check engine YAMAHA SUPERJET 2017 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2017, Model line: SUPERJET, Model: YAMAHA SUPERJET 2017Pages: 78, PDF Size: 2.66 MB

Page 44 of 78

Pre-operation checks

38

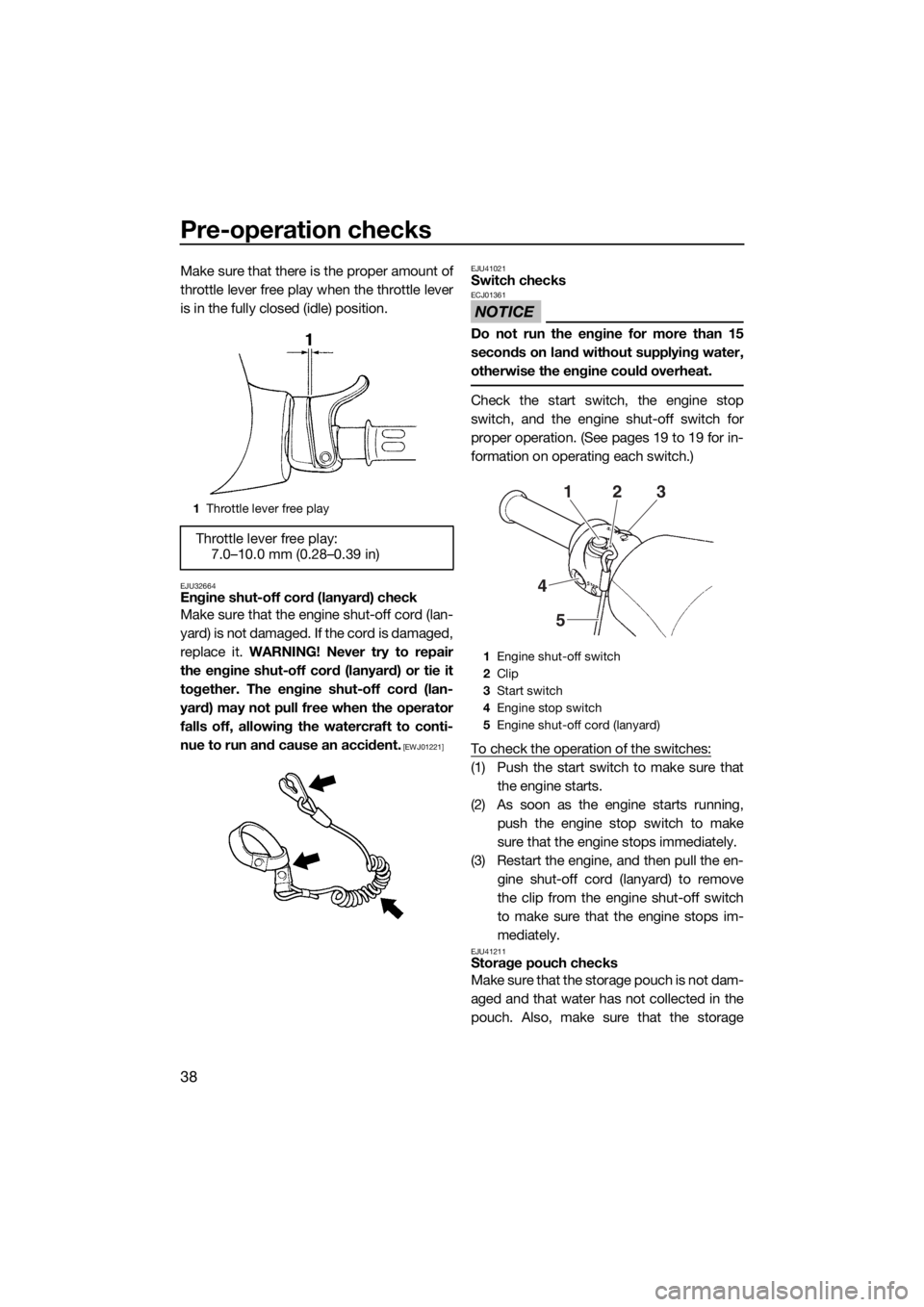

Make sure that there is the proper amount of

throttle lever free play when the throttle lever

is in the fully closed (idle) position.

EJU32664Engine shut-off cord (lanyard) check

Make sure that the engine shut-off cord (lan-

yard) is not damaged. If the cord is damaged,

replace it. WARNING! Never try to repair

the engine shut-off cord (lanyard) or tie it

together. The engine shut-off cord (lan-

yard) may not pull free when the operator

falls off, allowing the watercraft to conti-

nue to run and cause an accident.

[EWJ01221]EJU41021

Switch checks

NOTICE

ECJ01361

Do not run the engine for more than 15

seconds on land without supplying water,

otherwise the engine could overheat.

Check the start switch, the engine stop

switch, and the engine shut-off switch for

proper operation. (See pages 19 to 19 for in-

formation on operating each switch.)

To check the operation of the switches:

(1) Push the start switch to make sure that

the engine starts.

(2) As soon as the engine starts running,

push the engine stop switch to make

sure that the engine stops immediately.

(3) Restart the engine, and then pull the en-

gine shut-off cord (lanyard) to remove

the clip from the engine shut-off switch

to make sure that the engine stops im-

mediately.

EJU41211Storage pouch checks

Make sure that the storage pouch is not dam-

aged and that water has not collected in the

pouch. Also, make sure that the storage

1Throttle lever free play

Throttle lever free play:

7.0–10.0 mm (0.28–0.39 in)

1Engine shut-off switch

2Clip

3Start switch

4Engine stop switch

5Engine shut-off cord (lanyard)

123

4

5

UF4D73E0.book Page 38 Wednesday, March 23, 2016 11:40 AM

Page 45 of 78

Pre-operation checks

39

pouch is securely installed. (See page 25 for

information on the storage pouch.)

EJU41072Fire extinguisher container checks

Make sure that the fire extinguisher container

is not damaged and is securely held in place.

(See page 26 for information on the fire extin-

guisher container.)

EJU32504Fire extinguisher check

Check that there is a full fire extinguisher on

board.

To check the fire extinguisher, see the in-

structions supplied by the fire extinguisher

manufacturer. Always keep the fire extin-

guisher in the fire extinguisher container.

Always carry a fire extinguisher on board. A

fire extinguisher is not standard equipment

with this watercraft. If you do not have one,

contact a Yamaha dealer or a fire extinguish-

er dealer to obtain one meeting the proper

specifications.

EJU40122Safety equipment check

Check that safety equipment meeting the ap-

plicable regulations is on board.

EJU32353Hull and deck check

Check the hull and deck for damage or other

problem.

EJU32657Jet intake checks

Make sure that the jet intake is not damaged

or clogged with weeds or debris. If the jet in-take is clogged, clean it. (See page 66 for in-

formation on the jet intake.)

EJU40703Hood check

Make sure that the hood is securely closed.

(See page 24 for information on the hood.)

EJU40146Post-launch checks

Perform the post-launch checks in the pre-

operation checklist while the watercraft is in

the water and the engine is running.

To perform the post-launch checks:

(1) Launch the watercraft. (See page 41 for

information on launching the watercraft.)

(2) Perform the checks and make sure that

there are no malfunctioning items or oth-

er problems.

EJU40553Cooling water pilot outlet check

Make sure that water is discharged from the

cooling water pilot outlet while the engine is

running. (See page 21 for information on the

cooling water pilot outlet.)

UF4D73E0.book Page 39 Wednesday, March 23, 2016 11:40 AM

Page 48 of 78

Operation

42

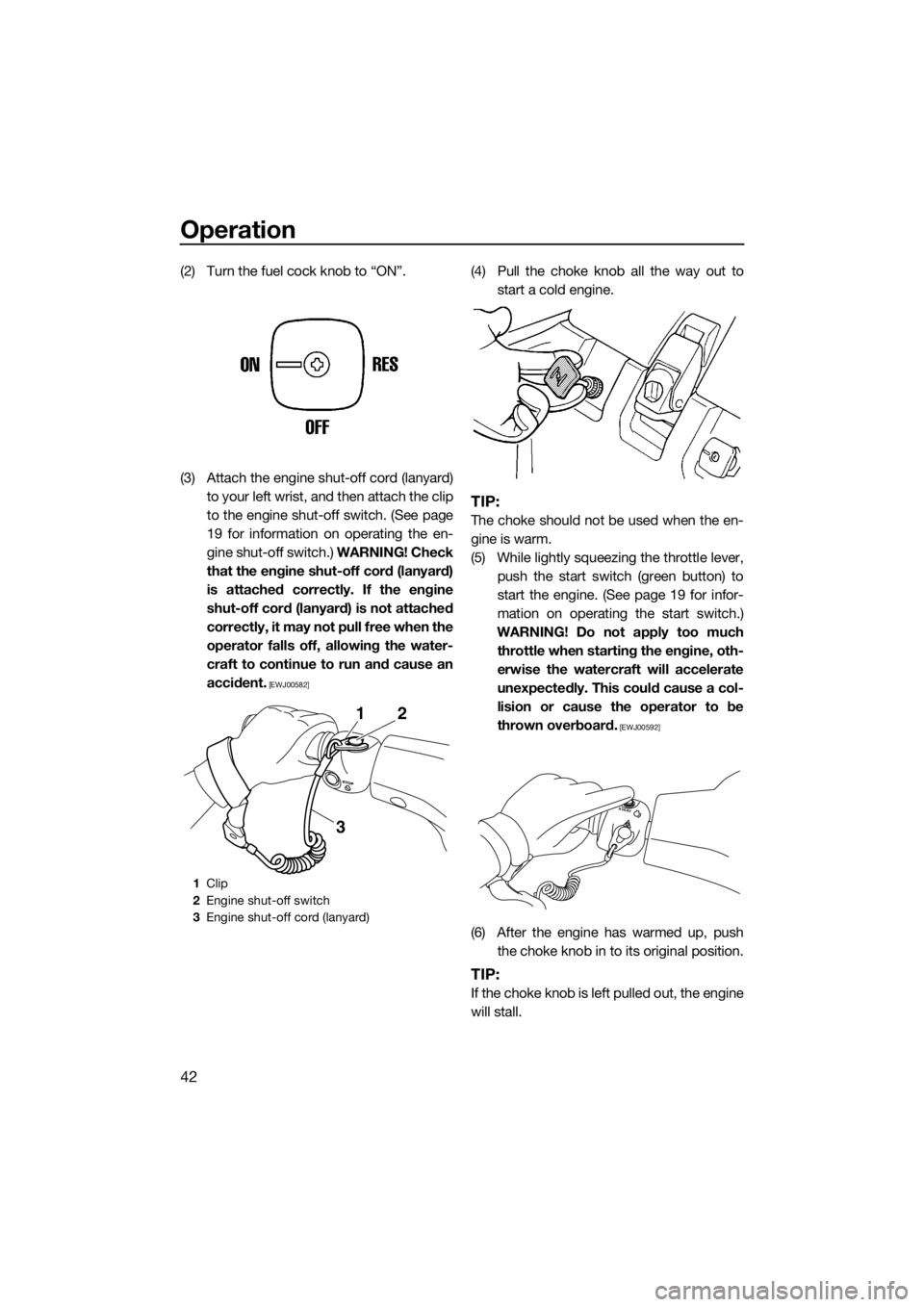

(2) Turn the fuel cock knob to “ON”.

(3) Attach the engine shut-off cord (lanyard)

to your left wrist, and then attach the clip

to the engine shut-off switch. (See page

19 for information on operating the en-

gine shut-off switch.) WARNING! Check

that the engine shut-off cord (lanyard)

is attached correctly. If the engine

shut-off cord (lanyard) is not attached

correctly, it may not pull free when the

operator falls off, allowing the water-

craft to continue to run and cause an

accident.

[EWJ00582]

(4) Pull the choke knob all the way out to

start a cold engine.

TIP:

The choke should not be used when the en-

gine is warm.

(5) While lightly squeezing the throttle lever,

push the start switch (green button) to

start the engine. (See page 19 for infor-

mation on operating the start switch.)

WARNING! Do not apply too much

throttle when starting the engine, oth-

erwise the watercraft will accelerate

unexpectedly. This could cause a col-

lision or cause the operator to be

thrown overboard.

[EWJ00592]

(6) After the engine has warmed up, push

the choke knob in to its original position.

TIP:

If the choke knob is left pulled out, the engine

will stall.

1Clip

2Engine shut-off switch

3Engine shut-off cord (lanyard)

12

3

START

UF4D73E0.book Page 42 Wednesday, March 23, 2016 11:40 AM

Page 57 of 78

Care and storage

51

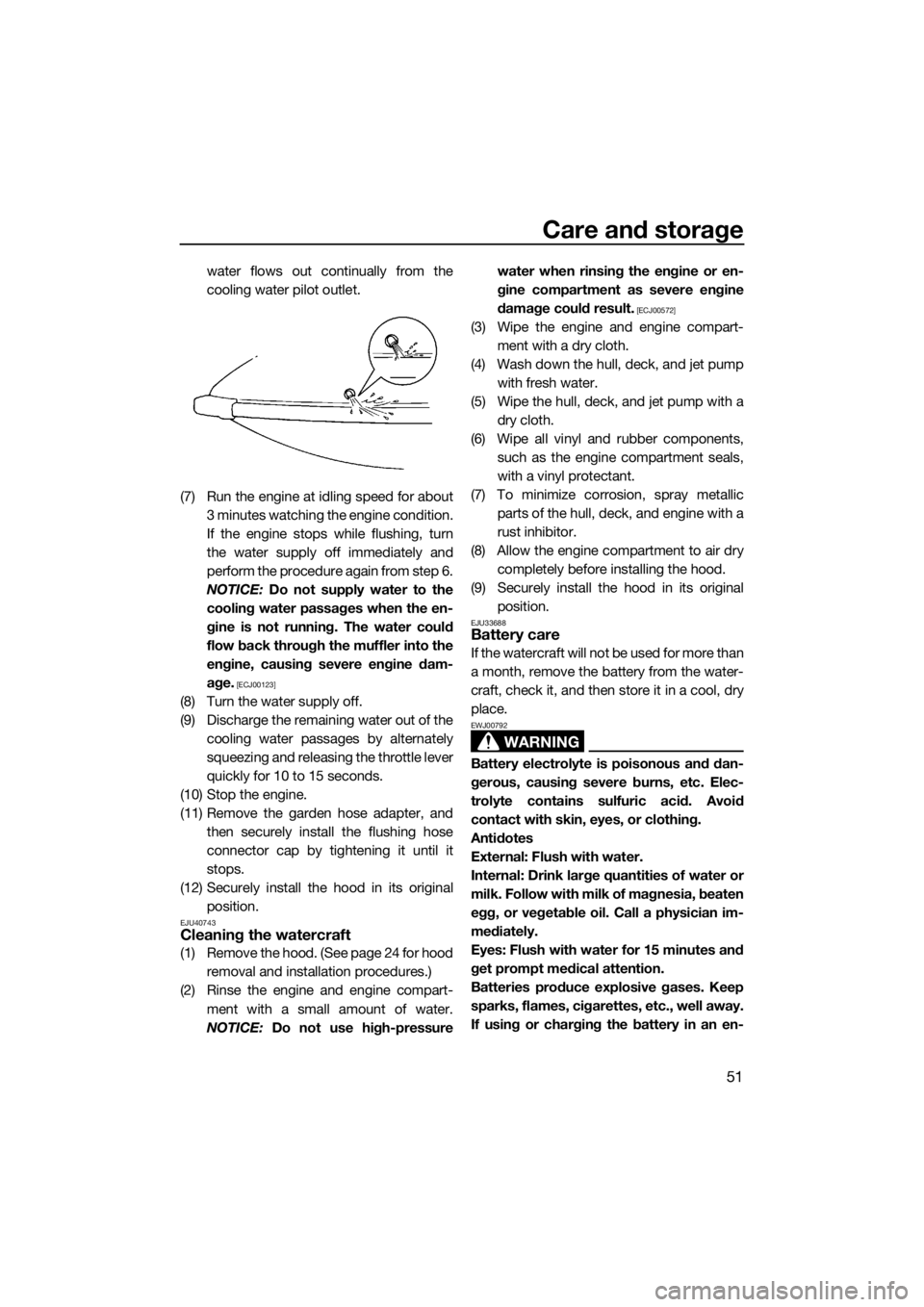

water flows out continually from the

cooling water pilot outlet.

(7) Run the engine at idling speed for about

3 minutes watching the engine condition.

If the engine stops while flushing, turn

the water supply off immediately and

perform the procedure again from step 6.

NOTICE: Do not supply water to the

cooling water passages when the en-

gine is not running. The water could

flow back through the muffler into the

engine, causing severe engine dam-

age.

[ECJ00123]

(8) Turn the water supply off.

(9) Discharge the remaining water out of the

cooling water passages by alternately

squeezing and releasing the throttle lever

quickly for 10 to 15 seconds.

(10) Stop the engine.

(11) Remove the garden hose adapter, and

then securely install the flushing hose

connector cap by tightening it until it

stops.

(12) Securely install the hood in its original

position.

EJU40743Cleaning the watercraft

(1) Remove the hood. (See page 24 for hood

removal and installation procedures.)

(2) Rinse the engine and engine compart-

ment with a small amount of water.

NOTICE: Do not use high-pressurewater when rinsing the engine or en-

gine compartment as severe engine

damage could result.

[ECJ00572]

(3) Wipe the engine and engine compart-

ment with a dry cloth.

(4) Wash down the hull, deck, and jet pump

with fresh water.

(5) Wipe the hull, deck, and jet pump with a

dry cloth.

(6) Wipe all vinyl and rubber components,

such as the engine compartment seals,

with a vinyl protectant.

(7) To minimize corrosion, spray metallic

parts of the hull, deck, and engine with a

rust inhibitor.

(8) Allow the engine compartment to air dry

completely before installing the hood.

(9) Securely install the hood in its original

position.

EJU33688Battery care

If the watercraft will not be used for more than

a month, remove the battery from the water-

craft, check it, and then store it in a cool, dry

place.

WARNING

EWJ00792

Battery electrolyte is poisonous and dan-

gerous, causing severe burns, etc. Elec-

trolyte contains sulfuric acid. Avoid

contact with skin, eyes, or clothing.

Antidotes

External: Flush with water.

Internal: Drink large quantities of water or

milk. Follow with milk of magnesia, beaten

egg, or vegetable oil. Call a physician im-

mediately.

Eyes: Flush with water for 15 minutes and

get prompt medical attention.

Batteries produce explosive gases. Keep

sparks, flames, cigarettes, etc., well away.

If using or charging the battery in an en-

UF4D73E0.book Page 51 Wednesday, March 23, 2016 11:40 AM

Page 62 of 78

Maintenance

56

EJU33769

Maintenance

Periodic checks and lubrication will keep

your watercraft in the safest and most effi-

cient condition possible. Therefore, make

sure to carry out the periodic maintenance.

Safety is an obligation of the watercraft own-

er. Proper maintenance must be carried out

to keep the exhaust emission and sound lev-

els within the regulated limits. The most im-

portant points of watercraft inspection and

lubrication are explained on the following pa-

ges.

See a Yamaha dealer for genuine Yamaha re-

placement parts and optional accessories

designed for your watercraft.

Remember, failures that are the result of the

installation of parts or accessories which are

not qualitatively equivalent to genuine

Yamaha parts are not covered by the limited

warranty.

Maintenance, replacement, or repair of

the emission control devices and system

may be performed by any marine SI engine

repair establishment or individual. War-

ranty repair, however, must be performed

at an authorized Yamaha marine dealer-

ship.

WARNING

EWJ00312

Be sure to turn off the engine when you

perform maintenance unless otherwise

specified. If you are not familiar with ma-

chine servicing, this work should be done

by a Yamaha dealer or other qualified me-

chanic.

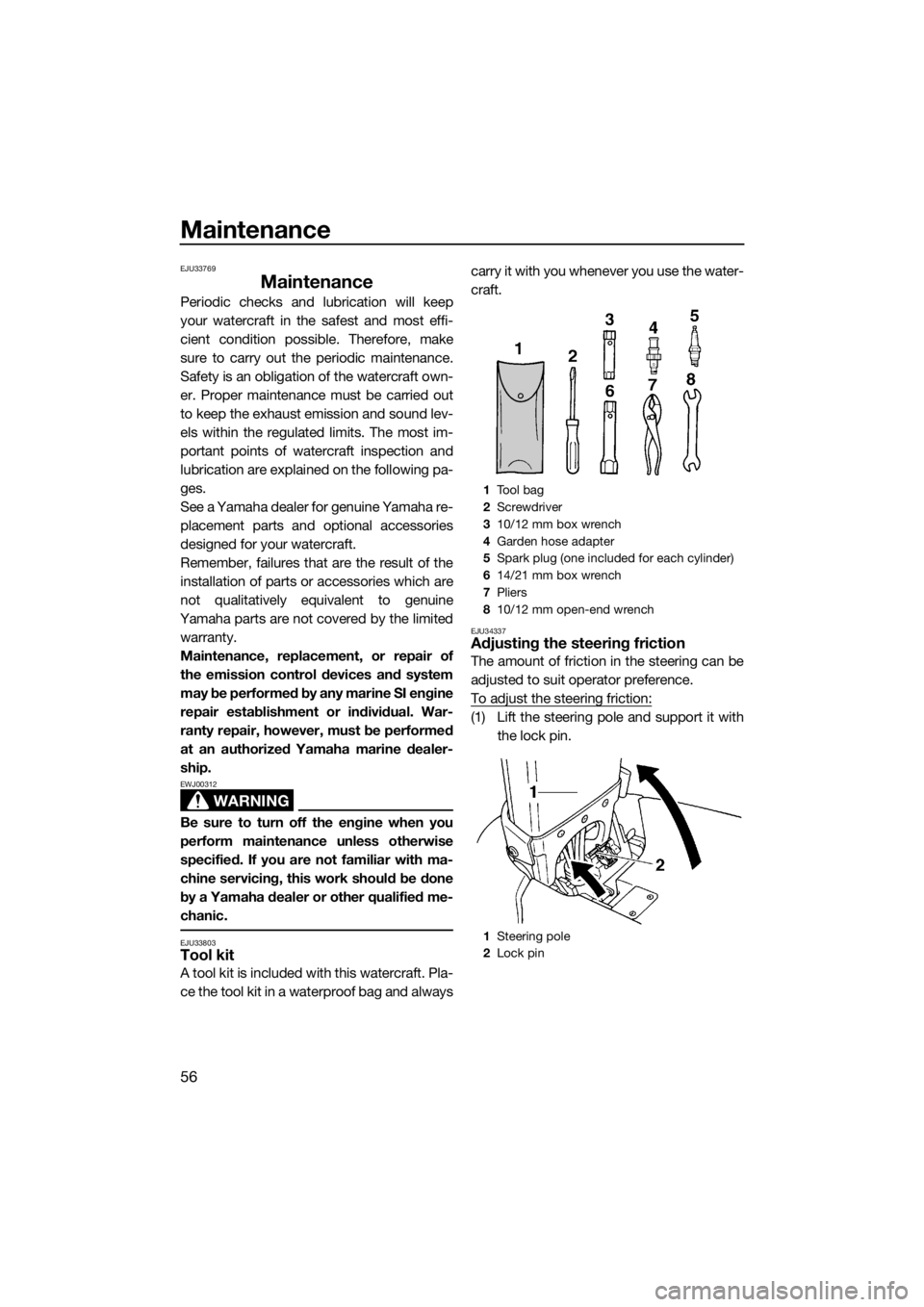

EJU33803Tool kit

A tool kit is included with this watercraft. Pla-

ce the tool kit in a waterproof bag and alwayscarry it with you whenever you use the water-

craft.

EJU34337Adjusting the steering friction

The amount of friction in the steering can be

adjusted to suit operator preference.

To adjust the steering friction:

(1) Lift the steering pole and support it with

the lock pin.

1Tool bag

2Screwdriver

310/12 mm box wrench

4Garden hose adapter

5Spark plug (one included for each cylinder)

614/21 mm box wrench

7Pliers

810/12 mm open-end wrench

1Steering pole

2Lock pin

UF4D73E0.book Page 56 Wednesday, March 23, 2016 11:40 AM

Page 65 of 78

Maintenance

59

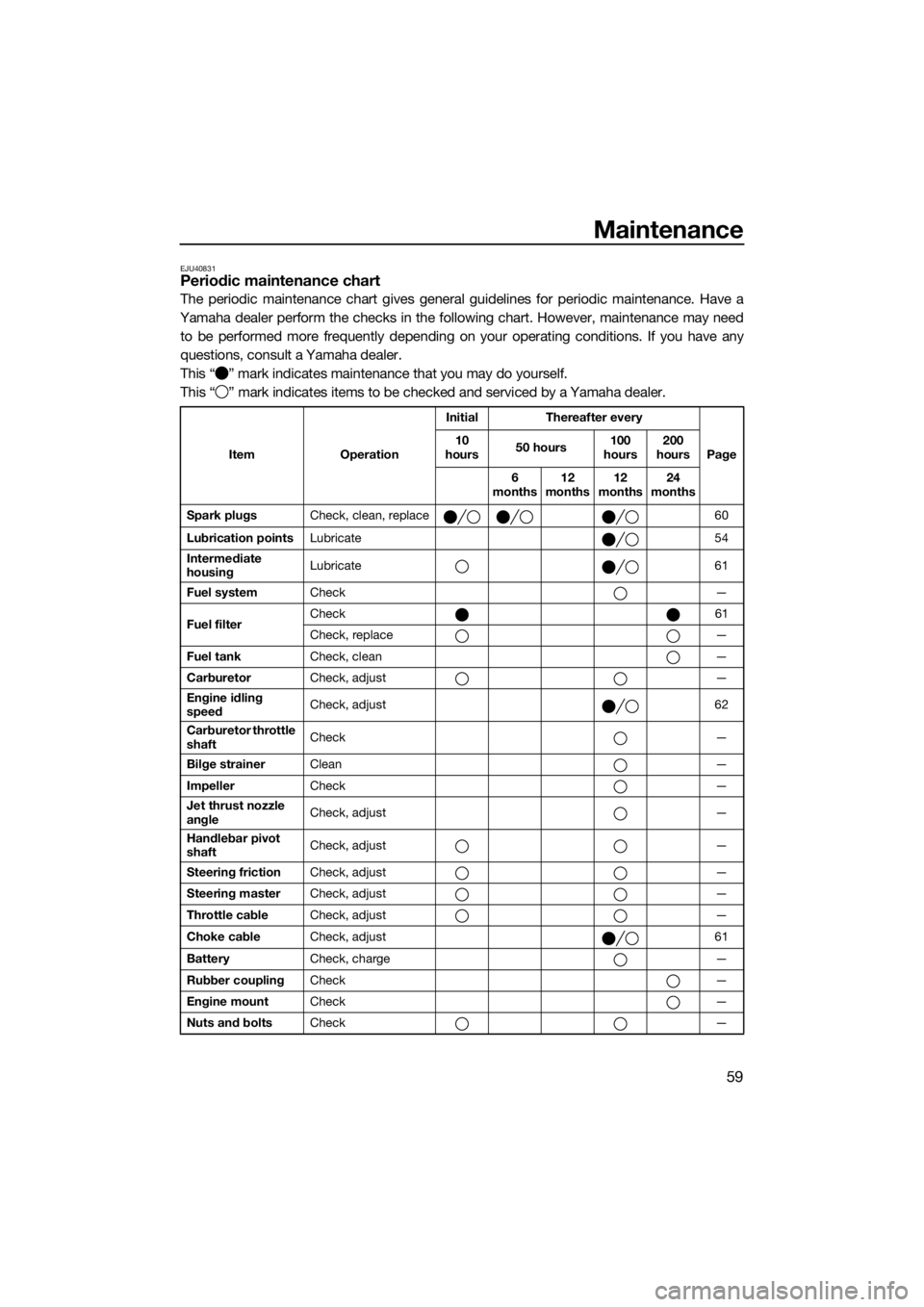

EJU40831Periodic maintenance chart

The periodic maintenance chart gives general guidelines for periodic maintenance. Have a

Yamaha dealer perform the checks in the following chart. However, maintenance may need

to be performed more frequently depending on your operating conditions. If you have any

questions, consult a Yamaha dealer.

This “ ” mark indicates maintenance that you may do yourself.

This “ ” mark indicates items to be checked and serviced by a Yamaha dealer.

Item OperationInitial Thereafter every

Page 10

hours50 hours100

hours200

hours

6

months12

months12

months24

months

Spark plugsCheck, clean, replace 60

Lubrication pointsLubricate 54

Intermediate

housingLubricate 61

Fuel systemCheck —

Fuel filterCheck 61

Check, replace —

Fuel tankCheck, clean —

CarburetorCheck, adjust —

Engine idling

speedCheck, adjust 62

Carburetor throttle

shaftCheck —

Bilge strainerClean —

ImpellerCheck —

Jet thrust nozzle

angleCheck, adjust —

Handlebar pivot

shaftCheck, adjust —

Steering frictionCheck, adjust —

Steering masterCheck, adjust —

Throttle cableCheck, adjust —

Choke cableCheck, adjust 61

BatteryCheck, charge —

Rubber couplingCheck —

Engine mountCheck —

Nuts and boltsCheck —

UF4D73E0.book Page 59 Wednesday, March 23, 2016 11:40 AM

Page 66 of 78

Maintenance

60

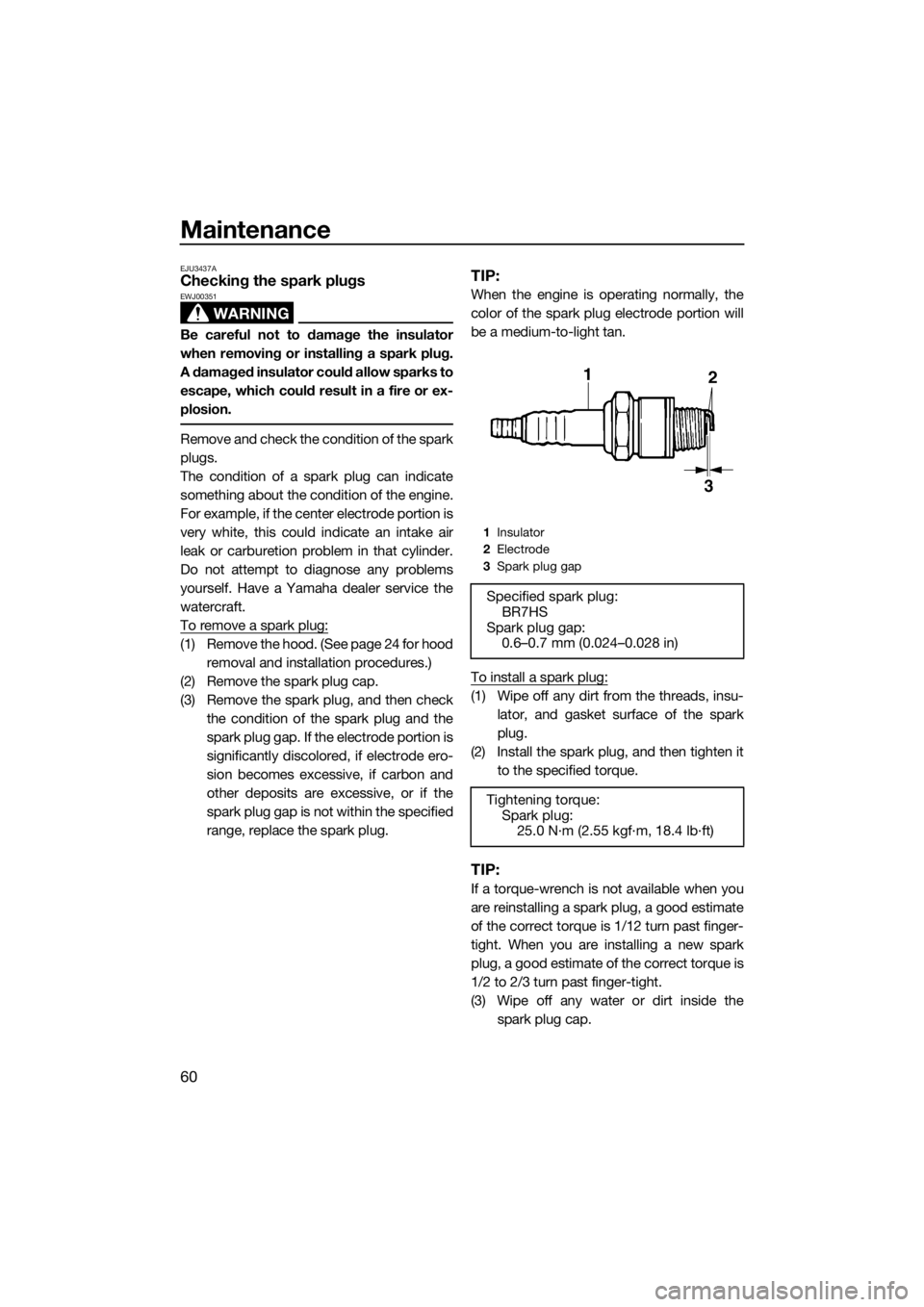

EJU3437AChecking the spark plugs

WARNING

EWJ00351

Be careful not to damage the insulator

when removing or installing a spark plug.

A damaged insulator could allow sparks to

escape, which could result in a fire or ex-

plosion.

Remove and check the condition of the spark

plugs.

The condition of a spark plug can indicate

something about the condition of the engine.

For example, if the center electrode portion is

very white, this could indicate an intake air

leak or carburetion problem in that cylinder.

Do not attempt to diagnose any problems

yourself. Have a Yamaha dealer service the

watercraft.

To remove a spark plug:

(1) Remove the hood. (See page 24 for hood

removal and installation procedures.)

(2) Remove the spark plug cap.

(3) Remove the spark plug, and then check

the condition of the spark plug and the

spark plug gap. If the electrode portion is

significantly discolored, if electrode ero-

sion becomes excessive, if carbon and

other deposits are excessive, or if the

spark plug gap is not within the specified

range, replace the spark plug.

TIP:

When the engine is operating normally, the

color of the spark plug electrode portion will

be a medium-to-light tan.

To install a spark plug:

(1) Wipe off any dirt from the threads, insu-

lator, and gasket surface of the spark

plug.

(2) Install the spark plug, and then tighten it

to the specified torque.

TIP:

If a torque-wrench is not available when you

are reinstalling a spark plug, a good estimate

of the correct torque is 1/12 turn past finger-

tight. When you are installing a new spark

plug, a good estimate of the correct torque is

1/2 to 2/3 turn past finger-tight.

(3) Wipe off any water or dirt inside the

spark plug cap.

1Insulator

2Electrode

3Spark plug gap

Specified spark plug:

BR7HS

Spark plug gap:

0.6–0.7 mm (0.024–0.028 in)

Tightening torque:

Spark plug:

25.0 N·m (2.55 kgf·m, 18.4 lb·ft)

UF4D73E0.book Page 60 Wednesday, March 23, 2016 11:40 AM

Page 70 of 78

Trouble recovery

64

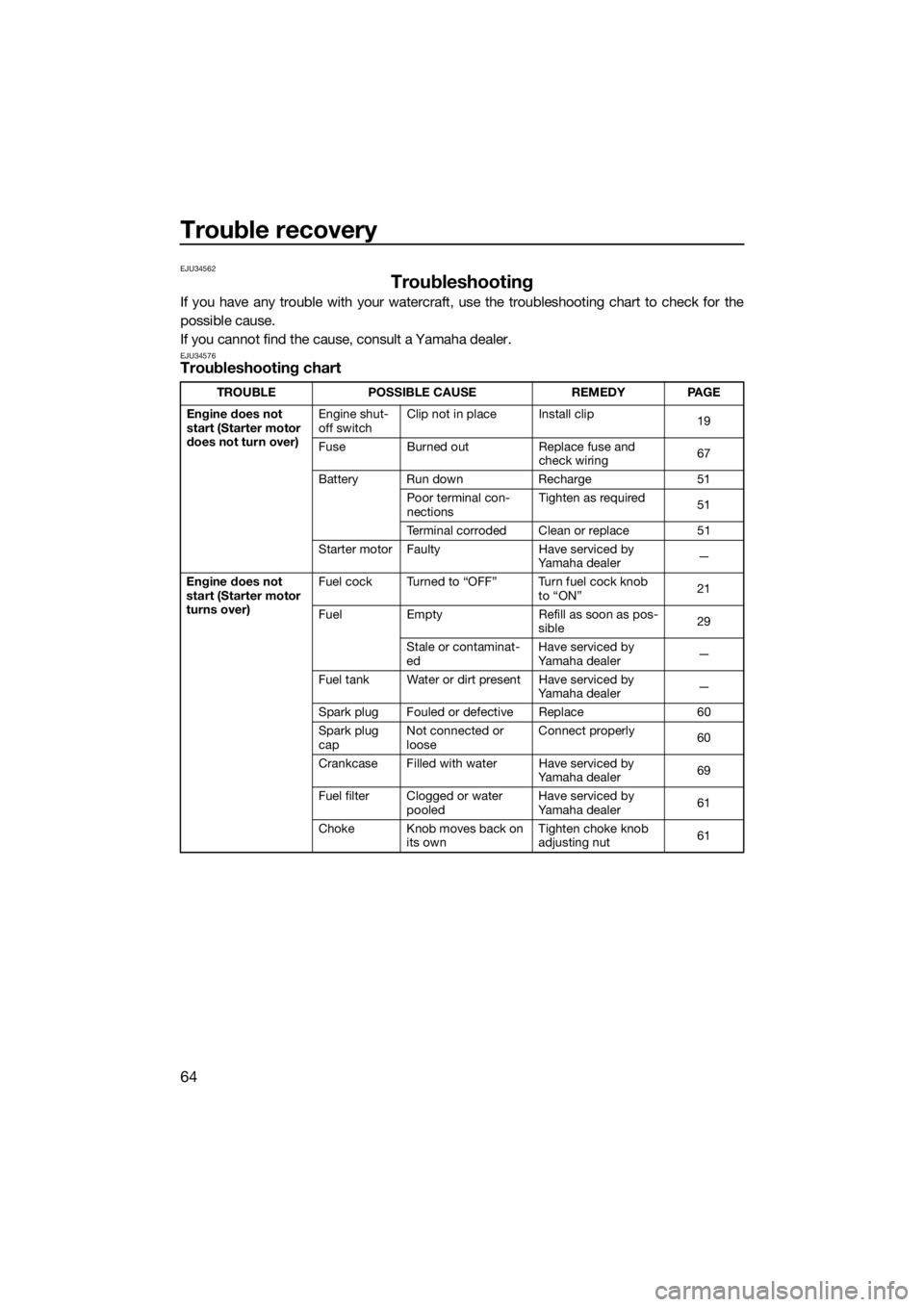

EJU34562

Troubleshooting

If you have any trouble with your watercraft, use the troubleshooting chart to check for the

possible cause.

If you cannot find the cause, consult a Yamaha dealer.

EJU34576Troubleshooting chart

TROUBLE POSSIBLE CAUSE REMEDY PAGE

Engine does not

start (Starter motor

does not turn over)Engine shut-

off switchClip not in place Install clip

19

Fuse Burned out Replace fuse and

check wiring67

Battery Run down Recharge 51

Poor terminal con-

nectionsTighten as required

51

Terminal corroded Clean or replace 51

Starter motor Faulty Have serviced by

Yamaha dealer—

Engine does not

start (Starter motor

turns over)Fuel cock Turned to “OFF” Turn fuel cock knob

to “ON”21

Fuel Empty Refill as soon as pos-

sible29

Stale or contaminat-

edHave serviced by

Yamaha dealer—

Fuel tank Water or dirt present Have serviced by

Yamaha dealer—

Spark plug Fouled or defective Replace 60

Spark plug

capNot connected or

looseConnect properly

60

Crankcase Filled with water Have serviced by

Yamaha dealer69

Fuel filter Clogged or water

pooledHave serviced by

Yamaha dealer61

Choke Knob moves back on

its ownTighten choke knob

adjusting nut61

UF4D73E0.book Page 64 Wednesday, March 23, 2016 11:40 AM

Page 72 of 78

Trouble recovery

66

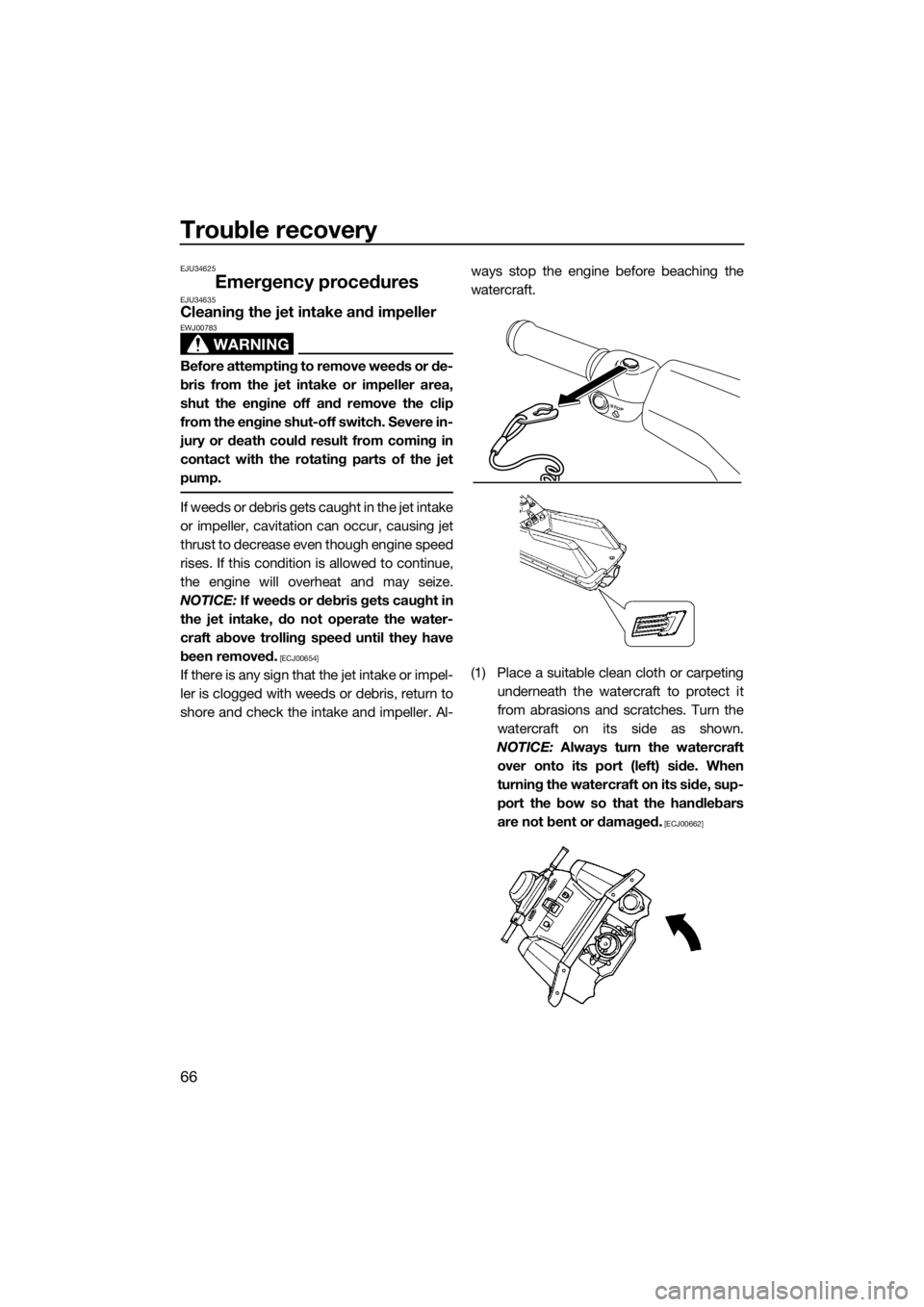

EJU34625

Emergency proceduresEJU34635Cleaning the jet intake and impeller

WARNING

EWJ00783

Before attempting to remove weeds or de-

bris from the jet intake or impeller area,

shut the engine off and remove the clip

from the engine shut-off switch. Severe in-

jury or death could result from coming in

contact with the rotating parts of the jet

pump.

If weeds or debris gets caught in the jet intake

or impeller, cavitation can occur, causing jet

thrust to decrease even though engine speed

rises. If this condition is allowed to continue,

the engine will overheat and may seize.

NOTICE: If weeds or debris gets caught in

the jet intake, do not operate the water-

craft above trolling speed until they have

been removed.

[ECJ00654]

If there is any sign that the jet intake or impel-

ler is clogged with weeds or debris, return to

shore and check the intake and impeller. Al-ways stop the engine before beaching the

watercraft.

(1) Place a suitable clean cloth or carpeting

underneath the watercraft to protect it

from abrasions and scratches. Turn the

watercraft on its side as shown.

NOTICE: Always turn the watercraft

over onto its port (left) side. When

turning the watercraft on its side, sup-

port the bow so that the handlebars

are not bent or damaged.

[ECJ00662]

STOP

UF4D73E0.book Page 66 Wednesday, March 23, 2016 11:40 AM

Page 76 of 78

70

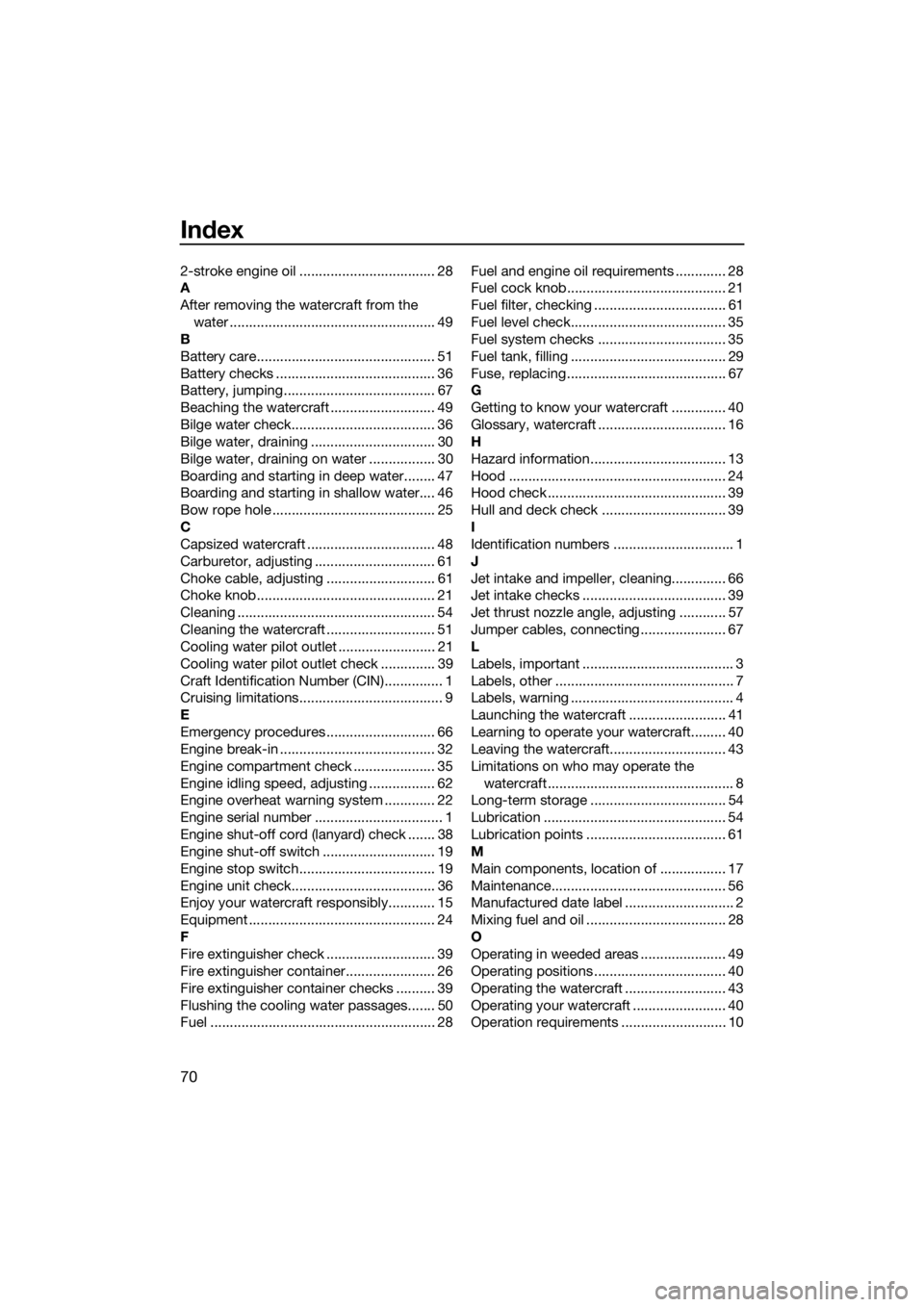

Index

2-stroke engine oil ................................... 28

A

After removing the watercraft from the

water ..................................................... 49

B

Battery care.............................................. 51

Battery checks ......................................... 36

Battery, jumping ....................................... 67

Beaching the watercraft ........................... 49

Bilge water check..................................... 36

Bilge water, draining ................................ 30

Bilge water, draining on water ................. 30

Boarding and starting in deep water........ 47

Boarding and starting in shallow water.... 46

Bow rope hole .......................................... 25

C

Capsized watercraft ................................. 48

Carburetor, adjusting ............................... 61

Choke cable, adjusting ............................ 61

Choke knob.............................................. 21

Cleaning ................................................... 54

Cleaning the watercraft ............................ 51

Cooling water pilot outlet ......................... 21

Cooling water pilot outlet check .............. 39

Craft Identification Number (CIN)............... 1

Cruising limitations..................................... 9

E

Emergency procedures ............................ 66

Engine break-in ........................................ 32

Engine compartment check ..................... 35

Engine idling speed, adjusting ................. 62

Engine overheat warning system ............. 22

Engine serial number ................................. 1

Engine shut-off cord (lanyard) check ....... 38

Engine shut-off switch ............................. 19

Engine stop switch................................... 19

Engine unit check..................................... 36

Enjoy your watercraft responsibly............ 15

Equipment ................................................ 24

F

Fire extinguisher check ............................ 39

Fire extinguisher container....................... 26

Fire extinguisher container checks .......... 39

Flushing the cooling water passages....... 50

Fuel .......................................................... 28Fuel and engine oil requirements ............. 28

Fuel cock knob......................................... 21

Fuel filter, checking .................................. 61

Fuel level check........................................ 35

Fuel system checks ................................. 35

Fuel tank, filling ........................................ 29

Fuse, replacing ......................................... 67

G

Getting to know your watercraft .............. 40

Glossary, watercraft ................................. 16

H

Hazard information................................... 13

Hood ........................................................ 24

Hood check .............................................. 39

Hull and deck check ................................ 39

I

Identification numbers ............................... 1

J

Jet intake and impeller, cleaning.............. 66

Jet intake checks ..................................... 39

Jet thrust nozzle angle, adjusting ............ 57

Jumper cables, connecting ...................... 67

L

Labels, important ....................................... 3

Labels, other .............................................. 7

Labels, warning .......................................... 4

Launching the watercraft ......................... 41

Learning to operate your watercraft......... 40

Leaving the watercraft.............................. 43

Limitations on who may operate the

watercraft ................................................ 8

Long-term storage ................................... 54

Lubrication ............................................... 54

Lubrication points .................................... 61

M

Main components, location of ................. 17

Maintenance............................................. 56

Manufactured date label ............................ 2

Mixing fuel and oil .................................... 28

O

Operating in weeded areas ...................... 49

Operating positions .................................. 40

Operating the watercraft .......................... 43

Operating your watercraft ........................ 40

Operation requirements ........................... 10

UF4D73E0.book Page 70 Wednesday, March 23, 2016 11:40 AM