YAMAHA PW50 2016 Repair Manual

Manufacturer: YAMAHA, Model Year: 2016, Model line: PW50, Model: YAMAHA PW50 2016Pages: 80, PDF Size: 1.84 MB

Page 61 of 80

Periodic maintenance an d a djustment

7-20

7

EAU43634

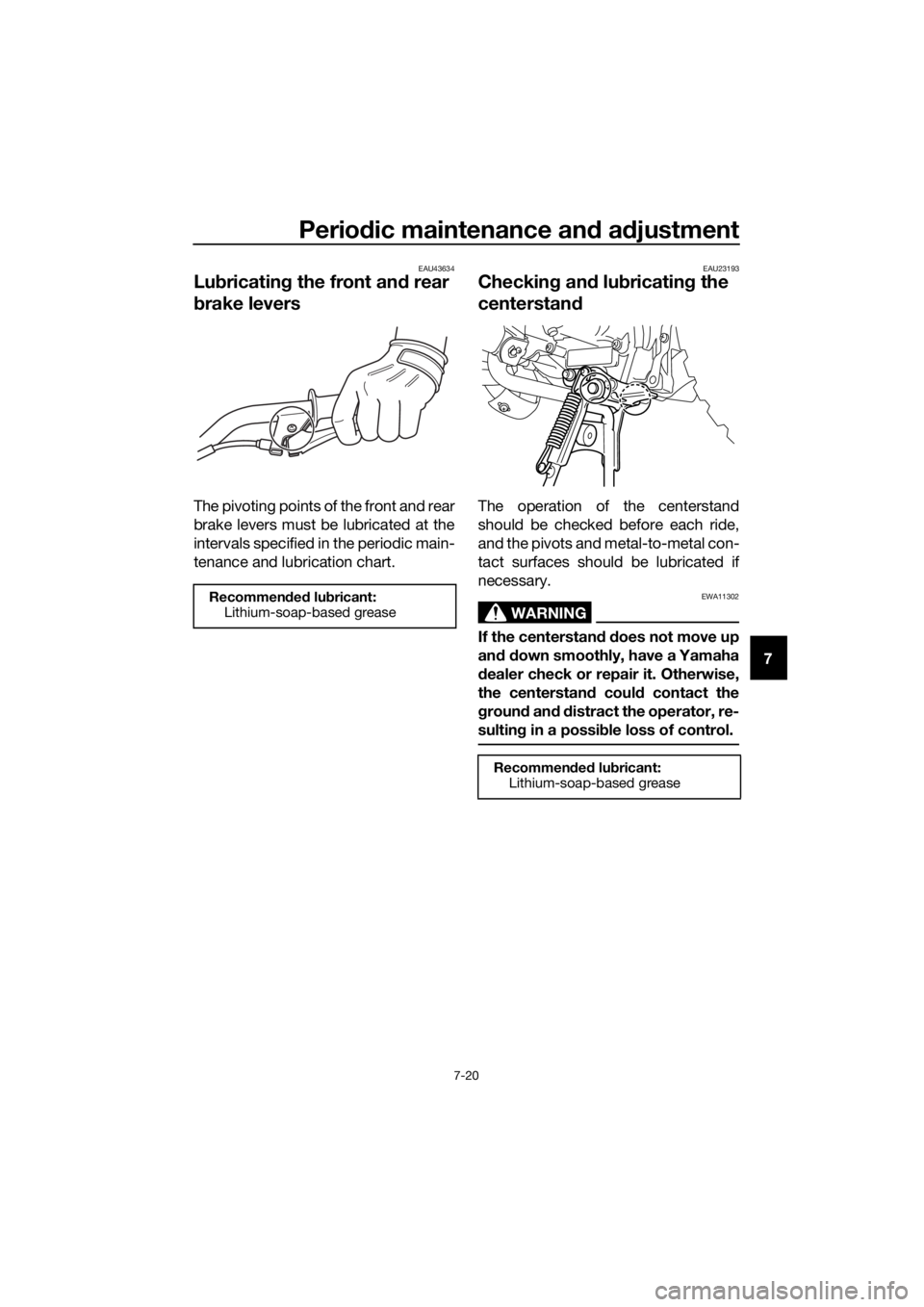

Lub ricatin g the front an d rear

b rake levers

The pivoting points of the front and rear

brake levers must be lubricated at the

intervals specified in the periodic main-

tenance and lubrication chart.

EAU23193

Checkin g an d lu bricatin g the

centerstan d

The operation of the centerstand

should be checked before each ride,

and the pivots and metal-to-metal con-

tact surfaces should be lubricated if

necessary.

WARNING

EWA11302

If the centerstan d d oes not move up

an d d own smoothly, have a Yamaha

d ealer check or repair it. Otherwise,

the centerstan d coul d contact the

g roun d an d d istract the operator, re-

sultin g in a possib le loss of control.

Recommen ded lu bricant:

Lithium-soap-based grease

Recommen ded lu bricant:

Lithium-soap-based grease

U2SA82E0.book Page 20 Monday, June 8, 2015 1:09 PM

Page 62 of 80

Periodic maintenance an d a djustment

7-21

7

EAU42082

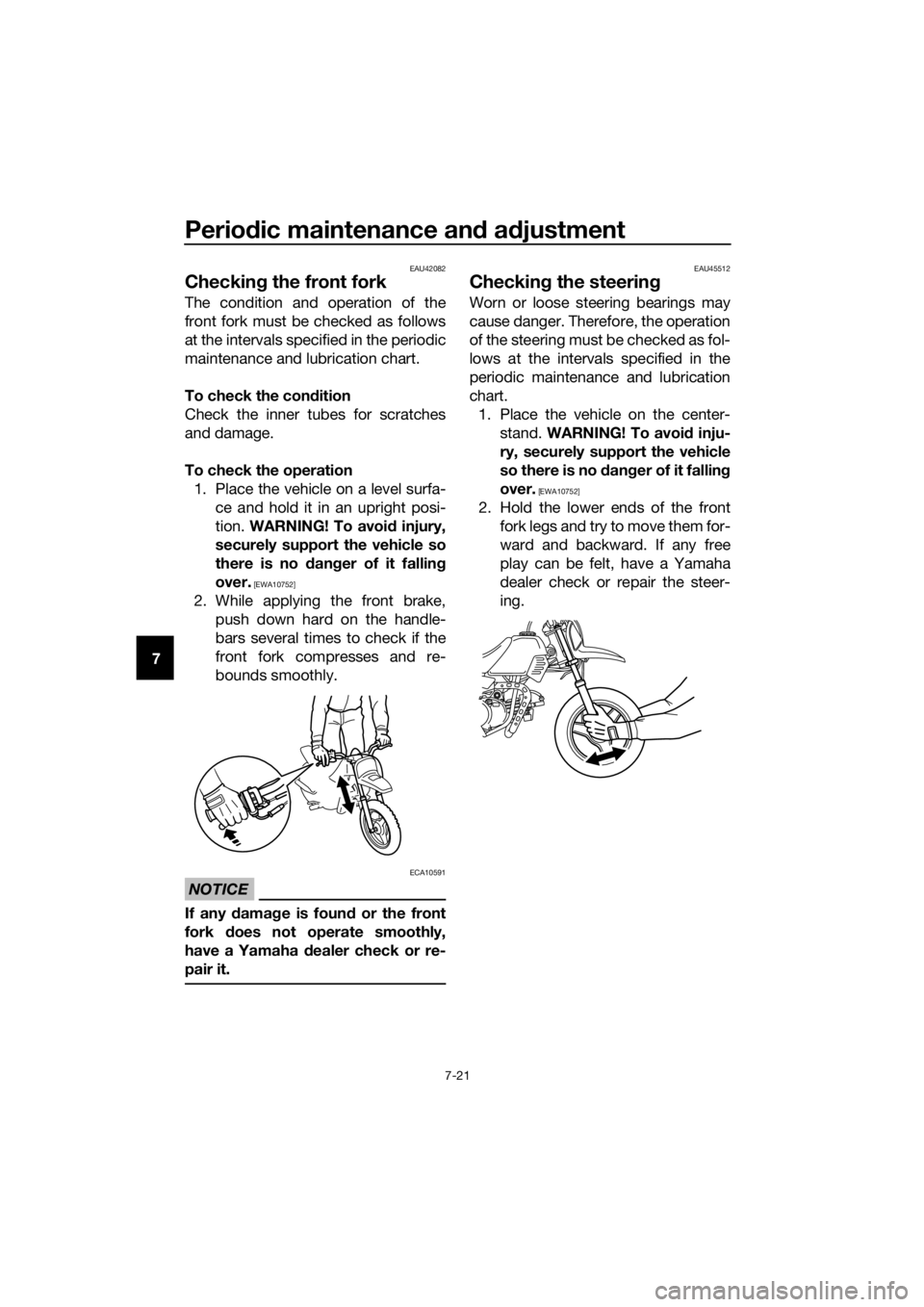

Checkin g the front fork

The condition and operation of the

front fork must be checked as follows

at the intervals specified in the periodic

maintenance and lubrication chart.

To check the con dition

Check the inner tubes for scratches

and damage.

To check the operation 1. Place the vehicle on a level surfa- ce and hold it in an upright posi-

tion. WARNING! To avoi d injury,

securely support the vehicle so

there is no dan ger of it fallin g

over.

[EWA10752]

2. While applying the front brake, push down hard on the handle-

bars several times to check if the

front fork compresses and re-

bounds smoothly.

NOTICE

ECA10591

If any d amage is foun d or the front

fork does not operate smoothly,

have a Yamaha dealer check or re-

pair it.

EAU45512

Checkin g the steerin g

Worn or loose steering bearings may

cause danger. Therefore, the operation

of the steering must be checked as fol-

lows at the intervals specified in the

periodic maintenance and lubrication

chart.

1. Place the vehicle on the center- stand. WARNING! To avoi d inju-

ry, securely support the vehicle

so there is no dan ger of it fallin g

over.

[EWA10752]

2. Hold the lower ends of the front fork legs and try to move them for-

ward and backward. If any free

play can be felt, have a Yamaha

dealer check or repair the steer-

ing.

U2SA82E0.book Page 21 Monday, June 8, 2015 1:09 PM

Page 63 of 80

Periodic maintenance an d a djustment

7-22

7

EAU23292

Checkin g the wheel b earings

The front and rear wheel bearings must

be checked at the intervals specified in

the periodic maintenance and lubrica-

tion chart. If there is play in the wheel

hub or if the wheel does not turn

smoothly, have a Yamaha dealer

check the wheel bearings.

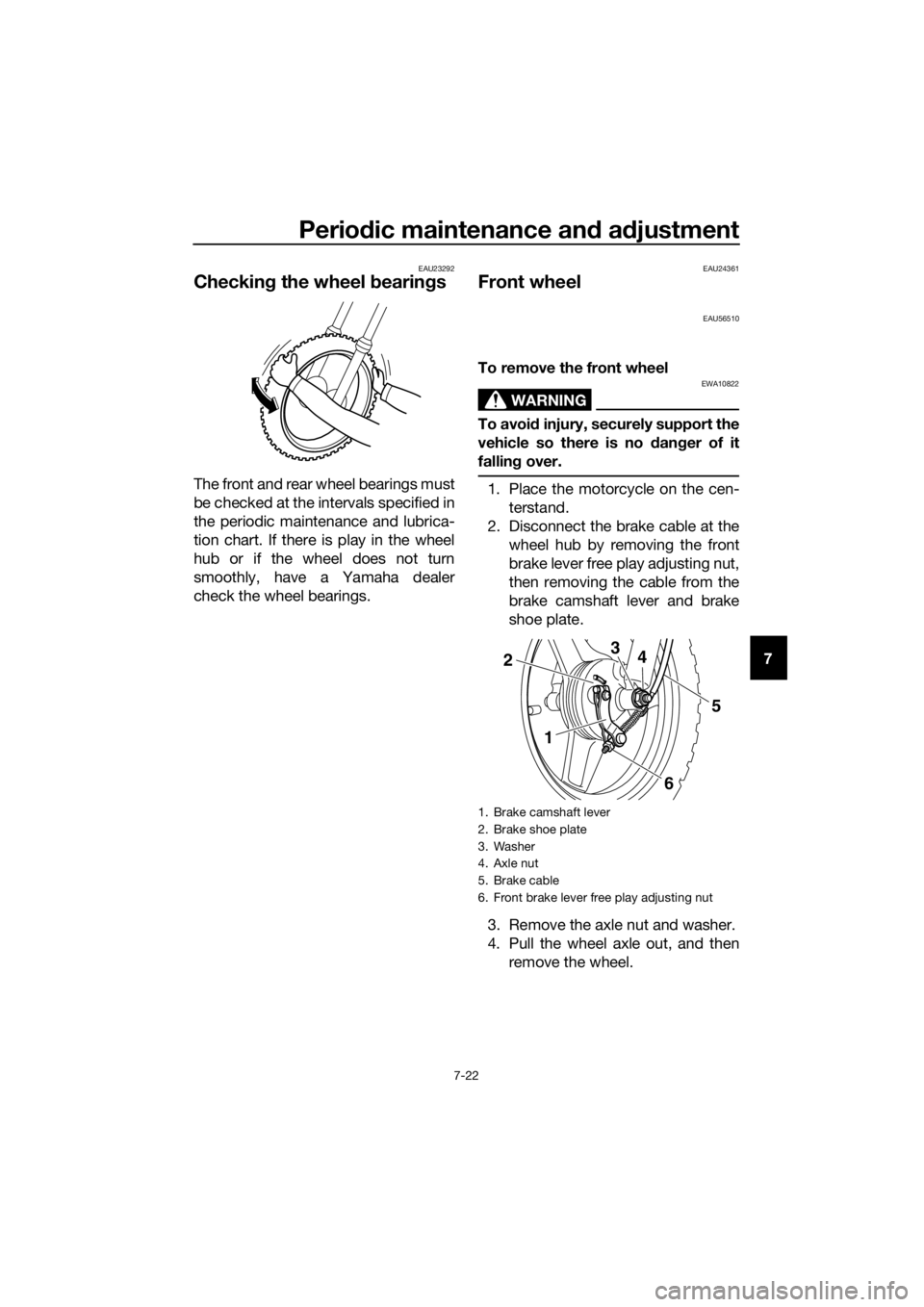

EAU24361

Front wheel

EAU56510

To remove the front wheel

WARNING

EWA10822

To avoi d injury, securely support the

vehicle so there is no dan ger of it

fallin g over.

1. Place the motorcycle on the cen-

terstand.

2. Disconnect the brake cable at the wheel hub by removing the front

brake lever free play adjusting nut,

then removing the cable from the

brake camshaft lever and brake

shoe plate.

3. Remove the axle nut and washer.

4. Pull the wheel axle out, and then remove the wheel.

1. Brake camshaft lever

2. Brake shoe plate

3. Washer

4. Axle nut

5. Brake cable

6. Front brake lever free play adjusting nut

5

6

1 3

4

2

U2SA82E0.book Page 22 Monday, June 8, 2015 1:09 PM

Page 64 of 80

Periodic maintenance an d a djustment

7-23

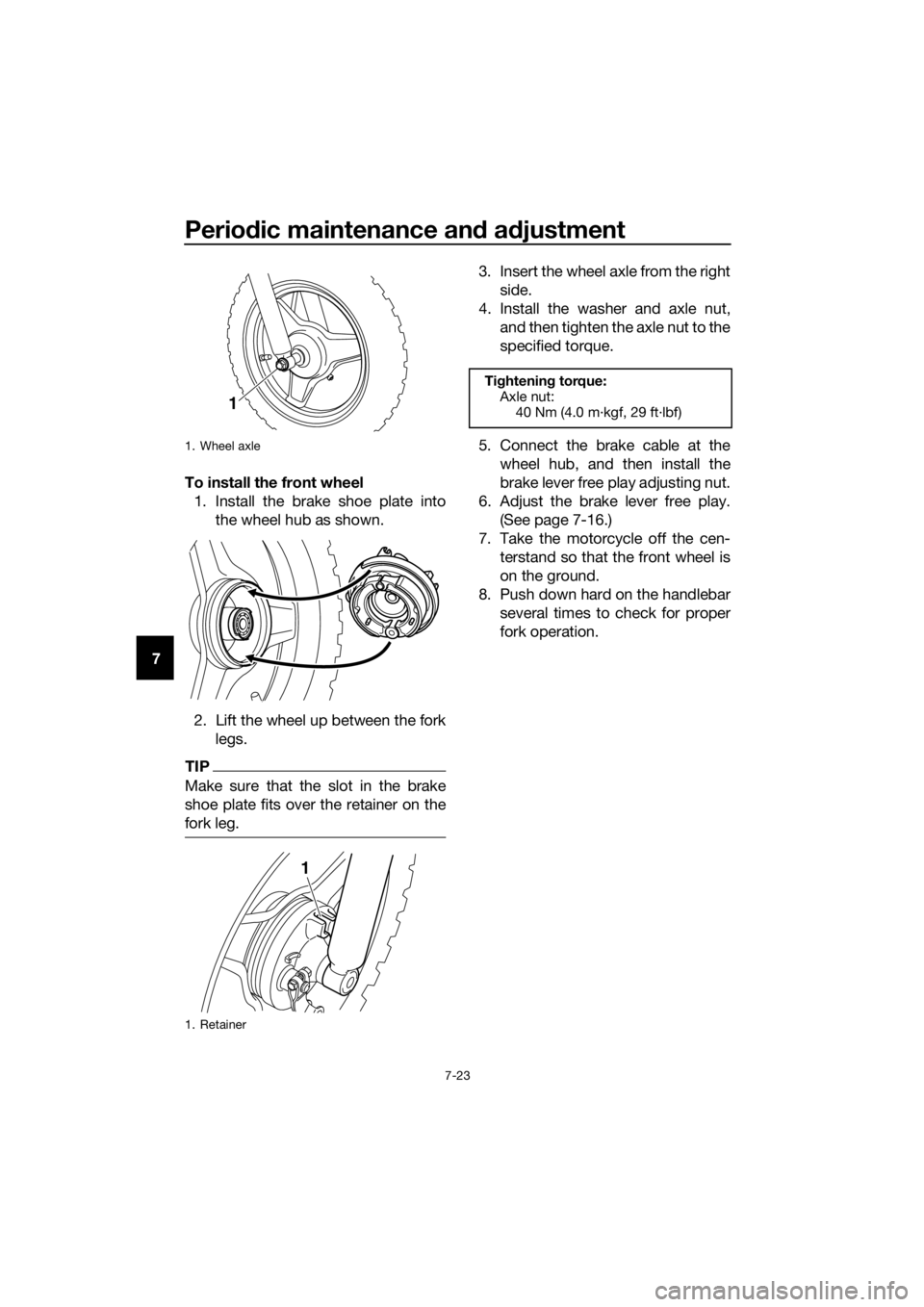

7 To install the front wheel

1. Install the brake shoe plate into the wheel hub as shown.

2. Lift the wheel up between the fork legs.

TIP

Make sure that the slot in the brake

shoe plate fits over the retainer on the

fork leg.

3. Insert the wheel axle from the rightside.

4. Install the washer and axle nut, and then tighten the axle nut to the

specified torque.

5. Connect the brake cable at the wheel hub, and then install the

brake lever free play adjusting nut.

6. Adjust the brake lever free play. (See page 7-16.)

7. Take the motorcycle off the cen- terstand so that the front wheel is

on the ground.

8. Push down hard on the handlebar several times to check for proper

fork operation.

1. Wheel axle

1. Retainer

1

1

Tightening torque:

Axle nut: 40 Nm (4.0 m·kgf, 29 ft·lbf)

U2SA82E0.book Page 23 Monday, June 8, 2015 1:09 PM

Page 65 of 80

Periodic maintenance an d a djustment

7-24

7

EAU25081

Rear wheel

EAU56822

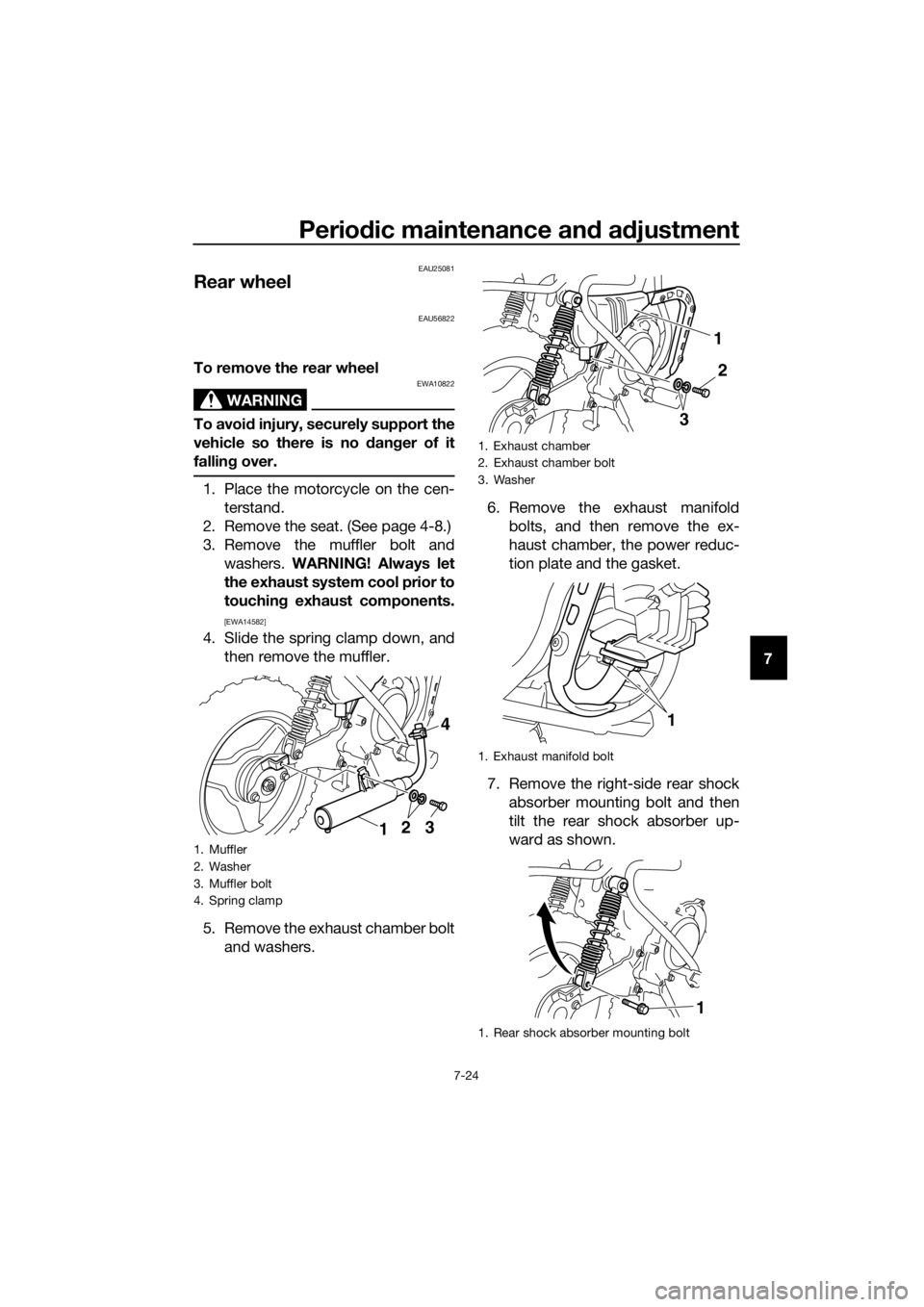

To remove the rear wheel

WARNING

EWA10822

To avoi d injury, securely support the

vehicle so there is no d anger of it

fallin g over.

1. Place the motorcycle on the cen-

terstand.

2. Remove the seat. (See page 4-8.)

3. Remove the muffler bolt and washers. WARNING! Always let

the exhaust system cool prior to

touchin g exhaust components.

[EWA14582]

4. Slide the spring clamp down, and

then remove the muffler.

5. Remove the exhaust chamber bolt and washers. 6. Remove the exhaust manifold

bolts, and then remove the ex-

haust chamber, the power reduc-

tion plate and the gasket.

7. Remove the right-side rear shock absorber mounting bolt and then

tilt the rear shock absorber up-

ward as shown.

1. Muffler

2. Washer

3. Muffler bolt

4. Spring clamp

312 4

1. Exhaust chamber

2. Exhaust chamber bolt

3. Washer

1. Exhaust manifold bolt

1. Rear shock absorber mounting bolt

2

1

3

1

1

U2SA82E0.book Page 24 Monday, June 8, 2015 1:09 PM

Page 66 of 80

Periodic maintenance an d a djustment

7-25

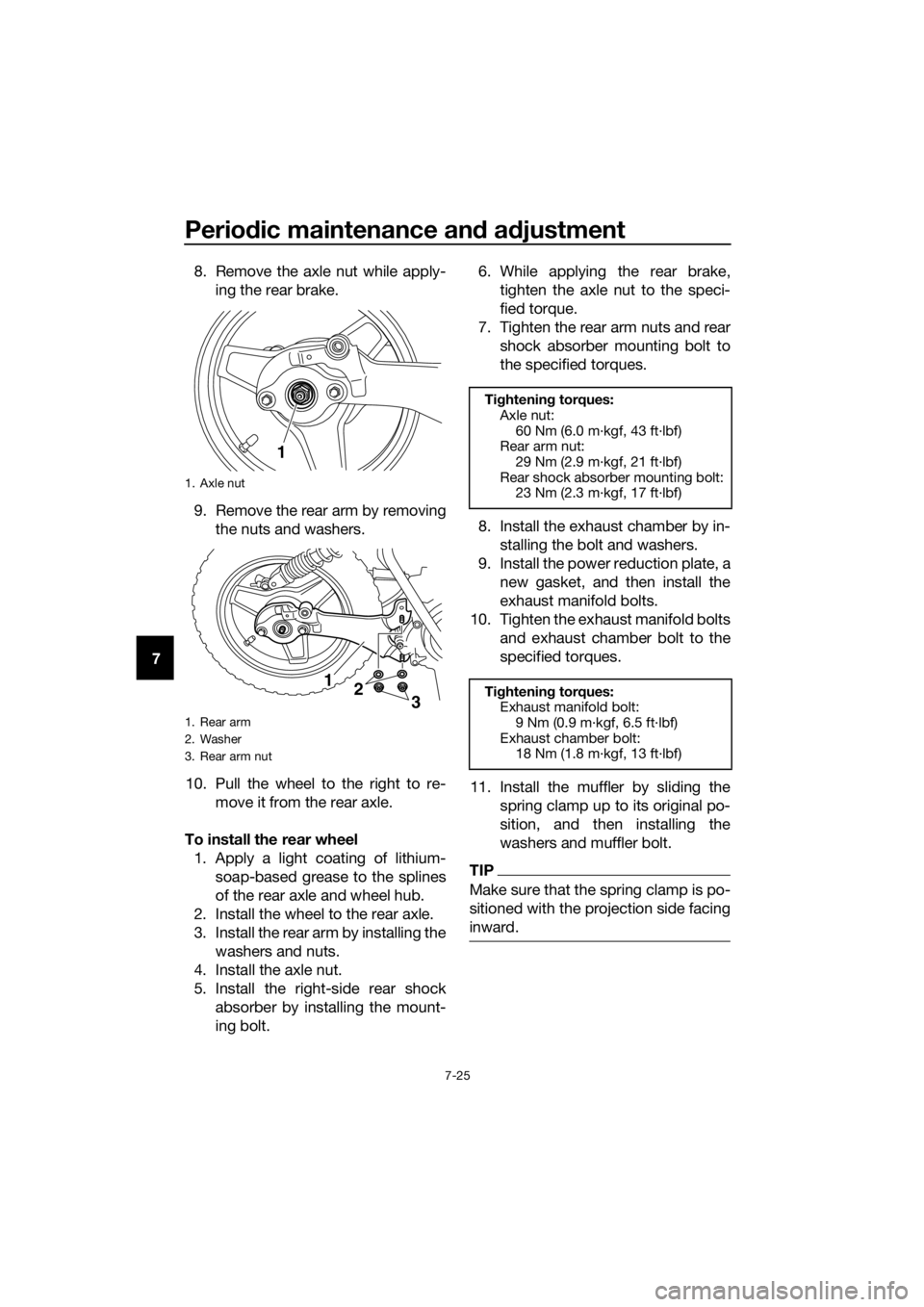

7 8. Remove the axle nut while apply-

ing the rear brake.

9. Remove the rear arm by removing the nuts and washers.

10. Pull the wheel to the right to re- move it from the rear axle.

To install the rear wheel 1. Apply a light coating of lithium- soap-based grease to the splines

of the rear axle and wheel hub.

2. Install the wheel to the rear axle.

3. Install the rear arm by installing the washers and nuts.

4. Install the axle nut.

5. Install the right-side rear shock absorber by installing the mount-

ing bolt. 6. While applying the rear brake,

tighten the axle nut to the speci-

fied torque.

7. Tighten the rear arm nuts and rear shock absorber mounting bolt to

the specified torques.

8. Install the exhaust chamber by in- stalling the bolt and washers.

9. Install the power reduction plate, a new gasket, and then install the

exhaust manifold bolts.

10. Tighten the exhaust manifold bolts and exhaust chamber bolt to the

specified torques.

11. Install the muffler by sliding the spring clamp up to its original po-

sition, and then installing the

washers and muffler bolt.

TIP

Make sure that the spring clamp is po-

sitioned with the projection side facing

inward.

1. Axle nut

1. Rear arm

2. Washer

3. Rear arm nut

1

12

3

Tightening torques:

Axle nut: 60 Nm (6.0 m·kgf, 43 ft·lbf)

Rear arm nut:

29 Nm (2.9 m·kgf, 21 ft·lbf)

Rear shock absorber mounting bolt: 23 Nm (2.3 m·kgf, 17 ft·lbf)

Ti ghtening torques:

Exhaust manifold bolt:

9 Nm (0.9 m·kgf, 6.5 ft·lbf)

Exhaust chamber bolt: 18 Nm (1.8 m·kgf, 13 ft·lbf)

U2SA82E0.book Page 25 Monday, June 8, 2015 1:09 PM

Page 67 of 80

Periodic maintenance an d a djustment

7-26

7

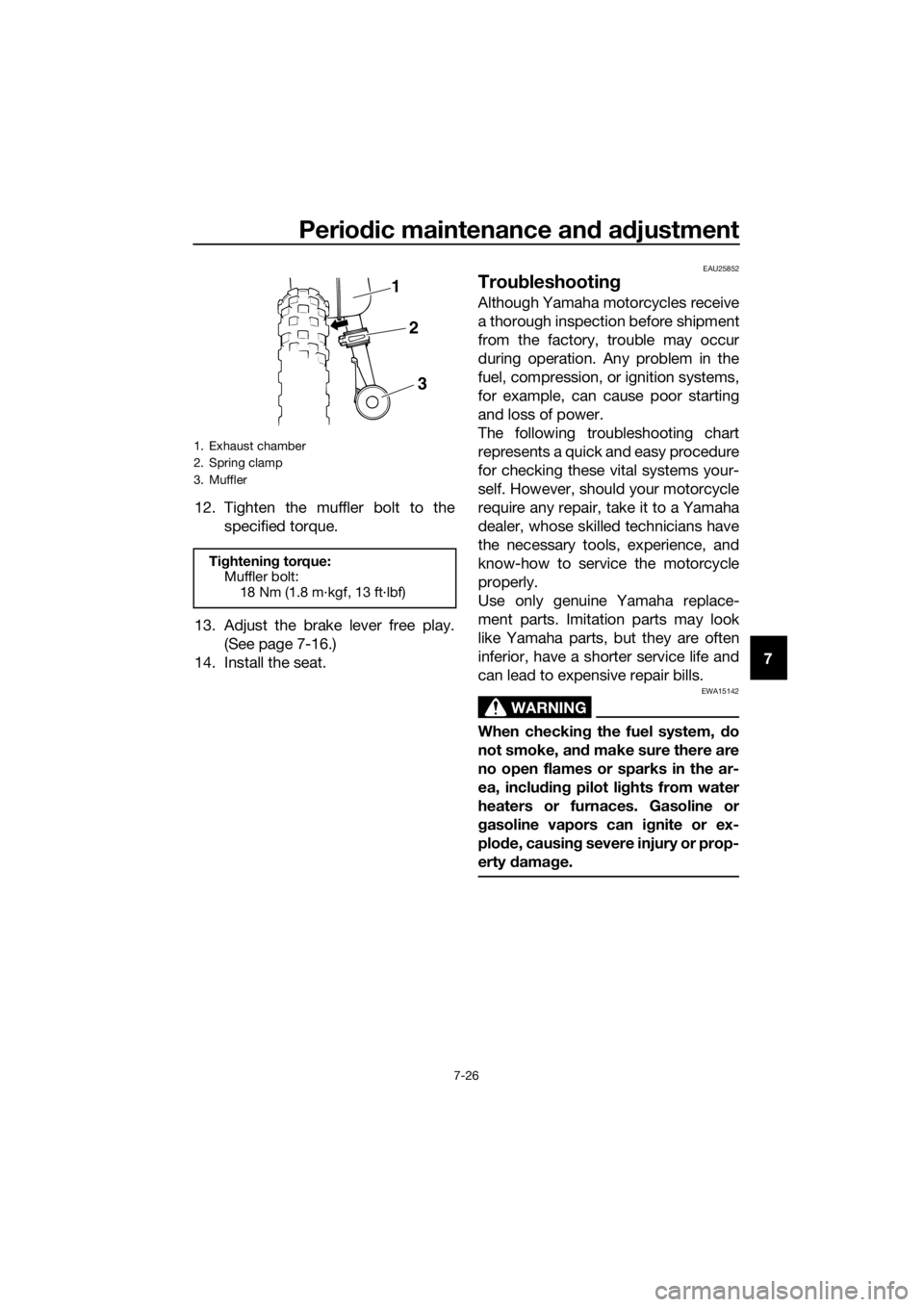

12. Tighten the muffler bolt to the

specified torque.

13. Adjust the brake lever free play. (See page 7-16.)

14. Install the seat.

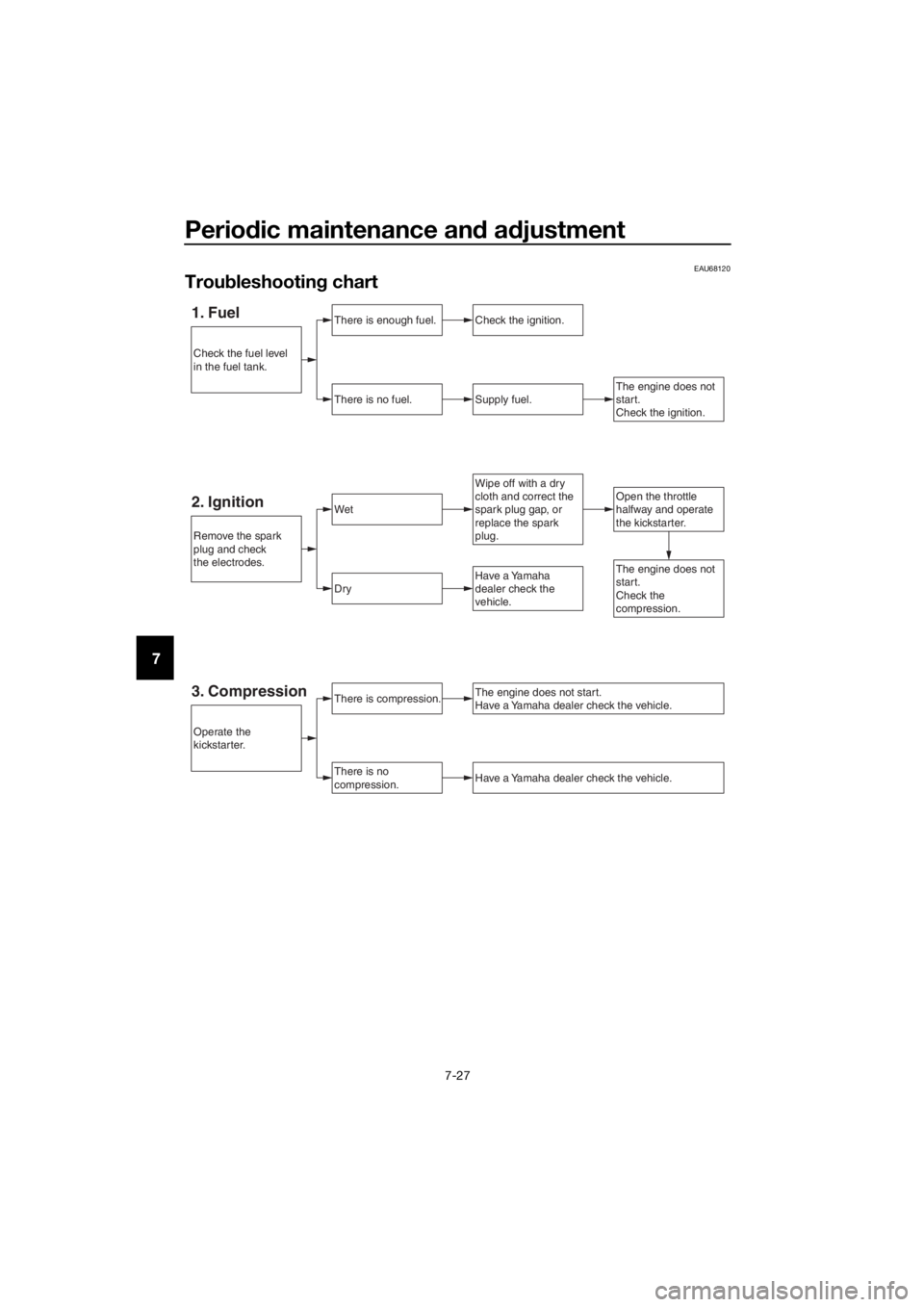

EAU25852

Trou bleshootin g

Although Yamaha motorcycles receive

a thorough inspection before shipment

from the factory, trouble may occur

during operation. Any problem in the

fuel, compression, or ignition systems,

for example, can cause poor starting

and loss of power.

The following troubleshooting chart

represents a quick and easy procedure

for checking these vital systems your-

self. However, should your motorcycle

require any repair, take it to a Yamaha

dealer, whose skilled technicians have

the necessary tools, experience, and

know-how to service the motorcycle

properly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look

like Yamaha parts, but they are often

inferior, have a shorter service life and

can lead to expensive repair bills.

WARNING

EWA15142

When checkin g the fuel system, do

not smoke, an d make sure there are

no open flames or sparks in the ar-

ea, inclu din g pilot li ghts from water

heaters or furnaces. Gasoline or

g asoline vapors can i gnite or ex-

plo de, causin g severe injury or prop-

erty damag e.

1. Exhaust chamber

2. Spring clamp

3. Muffler

Tightening torque:

Muffler bolt:

18 Nm (1.8 m·kgf, 13 ft·lbf)

1

2

3

U2SA82E0.book Page 26 Monday, June 8, 2015 1:09 PM

Page 68 of 80

Periodic maintenance an d a djustment

7-27

7

EAU68120

Trou bleshootin g chart

1. FuelThere is enough fuel.

There is no fuel.

Check the ignition.

Supply fuel.The engine does not

start.

Check the ignition.

Open the throttle

halfway and operate

the kickstarter.Wipe off with a dry

cloth and correct the

spark plug gap, or

replace the spark

plug.

2. IgnitionWet

Dry

There is compression.

There is no

compression.

The engine does not start.

Have a Yamaha dealer check the vehicle.

Have a Yamaha dealer check the vehicle.

The engine does not

start.

Check the

compression.Have a Yamaha

dealer check the

vehicle.

Remove the spark

plug and check

the electrodes.

Operate the

kickstarter.

Check the fuel level

in the fuel tank.

3. Compression

U2SA82E0.book Page 27 Monday, June 8, 2015 1:09 PM

Page 69 of 80

Motorcycle care and stora ge

8-1

8

EAU37834

Matte color caution

NOTICE

ECA15193

Some mo dels are equipped with

matte colored finished parts. Be

sure to consult a Yamaha dealer for

a d vice on what pro ducts to use be-

fore cleanin g the vehicle. Usin g a

b rush, harsh chemical prod ucts or

cleanin g compoun ds when cleanin g

these parts will scratch or damag e

their surface. Wax also shoul d not

b e applie d to any matte colored fin-

ishe d parts.

EAU40636

Care

While the open design of a motorcycle

reveals the attractiveness of the tech-

nology, it also makes it more vulnera-

ble. Rust and corrosion can develop

even if high-quality components are

used. A rusty exhaust pipe may go un-

noticed on a car, however, it detracts

from the overall appearance of a mo-

torcycle. Frequent and proper care

does not only comply with the terms of

the warranty, but it will also keep your

motorcycle looking good, extend its

life and optimize its performance.

Before cleanin g

1. Cover the muffler outlet with a plastic bag after the engine has

cooled down.

2. Make sure that all caps and cov- ers as well as all electrical cou-

plers and connectors, including

the spark plug cap, are tightly in-

stalled.

3. Remove extremely stubborn dirt, like oil burnt onto the crankcase,

with a degreasing agent and a

brush, but never apply such prod-

ucts onto seals, gaskets and

wheel axles. Always rinse the dirt

and degreaser off with water.

Cleanin g

NOTICE

ECA17111

Avoi d using strong aci dic wheel

cleaners, especially on spoked

wheels. If such pro ducts are

use d on har d-to-remove dirt, do

not leave the cleaner on the af-

fected area any lon ger than in-

U2SA82E0.book Page 1 Monday, June 8, 2015 1:09 PM

Page 70 of 80

Motorcycle care and stora ge

8-2

8 structe

d. Also, thorou ghly rinse

the area off with water, imme di-

ately dry it, an d then apply a cor-

rosion protection spray.

Improper cleanin g can d amage

plastic parts (such as cowlin gs,

panels, etc.) an d the mufflers.

Use only a soft, clean cloth or

spon ge with water to clean

plastic. However, if the plastic

parts cannot be thorou ghly

cleaned with water, dilute d mil d

d eter gent with water may b e

use d. Be sure to rinse off any

d eter gent resi due using plenty

of water, as it is harmful to plas-

tic parts.

Do not use any harsh chemical

prod ucts on plastic parts. Be

sure to avoi d using cloths or

spon ges which have been in

contact with stron g or a brasive

cleanin g prod ucts, solvent or

thinner, fuel (g asoline), rust re-

movers or inhi bitors, brake flui d,

antifreeze or electrolyte.

Do not use hi

gh-pr

essure wash-

ers or steam-jet cleaners since

they cause water seepa ge an d

d eterioration in the followin g ar-

eas: seals (of wheel an d swin g-

arm bearin gs, fork an d b rakes),

electric components (couplers,

connectors, an d switches),

b reather hoses an d vents.

After normal use

Remove dirt with warm water, a mild

detergent, and a soft, clean sponge,

and then rinse thoroughly with clean

water. Use a toothbrush or bottlebrush

for hard-to-reach areas. Stubborn dirt and insects will come off more easily if

the area is covered with a wet cloth for

a few minutes before cleaning.

After riding in the rain or near the sea

Since sea salt is extremely corrosive,

carry out the following steps after each

ride in the rain or near the sea.

1. Clean the motorcycle with cold water and a mild detergent, after

the engine has cooled down.

NOTICE: Do not use warm wa-

ter since it increases the corro-

sive action of the salt.

[ECA10792]

2. Apply a corrosion protection spray on all metal, including chrome-

and nickel-plated, surfaces to pre-

vent corrosion.

After cleaning 1. Dry the motorcycle with a chamois or an absorbing cloth.

2. Use a chrome polish to shine chrome, aluminum and stainless-

steel parts.

3. To prevent corrosion, it is recom- mended to apply a corrosion pro-

tection spray on all metal,

including chrome- and nickel-plat-

ed, surfaces.

4. Use spray oil as a universal clean- er to remove any remaining dirt.

5. Touch up minor paint damage caused by stones, etc.

6. Wax all painted surfaces.

7. Let the motorcycle dry completely before storing or covering it.

WARNING

EWA14502

Contaminants on the brakes or tires

can cause loss of control.

U2SA82E0.book Page 2 Monday, June 8, 2015 1:09 PM