Tip YAMAHA RHINO 700 2013 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2013, Model line: RHINO 700, Model: YAMAHA RHINO 700 2013Pages: 188, PDF Size: 4.9 MB

Page 59 of 188

4-29

TIPMake sure that the position indicator mark is

aligned with the match mark when the shock

absorber assembly is set to the standard set-

ting.

TIPAlthough the total number of clicks of a damp-

ing force adjusting mechanism may not exact-

ly match the above specifications due to small

differences in production, the actual number

of clicks always represents the entire adjust-

ing range. To obtain a precise adjustment, it

would be advisable to check the number of

clicks of each damping force adjusting mech-

anism and to modify the specifications as nec-

essary.

Compression damping setting:Minimum (soft): 12 click(s) in direction b*

Standard: 10 click(s) in direction b*

Maximum (hard):

9 click(s) in direction b*

* With the adjusting screw fully turned in direction a

1RB7A_EE.book Page 29 Tuesday, April 24, 2012 9:07 AM

Page 62 of 188

4-32

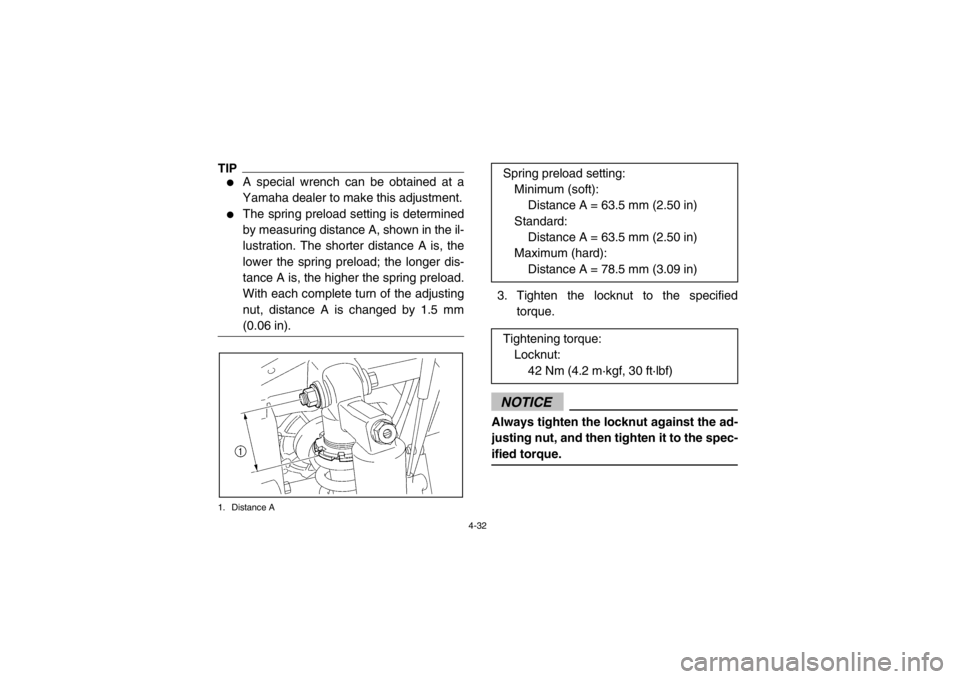

TIP●

A special wrench can be obtained at a

Yamaha dealer to make this adjustment.

●

The spring preload setting is determined

by measuring distance A, shown in the il-

lustration. The shorter distance A is, the

lower the spring preload; the longer dis-

tance A is, the higher the spring preload.

With each complete turn of the adjusting

nut, distance A is changed by 1.5 mm

(0.06 in).

1. Distance A

3. Tighten the locknut to the specifiedtorque.NOTICEAlways tighten the locknut against the ad-

justing nut, and then tighten it to the spec-

ified torque.

Spring preload setting:

Minimum (soft): Distance A = 63.5 mm (2.50 in)

Standard: Distance A = 63.5 mm (2.50 in)

Maximum (hard):

Distance A = 78.5 mm (3.09 in)

Tightening torque: Locknut: 42 Nm (4.2 m·kgf, 30 ft·lbf)

1RB7A_EE.book Page 32 Tuesday, April 24, 2012 9:07 AM

Page 63 of 188

4-33

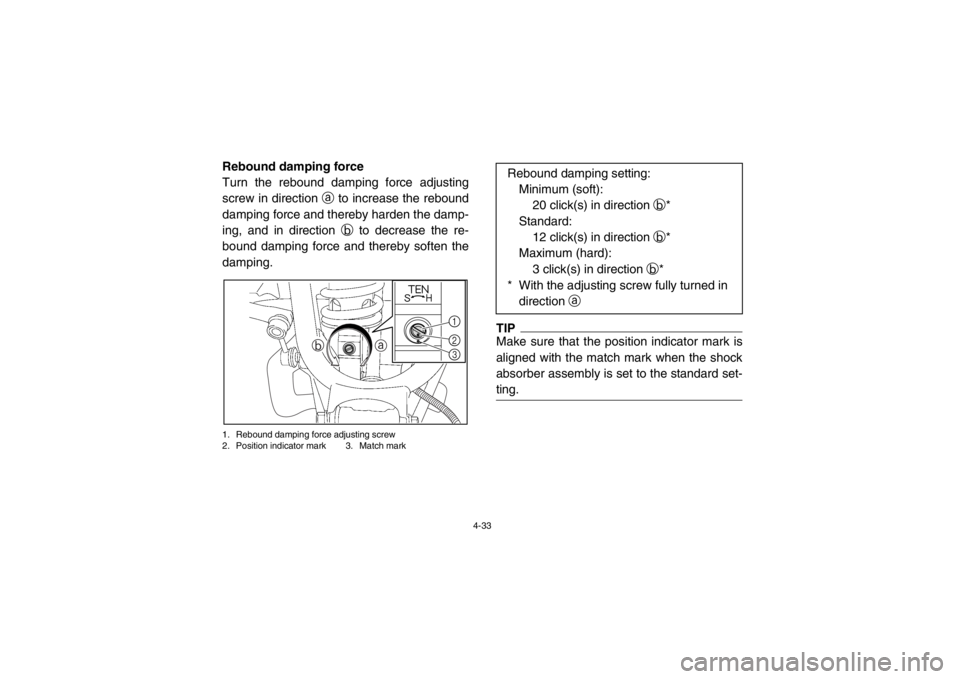

Rebound damping force

Turn the rebound damping force adjusting

screw in direction a to increase the rebound

damping force and thereby harden the damp-

ing, and in direction b to decrease the re-

bound damping force and thereby soften the

damping.1. Rebound damping force adjusting screw

2. Position indicator mark 3. Match mark

TIPMake sure that the position indicator mark is

aligned with the match mark when the shock

absorber assembly is set to the standard set-

ting.

a

b

123

Rebound damping setting:

Minimum (soft): 20 click(s) in direction b*

Standard: 12 click(s) in direction b*

Maximum (hard):

3 click(s) in direction b*

* With the adjusting screw fully turned in direction a

1RB7A_EE.book Page 33 Tuesday, April 24, 2012 9:07 AM

Page 64 of 188

4-34

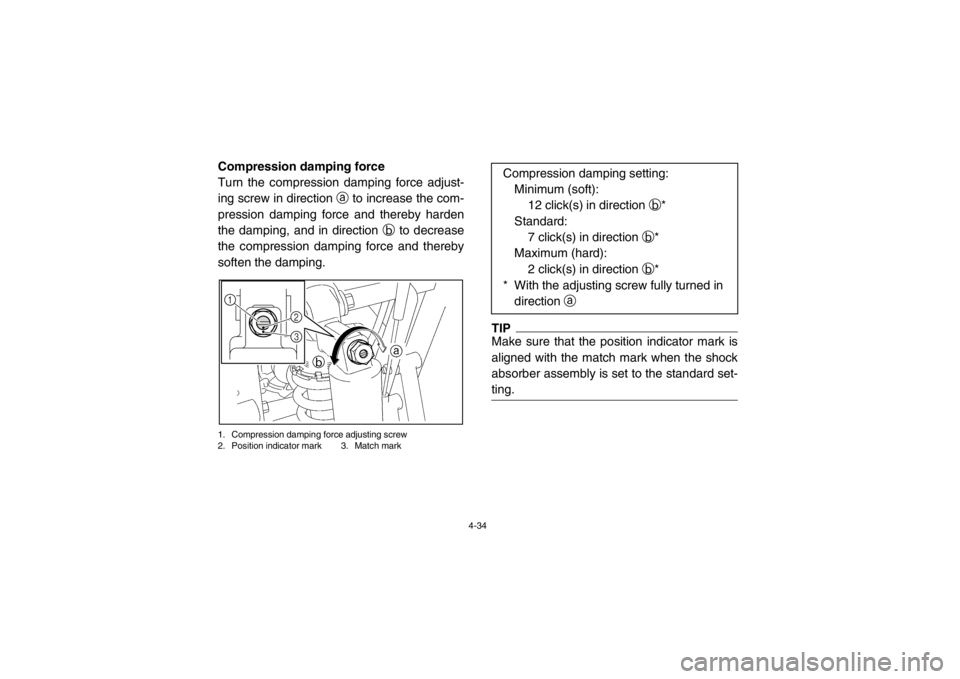

Compression damping force

Turn the compression damping force adjust-

ing screw in direction a to increase the com-

pression damping force and thereby harden

the damping, and in direction b to decrease

the compression damping force and thereby

soften the damping.1. Compression damping force adjusting screw

2. Position indicator mark 3. Match mark

TIPMake sure that the position indicator mark is

aligned with the match mark when the shock

absorber assembly is set to the standard set-

ting.

1

3 2

Compression damping setting:Minimum (soft): 12 click(s) in direction b*

Standard: 7 click(s) in direction b*

Maximum (hard):

2 click(s) in direction b*

* With the adjusting screw fully turned in direction a

1RB7A_EE.book Page 34 Tuesday, April 24, 2012 9:07 AM

Page 65 of 188

4-35

TIPAlthough the total number of clicks of a damp-

ing force adjusting mechanism may not exact-

ly match the above specifications due to small

differences in production, the actual number

of clicks always represents the entire adjust-

ing range. To obtain a precise adjustment, it

would be advisable to check the number of

clicks of each damping force adjusting mech-

anism and to modify the specifications as nec-

essary.

WARNING

●

Suspension components become hot

during operation. Never touch the

compression damping force adjusting

screw, the rebound damping force ad-

justing screw or the oil reservoir with

your bare hand or skin until suspen-

sion components have cooled.

●

Always adjust the shock absorber as-

semblies on the left and right side to

the same setting. Uneven adjustment

can cause poor handling and loss of

stability, which could lead to an acci-

dent.

1RB7A_EE.book Page 35 Tuesday, April 24, 2012 9:07 AM

Page 74 of 188

5-7

EVU00430Final gear oil

Make sure the final gear oil is at the specified

level. Add oil as necessary. (See pages 8-15–

8-18 for details.)

If desired, an SAE 80W-90 hypoid gear oil

may be used for all conditions.TIPTIPGL-4 is a quality and additive rating; GL-5 or

GL-6 rated hypoid gear oils may also be used.EVU00440Differential gear oil

Make sure the differential gear oil is at the

specified level. Add oil as necessary. (See

pages 8-18–8-21 for details.)

EVU00450Accelerator pedal

Check to see that the accelerator pedal oper-

ates correctly. It must operate smoothly and

spring back to the idle position fully when re-

leased. Have a Yamaha dealer repair as nec-

essary for proper operation.EVU00460Seat belts

Make sure that the seat belts are not frayed,

torn, stretched, or damaged. The seat belts

must move smoothly when pulled out and re-

tract on its own when released. The seat belts

must also lock up when quickly pulled out.

The latch plate should click securely into the

buckle and release when the release button is

pushed firmly. Wash off any dirt or mud that

could affect operation. Have a Yamaha dealer

repair as necessary for proper operation.

Recommended oil:

SAE 80 API GL-4 Hypoid gear oil

Recommended oil: SAE 80 API GL-4 Hypoid gear oil

1RB7A_EE.book Page 7 Tuesday, April 24, 2012 9:07 AM

Page 80 of 188

6-3

●

The engine can be started in any gear

if the brake pedal is applied. However,

it is recommended to shift into neutral

before starting the engine.

4. With your foot off the accelerator pedal, start the engine by turning the key to

“START”.

If the engine fails to start, release the key, and

then try starting it again. Wait a few seconds

before the next attempt. Each attempt should

be as short as possible, to preserve battery

energy. NOTICE: Do not crank the engine

more than 5 seconds on each attempt, or

starter damage could occur. Wait at least 5

seconds between each operation of the

electric starter to let it cool.

Do not turn the key to the “START” position

with the engine running; otherwise, damage

to the electric starter may result.

TIPFor maximum engine life, never accelerate

hard when the engine is cold!

1RB7A_EE.book Page 3 Tuesday, April 24, 2012 9:07 AM

Page 94 of 188

7-6

Protective structure

The vehicle cage/frame provides a protective

structure that helps limit intrusions by branch-

es or other objects and may reduce your risk

of injury in accidents. The protective structure

will not protect occupants in all rollovers or ac-

cidents.

Body parts outside of vehicle can be struck by

passing objects or crushed during vehicle roll-

over. Do not put your hands or feet outside of

the vehicle for any reason. Do not hold onto

the door, cage/frame or hip restraint. Wear

your seat belt and helmet.

If you think or feel that the vehicle may tip or

roll, do not put your hands or feet outside the

vehicle for any reason. You will not be able to

stop the vehicle from tipping over using your

body. Any part of your body (arms, legs, or

head) outside of the vehicle can be crushed

by the vehicle cage/frame.Seat belts

Seat belts should be worn by both driver and

passenger. Driver must be sure that the pas-

senger is belted before driving.

●

Be sure the seat belt is not twisted, is

close-fitting across the hips and chest,

and is latched securely.

●

Do not wear the lap belt across the abdo-

men or stomach.

●

Do not put the shoulder belt behind the

back.

Failure to use seat belts properly may lead to

an increased likelihood and severity of injury.

1RB7A_EE.book Page 6 Tuesday, April 24, 2012 9:07 AM

Page 97 of 188

7-9

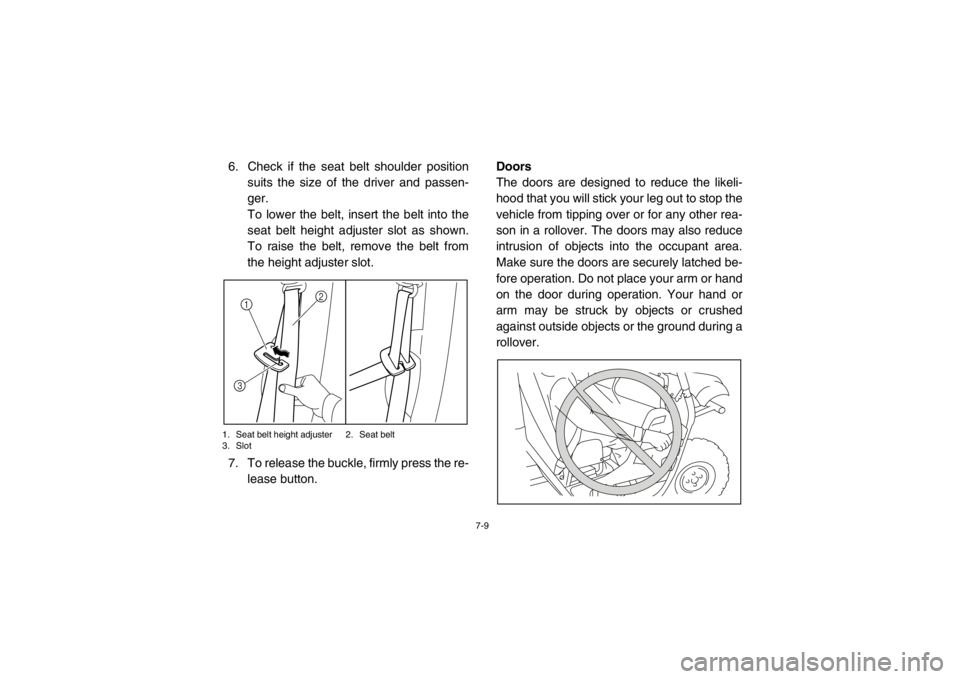

6. Check if the seat belt shoulder positionsuits the size of the driver and passen-

ger.

To lower the belt, insert the belt into the

seat belt height adjuster slot as shown.

To raise the belt, remove the belt from

the height adjuster slot.1. Seat belt height adjuster 2. Seat belt

3. Slot7. To release the buckle, firmly press the re-lease button. Doors

The doors are designed to reduce the likeli-

hood that you will stick your leg out to stop the

vehicle from tipping over or for any other rea-

son in a rollover. The doors may also reduce

intrusion of objects into the occupant area.

Make sure the doors are securely latched be-

fore operation. Do not place your arm or hand

on the door during operation. Your hand or

arm may be struck by objects or crushed

against outside objects or the ground during a

rollover.

1

2

3

1RB7A_EE.book Page 9 Tuesday, April 24, 2012 9:07 AM

Page 98 of 188

7-10

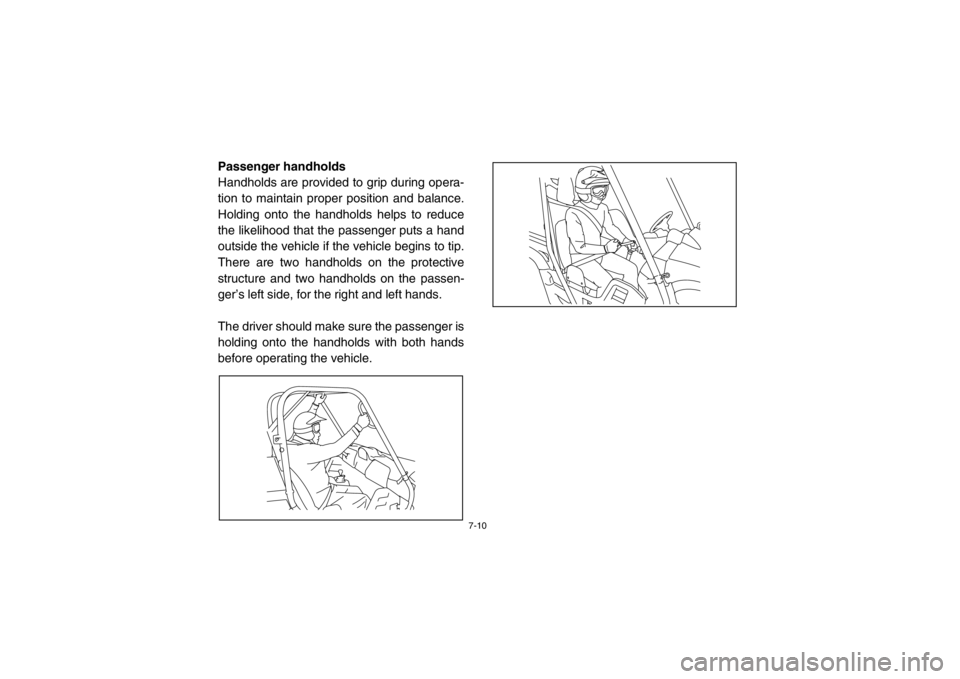

Passenger handholds

Handholds are provided to grip during opera-

tion to maintain proper position and balance.

Holding onto the handholds helps to reduce

the likelihood that the passenger puts a hand

outside the vehicle if the vehicle begins to tip.

There are two handholds on the protective

structure and two handholds on the passen-

ger’s left side, for the right and left hands.

The driver should make sure the passenger is

holding onto the handholds with both hands

before operating the vehicle.1RB7A_EE.book Page 10 Tuesday, April 24, 2012 9:07 AM