warning YAMAHA SUPERJET 2017 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2017, Model line: SUPERJET, Model: YAMAHA SUPERJET 2017Pages: 78, PDF Size: 2.66 MB

Page 56 of 78

Care and storage

50

EJU41192

Post-operation care

WARNING

EWJ00321

Always turn the fuel cock knob to “OFF”

when storing the watercraft, otherwise

fuel could leak out into the engine or en-

gine compartment, which would create a

fire hazard.

After using the watercraft, always take it out

of the water, clean it, and store it. Leaving the

watercraft in the water for extended periods

will accelerate the rate of normal deteriora-

tion of the jet pump and hull. Marine organ-

isms and corrosion are some of the

conditions that can shorten the life of many

watercraft components.

EJU3351AFlushing the cooling water passages

NOTICE

ECJ01361

Do not run the engine for more than 15

seconds on land without supplying water,

otherwise the engine could overheat.

Flush the cooling water passages to prevent

them from clogging with salt, sand, or dirt.

(1) Place the watercraft in a horizontal posi-

tion.

(2) Remove the hood. (See page 24 for hood

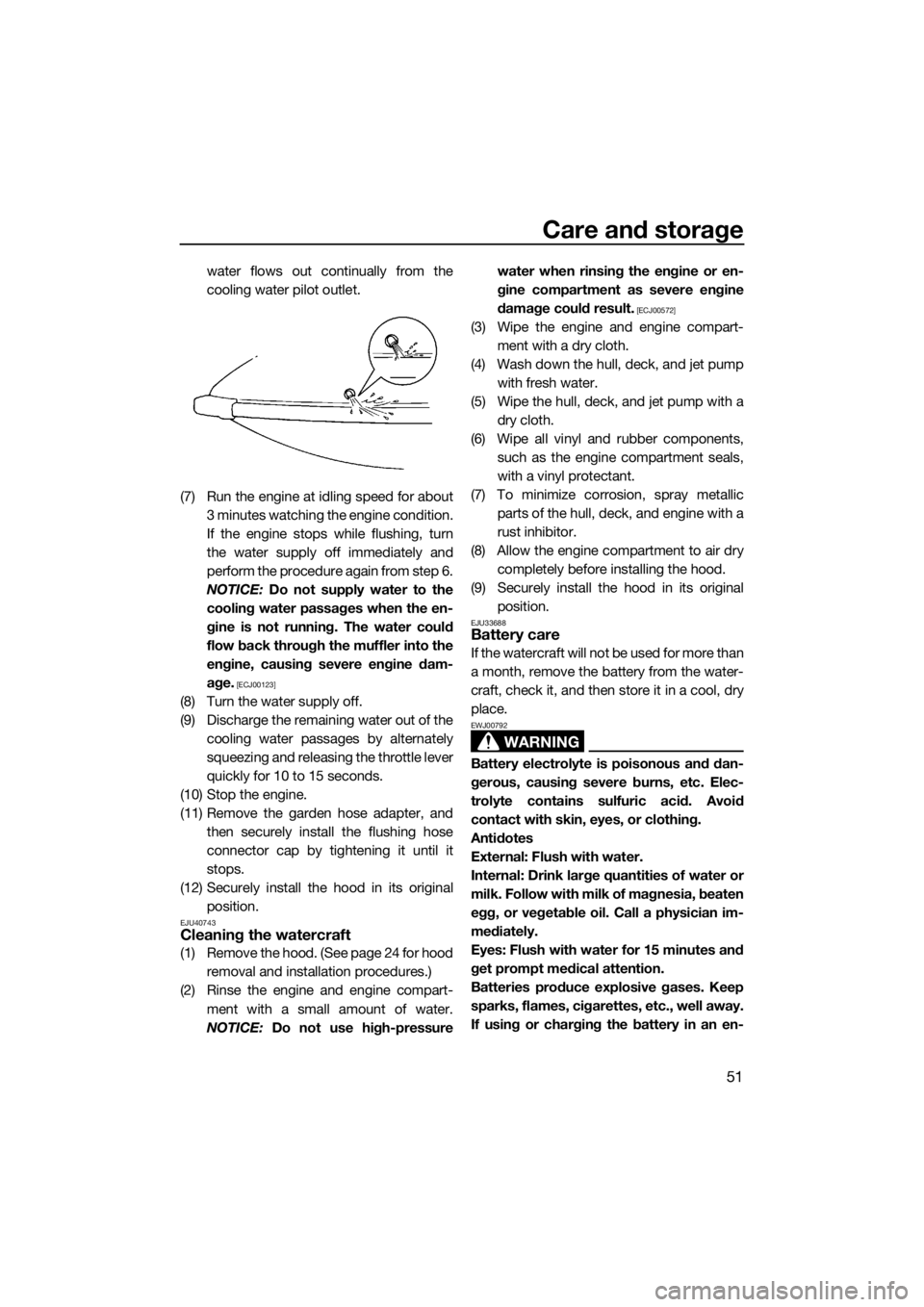

removal and installation procedures.)(3) Connect the garden hose adapter to a

garden hose.

(4) Loosen the flushing hose connector cap

and remove it. Insert the garden hose

adapter into the flushing hose connector

by pushing and twisting it until it is se-

curely connected.

(5) Connect the garden hose to a water tap.

(6) Make sure that the area around the wa-

tercraft is clear, and then start the en-

gine. Immediately after the engine starts,

turn the water supply on gradually until

1Garden hose adapter

1Flushing hose connector

2Flushing hose connector cap

3Garden hose adapter

UF4D73E0.book Page 50 Wednesday, March 23, 2016 11:40 AM

Page 57 of 78

Care and storage

51

water flows out continually from the

cooling water pilot outlet.

(7) Run the engine at idling speed for about

3 minutes watching the engine condition.

If the engine stops while flushing, turn

the water supply off immediately and

perform the procedure again from step 6.

NOTICE: Do not supply water to the

cooling water passages when the en-

gine is not running. The water could

flow back through the muffler into the

engine, causing severe engine dam-

age.

[ECJ00123]

(8) Turn the water supply off.

(9) Discharge the remaining water out of the

cooling water passages by alternately

squeezing and releasing the throttle lever

quickly for 10 to 15 seconds.

(10) Stop the engine.

(11) Remove the garden hose adapter, and

then securely install the flushing hose

connector cap by tightening it until it

stops.

(12) Securely install the hood in its original

position.

EJU40743Cleaning the watercraft

(1) Remove the hood. (See page 24 for hood

removal and installation procedures.)

(2) Rinse the engine and engine compart-

ment with a small amount of water.

NOTICE: Do not use high-pressurewater when rinsing the engine or en-

gine compartment as severe engine

damage could result.

[ECJ00572]

(3) Wipe the engine and engine compart-

ment with a dry cloth.

(4) Wash down the hull, deck, and jet pump

with fresh water.

(5) Wipe the hull, deck, and jet pump with a

dry cloth.

(6) Wipe all vinyl and rubber components,

such as the engine compartment seals,

with a vinyl protectant.

(7) To minimize corrosion, spray metallic

parts of the hull, deck, and engine with a

rust inhibitor.

(8) Allow the engine compartment to air dry

completely before installing the hood.

(9) Securely install the hood in its original

position.

EJU33688Battery care

If the watercraft will not be used for more than

a month, remove the battery from the water-

craft, check it, and then store it in a cool, dry

place.

WARNING

EWJ00792

Battery electrolyte is poisonous and dan-

gerous, causing severe burns, etc. Elec-

trolyte contains sulfuric acid. Avoid

contact with skin, eyes, or clothing.

Antidotes

External: Flush with water.

Internal: Drink large quantities of water or

milk. Follow with milk of magnesia, beaten

egg, or vegetable oil. Call a physician im-

mediately.

Eyes: Flush with water for 15 minutes and

get prompt medical attention.

Batteries produce explosive gases. Keep

sparks, flames, cigarettes, etc., well away.

If using or charging the battery in an en-

UF4D73E0.book Page 51 Wednesday, March 23, 2016 11:40 AM

Page 59 of 78

Care and storage

53

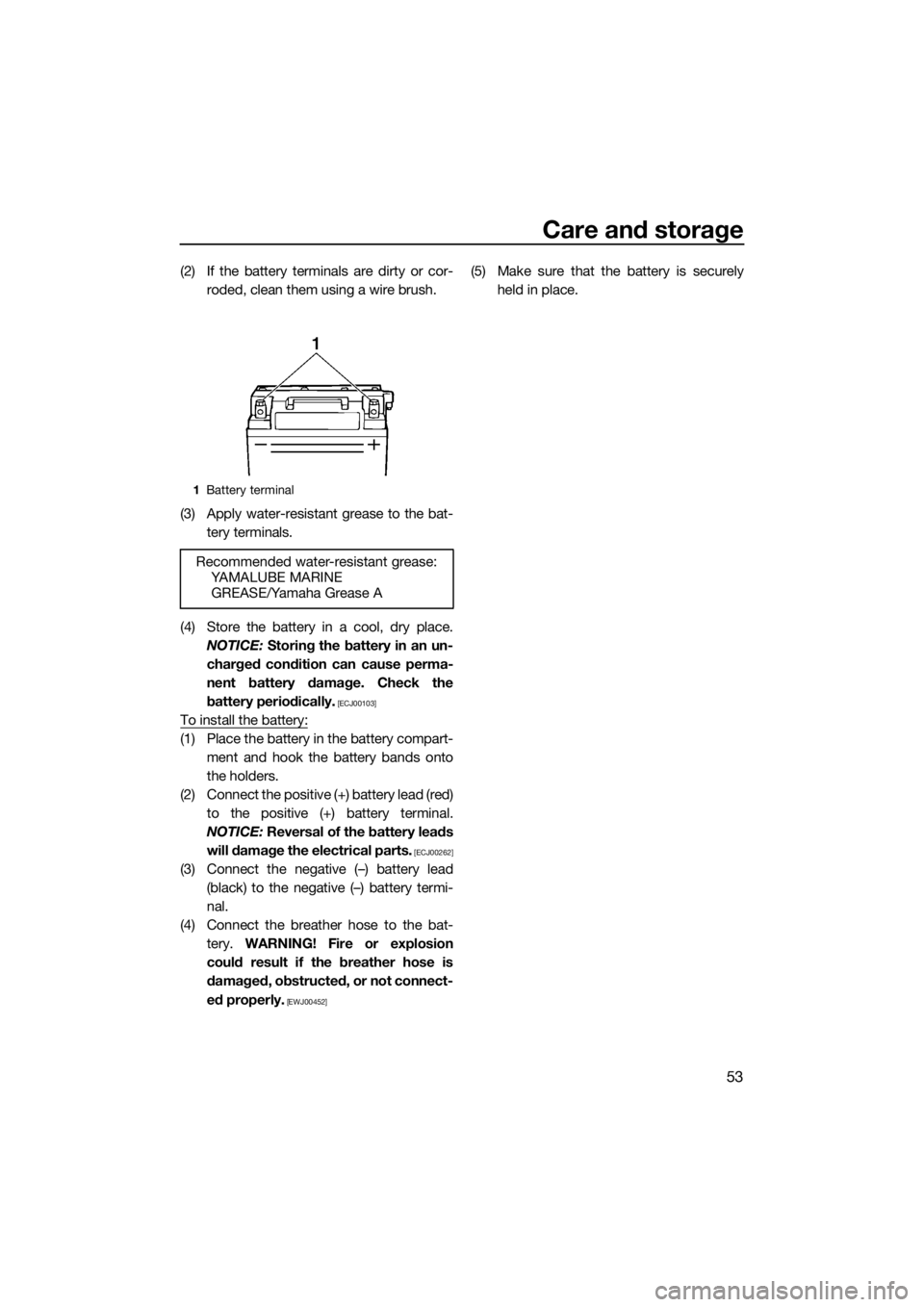

(2) If the battery terminals are dirty or cor-

roded, clean them using a wire brush.

(3) Apply water-resistant grease to the bat-

tery terminals.

(4) Store the battery in a cool, dry place.

NOTICE: Storing the battery in an un-

charged condition can cause perma-

nent battery damage. Check the

battery periodically.

[ECJ00103]

To install the battery:

(1) Place the battery in the battery compart-

ment and hook the battery bands onto

the holders.

(2) Connect the positive (+) battery lead (red)

to the positive (+) battery terminal.

NOTICE: Reversal of the battery leads

will damage the electrical parts.

[ECJ00262]

(3) Connect the negative (–) battery lead

(black) to the negative (–) battery termi-

nal.

(4) Connect the breather hose to the bat-

tery. WARNING! Fire or explosion

could result if the breather hose is

damaged, obstructed, or not connect-

ed properly.

[EWJ00452]

(5) Make sure that the battery is securely

held in place.

1Battery terminal

Recommended water-resistant grease:

YAMALUBE MARINE

GREASE/Yamaha Grease A

UF4D73E0.book Page 53 Wednesday, March 23, 2016 11:40 AM

Page 60 of 78

Care and storage

54

EJU33484

Long-term storage

WARNING

EWJ00321

Always turn the fuel cock knob to “OFF”

when storing the watercraft, otherwise

fuel could leak out into the engine or en-

gine compartment, which would create a

fire hazard.

Storage for long periods of time, such as win-

ter storage, requires preventive maintenance

to ensure against deterioration. It is advisable

to have the watercraft serviced by a Yamaha

dealer prior to storage.

However, the following procedures can be

performed easily by the owner.

EJU40763Cleaning

(1) Flush the cooling water passages. (See

page 50 for information on flushing the

cooling water passages.)

TIP:

If you will be storing the watercraft for a pro-

longed period, such as winter storage, top off

the fuel tank with fresh gasoline and add fuel

stabilizer and conditioner to the fuel tank ac-

cording to the manufacturer’s instruction be-

fore starting the engine.

(2) Clean the watercraft. (See page 51 for in-

formation on cleaning the watercraft.)

Wax the hull with a non-abrasive wax.

EJU40795Lubrication

Use a suitable marine grease applicator and

spray a rust inhibitor between the inner and

outer cables to lubricate the cables and

purge out any dirt and moisture.

To keep moving parts sliding or rotating

smoothly, lubricate them with water-resistant

grease.

Throttle cable (carburetor end) and choke

cable (carburetor end)

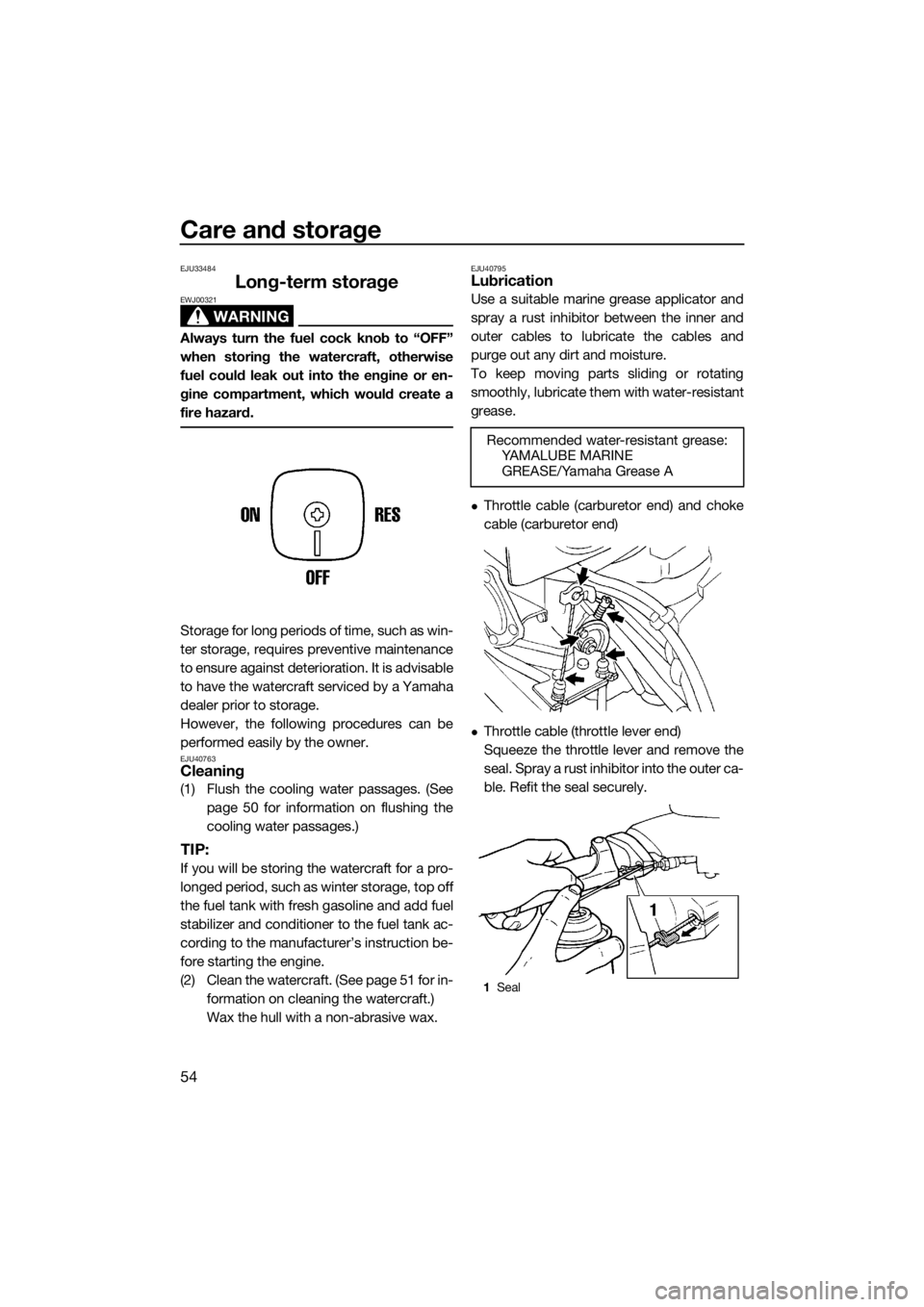

Throttle cable (throttle lever end)

Squeeze the throttle lever and remove the

seal. Spray a rust inhibitor into the outer ca-

ble. Refit the seal securely.

Recommended water-resistant grease:

YAMALUBE MARINE

GREASE/Yamaha Grease A

1Seal

UF4D73E0.book Page 54 Wednesday, March 23, 2016 11:40 AM

Page 61 of 78

Care and storage

55

Steering cable ball joint (handlebar end)

and steering cable inner wire (handlebar

end)

To access the steering cable ball joint (han-

dlebar end) and steering cable inner wire

(handlebar end), remove the steering pole

cover. (See step 1 in “Adjusting the jet

thrust nozzle angle” on page 57 for infor-

mation on removing the steering pole cov-

er.)

Steering cable ball joint (jet thrust nozzle

end) and steering cable inner wire (jet

thrust nozzle end)

EJU40944Rustproofing

NOTICE

ECJ01361

Do not run the engine for more than 15

seconds on land without supplying water,

otherwise the engine could overheat.

Spray metallic parts of the hull and engine

with a rust inhibitor.

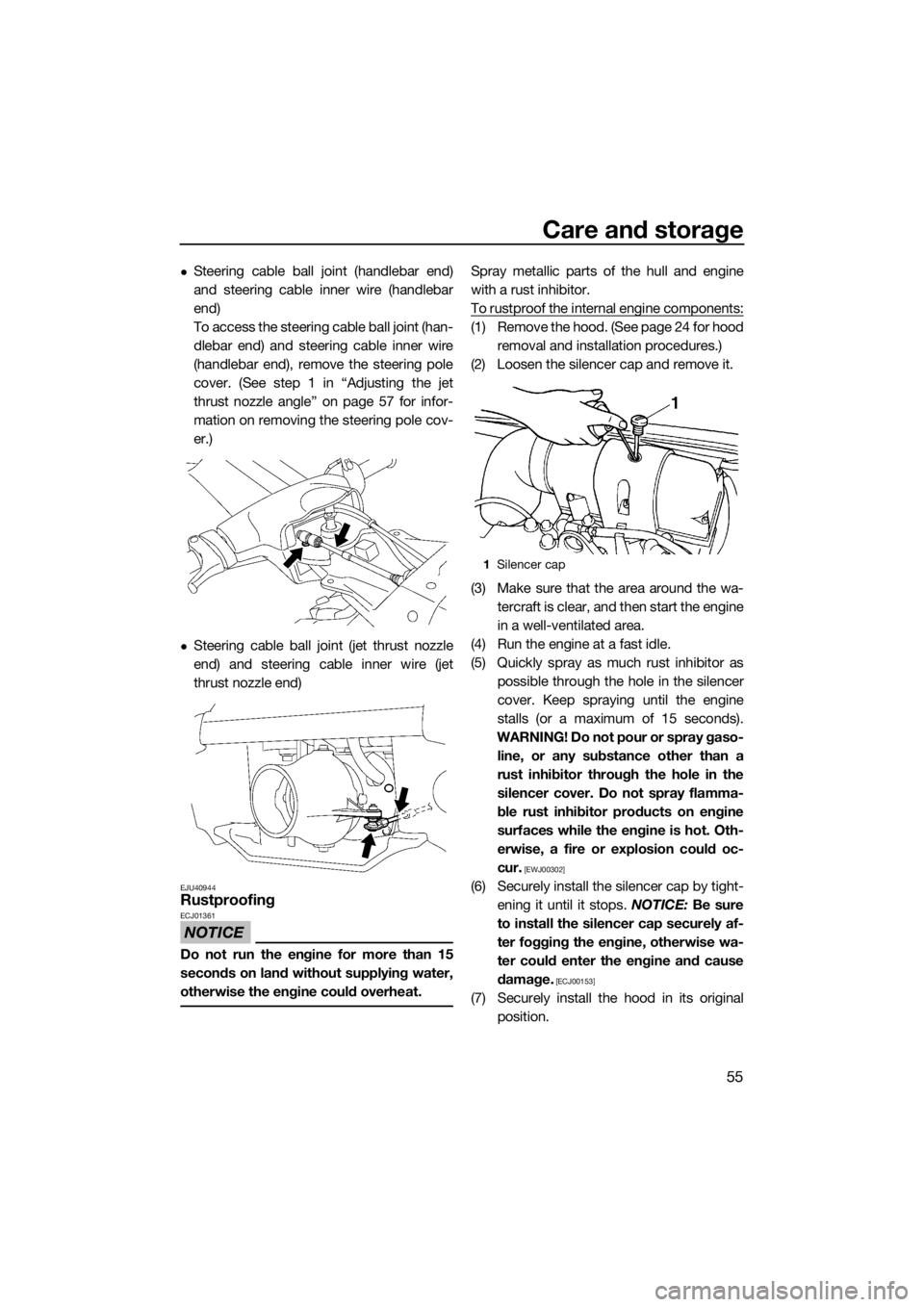

To rustproof the internal engine components:

(1) Remove the hood. (See page 24 for hood

removal and installation procedures.)

(2) Loosen the silencer cap and remove it.

(3) Make sure that the area around the wa-

tercraft is clear, and then start the engine

in a well-ventilated area.

(4) Run the engine at a fast idle.

(5) Quickly spray as much rust inhibitor as

possible through the hole in the silencer

cover. Keep spraying until the engine

stalls (or a maximum of 15 seconds).

WARNING! Do not pour or spray gaso-

line, or any substance other than a

rust inhibitor through the hole in the

silencer cover. Do not spray flamma-

ble rust inhibitor products on engine

surfaces while the engine is hot. Oth-

erwise, a fire or explosion could oc-

cur.

[EWJ00302]

(6) Securely install the silencer cap by tight-

ening it until it stops. NOTICE: Be sure

to install the silencer cap securely af-

ter fogging the engine, otherwise wa-

ter could enter the engine and cause

damage.

[ECJ00153]

(7) Securely install the hood in its original

position.

1Silencer cap

UF4D73E0.book Page 55 Wednesday, March 23, 2016 11:40 AM

Page 62 of 78

Maintenance

56

EJU33769

Maintenance

Periodic checks and lubrication will keep

your watercraft in the safest and most effi-

cient condition possible. Therefore, make

sure to carry out the periodic maintenance.

Safety is an obligation of the watercraft own-

er. Proper maintenance must be carried out

to keep the exhaust emission and sound lev-

els within the regulated limits. The most im-

portant points of watercraft inspection and

lubrication are explained on the following pa-

ges.

See a Yamaha dealer for genuine Yamaha re-

placement parts and optional accessories

designed for your watercraft.

Remember, failures that are the result of the

installation of parts or accessories which are

not qualitatively equivalent to genuine

Yamaha parts are not covered by the limited

warranty.

Maintenance, replacement, or repair of

the emission control devices and system

may be performed by any marine SI engine

repair establishment or individual. War-

ranty repair, however, must be performed

at an authorized Yamaha marine dealer-

ship.

WARNING

EWJ00312

Be sure to turn off the engine when you

perform maintenance unless otherwise

specified. If you are not familiar with ma-

chine servicing, this work should be done

by a Yamaha dealer or other qualified me-

chanic.

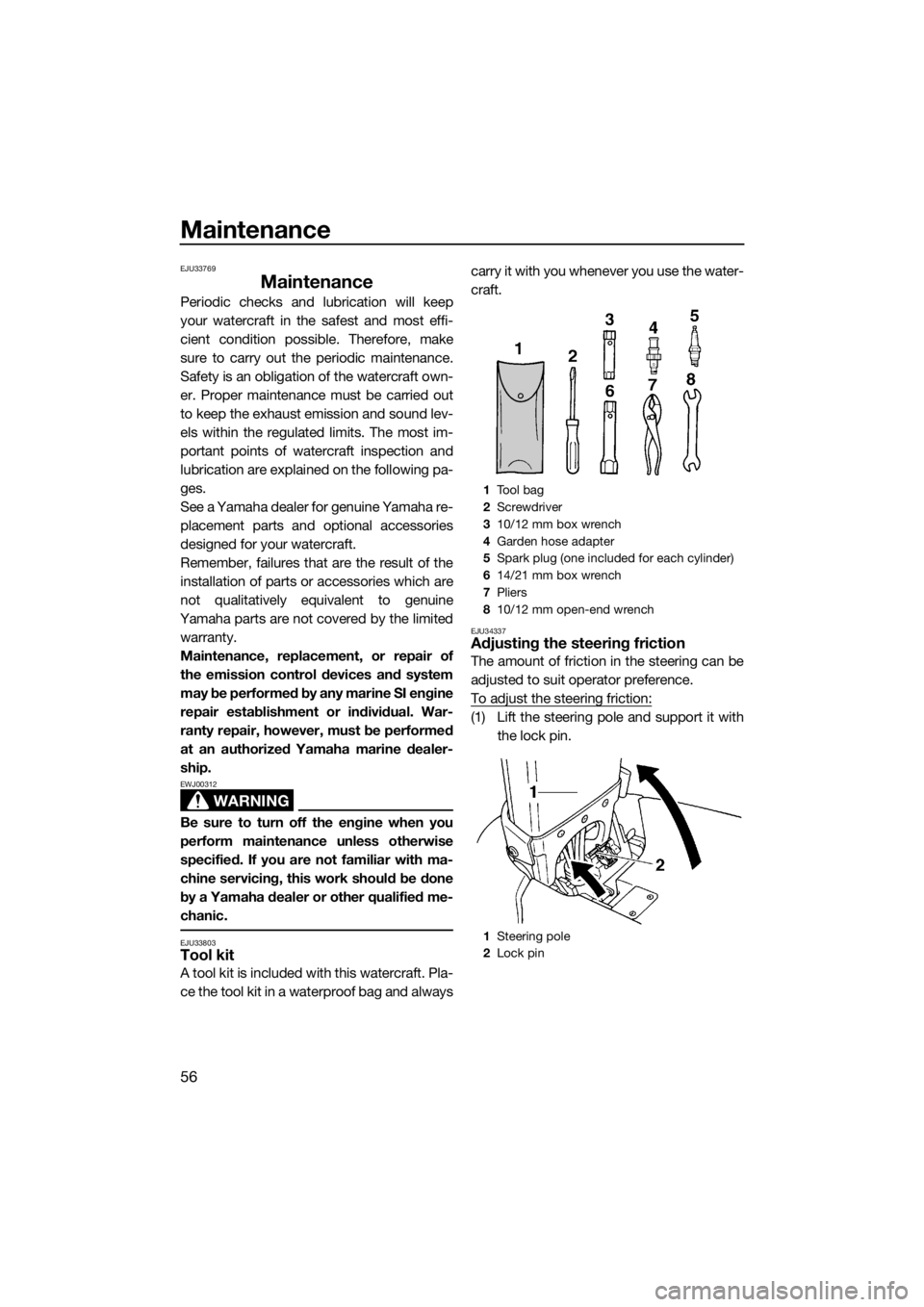

EJU33803Tool kit

A tool kit is included with this watercraft. Pla-

ce the tool kit in a waterproof bag and alwayscarry it with you whenever you use the water-

craft.

EJU34337Adjusting the steering friction

The amount of friction in the steering can be

adjusted to suit operator preference.

To adjust the steering friction:

(1) Lift the steering pole and support it with

the lock pin.

1Tool bag

2Screwdriver

310/12 mm box wrench

4Garden hose adapter

5Spark plug (one included for each cylinder)

614/21 mm box wrench

7Pliers

810/12 mm open-end wrench

1Steering pole

2Lock pin

UF4D73E0.book Page 56 Wednesday, March 23, 2016 11:40 AM

Page 66 of 78

Maintenance

60

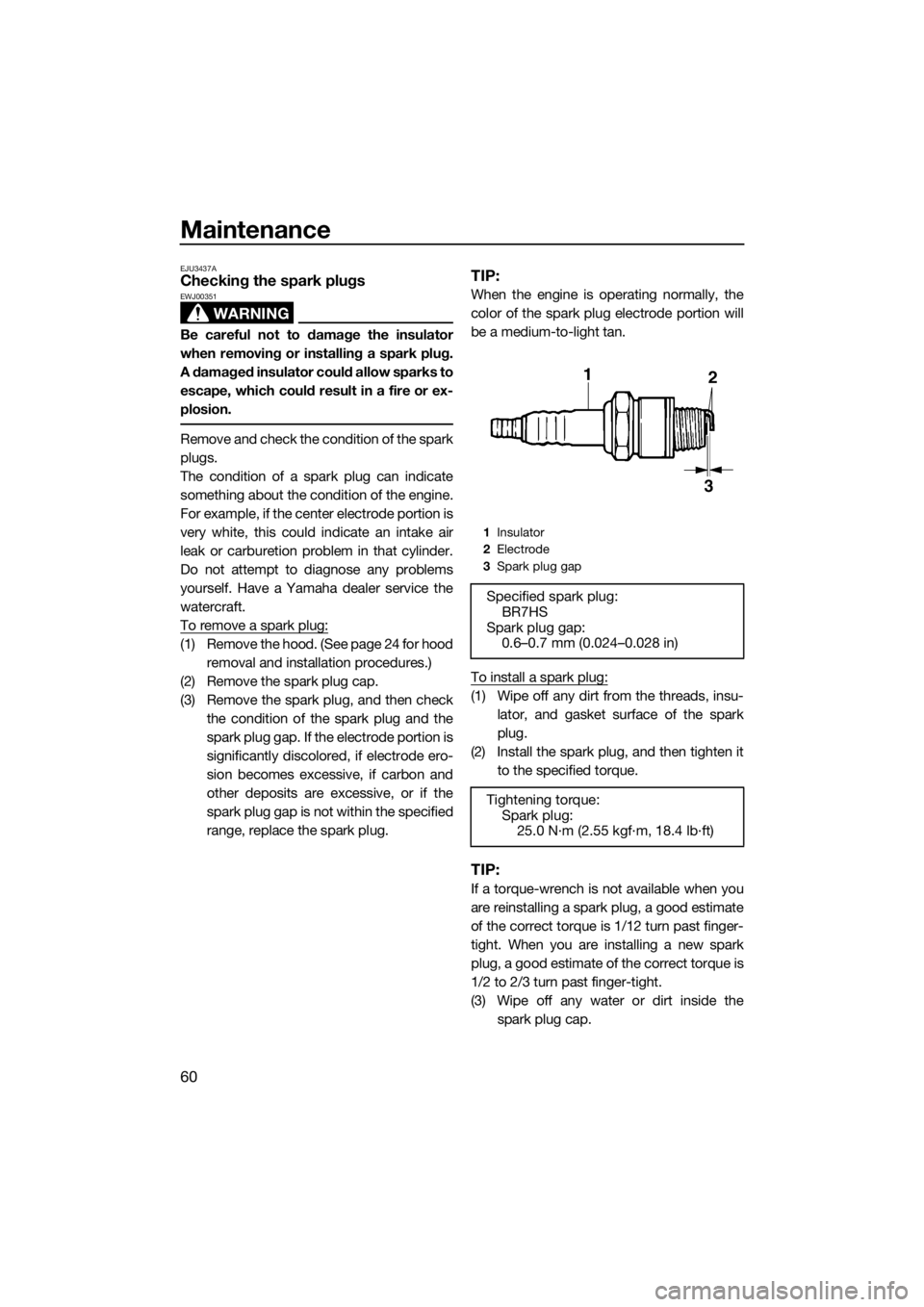

EJU3437AChecking the spark plugs

WARNING

EWJ00351

Be careful not to damage the insulator

when removing or installing a spark plug.

A damaged insulator could allow sparks to

escape, which could result in a fire or ex-

plosion.

Remove and check the condition of the spark

plugs.

The condition of a spark plug can indicate

something about the condition of the engine.

For example, if the center electrode portion is

very white, this could indicate an intake air

leak or carburetion problem in that cylinder.

Do not attempt to diagnose any problems

yourself. Have a Yamaha dealer service the

watercraft.

To remove a spark plug:

(1) Remove the hood. (See page 24 for hood

removal and installation procedures.)

(2) Remove the spark plug cap.

(3) Remove the spark plug, and then check

the condition of the spark plug and the

spark plug gap. If the electrode portion is

significantly discolored, if electrode ero-

sion becomes excessive, if carbon and

other deposits are excessive, or if the

spark plug gap is not within the specified

range, replace the spark plug.

TIP:

When the engine is operating normally, the

color of the spark plug electrode portion will

be a medium-to-light tan.

To install a spark plug:

(1) Wipe off any dirt from the threads, insu-

lator, and gasket surface of the spark

plug.

(2) Install the spark plug, and then tighten it

to the specified torque.

TIP:

If a torque-wrench is not available when you

are reinstalling a spark plug, a good estimate

of the correct torque is 1/12 turn past finger-

tight. When you are installing a new spark

plug, a good estimate of the correct torque is

1/2 to 2/3 turn past finger-tight.

(3) Wipe off any water or dirt inside the

spark plug cap.

1Insulator

2Electrode

3Spark plug gap

Specified spark plug:

BR7HS

Spark plug gap:

0.6–0.7 mm (0.024–0.028 in)

Tightening torque:

Spark plug:

25.0 N·m (2.55 kgf·m, 18.4 lb·ft)

UF4D73E0.book Page 60 Wednesday, March 23, 2016 11:40 AM

Page 72 of 78

Trouble recovery

66

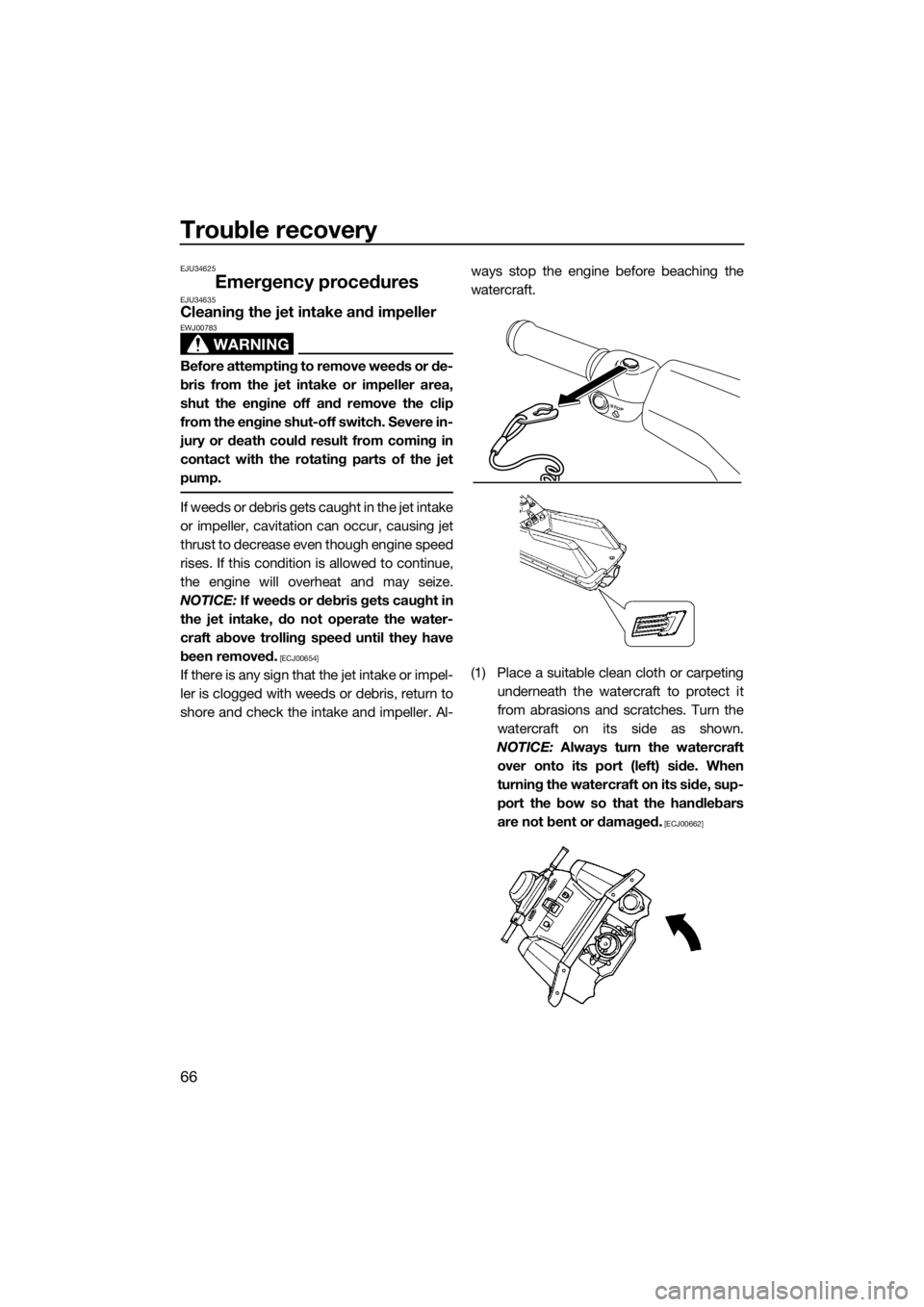

EJU34625

Emergency proceduresEJU34635Cleaning the jet intake and impeller

WARNING

EWJ00783

Before attempting to remove weeds or de-

bris from the jet intake or impeller area,

shut the engine off and remove the clip

from the engine shut-off switch. Severe in-

jury or death could result from coming in

contact with the rotating parts of the jet

pump.

If weeds or debris gets caught in the jet intake

or impeller, cavitation can occur, causing jet

thrust to decrease even though engine speed

rises. If this condition is allowed to continue,

the engine will overheat and may seize.

NOTICE: If weeds or debris gets caught in

the jet intake, do not operate the water-

craft above trolling speed until they have

been removed.

[ECJ00654]

If there is any sign that the jet intake or impel-

ler is clogged with weeds or debris, return to

shore and check the intake and impeller. Al-ways stop the engine before beaching the

watercraft.

(1) Place a suitable clean cloth or carpeting

underneath the watercraft to protect it

from abrasions and scratches. Turn the

watercraft on its side as shown.

NOTICE: Always turn the watercraft

over onto its port (left) side. When

turning the watercraft on its side, sup-

port the bow so that the handlebars

are not bent or damaged.

[ECJ00662]

STOP

UF4D73E0.book Page 66 Wednesday, March 23, 2016 11:40 AM

Page 73 of 78

Trouble recovery

67

(2) Remove any weeds or debris from

around the jet intake, drive shaft, impel-

ler, jet pump housing, and jet thrust noz-

zle.

If debris is difficult to remove, consult a

Yamaha dealer.

EJU34642Jumping the battery

If the watercraft battery has run down, the en-

gine can be started using a 12-volt booster

battery and jumper cables.

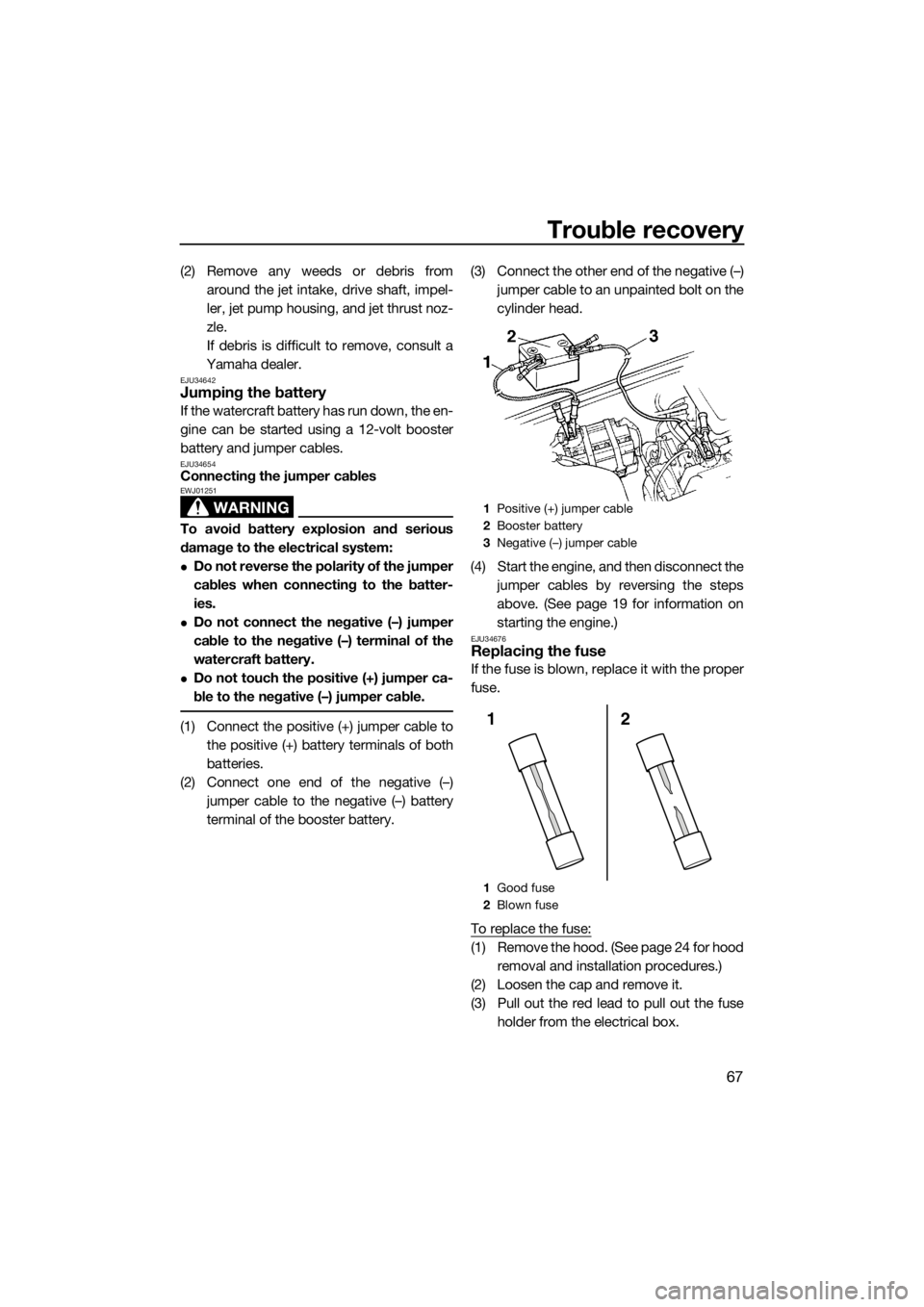

EJU34654Connecting the jumper cables

WARNING

EWJ01251

To avoid battery explosion and serious

damage to the electrical system:

Do not reverse the polarity of the jumper

cables when connecting to the batter-

ies.

Do not connect the negative (–) jumper

cable to the negative (–) terminal of the

watercraft battery.

Do not touch the positive (+) jumper ca-

ble to the negative (–) jumper cable.

(1) Connect the positive (+) jumper cable to

the positive (+) battery terminals of both

batteries.

(2) Connect one end of the negative (–)

jumper cable to the negative (–) battery

terminal of the booster battery.(3) Connect the other end of the negative (–)

jumper cable to an unpainted bolt on the

cylinder head.

(4) Start the engine, and then disconnect the

jumper cables by reversing the steps

above. (See page 19 for information on

starting the engine.)

EJU34676Replacing the fuse

If the fuse is blown, replace it with the proper

fuse.

To replace the fuse:

(1) Remove the hood. (See page 24 for hood

removal and installation procedures.)

(2) Loosen the cap and remove it.

(3) Pull out the red lead to pull out the fuse

holder from the electrical box.

1Positive (+) jumper cable

2Booster battery

3Negative (–) jumper cable

1Good fuse

2Blown fuse

2 1

UF4D73E0.book Page 67 Wednesday, March 23, 2016 11:40 AM

Page 74 of 78

Trouble recovery

68

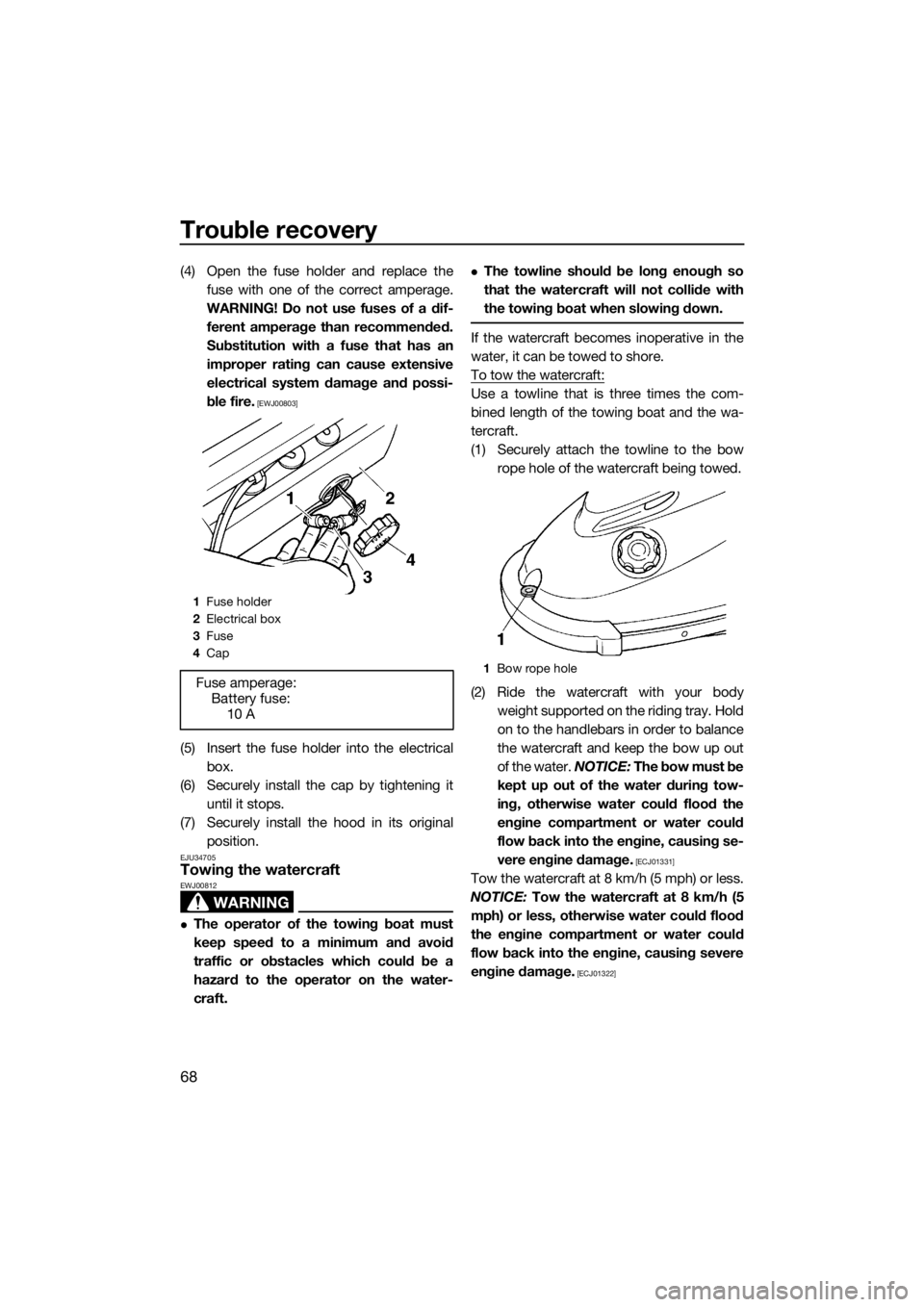

(4) Open the fuse holder and replace the

fuse with one of the correct amperage.

WARNING! Do not use fuses of a dif-

ferent amperage than recommended.

Substitution with a fuse that has an

improper rating can cause extensive

electrical system damage and possi-

ble fire.

[EWJ00803]

(5) Insert the fuse holder into the electrical

box.

(6) Securely install the cap by tightening it

until it stops.

(7) Securely install the hood in its original

position.

EJU34705Towing the watercraft

WARNING

EWJ00812

The operator of the towing boat must

keep speed to a minimum and avoid

traffic or obstacles which could be a

hazard to the operator on the water-

craft.

The towline should be long enough so

that the watercraft will not collide with

the towing boat when slowing down.

If the watercraft becomes inoperative in the

water, it can be towed to shore.

To tow the watercraft:

Use a towline that is three times the com-

bined length of the towing boat and the wa-

tercraft.

(1) Securely attach the towline to the bow

rope hole of the watercraft being towed.

(2) Ride the watercraft with your body

weight supported on the riding tray. Hold

on to the handlebars in order to balance

the watercraft and keep the bow up out

of the water. NOTICE: The bow must be

kept up out of the water during tow-

ing, otherwise water could flood the

engine compartment or water could

flow back into the engine, causing se-

vere engine damage.

[ECJ01331]

Tow the watercraft at 8 km/h (5 mph) or less.

NOTICE: Tow the watercraft at 8 km/h (5

mph) or less, otherwise water could flood

the engine compartment or water could

flow back into the engine, causing severe

engine damage.

[ECJ01322]

1Fuse holder

2Electrical box

3Fuse

4Cap

Fuse amperage:

Battery fuse:

10 A1Bow rope hole

UF4D73E0.book Page 68 Wednesday, March 23, 2016 11:40 AM