YAMAHA SVHO 2009 Repair Manual

Manufacturer: YAMAHA, Model Year: 2009, Model line: SVHO, Model: YAMAHA SVHO 2009Pages: 108, PDF Size: 8.04 MB

Page 61 of 108

Operation

54

EJU31980

Pre-operation checks EJU31991Pre-operation check list

Before operating this watercraft, perform the checks in the following check list.

WARNING

EWJ00411

Failure to inspect or maintain the watercraft properly increases the possibility of an ac-

cident or damage to the watercraft. Do not operate the watercraft if you find any prob-

lem. If a problem cannot be corrected by the procedures provided in this manual, have

the watercraft inspected by a Yamaha dealer.

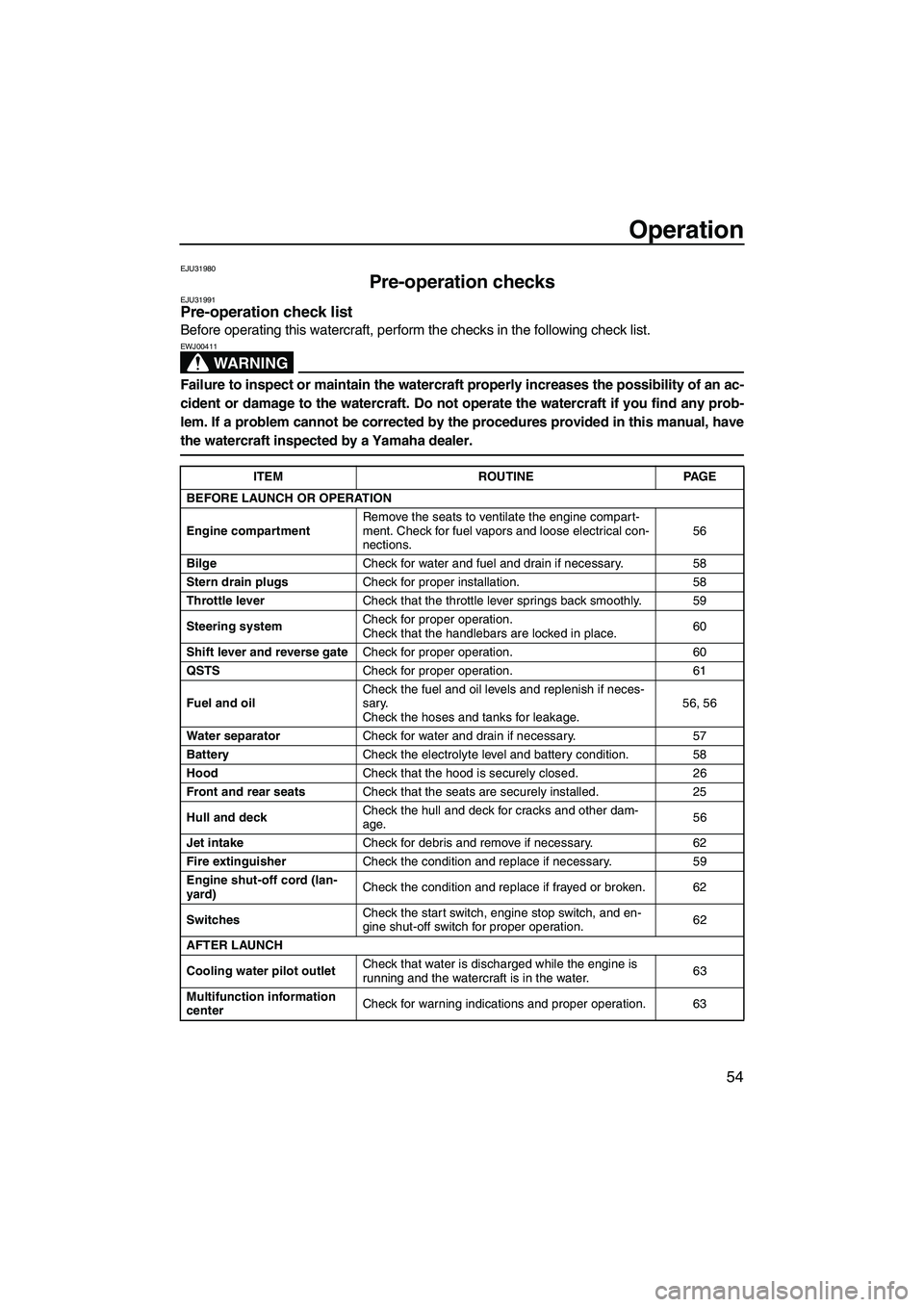

ITEM ROUTINE PAGE

BEFORE LAUNCH OR OPERATION

Engine compartmentRemove the seats to ventilate the engine compart-

ment. Check for fuel vapors and loose electrical con-

nections.56

BilgeCheck for water and fuel and drain if necessary. 58

Stern drain plugsCheck for proper installation. 58

Throttle leverCheck that the throttle lever springs back smoothly. 59

Steering systemCheck for proper operation.

Check that the handlebars are locked in place.60

Shift lever and reverse gateCheck for proper operation. 60

QSTSCheck for proper operation. 61

Fuel and oilCheck the fuel and oil levels and replenish if neces-

sary.

Check the hoses and tanks for leakage.56, 56

Water separatorCheck for water and drain if necessary. 57

BatteryCheck the electrolyte level and battery condition. 58

HoodCheck that the hood is securely closed. 26

Front and rear seatsCheck that the seats are securely installed. 25

Hull and deckCheck the hull and deck for cracks and other dam-

age.56

Jet intakeCheck for debris and remove if necessary. 62

Fire extinguisherCheck the condition and replace if necessary. 59

Engine shut-off cord (lan-

yard)Check the condition and replace if frayed or broken. 62

SwitchesCheck the start switch, engine stop switch, and en-

gine shut-off switch for proper operation.62

AFTER LAUNCH

Cooling water pilot outletCheck that water is discharged while the engine is

running and the watercraft is in the water.63

Multifunction information

centerCheck for warning indications and proper operation. 63

UF1W71E0.book Page 54 Tuesday, June 24, 2008 11:46 AM

Page 62 of 108

Operation

55

TIP:

Pre-operation checks should be made each time the watercraft is used. These checks can be

completed in a short time. It is worth the time spent to ensure safety and reliability.

UF1W71E0.book Page 55 Tuesday, June 24, 2008 11:46 AM

Page 63 of 108

Operation

56

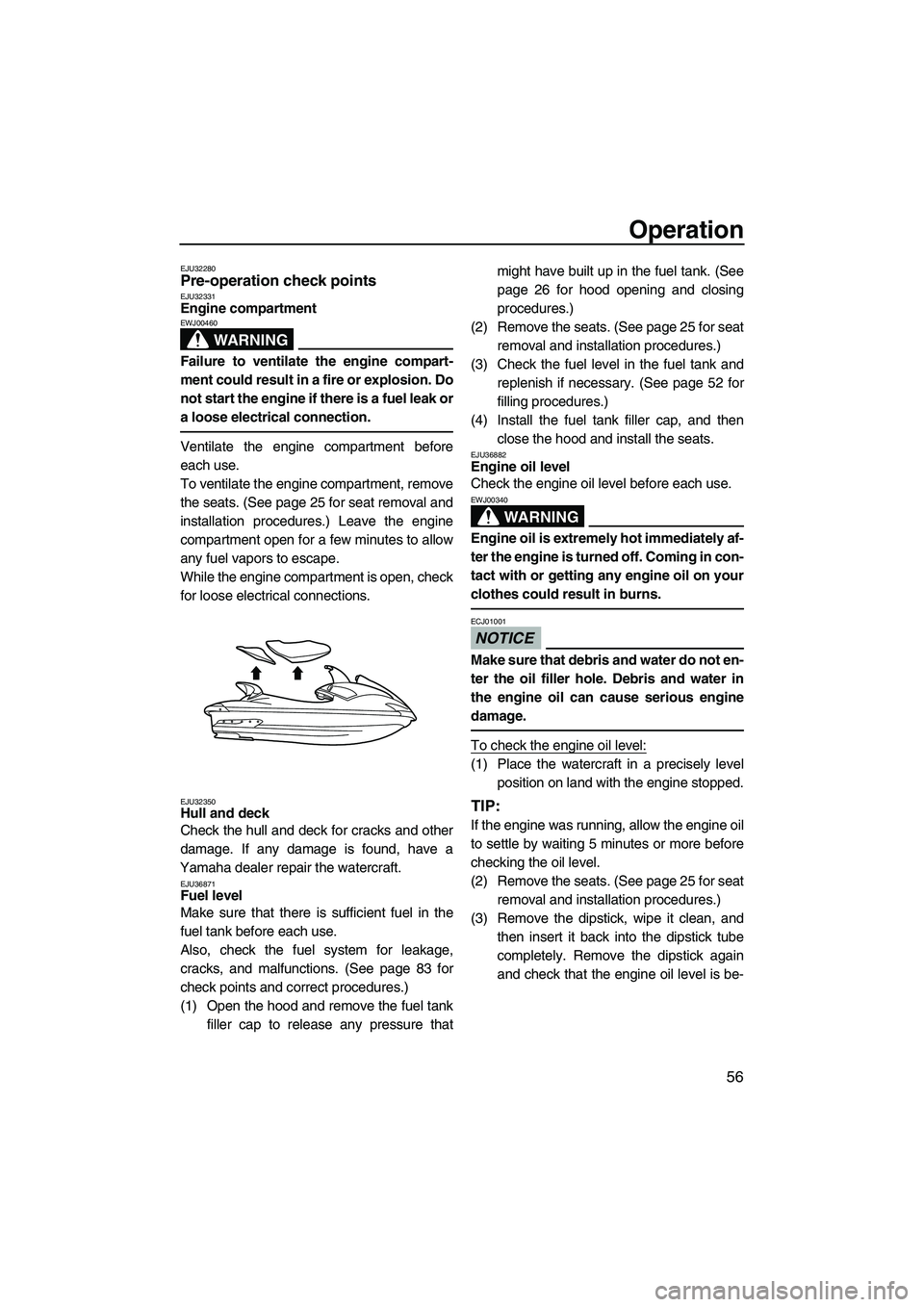

EJU32280Pre-operation check points EJU32331Engine compartment

WARNING

EWJ00460

Failure to ventilate the engine compart-

ment could result in a fire or explosion. Do

not start the engine if there is a fuel leak or

a loose electrical connection.

Ventilate the engine compartment before

each use.

To ventilate the engine compartment, remove

the seats. (See page 25 for seat removal and

installation procedures.) Leave the engine

compartment open for a few minutes to allow

any fuel vapors to escape.

While the engine compartment is open, check

for loose electrical connections.

EJU32350Hull and deck

Check the hull and deck for cracks and other

damage. If any damage is found, have a

Yamaha dealer repair the watercraft.

EJU36871Fuel level

Make sure that there is sufficient fuel in the

fuel tank before each use.

Also, check the fuel system for leakage,

cracks, and malfunctions. (See page 83 for

check points and correct procedures.)

(1) Open the hood and remove the fuel tank

filler cap to release any pressure thatmight have built up in the fuel tank. (See

page 26 for hood opening and closing

procedures.)

(2) Remove the seats. (See page 25 for seat

removal and installation procedures.)

(3) Check the fuel level in the fuel tank and

replenish if necessary. (See page 52 for

filling procedures.)

(4) Install the fuel tank filler cap, and then

close the hood and install the seats.

EJU36882Engine oil level

Check the engine oil level before each use.

WARNING

EWJ00340

Engine oil is extremely hot immediately af-

ter the engine is turned off. Coming in con-

tact with or getting any engine oil on your

clothes could result in burns.

NOTICE

ECJ01001

Make sure that debris and water do not en-

ter the oil filler hole. Debris and water in

the engine oil can cause serious engine

damage.

To check the engine oil level:

(1) Place the watercraft in a precisely level

position on land with the engine stopped.

TIP:

If the engine was running, allow the engine oil

to settle by waiting 5 minutes or more before

checking the oil level.

(2) Remove the seats. (See page 25 for seat

removal and installation procedures.)

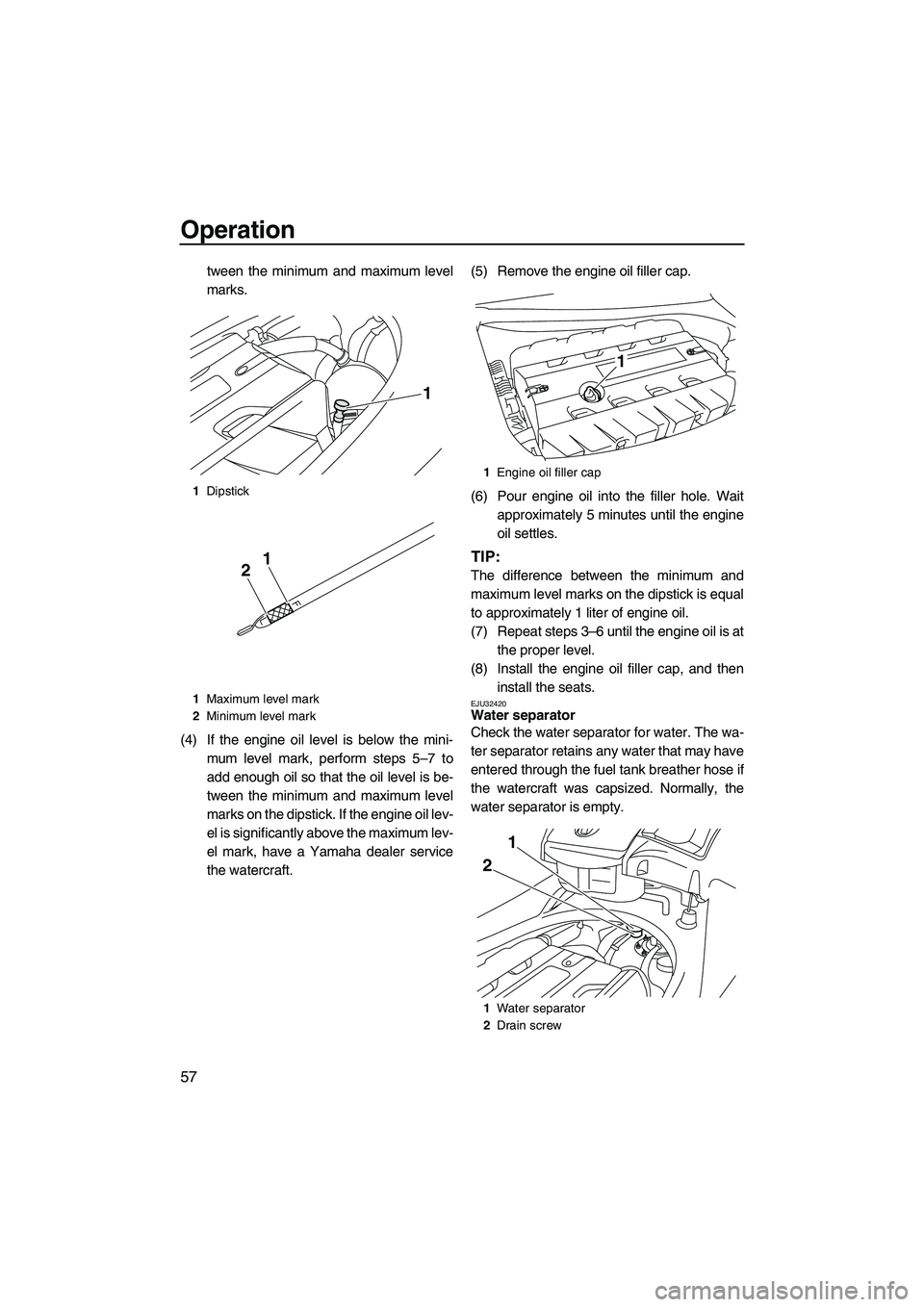

(3) Remove the dipstick, wipe it clean, and

then insert it back into the dipstick tube

completely. Remove the dipstick again

and check that the engine oil level is be-

UF1W71E0.book Page 56 Tuesday, June 24, 2008 11:46 AM

Page 64 of 108

Operation

57

tween the minimum and maximum level

marks.

(4) If the engine oil level is below the mini-

mum level mark, perform steps 5–7 to

add enough oil so that the oil level is be-

tween the minimum and maximum level

marks on the dipstick. If the engine oil lev-

el is significantly above the maximum lev-

el mark, have a Yamaha dealer service

the watercraft.(5) Remove the engine oil filler cap.

(6) Pour engine oil into the filler hole. Wait

approximately 5 minutes until the engine

oil settles.

TIP:

The difference between the minimum and

maximum level marks on the dipstick is equal

to approximately 1 liter of engine oil.

(7) Repeat steps 3–6 until the engine oil is at

the proper level.

(8) Install the engine oil filler cap, and then

install the seats.

EJU32420Water separator

Check the water separator for water. The wa-

ter separator retains any water that may have

entered through the fuel tank breather hose if

the watercraft was capsized. Normally, the

water separator is empty.

1Dipstick

1Maximum level mark

2Minimum level mark

1

12

1Engine oil filler cap

1Water separator

2Drain screw

1

1

2

UF1W71E0.book Page 57 Tuesday, June 24, 2008 11:46 AM

Page 65 of 108

Operation

58

If water remains in the water separator, drain

it by removing the drain screw. Place a drain

pan under the water separator to catch the

draining water or use a dry cloth to soak up

any water that could spill into the watercraft. If

any water spills into the watercraft, be sure to

wipe it up with a dry cloth. Also, be sure to in-

stall the drain screw after draining the water

separator.

EJU32452Bilge

Check the bilge for moisture and fuel residue.

NOTICE: Excessive water in the engine

compartment can splash into the engine,

which can result in severe damage.

[ECJ00341]

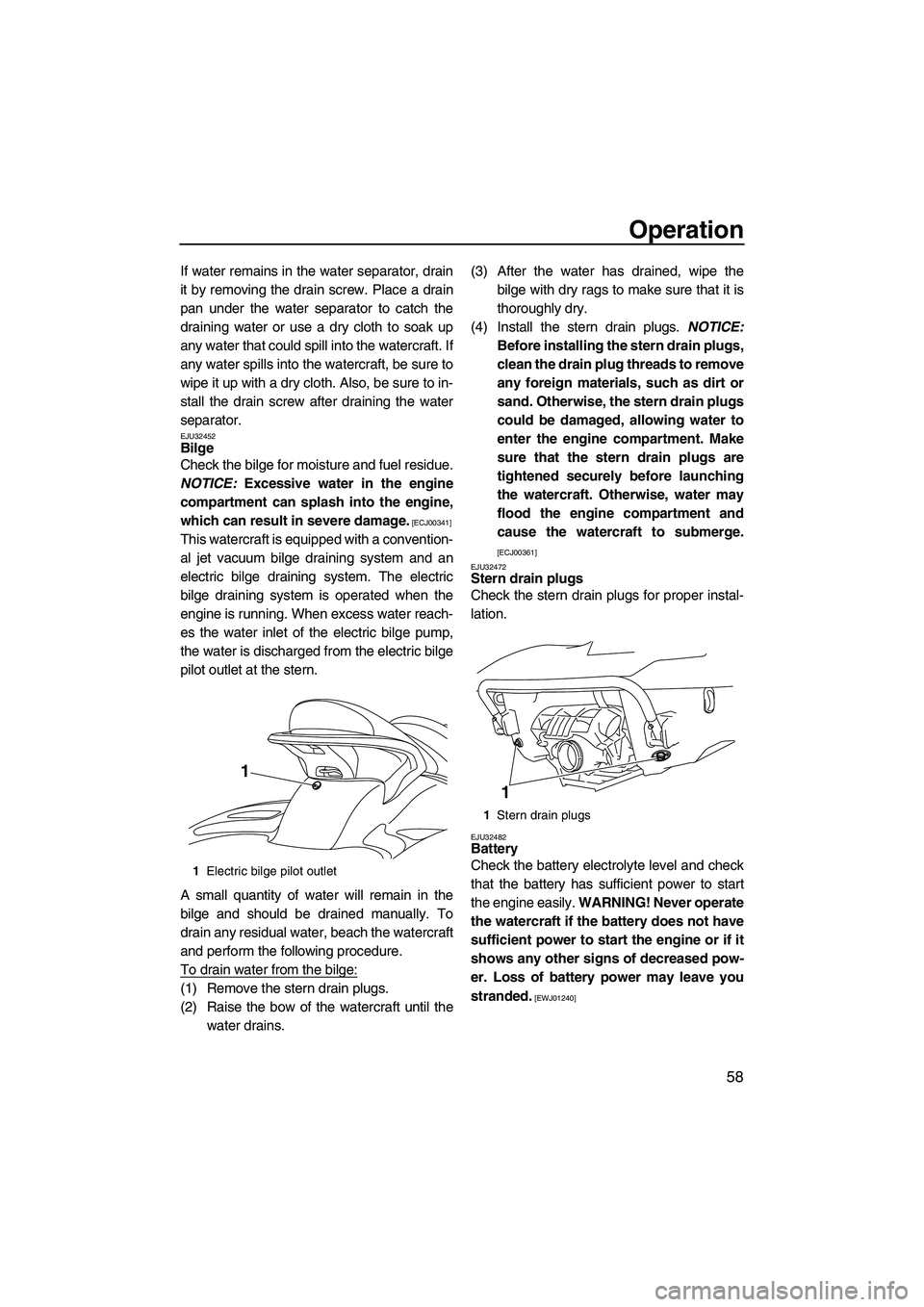

This watercraft is equipped with a convention-

al jet vacuum bilge draining system and an

electric bilge draining system. The electric

bilge draining system is operated when the

engine is running. When excess water reach-

es the water inlet of the electric bilge pump,

the water is discharged from the electric bilge

pilot outlet at the stern.

A small quantity of water will remain in the

bilge and should be drained manually. To

drain any residual water, beach the watercraft

and perform the following procedure.

To drain water from the bilge:

(1) Remove the stern drain plugs.

(2) Raise the bow of the watercraft until the

water drains.(3) After the water has drained, wipe the

bilge with dry rags to make sure that it is

thoroughly dry.

(4) Install the stern drain plugs. NOTICE:

Before installing the stern drain plugs,

clean the drain plug threads to remove

any foreign materials, such as dirt or

sand. Otherwise, the stern drain plugs

could be damaged, allowing water to

enter the engine compartment. Make

sure that the stern drain plugs are

tightened securely before launching

the watercraft. Otherwise, water may

flood the engine compartment and

cause the watercraft to submerge.

[ECJ00361]

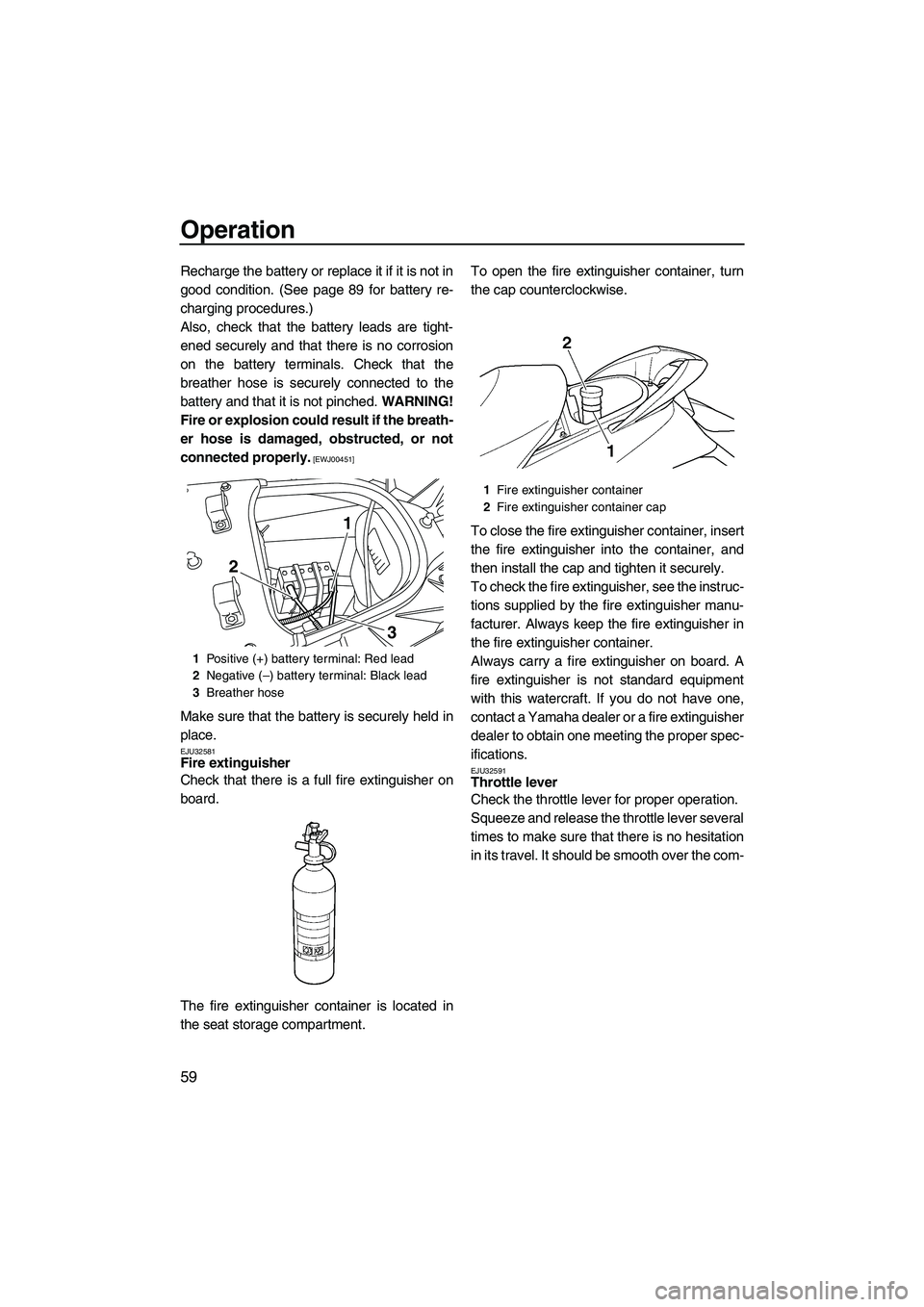

EJU32472

Stern drain plugs

Check the stern drain plugs for proper instal-

lation.

EJU32482Battery

Check the battery electrolyte level and check

that the battery has sufficient power to start

the engine easily. WARNING! Never operate

the watercraft if the battery does not have

sufficient power to start the engine or if it

shows any other signs of decreased pow-

er. Loss of battery power may leave you

stranded.

[EWJ01240]

1Electric bilge pilot outlet

1

1Stern drain plugs

1

UF1W71E0.book Page 58 Tuesday, June 24, 2008 11:46 AM

Page 66 of 108

Operation

59

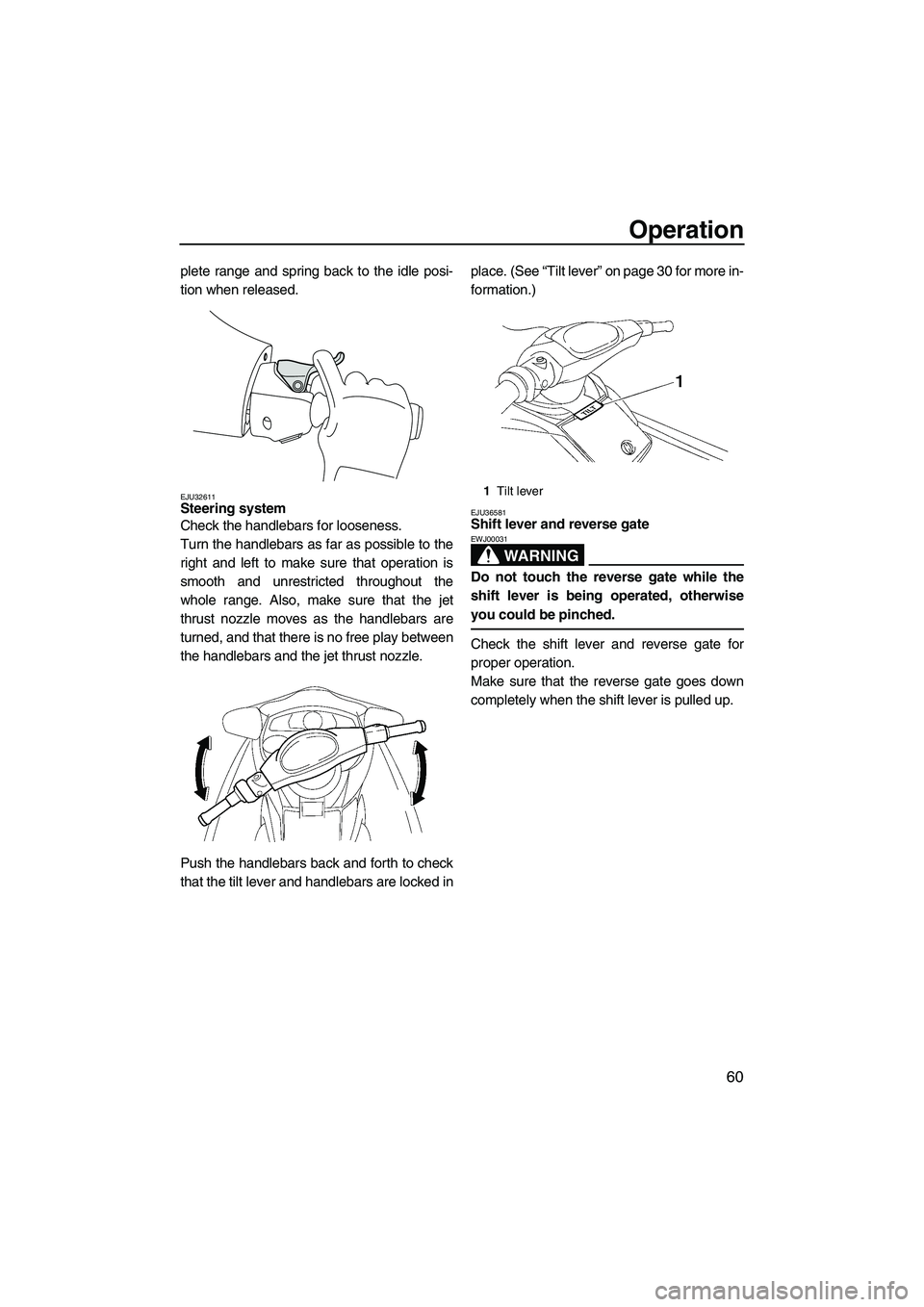

Recharge the battery or replace it if it is not in

good condition. (See page 89 for battery re-

charging procedures.)

Also, check that the battery leads are tight-

ened securely and that there is no corrosion

on the battery terminals. Check that the

breather hose is securely connected to the

battery and that it is not pinched. WARNING!

Fire or explosion could result if the breath-

er hose is damaged, obstructed, or not

connected properly.

[EWJ00451]

Make sure that the battery is securely held in

place.

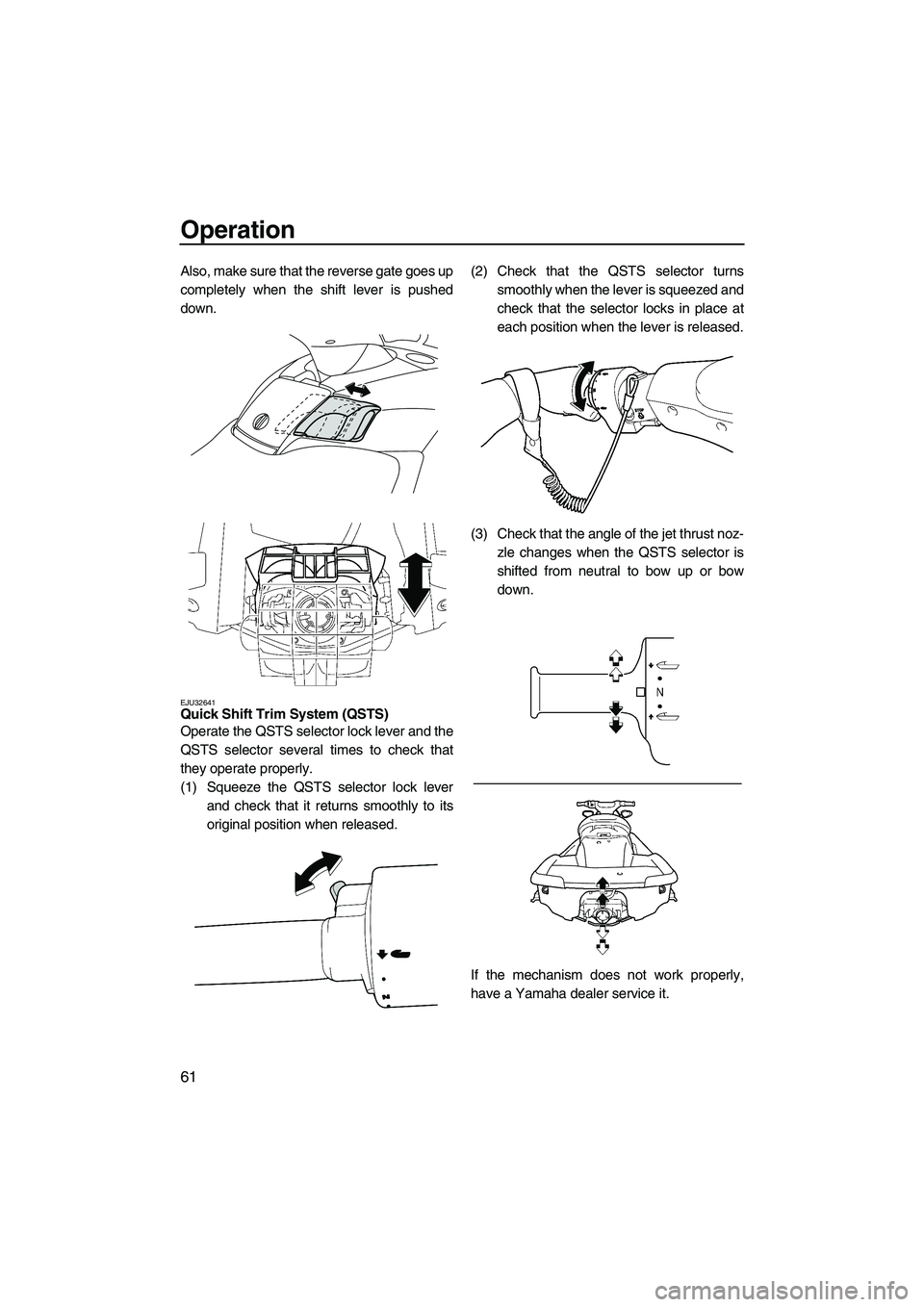

EJU32581Fire extinguisher

Check that there is a full fire extinguisher on

board.

The fire extinguisher container is located in

the seat storage compartment.To open the fire extinguisher container, turn

the cap counterclockwise.

To close the fire extinguisher container, insert

the fire extinguisher into the container, and

then install the cap and tighten it securely.

To check the fire extinguisher, see the instruc-

tions supplied by the fire extinguisher manu-

facturer. Always keep the fire extinguisher in

the fire extinguisher container.

Always carry a fire extinguisher on board. A

fire extinguisher is not standard equipment

with this watercraft. If you do not have one,

contact a Yamaha dealer or a fire extinguisher

dealer to obtain one meeting the proper spec-

ifications.EJU32591Throttle lever

Check the throttle lever for proper operation.

Squeeze and release the throttle lever several

times to make sure that there is no hesitation

in its travel. It should be smooth over the com-

1Positive (+) battery terminal: Red lead

2Negative (–) battery terminal: Black lead

3Breather hose

3

1

2

1Fire extinguisher container

2Fire extinguisher container cap

UF1W71E0.book Page 59 Tuesday, June 24, 2008 11:46 AM

Page 67 of 108

Operation

60

plete range and spring back to the idle posi-

tion when released.

EJU32611Steering system

Check the handlebars for looseness.

Turn the handlebars as far as possible to the

right and left to make sure that operation is

smooth and unrestricted throughout the

whole range. Also, make sure that the jet

thrust nozzle moves as the handlebars are

turned, and that there is no free play between

the handlebars and the jet thrust nozzle.

Push the handlebars back and forth to check

that the tilt lever and handlebars are locked inplace. (See “Tilt lever” on page 30 for more in-

formation.)EJU36581Shift lever and reverse gate

WARNING

EWJ00031

Do not touch the reverse gate while the

shift lever is being operated, otherwise

you could be pinched.

Check the shift lever and reverse gate for

proper operation.

Make sure that the reverse gate goes down

completely when the shift lever is pulled up.

1Tilt lever

UF1W71E0.book Page 60 Tuesday, June 24, 2008 11:46 AM

Page 68 of 108

Operation

61

Also, make sure that the reverse gate goes up

completely when the shift lever is pushed

down.

EJU32641Quick Shift Trim System (QSTS)

Operate the QSTS selector lock lever and the

QSTS selector several times to check that

they operate properly.

(1) Squeeze the QSTS selector lock lever

and check that it returns smoothly to its

original position when released.(2) Check that the QSTS selector turns

smoothly when the lever is squeezed and

check that the selector locks in place at

each position when the lever is released.

(3) Check that the angle of the jet thrust noz-

zle changes when the QSTS selector is

shifted from neutral to bow up or bow

down.

If the mechanism does not work properly,

have a Yamaha dealer service it.

UF1W71E0.book Page 61 Tuesday, June 24, 2008 11:46 AM

Page 69 of 108

Operation

62

EJU32651Jet intake

Carefully check the jet intake for weeds, de-

bris, or anything else that might restrict the in-

take of water. If the jet intake is clogged, clean

it. (See page 95 for jet intake cleaning proce-

dures.)

If the watercraft is operated while the jet in-

take is clogged, cavitation could occur, reduc-

ing jet thrust, and possibly damaging the jet

pump. In some cases, the engine may over-

heat because of lack of cooling water, and

damage to the engine could result. Cooling

water is fed to the engine by the jet pump.

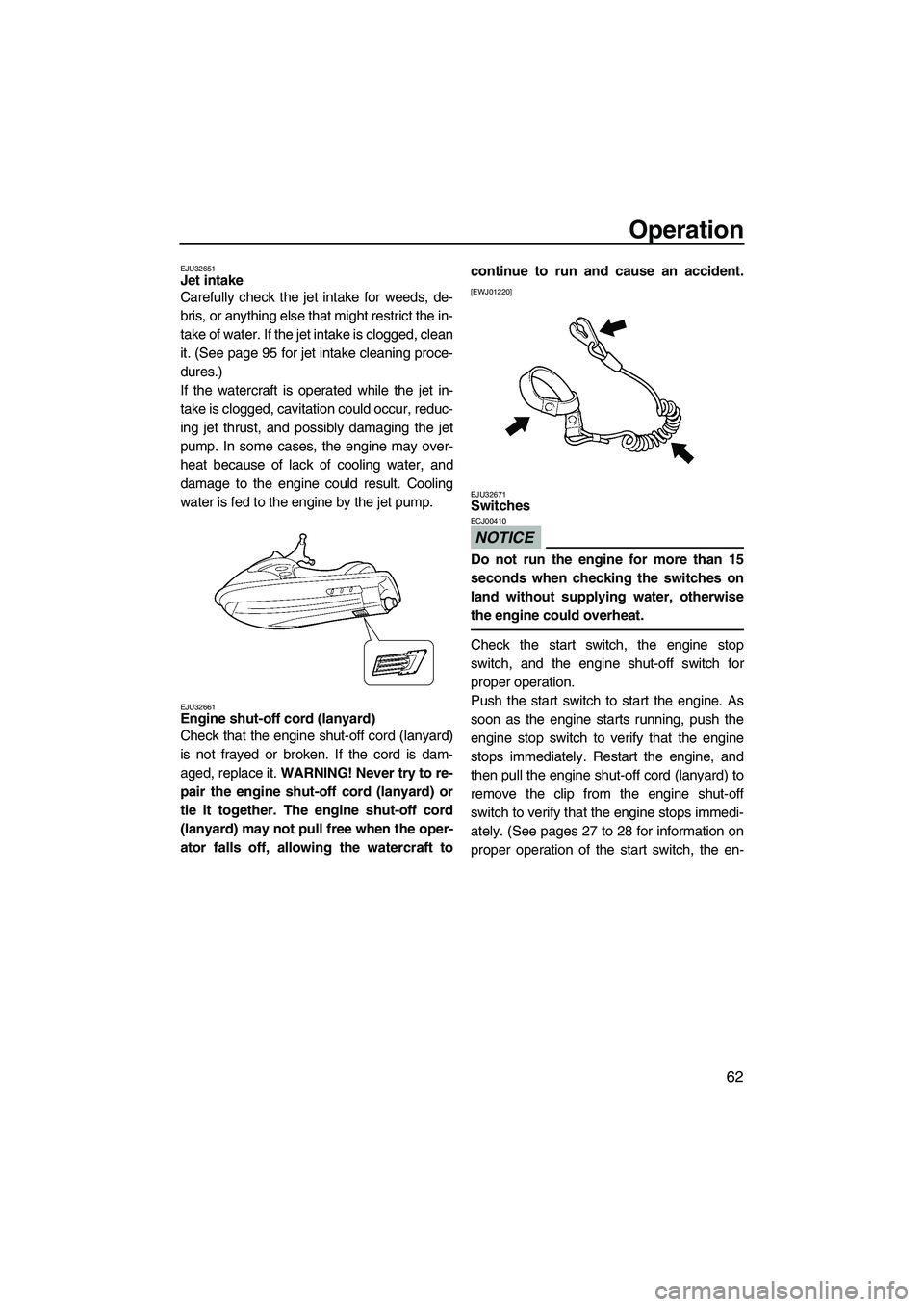

EJU32661Engine shut-off cord (lanyard)

Check that the engine shut-off cord (lanyard)

is not frayed or broken. If the cord is dam-

aged, replace it. WARNING! Never try to re-

pair the engine shut-off cord (lanyard) or

tie it together. The engine shut-off cord

(lanyard) may not pull free when the oper-

ator falls off, allowing the watercraft tocontinue to run and cause an accident.

[EWJ01220]

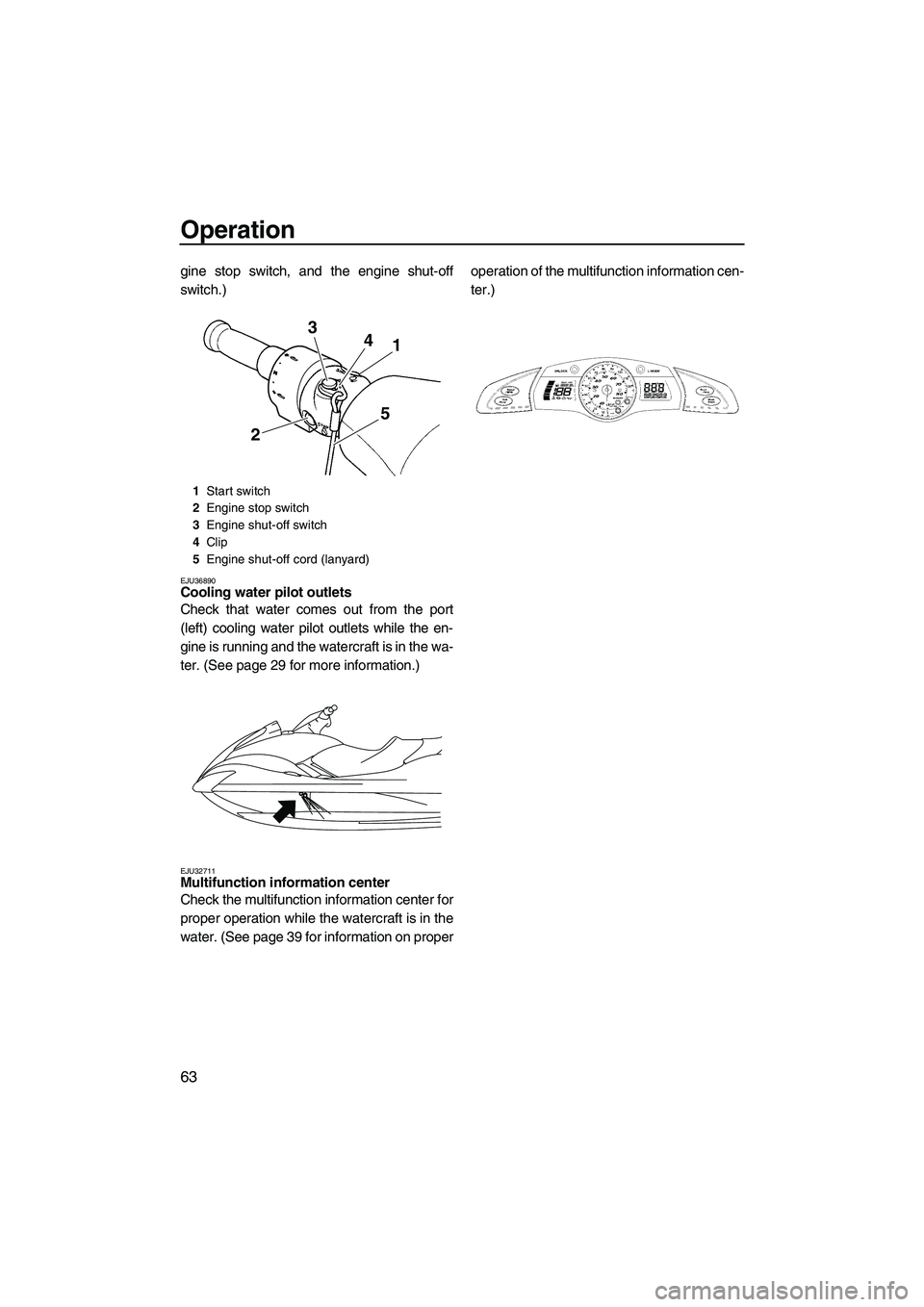

EJU32671

Switches

NOTICE

ECJ00410

Do not run the engine for more than 15

seconds when checking the switches on

land without supplying water, otherwise

the engine could overheat.

Check the start switch, the engine stop

switch, and the engine shut-off switch for

proper operation.

Push the start switch to start the engine. As

soon as the engine starts running, push the

engine stop switch to verify that the engine

stops immediately. Restart the engine, and

then pull the engine shut-off cord (lanyard) to

remove the clip from the engine shut-off

switch to verify that the engine stops immedi-

ately. (See pages 27 to 28 for information on

proper operation of the start switch, the en-

UF1W71E0.book Page 62 Tuesday, June 24, 2008 11:46 AM

Page 70 of 108

Operation

63

gine stop switch, and the engine shut-off

switch.)

EJU36890Cooling water pilot outlets

Check that water comes out from the port

(left) cooling water pilot outlets while the en-

gine is running and the watercraft is in the wa-

ter. (See page 29 for more information.)

EJU32711Multifunction information center

Check the multifunction information center for

proper operation while the watercraft is in the

water. (See page 39 for information on properoperation of the multifunction information cen-

ter.)

1Start switch

2Engine stop switch

3Engine shut-off switch

4Clip

5Engine shut-off cord (lanyard)

4

1 3

5

2

UF1W71E0.book Page 63 Tuesday, June 24, 2008 11:46 AM