check engine YAMAHA SUPERJET 2022 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2022, Model line: SUPERJET, Model: YAMAHA SUPERJET 2022Pages: 84, PDF Size: 3.76 MB

Page 73 of 84

Maintenance

66

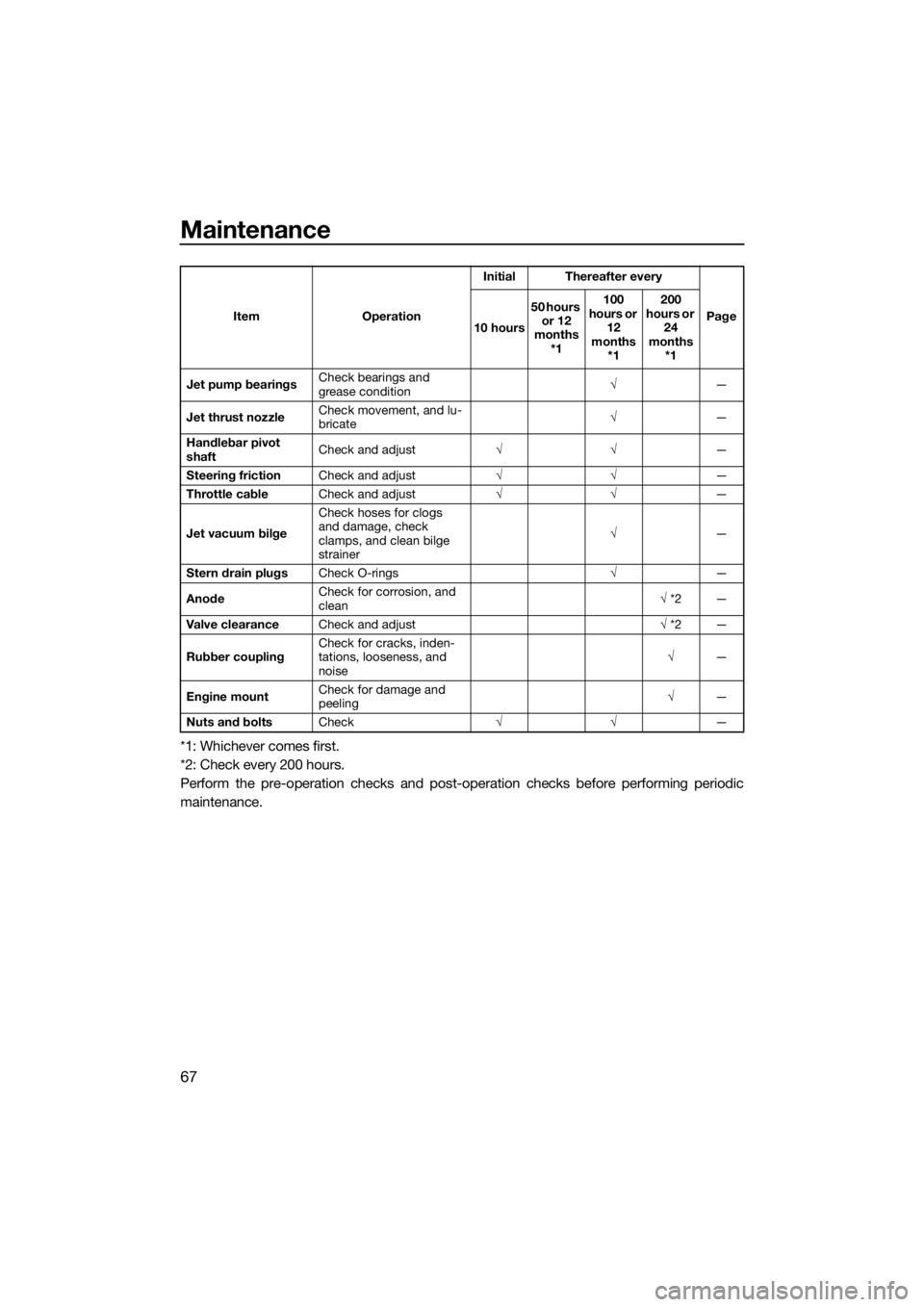

EJU43103Periodic maintenance chart

The periodic maintenance chart gives general guidelines for periodic maintenance. Have a

Yamaha dealer perform the checks in the following chart. However, maintenance may need to be performed more frequently depending on your operating conditions. If you have any

questions, consult a Yamaha dealer.

This “ √” mark indicates items to be checked and serviced by a Yamaha dealer.

Item OperationInitial Thereafter every

Page

10 hours 50 hours

or 12

months *1 100

hours or 12

months *1 200

hours or 24

months *1

Fuel line Check fuel hoses and

clamps

√

—

Fuel filler cap/Wa-

ter separator Check O-rings for cracks

and deformation

√

—

Fuel tank Check installation and

straps

√

—

Water inlet strainer Check for clogs and dam-

age

√

—

Cooling water hos-

es Check for damage and

leakage, and check

clamps

√

—

Engine oil Replace √√ 68

Oil filter Replace √68

Spark plugs Check √√ —

Battery Check state of charge,

terminals and bands

√

—

Battery leads Check terminals √—

Steering master Check and adjust √√ —

Steering cable Check exterior and con-

nections, and lubricate

√

—

Air intake hoses Check for damage, and

check clamps

√

—

Throttle body Lubricate throttle valve √—

Exhaust system Check for exhaust leak-

age, and check hoses and

clamps √

—

Breather hose Check breather hose and

clamps

√

—

Impeller Check for bends, dam-

age, and foreign material

√

—

Drive shaft spline Check for damage and lu-

bricate splines √

—

UF4R71E0.book Page 66 Monday, May 10, 2021 1:14 PM

Page 74 of 84

Maintenance

67

*1: Whichever comes first.

*2: Check every 200 hours.

Perform the pre-operation checks and post-operation checks before performing periodic

maintenance.

Jet pump bearingsCheck bearings and

grease condition

√

—

Jet thrust nozzle Check movement, and lu-

bricate

√

—

Handlebar pivot

shaft Check and adjust

√√ —

Steering friction Check and adjust √√ —

Throttle cable Check and adjust √√ —

Jet vacuum bilge Check hoses for clogs

and damage, check

clamps, and clean bilge

strainer

√

—

Stern drain plugs Check O-rings √—

Anode Check for corrosion, and

clean

√

*2 —

Valve clearance Check and adjust √ *2 —

Rubber coupling Check for cracks, inden-

tations, looseness, and

noise √

—

Engine mount Check for damage and

peeling

√

—

Nuts and bolts Check √√ —

Item

OperationInitial Thereafter every

Page

10 hours 50 hours

or 12

months *1 100

hours or 12

months *1 200

hours or 24

months *1

UF4R71E0.book Page 67 Monday, May 10, 2021 1:14 PM

Page 77 of 84

Trouble recovery

70

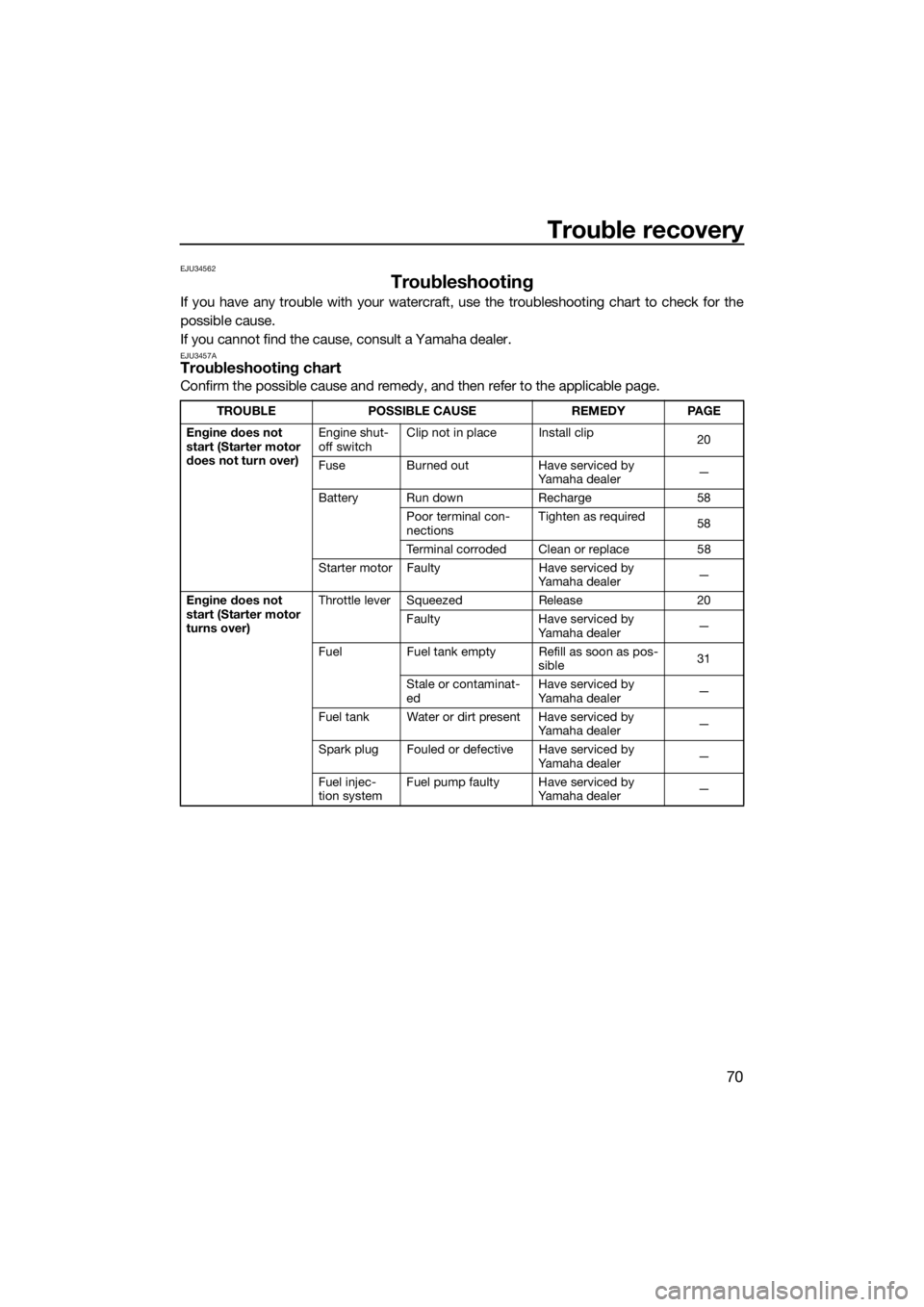

EJU34562

Troubleshooting

If you have any trouble with your watercraft, use the troubleshooting chart to check for the

possible cause.

If you cannot find the cause, consult a Yamaha dealer.

EJU3457ATroubleshooting chart

Confirm the possible cause and remedy, and then refer to the applicable page.

TROUBLEPOSSIBLE CAUSE REMEDYPAGE

Engine does not

start (Starter motor

does not turn over) Engine shut-

off switch

Clip not in place Install clip

20

Fuse Burned out Have serviced by

Yamaha dealer—

Battery Run down Recharge58

Poor terminal con-

nections Tighten as required

58

Terminal corroded Clean or replace 58

Starter motor Faulty Have serviced by

Yamaha dealer —

Engine does not

start (Starter motor

turns over) Throttle lever Squeezed

Release20

Faulty Have serviced by

Yamaha dealer —

Fuel Fuel tank empty Refill as soon as pos-

sible 31

Stale or contaminat-

ed Have serviced by

Yamaha dealer

—

Fuel tank Water or dirt present Have serviced by Yamaha dealer—

Spark plug Fouled or defective Have serviced by Yamaha dealer—

Fuel injec-

tion system Fuel pump faulty Have serviced by

Yamaha dealer —

UF4R71E0.book Page 70 Monday, May 10, 2021 1:14 PM

Page 78 of 84

Trouble recovery

71

Engine runs irregu-

larly or stallsFuel Fuel tank empty Refill as soon as pos-

sible31

Stale or contaminat-

ed Have serviced by

Yamaha dealer

—

Fuel tank Water or dirt present Have serviced by Yamaha dealer—

Spark plug Fouled or defective Have serviced by Yamaha dealer—

Incorrect heat range Have serviced by Yamaha dealer —

Gap incorrect Have serviced by Yamaha dealer —

Electrical wir-

ing Loose connection Have serviced by

Yamaha dealer —

Fuel injec-

tion system Faulty or clogged in-

jectors Have serviced by

Yamaha dealer

—

Warning light or in-

dicator blinks or

comes on Fuel level

warning

Fuel tank empty Refill as soon as pos-

sible 31

Oil pressure

warning Oil pressure dropped Have serviced by

Yamaha dealer 24

Engine over-

heat warning Jet intake clogged Clean

72

Check en-

gine warning Faulty sensors Have serviced by

Yamaha dealer 25

Watercraft slow or

loses power Cavitation Jet intake clogged Clean 72

Impeller damaged or

worn Have serviced by

Yamaha dealer

72

Engine over-

heat warning Engine speed reduc-

tion control activated Clean jet intake and

cool engine

25

Oil pressure

warning Engine speed reduc-

tion control activated Add oil

24

Spark plug Fouled or defective Have serviced by Yamaha dealer—

Incorrect heat range Have serviced by Yamaha dealer —

Gap incorrect Have serviced by Yamaha dealer —

Electrical wir-

ing Loose connection Have serviced by

Yamaha dealer —

Fuel Stale or contaminat- ed Have serviced by

Yamaha dealer

—

Throttle lever Faulty Have serviced by Yamaha dealer—

L-MODE L-MODE is activat- ing. Deactivate the L-

MODE.

23

T

R

OUBLE

POSSIBLE CAUSE REMEDYPAGE

UF4R71E0.book Page 71 Monday, May 10, 2021 1:14 PM

Page 79 of 84

Trouble recovery

72

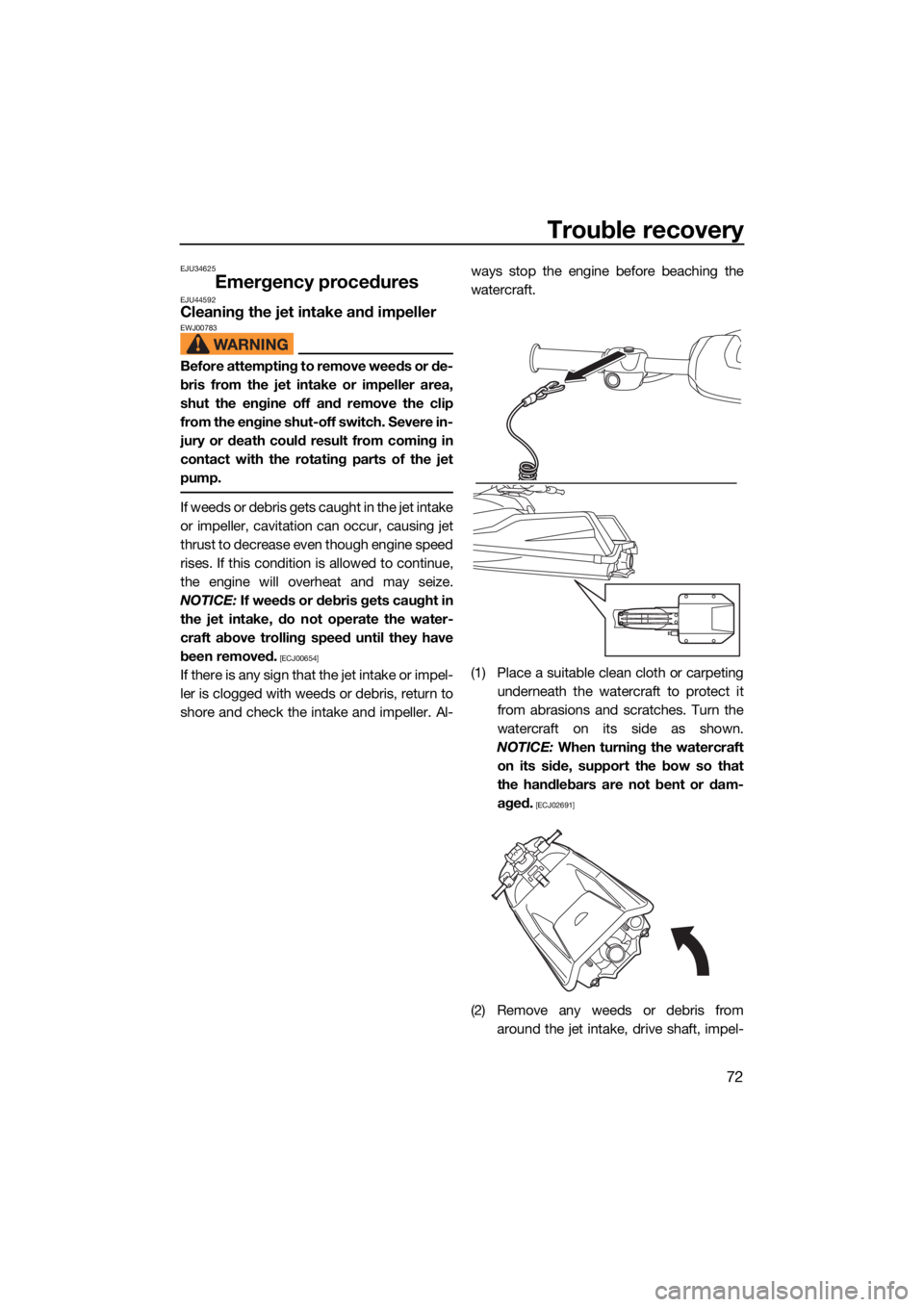

EJU34625

Emergency proceduresEJU44592Cleaning the jet intake and impellerEWJ00783

Before attempting to remove weeds or de-

bris from the jet intake or impeller area,

shut the engine off and remove the clip

from the engine shut-off switch. Severe in-

jury or death could result from coming in

contact with the rotating parts of the jet

pump.

If weeds or debris gets caught in the jet intake

or impeller, cavitation can occur, causing jet

thrust to decrease even though engine speed

rises. If this condition is allowed to continue,

the engine will overheat and may seize.

NOTICE: If weeds or debris gets caught in

the jet intake, do not operate the water-

craft above trolling speed until they have

been removed.

[ECJ00654]

If there is any sign that the jet intake or impel-

ler is clogged with weeds or debris, return to

shore and check the intake and impeller. Al- ways stop the engine before beaching the

watercraft.

(1) Place a suitable clean cloth or carpeting

underneath the watercraft to protect it

from abrasions and scratches. Turn the

watercraft on its side as shown.

NOTICE: When turning the watercraft

on its side, support the bow so that

the handlebars are not bent or dam-

aged.

[ECJ02691]

(2) Remove any weeds or debris from around the jet intake, drive shaft, impel-

UF4R71E0.book Page 72 Monday, May 10, 2021 1:14 PM

Page 82 of 84

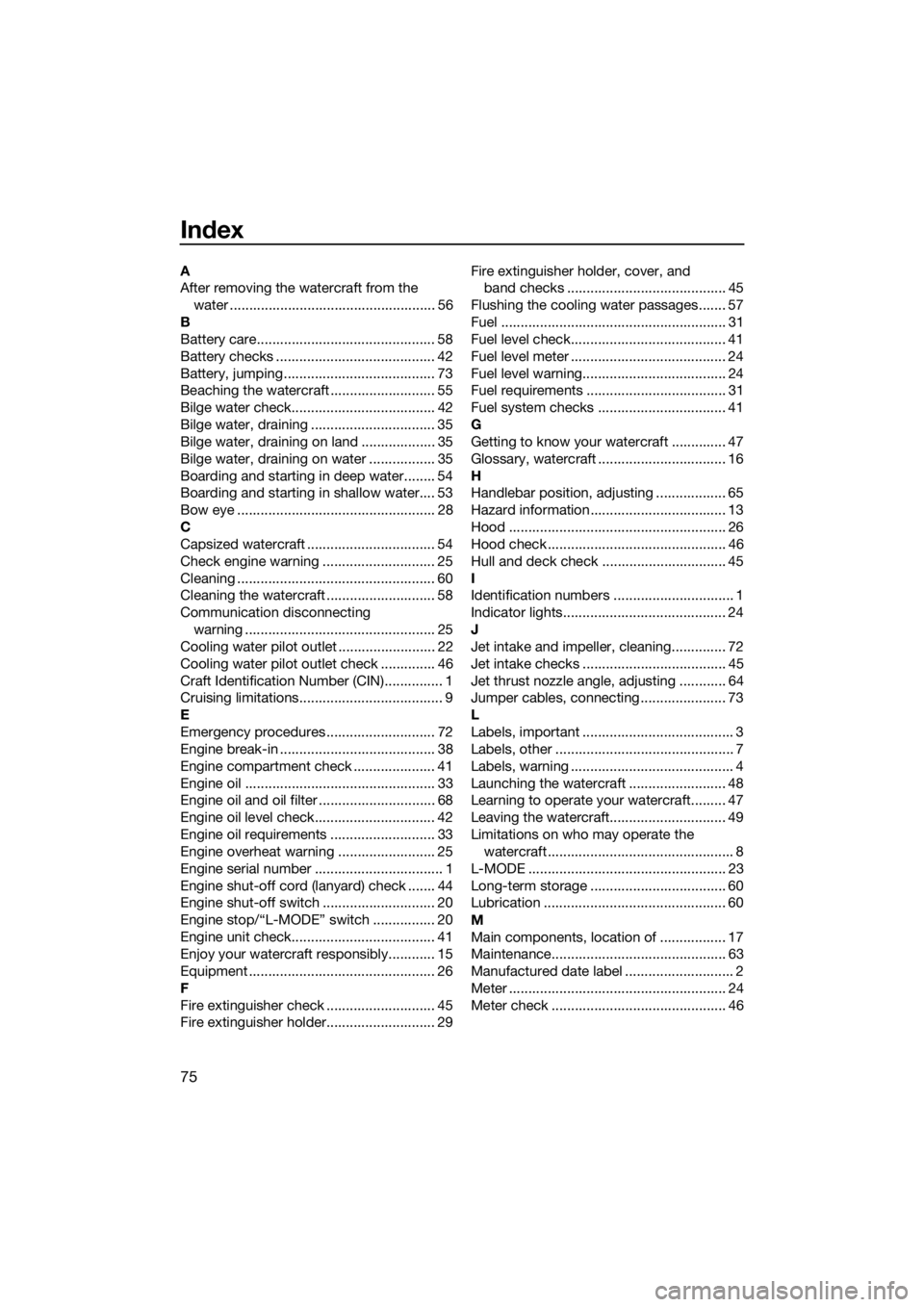

75

Index

A

After removing the watercraft from the water ..................................................... 56

B

Battery care.............................................. 58

Battery checks ......................................... 42

Battery, jumping....................................... 73

Beaching the watercraft ........................... 55

Bilge water check..................................... 42

Bilge water, draining ................................ 35

Bilge water, draining on land ................... 35

Bilge water, draining on water ................. 35

Boarding and starting in deep water........ 54

Boarding and starting in shallow water.... 53

Bow eye ................................................... 28

C

Capsized watercraft ................................. 54

Check engine warning ............................. 25

Cleaning ................................................... 60

Cleaning the watercraft ............................ 58

Communication disconnecting warning ................................................. 25

Cooling water pilot outlet ......................... 22

Cooling water pilot outlet check .............. 46

Craft Identification Number (CIN)............... 1

Cruising limitations..................................... 9

E

Emergency procedures ............................ 72

Engine break-in ........................................ 38

Engine compartment check ..................... 41

Engine oil ................................................. 33

Engine oil and oil filter .............................. 68

Engine oil level check............................... 42

Engine oil requirements ........................... 33

Engine overheat warning ......................... 25

Engine serial number ................................. 1

Engine shut-off cord (lanyard) check ....... 44

Engine shut-off switch ............................. 20

Engine stop/“L-MODE” switch ................ 20

Engine unit check..................................... 41

Enjoy your watercraft responsibly............ 15

Equipment ................................................ 26

F

Fire extinguisher check ............................ 45

Fire extinguisher holder............................ 29 Fire extinguisher holder, cover, and

band checks ......................................... 45

Flushing the cooling water passages....... 57

Fuel .......................................................... 31

Fuel level check........................................ 41

Fuel level meter ........................................ 24

Fuel level warning..................................... 24

Fuel requirements .................................... 31

Fuel system checks ................................. 41

G

Getting to know your watercraft .............. 47

Glossary, watercraft ................................. 16

H

Handlebar position, adjusting .................. 65

Hazard information................................... 13

Hood ........................................................ 26

Hood check .............................................. 46

Hull and deck check ................................ 45

I

Identification numbers ............................... 1

Indicator lights.......................................... 24

J

Jet intake and impeller, cleaning.............. 72

Jet intake checks ..................................... 45

Jet thrust nozzle angle, adjusting ............ 64

Jumper cables, connecting ...................... 73

L

Labels, important ....................................... 3

Labels, other .............................................. 7

Labels, warning .......................................... 4

Launching the watercraft ......................... 48

Learning to operate your watercraft......... 47

Leaving the watercraft.............................. 49

Limitations on who may operate the watercraft ................................................ 8

L-MODE ................................................... 23

Long-term storage ................................... 60

Lubrication ............................................... 60

M

Main components, location of ................. 17

Maintenance............................................. 63

Manufactured date label ............................ 2

Meter ........................................................ 24

Meter check ............................................. 46

UF4R71E0.book Page 75 Monday, May 10, 2021 1:14 PM

Page 83 of 84

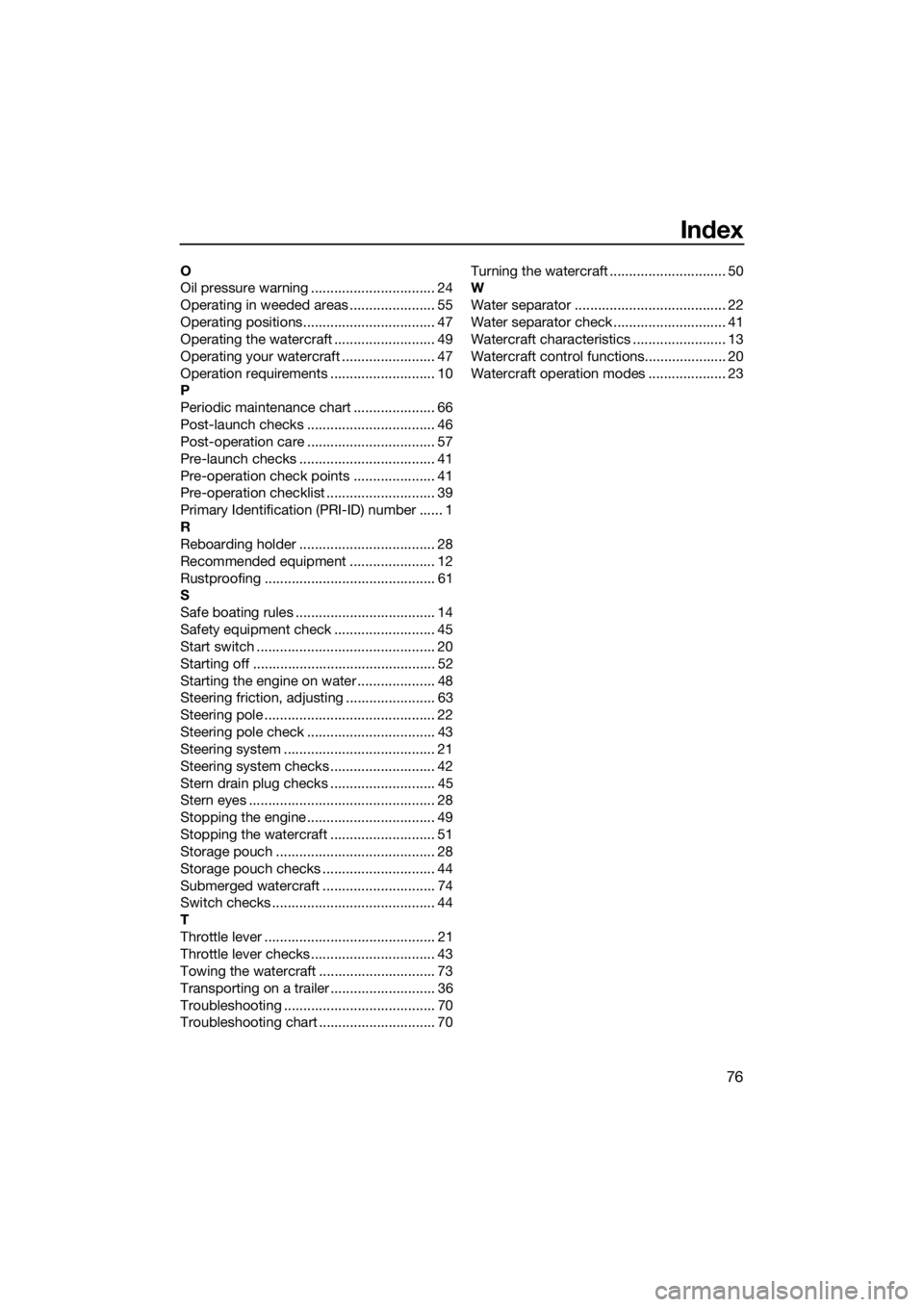

Index

76

O

Oil pressure warning ................................ 24

Operating in weeded areas ...................... 55

Operating positions.................................. 47

Operating the watercraft .......................... 49

Operating your watercraft ........................ 47

Operation requirements ........................... 10

P

Periodic maintenance chart ..................... 66

Post-launch checks ................................. 46

Post-operation care ................................. 57

Pre-launch checks ................................... 41

Pre-operation check points ..................... 41

Pre-operation checklist ............................ 39

Primary Identification (PRI-ID) number ...... 1

R

Reboarding holder ................................... 28

Recommended equipment ...................... 12

Rustproofing ............................................ 61

S

Safe boating rules .................................... 14

Safety equipment check .......................... 45

Start switch .............................................. 20

Starting off ............................................... 52

Starting the engine on water .................... 48

Steering friction, adjusting ....................... 63

Steering pole ............................................ 22

Steering pole check ................................. 43

Steering system ....................................... 21

Steering system checks ........................... 42

Stern drain plug checks ........................... 45

Stern eyes ................................................ 28

Stopping the engine ................................. 49

Stopping the watercraft ........................... 51

Storage pouch ......................................... 28

Storage pouch checks ............................. 44

Submerged watercraft ............................. 74

Switch checks .......................................... 44

T

Throttle lever ............................................ 21

Throttle lever checks ................................ 43

Towing the watercraft .............................. 73

Transporting on a trailer ........................... 36

Troubleshooting ....................................... 70

Troubleshooting chart .............................. 70Turning the watercraft .............................. 50

W

Water separator ....................................... 22

Water separator check ............................. 41

Watercraft characteristics ........................ 13

Watercraft control functions..................... 20

Watercraft operation modes .................... 23

UF4R71E0.book Page 76 Monday, May 10, 2021 1:14 PM