engine YAMAHA SUPERJET 2016 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: SUPERJET, Model: YAMAHA SUPERJET 2016Pages: 78, PDF Size: 2.7 MB

Page 26 of 78

![YAMAHA SUPERJET 2016 User Guide Control function operation

20

will not start. Also, the starter motor could

be damaged.

[ECJ01041]

The engine will not start when the clip is re-

moved from the engine shut-off switch.

EJU31212Thrott YAMAHA SUPERJET 2016 User Guide Control function operation

20

will not start. Also, the starter motor could

be damaged.

[ECJ01041]

The engine will not start when the clip is re-

moved from the engine shut-off switch.

EJU31212Thrott](/img/51/51274/w960_51274-25.png)

Control function operation

20

will not start. Also, the starter motor could

be damaged.

[ECJ01041]

The engine will not start when the clip is re-

moved from the engine shut-off switch.

EJU31212Throttle lever

The throttle lever increases the engine speed

when the lever is squeezed.

The throttle lever returns automatically to its

fully closed (idle) position when released.

EJU35933Steering system

By turning the handlebars in the direction you

wish to travel, the angle of the jet thrust noz-zle is changed, and the direction of the water-

craft is changed accordingly.

Since the strength of the jet thrust determines

the speed and degree of a turn, throttle must

always be applied when attempting a turn,

except at trolling speed.

The angle of the jet thrust nozzle can be ad-

justed to suit operator preference. (See page

57 for information on adjusting the jet thrust

nozzle angle.)

EJU31273Steering pole

The steering pole can be moved up or down

to change the height of the handlebars.

1Start switch

1Throttle lever

START

1

1Handlebar

2Jet thrust nozzle

UF4D71E0.book Page 20 Thursday, April 23, 2015 1:48 PM

Page 27 of 78

Control function operation

21

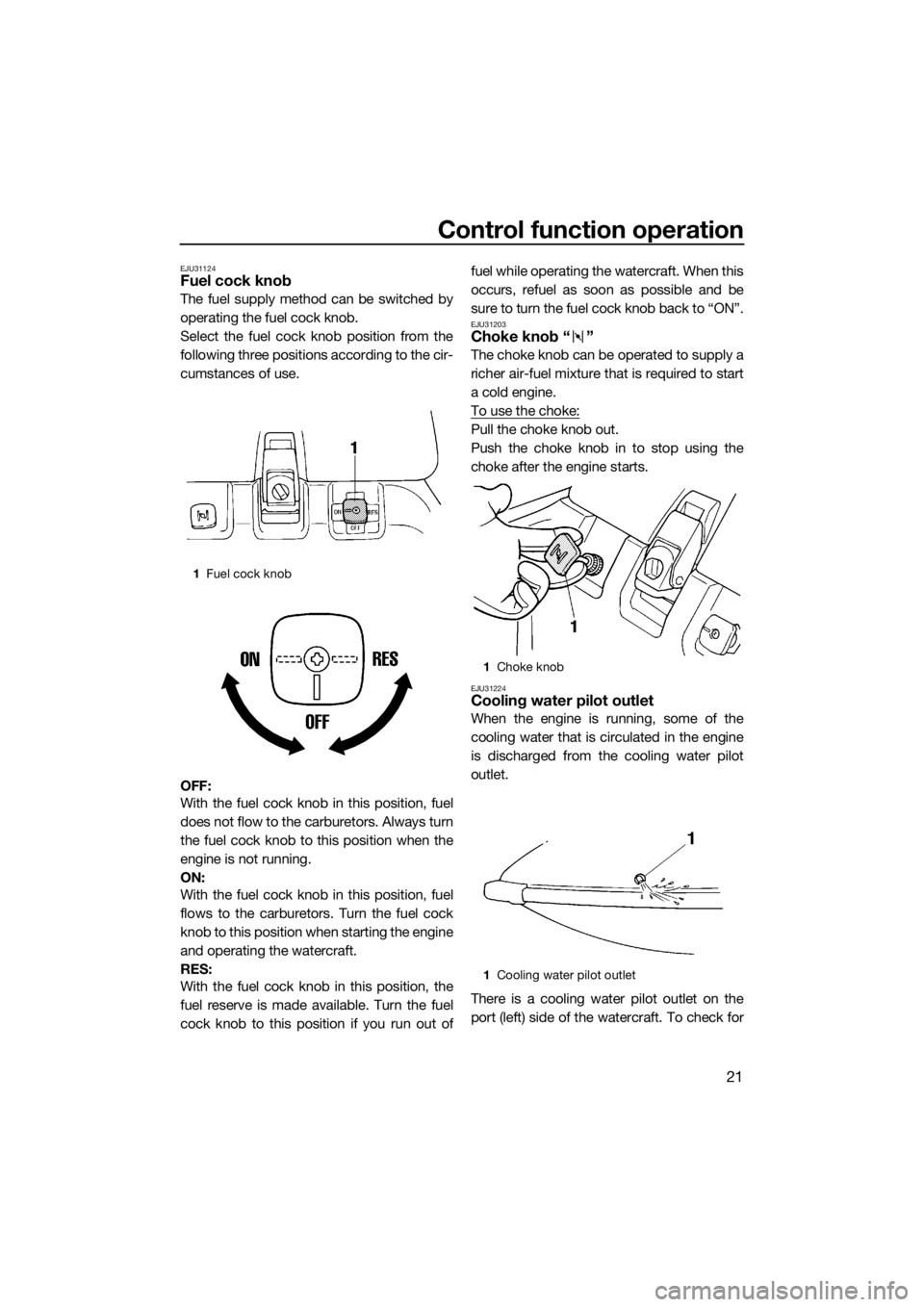

EJU31124Fuel cock knob

The fuel supply method can be switched by

operating the fuel cock knob.

Select the fuel cock knob position from the

following three positions according to the cir-

cumstances of use.

OFF:

With the fuel cock knob in this position, fuel

does not flow to the carburetors. Always turn

the fuel cock knob to this position when the

engine is not running.

ON:

With the fuel cock knob in this position, fuel

flows to the carburetors. Turn the fuel cock

knob to this position when starting the engine

and operating the watercraft.

RES:

With the fuel cock knob in this position, the

fuel reserve is made available. Turn the fuel

cock knob to this position if you run out offuel while operating the watercraft. When this

occurs, refuel as soon as possible and be

sure to turn the fuel cock knob back to “ON”.

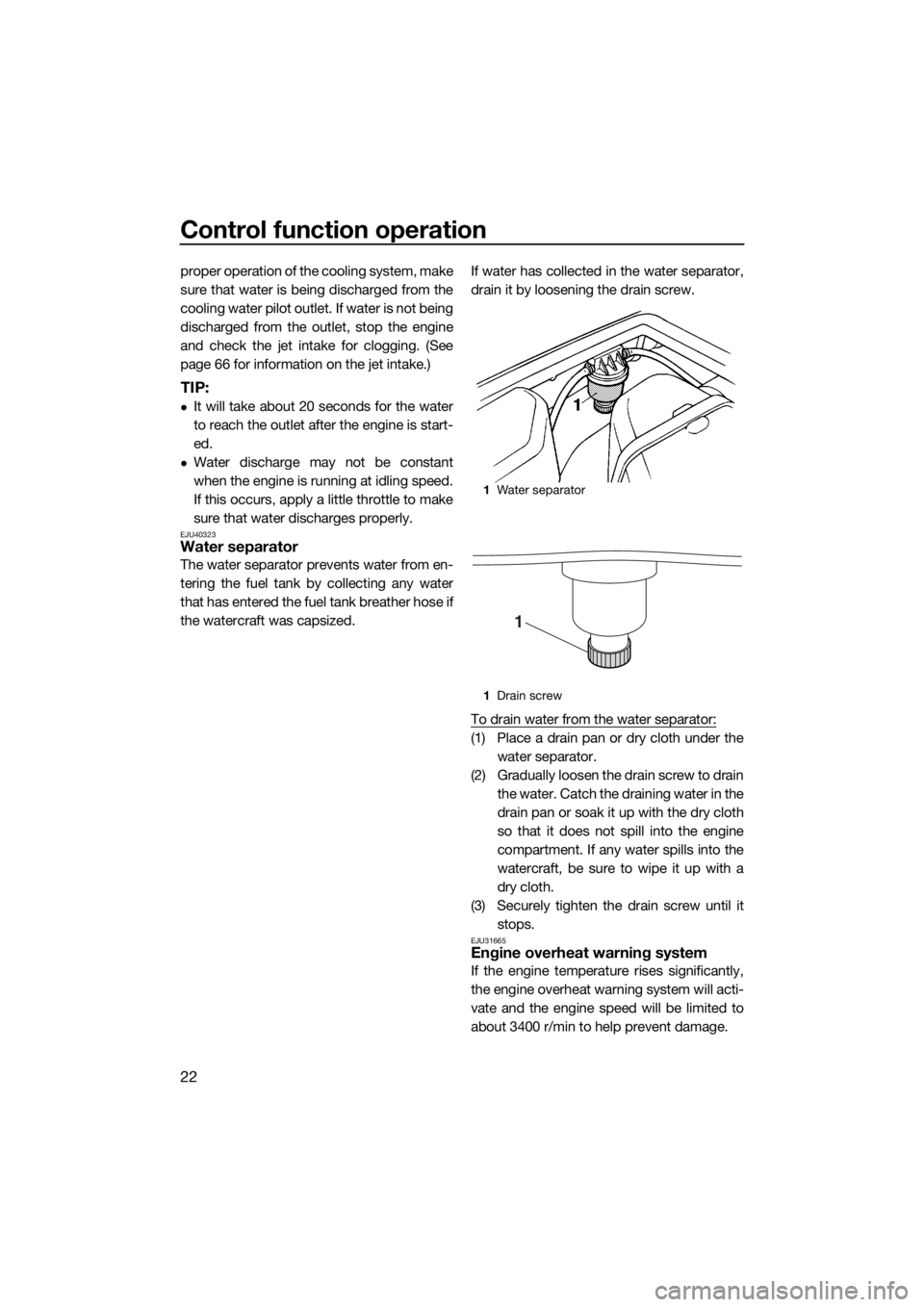

EJU31203Choke knob “ ”

The choke knob can be operated to supply a

richer air-fuel mixture that is required to start

a cold engine.

To use the choke:

Pull the choke knob out.

Push the choke knob in to stop using the

choke after the engine starts.

EJU31224Cooling water pilot outlet

When the engine is running, some of the

cooling water that is circulated in the engine

is discharged from the cooling water pilot

outlet.

There is a cooling water pilot outlet on the

port (left) side of the watercraft. To check for

1Fuel cock knob

1Choke knob

1Cooling water pilot outlet

UF4D71E0.book Page 21 Thursday, April 23, 2015 1:48 PM

Page 28 of 78

Control function operation

22

proper operation of the cooling system, make

sure that water is being discharged from the

cooling water pilot outlet. If water is not being

discharged from the outlet, stop the engine

and check the jet intake for clogging. (See

page 66 for information on the jet intake.)

TIP:

It will take about 20 seconds for the water

to reach the outlet after the engine is start-

ed.

Water discharge may not be constant

when the engine is running at idling speed.

If this occurs, apply a little throttle to make

sure that water discharges properly.

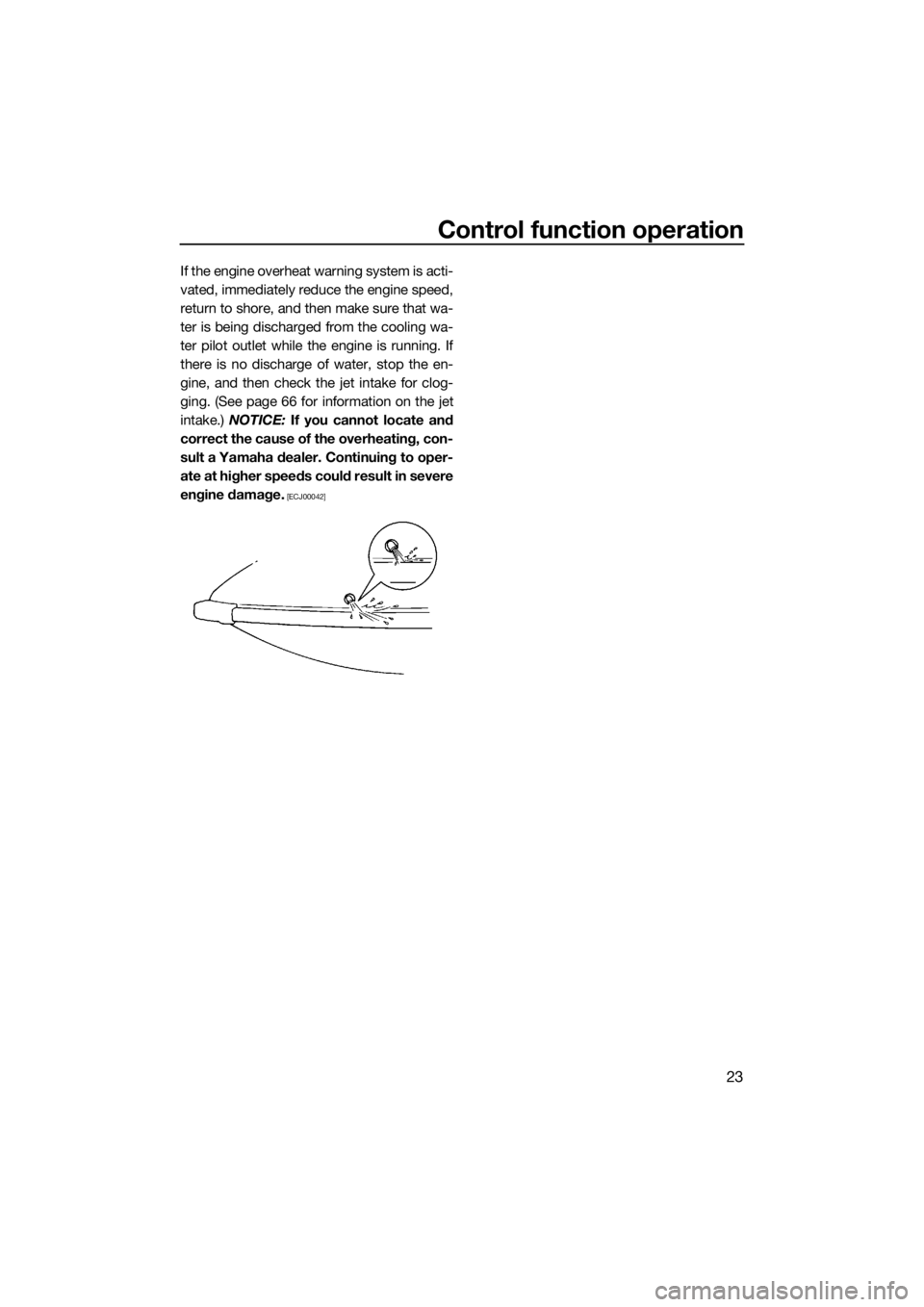

EJU40323Water separator

The water separator prevents water from en-

tering the fuel tank by collecting any water

that has entered the fuel tank breather hose if

the watercraft was capsized.If water has collected in the water separator,

drain it by loosening the drain screw.

To drain water from the water separator:

(1) Place a drain pan or dry cloth under the

water separator.

(2) Gradually loosen the drain screw to drain

the water. Catch the draining water in the

drain pan or soak it up with the dry cloth

so that it does not spill into the engine

compartment. If any water spills into the

watercraft, be sure to wipe it up with a

dry cloth.

(3) Securely tighten the drain screw until it

stops.

EJU31665Engine overheat warning system

If the engine temperature rises significantly,

the engine overheat warning system will acti-

vate and the engine speed will be limited to

about 3400 r/min to help prevent damage.

1Water separator

1Drain screw

1

UF4D71E0.book Page 22 Thursday, April 23, 2015 1:48 PM

Page 29 of 78

Control function operation

23

If the engine overheat warning system is acti-

vated, immediately reduce the engine speed,

return to shore, and then make sure that wa-

ter is being discharged from the cooling wa-

ter pilot outlet while the engine is running. If

there is no discharge of water, stop the en-

gine, and then check the jet intake for clog-

ging. (See page 66 for information on the jet

intake.) NOTICE: If you cannot locate and

correct the cause of the overheating, con-

sult a Yamaha dealer. Continuing to oper-

ate at higher speeds could result in severe

engine damage.

[ECJ00042]

UF4D71E0.book Page 23 Thursday, April 23, 2015 1:48 PM

Page 30 of 78

Equipment operation

24

EJU40334

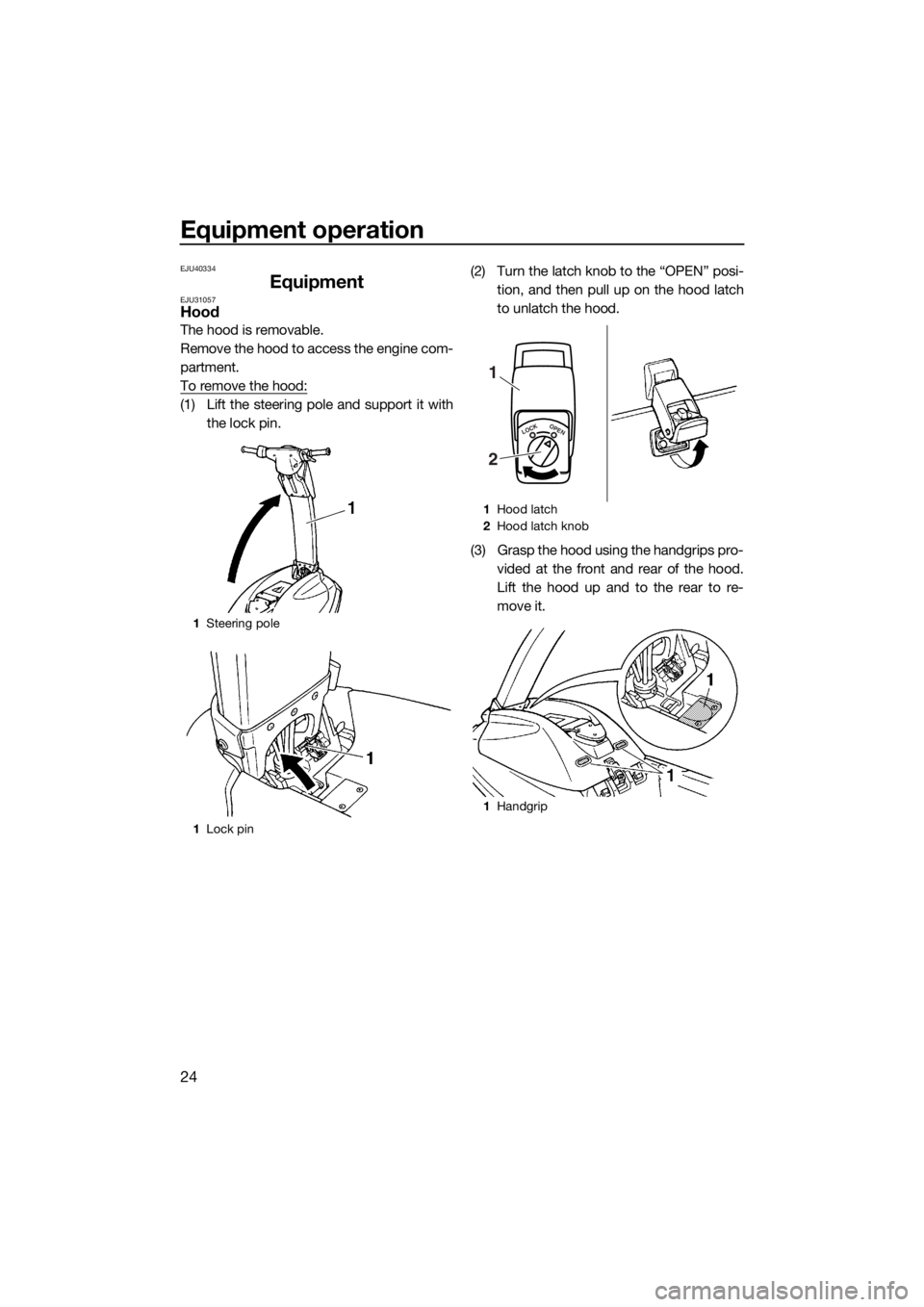

EquipmentEJU31057Hood

The hood is removable.

Remove the hood to access the engine com-

partment.

To remove the hood:

(1) Lift the steering pole and support it with

the lock pin.(2) Turn the latch knob to the “OPEN” posi-

tion, and then pull up on the hood latch

to unlatch the hood.

(3) Grasp the hood using the handgrips pro-

vided at the front and rear of the hood.

Lift the hood up and to the rear to re-

move it.

1Steering pole

1Lock pin

1Hood latch

2Hood latch knob

1Handgrip

LOCKOPEN

1

2

UF4D71E0.book Page 24 Thursday, April 23, 2015 1:48 PM

Page 34 of 78

Operation and handling requirements

28

EJU31793

Fuel and engine oil

requirements

EJU31834Fuel

WARNING

EWJ00283

Gasoline and gasoline vapors are ex-

tremely flammable. To avoid fires and

explosions and to reduce the risk of in-

jury when refueling, follow these in-

structions.

Gasoline is poisonous and can cause in-

jury or death. Handle gasoline with care.

Never siphon gasoline by mouth. If you

should swallow some gasoline, inhale a

lot of gasoline vapor, or get some gaso-

line in your eyes, see your doctor imme-

diately. If gasoline spills on your skin,

wash with soap and water. If gasoline

spills on your clothing, change your

clothes.

NOTICE

ECJ00322

Do not use leaded gasoline. Leaded

gasoline can seriously damage the en-

gine.

Avoid getting water and contaminants in

the fuel tank. Contaminated fuel can

cause poor performance and engine

damage. Use only fresh gasoline that

has been stored in clean containers.

Gasohol

There are two types of gasohol: gasohol con-

taining ethanol and that containing methanol.Gasohol containing ethanol can be used if

ethanol content does not exceed 10% and

the fuel meets the minimum octane ratings.

E-85 is a fuel blend containing 85% ethanol

and therefore must not be used in this water-

craft. All ethanol blends containing more than

10% ethanol can cause fuel system damage

or engine performance problems.

Yamaha does not recommend gasohol con-

taining methanol because it can cause fuel

system damage and engine performance

problems.

EJU318732-stroke engine oil

If YAMALUBE 2-W engine oil is not available,

another 2-stroke engine oil with an NMMA-

certified TC-W3 rating may be used.

EJU31903Mixing fuel and oil

NOTICE

ECJ00332

Make sure that the gasoline and oil are

thoroughly mixed in the correct ratio, oth-

erwise severe engine damage could re-

sult.

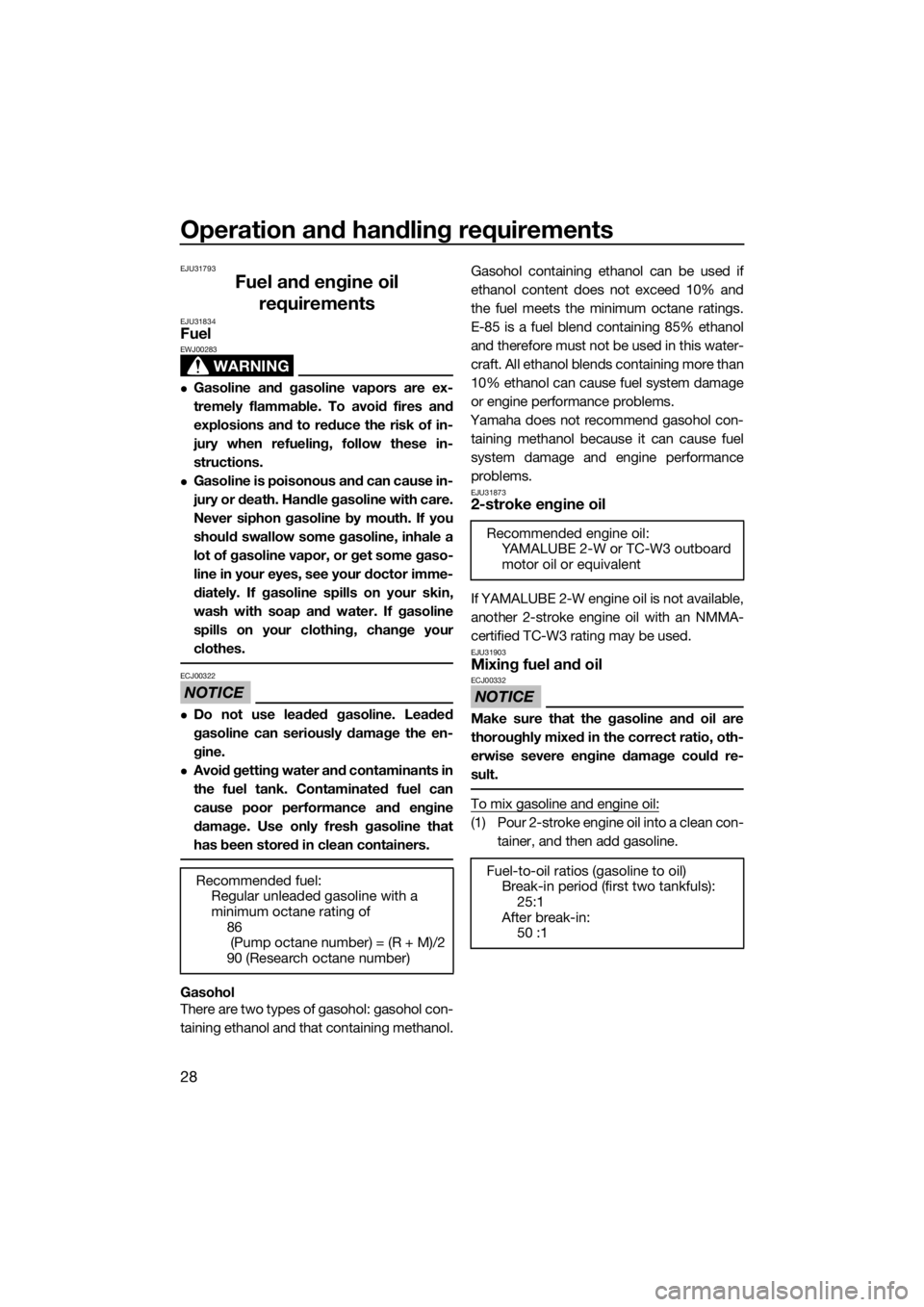

To mix gasoline and engine oil:

(1) Pour 2-stroke engine oil into a clean con-

tainer, and then add gasoline.

Recommended fuel:

Regular unleaded gasoline with a

minimum octane rating of

86

(Pump octane number) = (R + M)/2

90 (Research octane number)

Recommended engine oil:

YAMALUBE 2-W or TC-W3 outboard

motor oil or equivalent

Fuel-to-oil ratios (gasoline to oil)

Break-in period (first two tankfuls):

25:1

After break-in:

50 :1

UF4D71E0.book Page 28 Thursday, April 23, 2015 1:48 PM

Page 35 of 78

Operation and handling requirements

29

(2) To mix them thoroughly, shake the con-

tainer from side to side.

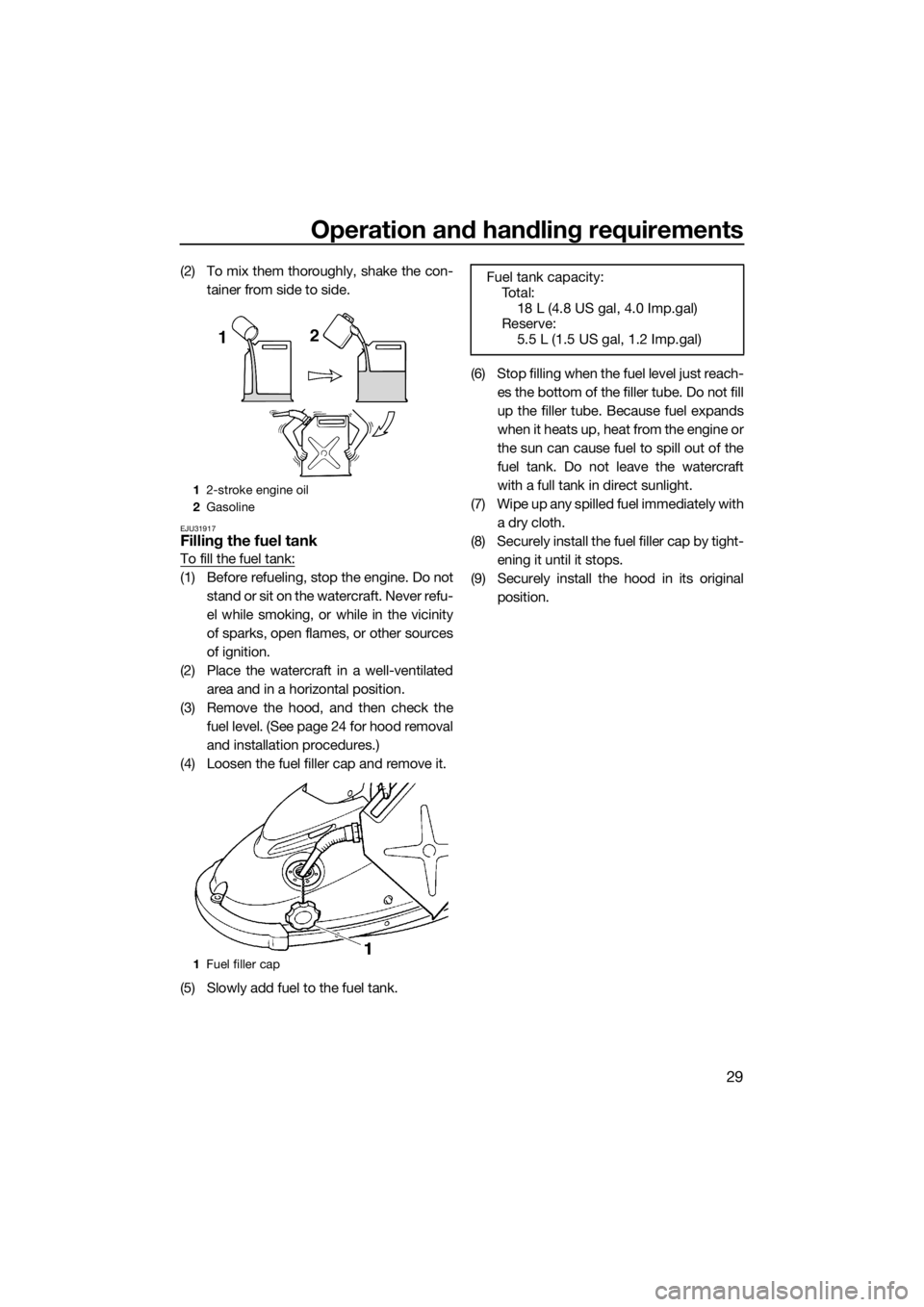

EJU31917Filling the fuel tank

To fill the fuel tank:

(1) Before refueling, stop the engine. Do not

stand or sit on the watercraft. Never refu-

el while smoking, or while in the vicinity

of sparks, open flames, or other sources

of ignition.

(2) Place the watercraft in a well-ventilated

area and in a horizontal position.

(3) Remove the hood, and then check the

fuel level. (See page 24 for hood removal

and installation procedures.)

(4) Loosen the fuel filler cap and remove it.

(5) Slowly add fuel to the fuel tank.(6) Stop filling when the fuel level just reach-

es the bottom of the filler tube. Do not fill

up the filler tube. Because fuel expands

when it heats up, heat from the engine or

the sun can cause fuel to spill out of the

fuel tank. Do not leave the watercraft

with a full tank in direct sunlight.

(7) Wipe up any spilled fuel immediately with

a dry cloth.

(8) Securely install the fuel filler cap by tight-

ening it until it stops.

(9) Securely install the hood in its original

position.

12-stroke engine oil

2Gasoline

1Fuel filler cap

Fuel tank capacity:

To t a l :

18 L (4.8 US gal, 4.0 Imp.gal)

Reserve:

5.5 L (1.5 US gal, 1.2 Imp.gal)

UF4D71E0.book Page 29 Thursday, April 23, 2015 1:48 PM

Page 36 of 78

Operation and handling requirements

30

EJU40022

Draining the bilge water

NOTICE

ECJ01302

Do not run the engine at full throttle when

bilge water remains in the engine com-

partment. The bilge water can splash into

the engine, which can result in severe

damage.

EJU40922Draining the bilge water on water

A small quantity of bilge water will remain in

the engine compartment even after the bilge

water is drained on water. To completely re-

move the bilge water, remove the watercraft

from the water and wipe up any remaining

moisture in the engine compartment with a

dry cloth.

Jet vacuum bilge draining system

While the watercraft is operating, bilge water

in the engine compartment is drawn in by the

vacuum that is generated in the jet pump and

discharged from the watercraft through the

jet thrust nozzle.

To drain the bilge water on water:

Operate the watercraft as straight as possible

and above planing speed for at least 2 min-

utes. NOTICE: Do not run the engine at full

throttle for at least 1 minute after the en-

gine has been restarted. Bilge water in the

engine compartment can splash into theengine, which can result in severe dam-

age.

[ECJ00554]

UF4D71E0.book Page 30 Thursday, April 23, 2015 1:48 PM

Page 37 of 78

Operation and handling requirements

31

EJU33424

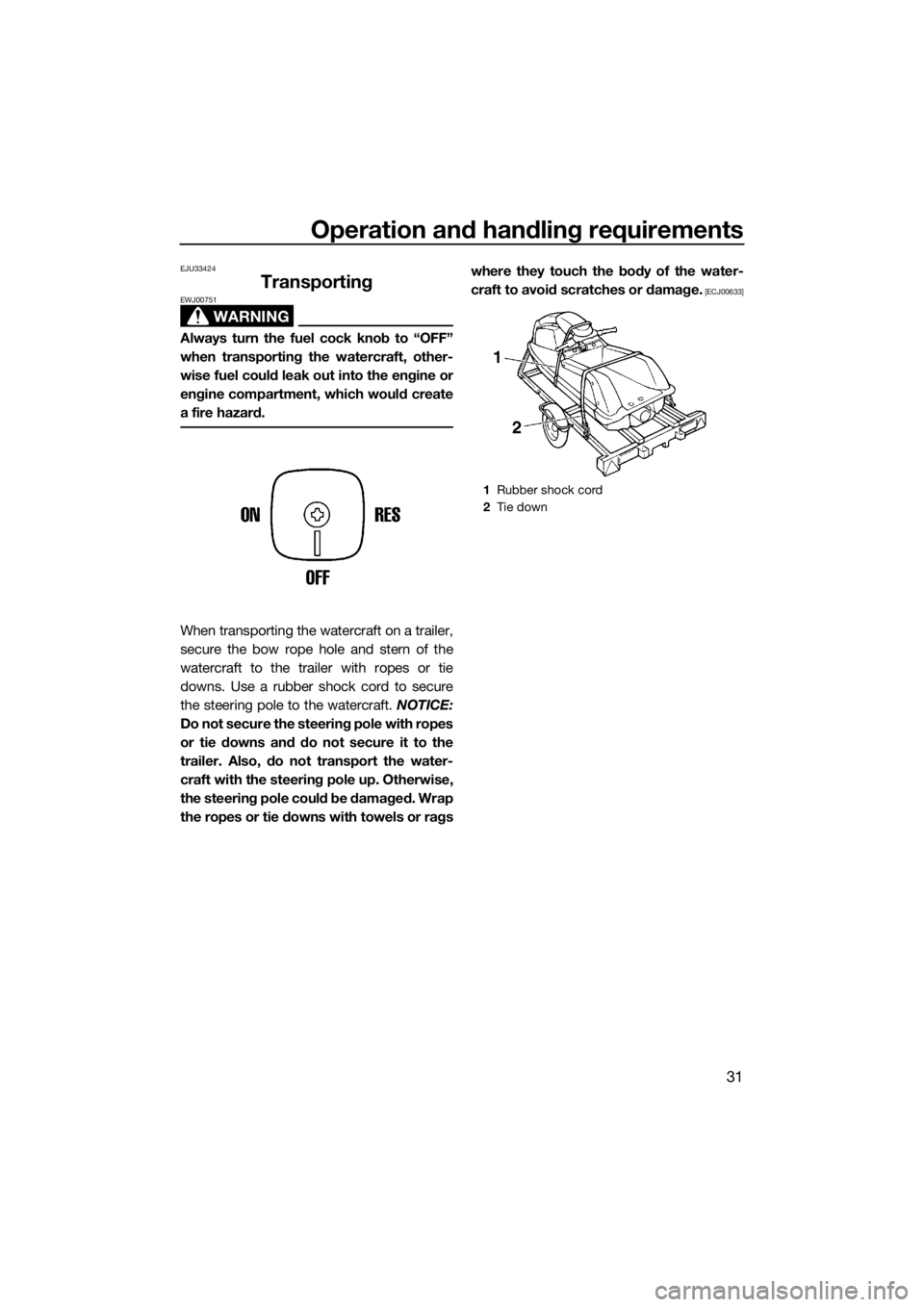

Transporting

WARNING

EWJ00751

Always turn the fuel cock knob to “OFF”

when transporting the watercraft, other-

wise fuel could leak out into the engine or

engine compartment, which would create

a fire hazard.

When transporting the watercraft on a trailer,

secure the bow rope hole and stern of the

watercraft to the trailer with ropes or tie

downs. Use a rubber shock cord to secure

the steering pole to the watercraft. NOTICE:

Do not secure the steering pole with ropes

or tie downs and do not secure it to the

trailer. Also, do not transport the water-

craft with the steering pole up. Otherwise,

the steering pole could be damaged. Wrap

the ropes or tie downs with towels or ragswhere they touch the body of the water-

craft to avoid scratches or damage.

[ECJ00633]

1Rubber shock cord

2Tie down

UF4D71E0.book Page 31 Thursday, April 23, 2015 1:48 PM

Page 38 of 78

First-time operation

32

EJU32757

Engine break-in

NOTICE

ECJ00432

Failure to perform the engine break-in

could result in reduced engine life or even

severe engine damage.

The engine break-in is essential to allow the

various components of the engine to wear

and polish themselves to the correct operat-

ing clearances. This ensures proper perfor-

mance and promotes longer component life.

To perform the engine break-in:

(1) Fill the fuel tank with fuel in a fuel-to-oil

ratio of 25:1. (See page 28 “Mixing fuel

and oil” and “Filling the fuel tank” for in-

formation on filling the fuel tank.)

(2) Launch the watercraft and start the en-

gine. (See page 41 for information on

starting the engine.)

(3) For the first 5 minutes, operate with the

engine at idling speed.

(4) For the first tankful of fuel, squeeze the

throttle lever slowly and operate at 3/4

throttle or less.

(5) Fill the fuel tank once more with fuel in a

fuel-to-oil ratio of 25:1, and then operate

with the engine at any speed.

After the engine break-in is complete, fill the

fuel tank with fuel in a fuel-to-oil ratio of 50:1.

The watercraft can be operated normally.

UF4D71E0.book Page 32 Thursday, April 23, 2015 1:48 PM