maintenance YAMAHA PW50 2014 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: PW50, Model: YAMAHA PW50 2014Pages: 76, PDF Size: 1.74 MB

Page 45 of 76

PERIODIC MAINTENANCE AND ADJUSTMENT

7-4

7

EAU41759

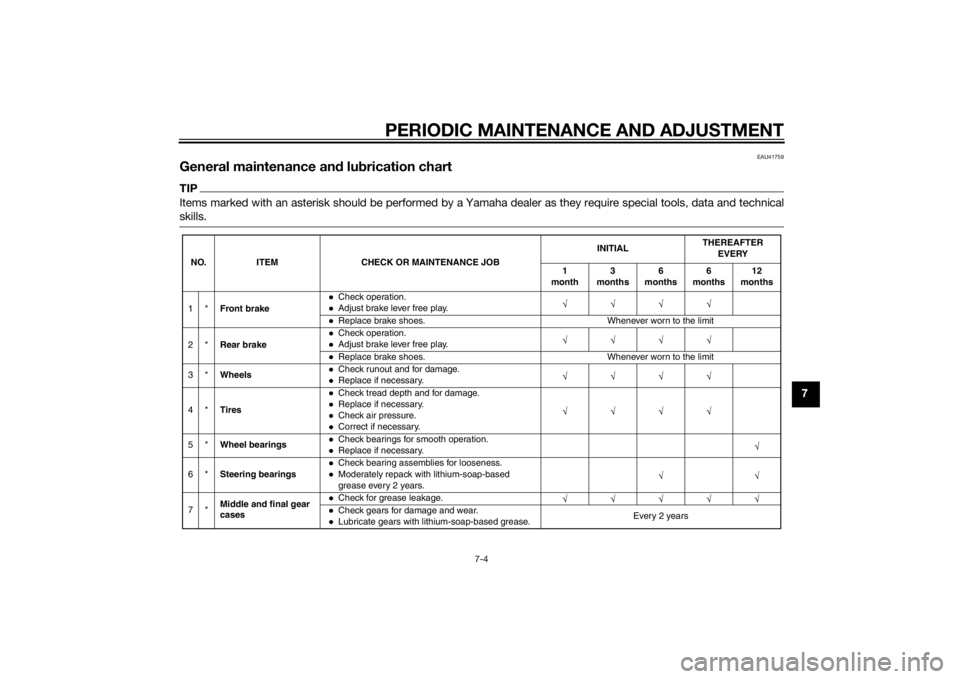

General maintenance and lu brication chartTIPItems marked with an asterisk should be performed by a Yamaha dealer as they require special tools, data and technical

skills.NO. ITEM CHECK OR MAINTENANCE JOB INITIAL

THEREAFTER

EVERY

1

month 3

months 6

months 6

months 12

months

1* Front brake

Check operation.Adjust brake lever free play.Replace brake shoes. Whenever worn to the limit

2* Rear brakeCheck operation.Adjust brake lever free play.Replace brake shoes. Whenever worn to the limit

3* WheelsCheck runout and for damage.Replace if necessary.

4* TiresCheck tread depth and for damage.Replace if necessary.Check air pressure.Correct if necessary.

5* Wheel bearingsCheck bearings for smooth operation.Replace if necessary.

6* Steering bearingsCheck bearing assemblies for looseness.Moderately repack with lithium-soap-based

grease every 2 years.

7*Check for grease leakage.Check gears for damage and wear.Lubricate gears with lithium-soap-based grease. Every 2 years

Middle and final gear

cases

U2SA80E0.book Page 4 Monday, June 3, 2013 5:25 PM

Page 46 of 76

PERIODIC MAINTENANCE AND ADJUSTMENT

7-5

7

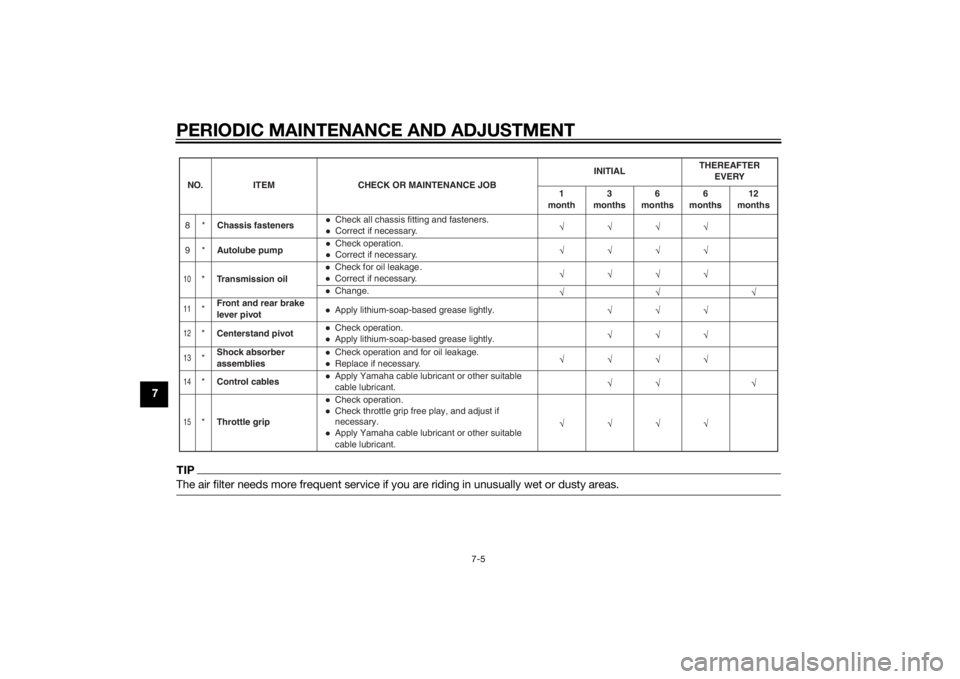

TIPThe air filter needs more frequent service if you are riding in unusually wet or dusty areas.10

*Transmission oil

Check for oil leakage .Correct if necessary.Change.

11

*Front and rear brake

lever pivot

Apply lithium-soap-based grease lightly.

12

*

Centerstand pivot

Check operation.Apply lithium-soap-based grease lightly.

13

*Shock absorber

assemblies

Check operation and for oil leakage.Replace if necessary.

14

*

Control cables

Apply Yamaha cable lubricant or other suitable

cable lubricant.

15

*Throttle grip

Check operation.Check throttle grip free play, and adjust if

necessary.Apply Yamaha cable lubricant or other suitable

cable lubricant.

NO. ITEM CHECK OR MAINTENANCE JOB

INITIAL

THEREAFTER

EVERY

1

month 3

months 6

months 6

months 12

months

8* Chassis fastenersCorrect if necessary.

A

9* utolube pumpCheck operation.Correct if necessary. Check all chassis fitting and fasteners.

U2SA80E0.book Page 5 Monday, June 3, 2013 5:25 PM

Page 47 of 76

PERIODIC MAINTENANCE AND ADJUSTMENT

7-6

7

EAU19605

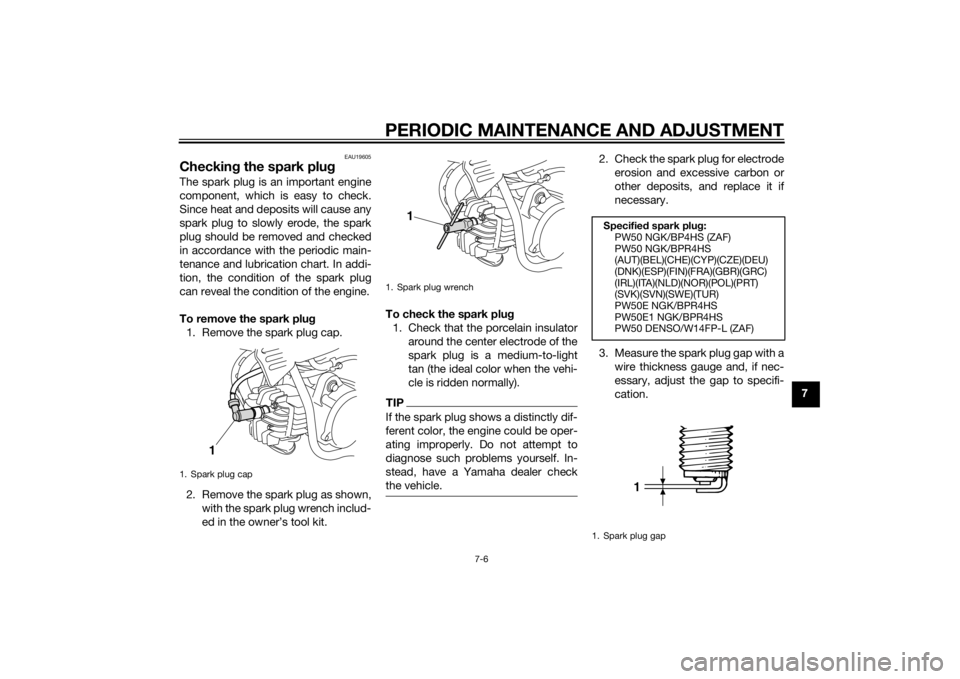

Checking the spark plugThe spark plug is an important engine

component, which is easy to check.

Since heat and deposits will cause any

spark plug to slowly erode, the spark

plug should be removed and checked

in accordance with the periodic main-

tenance and lubrication chart. In addi-

tion, the condition of the spark plug

can reveal the condition of the engine.

To remove the spark plu g

1. Remove the spark plug cap.

2. Remove the spark plug as shown, with the spark plug wrench includ-

ed in the owner’s tool kit. To check the spark plu

g

1. Check that the porcelain insulator around the center electrode of the

spark plug is a medium-to-light

tan (the ideal color when the vehi-

cle is ridden normally).

TIPIf the spark plug shows a distinctly dif-

ferent color, the engine could be oper-

ating improperly. Do not attempt to

diagnose such problems yourself. In-

stead, have a Yamaha dealer check

the vehicle.

2. Check the spark plug for electrodeerosion and excessive carbon or

other deposits, and replace it if

necessary.

3. Measure the spark plug gap with a wire thickness gauge and, if nec-

essary, adjust the gap to specifi-

cation.

1. Spark plug cap

1

1. Spark plug wrench

1

Specified spark plu g:

PW50 NGK/BP4HS (ZAF)

PW50 NGK/BPR4HS

(AUT)(BEL)(CHE)(CYP)(CZE)(DEU)

(DNK)(ESP)(FIN)(FRA)(GBR)(GRC)

(IRL)(ITA)(NLD)(NOR)(POL)(PRT)

(SVK)(SVN)(SWE)(TUR)

PW50E NGK/BPR4HS

PW50E1 NGK/BPR4HS

PW50 DENSO/W14FP-L (ZAF)

1. Spark plug gap

1

U2SA80E0.book Page 6 Monday, June 3, 2013 5:25 PM

Page 48 of 76

PERIODIC MAINTENANCE AND ADJUSTMENT

7-7

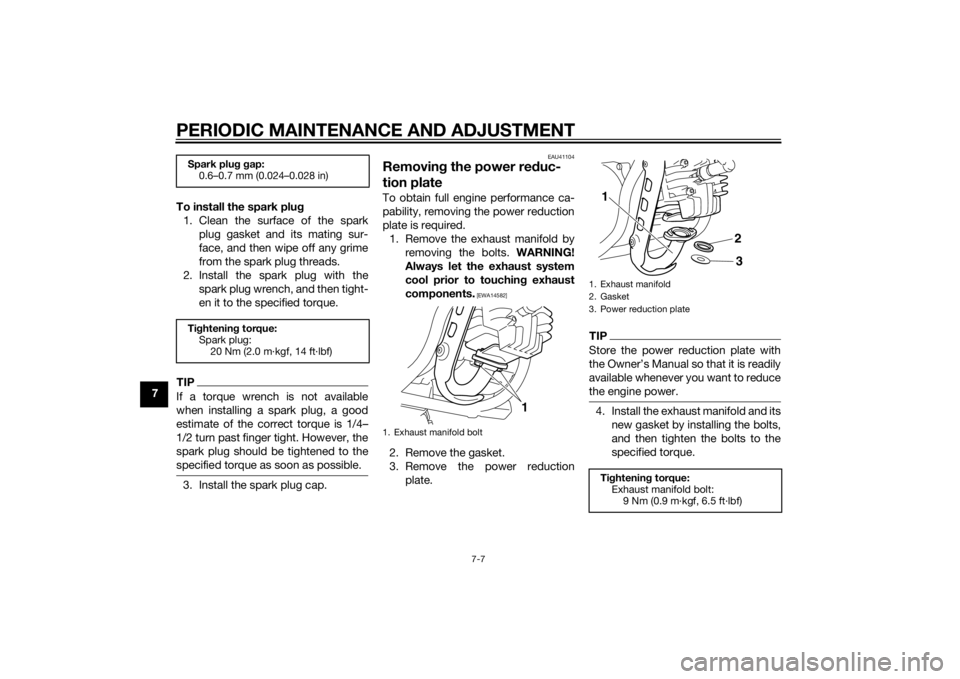

7To install the spark plu

g

1. Clean the surface of the spark plug gasket and its mating sur-

face, and then wipe off any grime

from the spark plug threads.

2. Install the spark plug with the spark plug wrench, and then tight-

en it to the specified torque.

TIPIf a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4–

1/2 turn past finger tight. However, the

spark plug should be tightened to the

specified torque as soon as possible.3. Install the spark plug cap.

EAU41104

Removin g the power re duc-

tion plateTo obtain full engine performance ca-

pability, removing the power reduction

plate is required.

1. Remove the exhaust manifold by removing the bolts. WARNING!

Always let the exhaust system

cool prior to touching exhaust

components.

[EWA14582]

2. Remove the gasket.

3. Remove the power reduction plate.

TIPStore the power reduction plate with

the Owner’s Manual so that it is readily

available whenever you want to reduce

the engine power.4. Install the exhaust manifold and itsnew gasket by installing the bolts,

and then tighten the bolts to the

specified torque.

Spark plu g g ap:

0.6–0.7 mm (0.024–0.028 in)

Ti ghtenin g torque:

Spark plug: 20 Nm (2.0 m·kgf, 14 ft·lbf)

1. Exhaust manifold bolt

1

1. Exhaust manifold

2. Gasket

3. Power reduction plateTightenin g torque:

Exhaust manifold bolt: 9 Nm (0.9 m·kgf, 6.5 ft·lbf)1

23

U2SA80E0.book Page 7 Monday, June 3, 2013 5:25 PM

Page 49 of 76

PERIODIC MAINTENANCE AND ADJUSTMENT

7-8

7

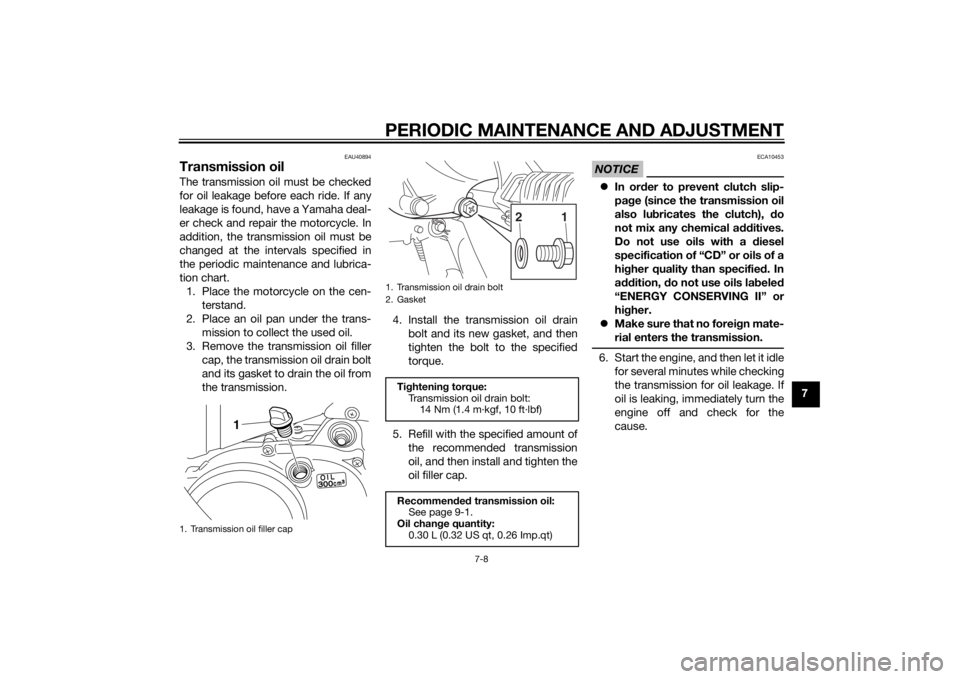

EAU40894

Transmission oilThe transmission oil must be checked

for oil leakage before each ride. If any

leakage is found, have a Yamaha deal-

er check and repair the motorcycle. In

addition, the transmission oil must be

changed at the intervals specified in

the periodic maintenance and lubrica-

tion chart.1. Place the motorcycle on the cen- terstand.

2. Place an oil pan under the trans- mission to collect the used oil.

3. Remove the transmission oil filler cap, the transmission oil drain bolt

and its gasket to drain the oil from

the transmission. 4. Install the transmission oil drain

bolt and its new gasket, and then

tighten the bolt to the specified

torque.

5. Refill with the specified amount of the recommended transmission

oil, and then install and tighten the

oil filler cap.

NOTICE

ECA10453

In or der to prevent clutch slip-

pa ge (since the transmission oil

also lu bricates the clutch), do

not mix any chemical additives.

Do not use oils with a diesel

specification of “CD” or oils of a

hi gher quality than specifie d. In

a dd ition, do not use oils la bele d

“ENERGY CONSERVING II” or

hi gher.

Make sure that no forei gn mate-

rial enters the transmission.6. Start the engine, and then let it idle for several minutes while checking

the transmission for oil leakage. If

oil is leaking, immediately turn the

engine off and check for the

cause.

1. Transmission oil filler cap

1

1. Transmission oil drain bolt

2. Gasket

Tightenin g torque:

Transmission oil drain bolt: 14 Nm (1.4 m·kgf, 10 ft·lbf)

Recommen ded transmission oil:

See page 9-1.

Oil chan ge quantity:

0.30 L (0.32 US qt, 0.26 Imp.qt)

1

2

U2SA80E0.book Page 8 Monday, June 3, 2013 5:25 PM

Page 50 of 76

PERIODIC MAINTENANCE AND ADJUSTMENT

7-9

7

EAU41712

Middle an d final g ear casesThe middle and final gear cases must

be checked for grease leakage before

each ride. If any leakage is found, have

a Yamaha dealer check and repair the

motorcycle. In addition, have a

Yamaha dealer check and lubricate the middle and final gears at the intervals

specified in the periodic maintenance

and lubrication chart.

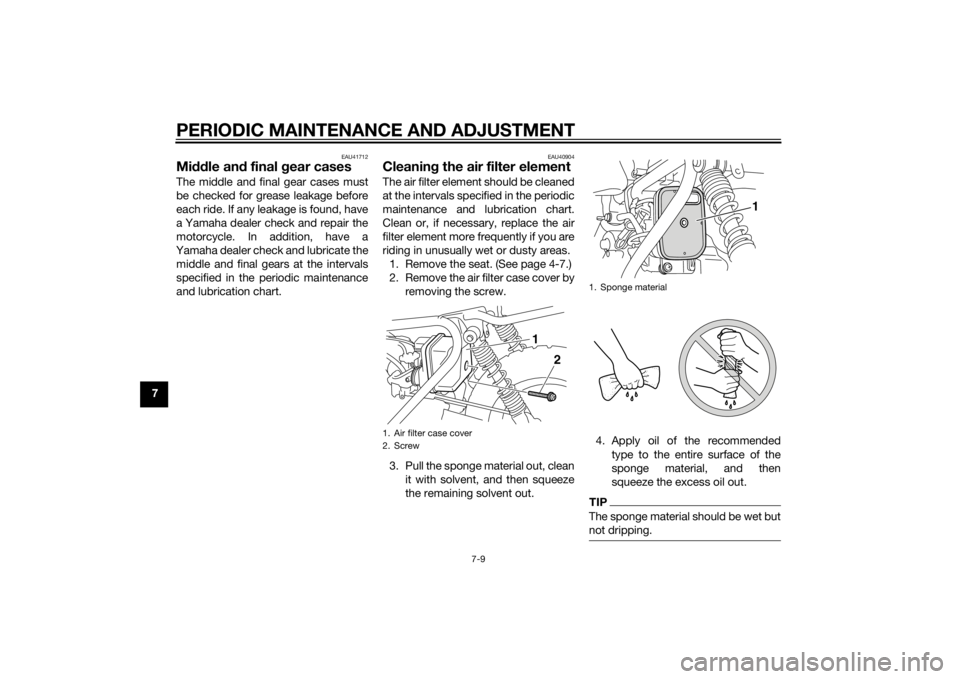

EAU40904

Cleanin g the air filter elementThe air filter element should be cleaned

at the intervals specified in the periodic

maintenance and lubrication chart.

Clean or, if necessary, replace the air

filter element more frequently if you are

riding in unusually wet or dusty areas.

1. Remove the seat. (See page 4-7.)

2. Remove the air filter case cover by removing the screw.

3. Pull the sponge material out, clean it with solvent, and then squeeze

the remaining solvent out. 4. Apply oil of the recommended

type to the entire surface of the

sponge material, and then

squeeze the excess oil out.

TIPThe sponge material should be wet but

not dripping.

1. Air filter case cover

2. Screw

2

1

1. Sponge material

1

U2SA80E0.book Page 9 Monday, June 3, 2013 5:25 PM

Page 51 of 76

PERIODIC MAINTENANCE AND ADJUSTMENT

7-10

7

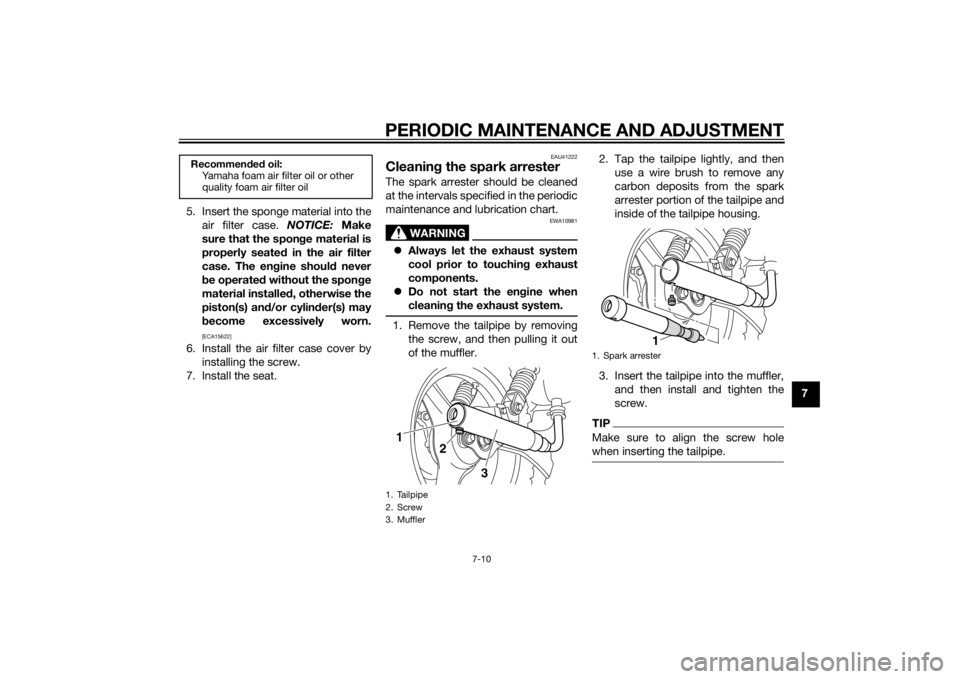

5. Insert the sponge material into the

air filter case. NOTICE: Make

sure that the spon ge material is

properly seate d in the air filter

case. The en gine should never

b e operated without the spon ge

material installe d, otherwise the

piston(s) an d/or cylin der(s) may

b ecome excessively worn.

[ECA15622]

6. Install the air filter case cover by

installing the screw.

7. Install the seat.

EAU41222

Cleanin g the spark arresterThe spark arrester should be cleaned

at the intervals specified in the periodic

maintenance and lubrication chart.

WARNING

EWA10981

Always let the exhaust system

cool prior to touching exhaust

components.

Do not start the en gine when

cleanin g the exhaust system.1. Remove the tailpipe by removing

the screw, and then pulling it out

of the muffler. 2. Tap the tailpipe lightly, and then

use a wire brush to remove any

carbon deposits from the spark

arrester portion of the tailpipe and

inside of the tailpipe housing.

3. Insert the tailpipe into the muffler, and then install and tighten the

screw.

TIPMake sure to align the screw hole

when inserting the tailpipe.

Recommen ded oil:

Yamaha foam air filter oil or other

quality foam air filter oil

1. Tailpipe

2. Screw

3. Muffler1

2

3

1. Spark arrester

1

U2SA80E0.book Page 10 Monday, June 3, 2013 5:25 PM

Page 52 of 76

PERIODIC MAINTENANCE AND ADJUSTMENT

7-11

7

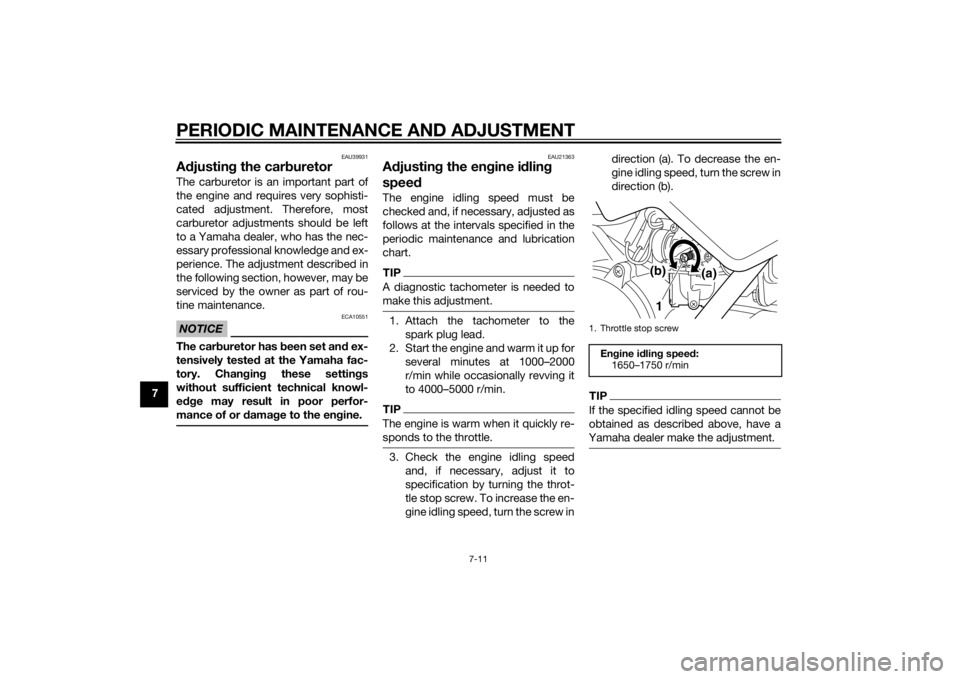

EAU39931

Adjustin g the car buretorThe carburetor is an important part of

the engine and requires very sophisti-

cated adjustment. Therefore, most

carburetor adjustments should be left

to a Yamaha dealer, who has the nec-

essary professional knowledge and ex-

perience. The adjustment described in

the following section, however, may be

serviced by the owner as part of rou-

tine maintenance.NOTICE

ECA10551

The car buretor has been set an d ex-

tensively teste d at the Yamaha fac-

tory. Chang ing these settin gs

without sufficient technical knowl-

e dge may result in poor perfor-

mance of or d amage to the en gine.

EAU21363

A djustin g the eng ine idlin g

spee dThe engine idling speed must be

checked and, if necessary, adjusted as

follows at the intervals specified in the

periodic maintenance and lubrication

chart.TIPA diagnostic tachometer is needed to

make this adjustment.1. Attach the tachometer to the

spark plug lead.

2. Start the engine and warm it up for several minutes at 1000–2000

r/min while occasionally revving it

to 4000–5000 r/min.TIPThe engine is warm when it quickly re-

sponds to the throttle.3. Check the engine idling speedand, if necessary, adjust it to

specification by turning the throt-

tle stop screw. To increase the en-

gine idling speed, turn the screw in direction (a). To decrease the en-

gine idling speed, turn the screw in

direction (b).

TIPIf the specified idling speed cannot be

obtained as described above, have a

Yamaha dealer make the adjustment.1. Throttle stop screwEn gine i dlin g spee d:

1650–1750 r/min

1 (a)

(b)

U2SA80E0.book Page 11 Monday, June 3, 2013 5:25 PM

Page 53 of 76

PERIODIC MAINTENANCE AND ADJUSTMENT

7-12

7

EAU21385

Checking the throttle grip free

playThe throttle grip free play should mea-

sure 1.5–3.5 mm (0.06–0.14 in) at the

inner edge of the throttle grip. Periodi-

cally check the throttle grip free play

and, if necessary, have a Yamaha deal-

er adjust it.

EAU40915

TiresTires are the only contact between the

vehicle and the road. Safety in all con-

ditions of riding depends on a relatively

small area of road contact. Therefore, it

is essential to maintain the tires in good

condition at all times and replace them

at the appropriate time with the speci-

fied tires.

Tire air pressure

The tire air pressure should be

checked and, if necessary, adjusted

before each ride.

WARNING

EWA15371

Operation of this vehicle with im-

proper tire pressure may cause se-

vere injury or d eath from loss of

control.

The tire air pressure must be

checked and a djuste d on col d tires

(i.e., when the temperature of the

tires equals the am bient tempera-

ture).

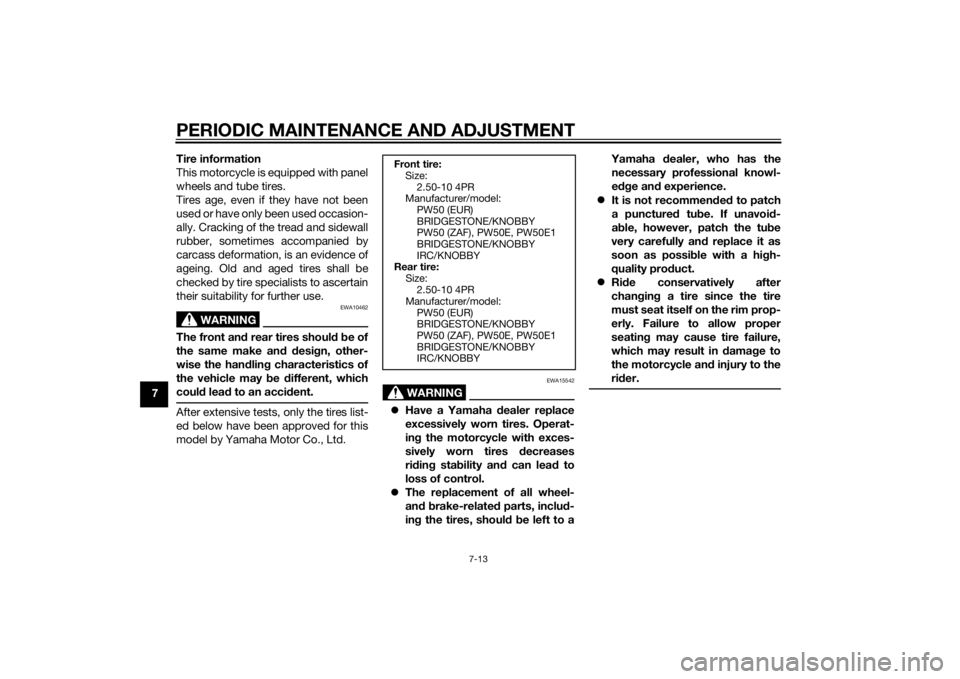

Tire inspection

The tires must be checked before each

ride. If the center tread depth reaches

the specified limit, if the tire has a nail

or glass fragments in it, or if the side-

wall is cracked, have a Yamaha dealer

replace the tire immediately.

1. Throttle grip free play

1

Stan dar d tire air pressure:

Front:

100 kPa (1.00 kgf/cm², 15 psi)

Rear:

100 kPa (1.00 kgf/cm², 15 psi)

1. Tire sidewall

2. Tire tread depth

Minimum tire trea d d epth (front an d

rear): 4.0 mm (0.16 in)

12

U2SA80E0.book Page 12 Monday, June 3, 2013 5:25 PM

Page 54 of 76

PERIODIC MAINTENANCE AND ADJUSTMENT

7-13

7Tire information

This motorcycle is equipped with panel

wheels and tube tires.

Tires age, even if they have not been

used or have only been used occasion-

ally. Cracking of the tread and sidewall

rubber, sometimes accompanied by

carcass deformation, is an evidence of

ageing. Old and aged tires shall be

checked by tire specialists to ascertain

their suitability for further use.

WARNING

EWA10462

The front an

d rear tires shoul d b e of

the same make an d d esi gn, other-

wise the han dlin g characteristics of

the vehicle may be different, which

coul d lea d to an acci dent.After extensive tests, only the tires list-

ed below have been approved for this

model by Yamaha Motor Co., Ltd.

WARNING

EWA15542

Have a Yamaha dealer replace

excessively worn tires. Operat-

in g the motorcycle with exces-

sively worn tires decreases

ri din g sta bility an d can lead to

loss of control.

The replacement of all wheel-

and b rake-relate d parts, inclu d-

in g the tires, shoul d b e left to a Yamaha

dealer, who has the

necessary professional knowl-

e dge an d experience.

It is not recommen ded to patch

a punctured tube. If unavoi d-

a b le, however, patch the tu be

very carefully an d replace it as

soon as possi ble with a hi gh-

quality pro duct.

Ride conservatively after

chan gin g a tire since the tire

must seat itself on the rim prop-

erly. Failure to allow proper

seatin g may cause tire failure,

which may result in damag e to

the motorcycle an d injury to the

ri der.Front tire:

Size:

2.50-10 4PR

Manufacturer/model:

PW50 (EUR)

BRIDGESTONE/KNOBBY

PW50 (ZAF), PW50E, PW50E1

BRIDGESTONE/KNOBBY

IRC/KNOBBY

Rear tire:

Size:2.50-10 4PR

Manufacturer/model:

PW50 (EUR)

BRIDGESTONE/KNOBBY

PW50 (ZAF), PW50E, PW50E1

BRIDGESTONE/KNOBBY

IRC/KNOBBY

U2SA80E0.book Page 13 Monday, June 3, 2013 5:25 PM