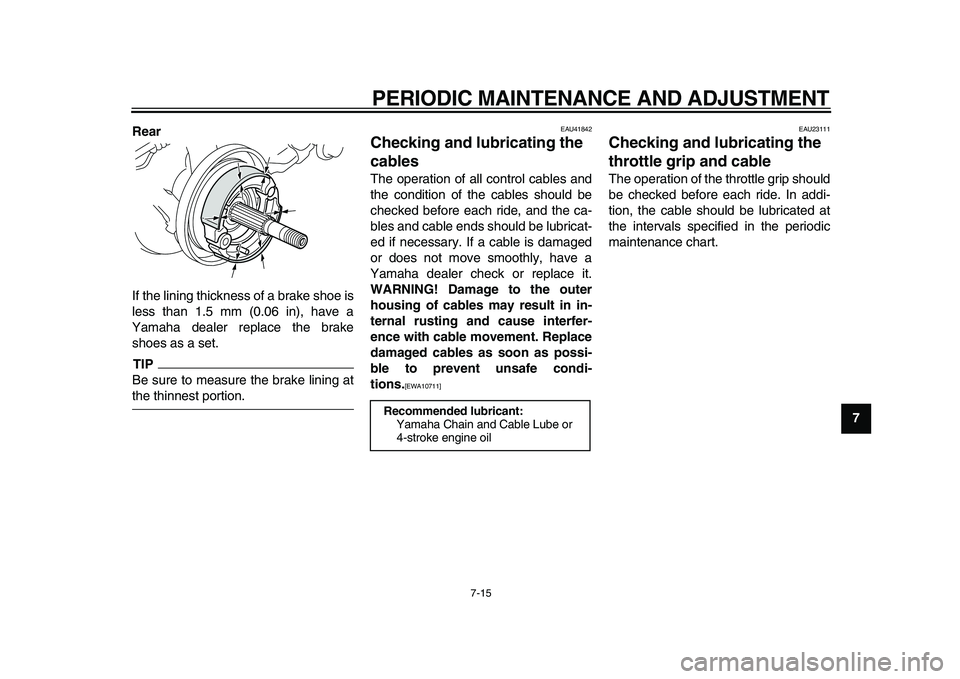

9 Rear

If the lining thickness of a brake shoe is

less than 1.5 mm (0.06 in), have a

Yamaha dealer replace the brake

shoes as a set.

TIP

Be sure to measure the brake lining at

the thinnest portion.

EAU41842

Checking and lubricating the

cables

The operation of all control cables and

the condition of the cables should be

checked before each ride, and the ca-

bles and cable ends should be lubricat-

ed if necessary. If a cable is damaged

or does not move smoothly, have a

Yamaha dealer check or replace it.

WARNING! Damage to the outer

housing of cables may result in in-

ternal rusting and cause interfer-

ence with cable movement. Replace

damaged cables as soon as possi-

ble to prevent unsafe condi-

tions.

[EWA10711]

EAU23111

Checking and lubricating the

throttle grip and cable

The operation of the throttle grip should

be checked before each ride. In addi-

tion, the cable should be lubricated at

the intervals specified in the periodic

maintenance chart.

Recommended lubricant:

Yamaha Chain and Cable Lube or

4-stroke engine oil

Page 52 of 70

PERIODIC MAINTENANCE AND ADJUSTMENT

7-16

1

2

3

4

5

6

7

8

9

EAU23120

Adjusting the Autolube pump

The Autolube pump is a vital and so-

phisticated component of the engine,

which must be adjusted by a Yamaha

dealer at the intervals specified in the

periodic maintenance and lubrication

chart.

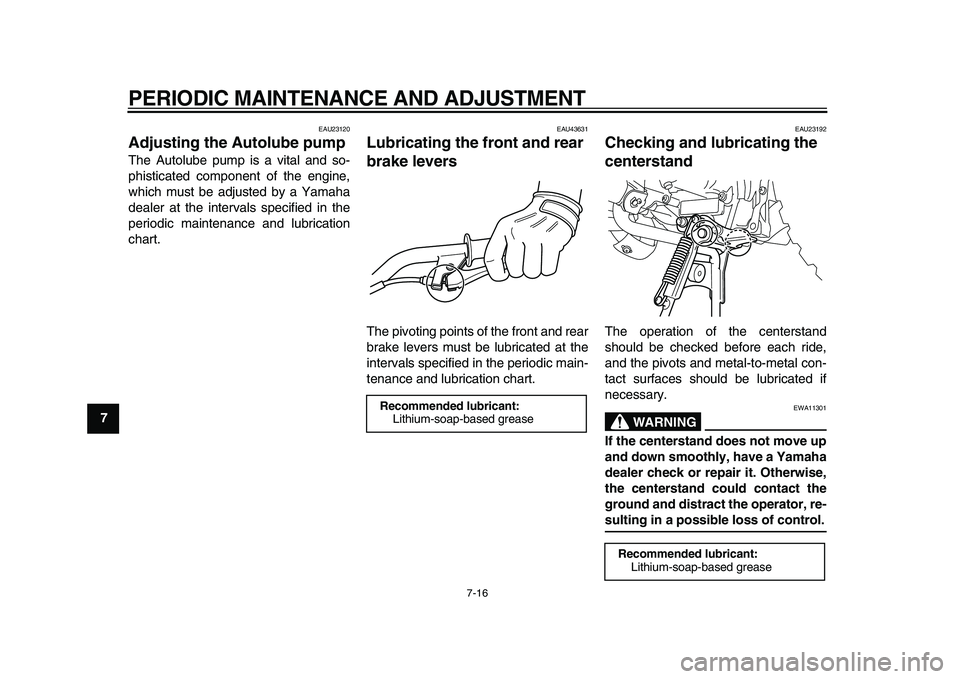

EAU43631

Lubricating the front and rear

brake levers

The pivoting points of the front and rear

brake levers must be lubricated at the

intervals specified in the periodic main-

tenance and lubrication chart.

EAU23192

Checking and lubricating the

centerstand

The operation of the centerstand

should be checked before each ride,

and the pivots and metal-to-metal con-

tact surfaces should be lubricated if

necessary.

WARNING

EWA11301

If the centerstand does not move up

and down smoothly, have a Yamaha

dealer check or repair it. Otherwise,

the centerstand could contact the

ground and distract the operator, re-

sulting in a possible loss of control.

Recommended lubricant:

Lithium-soap-based grease

Recommended lubricant:

Lithium-soap-based grease

Page 53 of 70

PERIODIC MAINTENANCE AND ADJUSTMENT

7-17

2

3

4

5

6

78

9

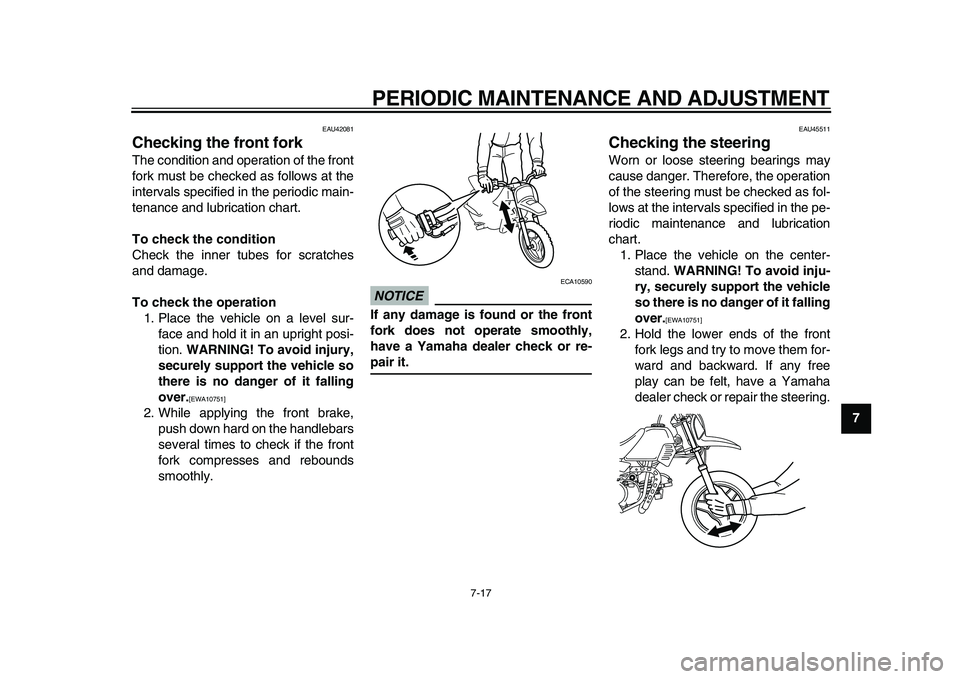

EAU42081

Checking the front fork

The condition and operation of the front

fork must be checked as follows at the

intervals specified in the periodic main-

tenance and lubrication chart.

To check the condition

Check the inner tubes for scratches

and damage.

To check the operation

1. Place the vehicle on a level sur-

face and hold it in an upright posi-

tion.

WARNING! To avoid injury,

securely support the vehicle so

there is no danger of it falling

over.

[EWA10751]

2. While applying the front brake,

push down hard on the handlebars

several times to check if the front

fork compresses and rebounds

smoothly.

NOTICE

ECA10590

If any damage is found or the front

fork does not operate smoothly,

have a Yamaha dealer check or re-

pair it.

EAU45511

Checking the steering

Worn or loose steering bearings may

cause danger. Therefore, the operation

of the steering must be checked as fol-

lows at the intervals specified in the pe-

riodic maintenance and lubrication

chart.

1. Place the vehicle on the center-

stand.

WARNING! To avoid inju-

ry, securely support the vehicle

so there is no danger of it falling

over.

[EWA10751]

2. Hold the lower ends of the front

fork legs and try to move them for-

ward and backward. If any free

play can be felt, have a Yamaha

dealer check or repair the steering.

Page 54 of 70

PERIODIC MAINTENANCE AND ADJUSTMENT

7-18

1

2

3

4

5

6

7

8

9

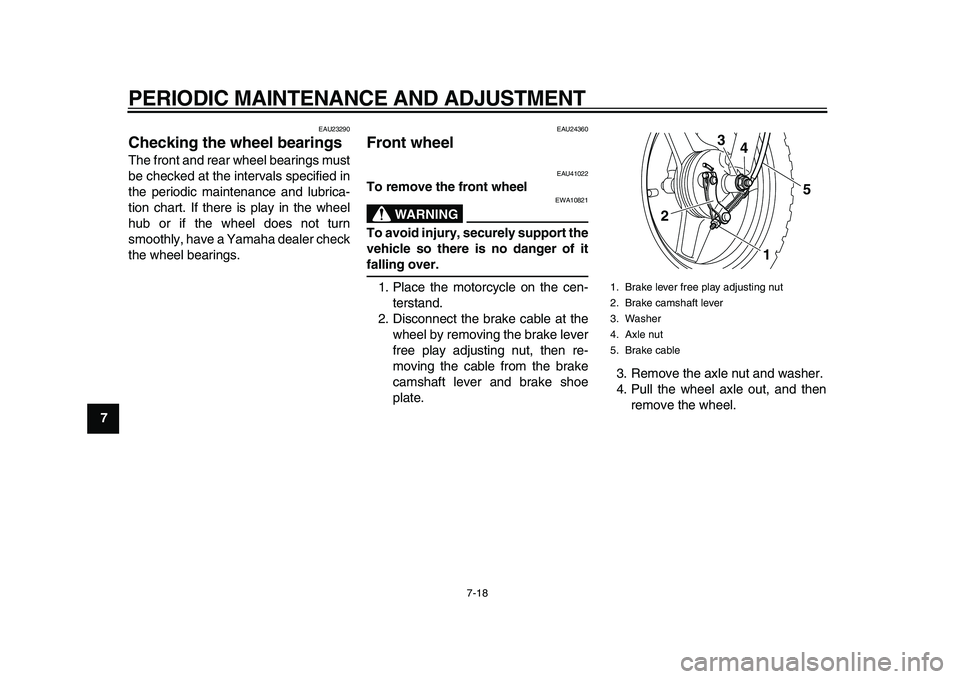

EAU23290

Checking the wheel bearings

The front and rear wheel bearings must

be checked at the intervals specified in

the periodic maintenance and lubrica-

tion chart. If there is play in the wheel

hub or if the wheel does not turn

smoothly, have a Yamaha dealer check

the wheel bearings.

EAU24360

Front wheel

EAU41022

To remove the front wheel

WARNING

EWA10821

To avoid injury, securely support the

vehicle so there is no danger of it

falling over.

1. Place the motorcycle on the cen-

terstand.

2. Disconnect the brake cable at the

wheel by removing the brake lever

free play adjusting nut, then re-

moving the cable from the brake

camshaft lever and brake shoe

plate.3. Remove the axle nut and washer.

4. Pull the wheel axle out, and then

remove the wheel.

1. Brake lever free play adjusting nut

2. Brake camshaft lever

3. Washer

4. Axle nut

5. Brake cable

5

1 23

4

Page 55 of 70

PERIODIC MAINTENANCE AND ADJUSTMENT

7-19

2

3

4

5

6

78

9

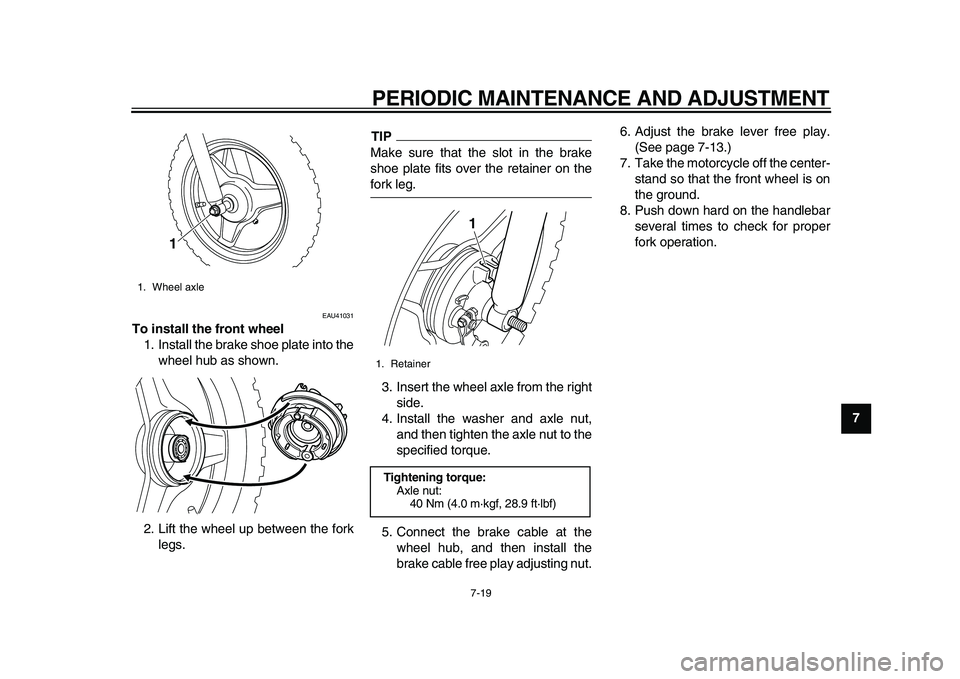

EAU41031

To install the front wheel

1. Install the brake shoe plate into the

wheel hub as shown.

2. Lift the wheel up between the fork

legs.

TIP

Make sure that the slot in the brake

shoe plate fits over the retainer on the

fork leg.

3. Insert the wheel axle from the right

side.

4. Install the washer and axle nut,

and then tighten the axle nut to the

specified torque.

5. Connect the brake cable at the

wheel hub, and then install the

brake cable free play adjusting nut.6. Adjust the brake lever free play.

(See page 7-13.)

7. Take the motorcycle off the center-

stand so that the front wheel is on

the ground.

8. Push down hard on the handlebar

several times to check for proper

fork operation.

1. Wheel axle

1

1. Retainer

Tightening torque:

Axle nut:

40 Nm (4.0 m·kgf, 28.9 ft·lbf)

1

Page 56 of 70

PERIODIC MAINTENANCE AND ADJUSTMENT

7-20

1

2

3

4

5

6

7

8

9

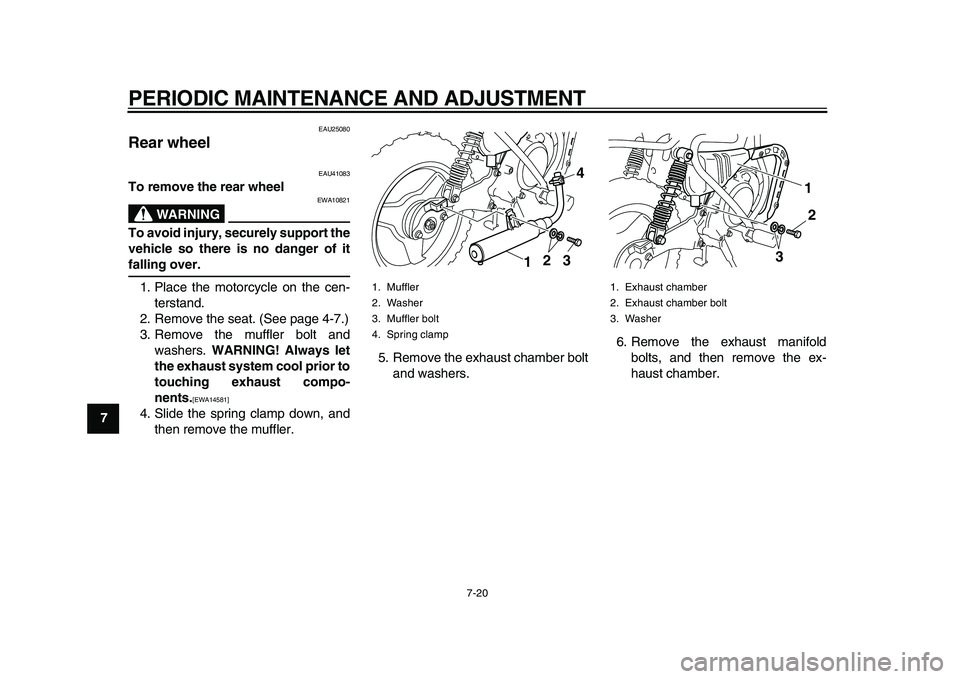

EAU25080

Rear wheel

EAU41083

To remove the rear wheel

WARNING

EWA10821

To avoid injury, securely support the

vehicle so there is no danger of it

falling over.

1. Place the motorcycle on the cen-

terstand.

2. Remove the seat. (See page 4-7.)

3. Remove the muffler bolt and

washers.

WARNING! Always let

the exhaust system cool prior to

touching exhaust compo-

nents.

[EWA14581]

4. Slide the spring clamp down, and

then remove the muffler.5. Remove the exhaust chamber bolt

and washers.6. Remove the exhaust manifold

bolts, and then remove the ex-

haust chamber.

1. Muffler

2. Washer

3. Muffler bolt

4. Spring clamp

3

1

24

1. Exhaust chamber

2. Exhaust chamber bolt

3. Washer

2 1

3

Page 57 of 70

PERIODIC MAINTENANCE AND ADJUSTMENT

7-21

2

3

4

5

6

78

9

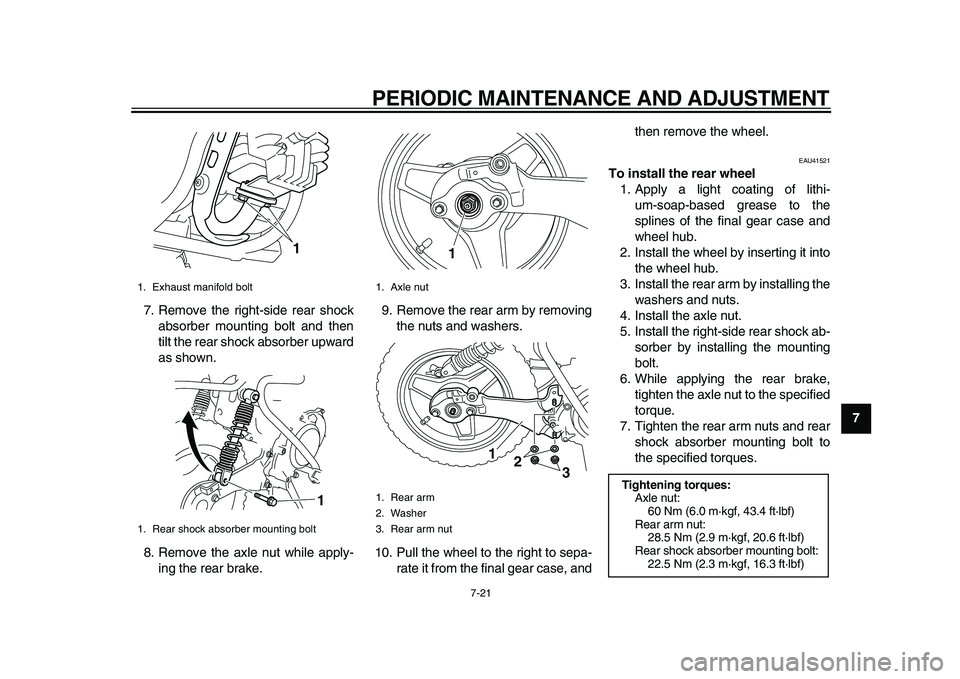

7. Remove the right-side rear shock

absorber mounting bolt and then

tilt the rear shock absorber upward

as shown.

8. Remove the axle nut while apply-

ing the rear brake.9. Remove the rear arm by removing

the nuts and washers.

10. Pull the wheel to the right to sepa-

rate it from the final gear case, andthen remove the wheel.

EAU41521

To install the rear wheel

1. Apply a light coating of lithi-

um-soap-based grease to the

splines of the final gear case and

wheel hub.

2. Install the wheel by inserting it into

the wheel hub.

3. Install the rear arm by installing the

washers and nuts.

4. Install the axle nut.

5. Install the right-side rear shock ab-

sorber by installing the mounting

bolt.

6. While applying the rear brake,

tighten the axle nut to the specified

torque.

7. Tighten the rear arm nuts and rear

shock absorber mounting bolt to

the specified torques.

1. Exhaust manifold bolt

1. Rear shock absorber mounting bolt

1

1

1. Axle nut

1. Rear arm

2. Washer

3. Rear arm nut1

1

2

3

Tightening torques:

Axle nut:

60 Nm (6.0 m·kgf, 43.4 ft·lbf)

Rear arm nut:

28.5 Nm (2.9 m·kgf, 20.6 ft·lbf)

Rear shock absorber mounting bolt:

22.5 Nm (2.3 m·kgf, 16.3 ft·lbf)

Page 58 of 70

PERIODIC MAINTENANCE AND ADJUSTMENT

7-22

1

2

3

4

5

6

7

8

9

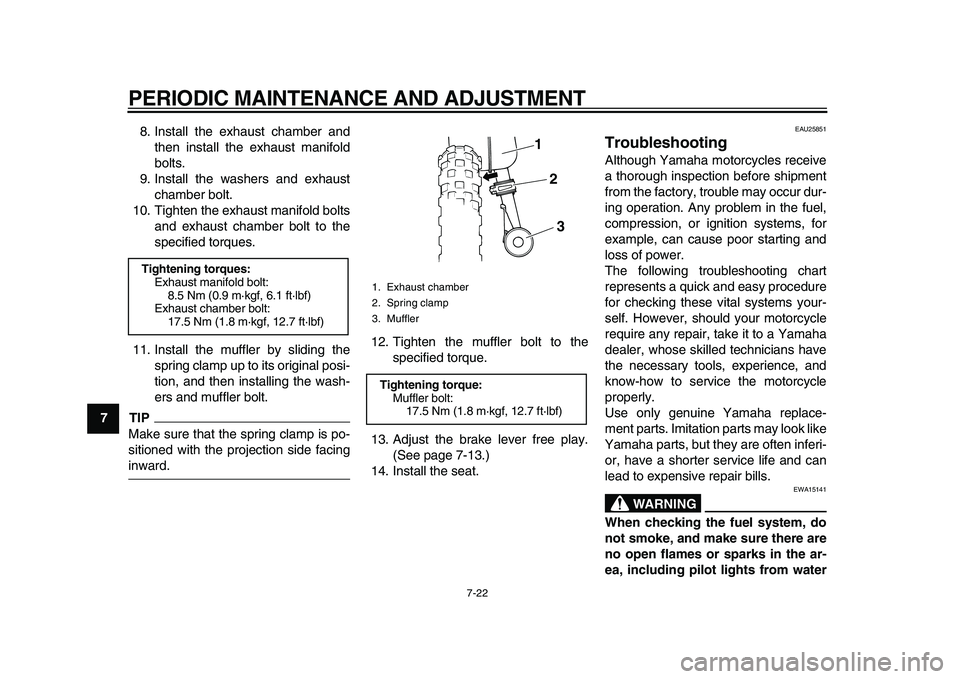

8. Install the exhaust chamber and

then install the exhaust manifold

bolts.

9. Install the washers and exhaust

chamber bolt.

10. Tighten the exhaust manifold bolts

and exhaust chamber bolt to the

specified torques.

11. Install the muffler by sliding the

spring clamp up to its original posi-

tion, and then installing the wash-

ers and muffler bolt.

TIP

Make sure that the spring clamp is po-

sitioned with the projection side facing

inward.12. Tighten the muffler bolt to the

specified torque.

13. Adjust the brake lever free play.

(See page 7-13.)

14. Install the seat.

EAU25851

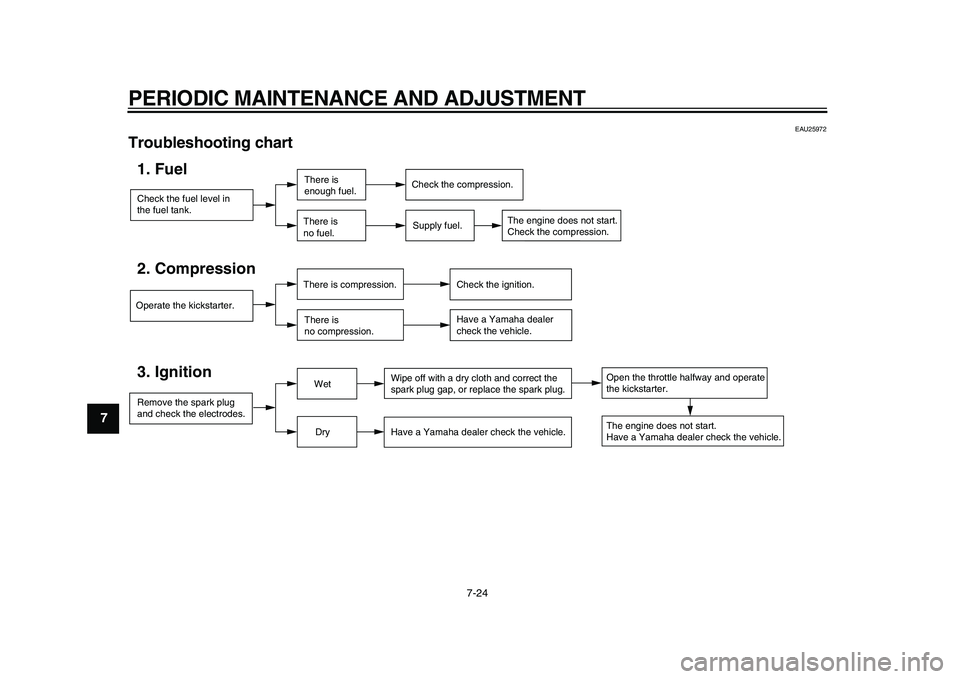

Troubleshooting

Although Yamaha motorcycles receive

a thorough inspection before shipment

from the factory, trouble may occur dur-

ing operation. Any problem in the fuel,

compression, or ignition systems, for

example, can cause poor starting and

loss of power.

The following troubleshooting chart

represents a quick and easy procedure

for checking these vital systems your-

self. However, should your motorcycle

require any repair, take it to a Yamaha

dealer, whose skilled technicians have

the necessary tools, experience, and

know-how to service the motorcycle

properly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look like

Yamaha parts, but they are often inferi-

or, have a shorter service life and can

lead to expensive repair bills.

WARNING

EWA15141

When checking the fuel system, do

not smoke, and make sure there are

no open flames or sparks in the ar-

ea, including pilot lights from water

Tightening torques:

Exhaust manifold bolt:

8.5 Nm (0.9 m·kgf, 6.1 ft·lbf)

Exhaust chamber bolt:

17.5 Nm (1.8 m·kgf, 12.7 ft·lbf)

1. Exhaust chamber

2. Spring clamp

3. Muffler

Tightening torque:

Muffler bolt:

17.5 Nm (1.8 m·kgf, 12.7 ft·lbf)

1

2

3

Page 59 of 70

PERIODIC MAINTENANCE AND ADJUSTMENT

7-23

2

3

4

5

6

78

9 heaters or furnaces. Gasoline or

gasoline vapors can ignite or ex-

plode, causing severe injury or

property damage.

Page 60 of 70

PERIODIC MAINTENANCE AND ADJUSTMENT

7-24

1

2

3

4

5

6

7

8

9

EAU25972

Troubleshooting chart

Check the fuel level in

the fuel tank.1. Fuel

There is

enough fuel.

There is

no fuel.

Supply fuel.

Operate the kickstarter.2. Compression

There is compression.

There is

no compression.Check the ignition.

Have a Yamaha dealer

check the vehicle.

Remove the spark plug

and check the electrodes.3. Ignition

Wet

DryWipe off with a dry cloth and correct the

spark plug gap, or replace the spark plug.

Have a Yamaha dealer check the vehicle.The engine does not start.

Have a Yamaha dealer check the vehicle.

Open the throttle halfway and operate

the kickstarter.

Check the compression.

The engine does not start.

Check the compression.