ABS YAMAHA TDM 900 2003 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2003, Model line: TDM 900, Model: YAMAHA TDM 900 2003Pages: 110, PDF Size: 7.38 MB

Page 11 of 110

2-1

EAU00026

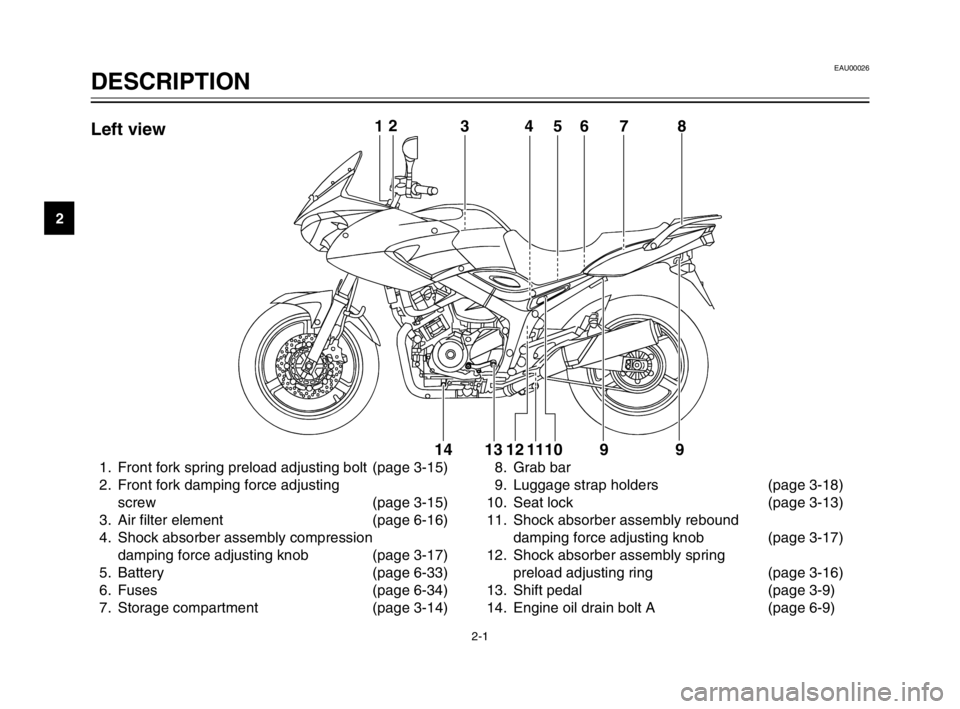

DESCRIPTIONPart locations

2

1. Front fork spring preload adjusting bolt (page 3-15)

2. Front fork damping force adjusting

screw (page 3-15)

3. Air filter element (page 6-16)

4. Shock absorber assembly compression

damping force adjusting knob (page 3-17)

5. Battery (page 6-33)

6. Fuses (page 6-34)

7. Storage compartment (page 3-14)8. Grab bar

9. Luggage strap holders (page 3-18)

10. Seat lock (page 3-13)

11. Shock absorber assembly rebound

damping force adjusting knob (page 3-17)

12. Shock absorber assembly spring

preload adjusting ring (page 3-16)

13. Shift pedal (page 3-9)

14. Engine oil drain bolt A (page 6-9)

12

345678

9 9 10 11 12 13 1412

345678

9 9 10 11 12 13 14Left view

5PS-28199-E1 8/29/02 9:16 AM Page 10

Page 14 of 110

INSTRUMENT AND CONTROL FUNCTIONS

Main switch/steering lock ...................................................................3-1

Indicator and warning lights ...............................................................3-2

Speedometer unit ..............................................................................3-4

Tachometer unit .................................................................................3-5

Coolant temperature gauge ...............................................................3-6

Anti-theft alarm (optional) ..................................................................3-7

Handlebar switches ...........................................................................3-7

Clutch lever ........................................................................................3-9

Shift pedal ..........................................................................................3-9

Brake lever ........................................................................................3-9

Brake pedal .....................................................................................3-10

Fuel tank cap ...................................................................................3-10

Fuel ..................................................................................................3-11

Fuel tank breather hose ...................................................................3-12

Catalytic converter ...........................................................................3-12

Seat .................................................................................................3-13

Storage compartment ......................................................................3-14

Adjusting the front fork .....................................................................3-14

Adjusting the shock absorber assembly ..........................................3-16

Luggage strap holders .....................................................................3-18

Sidestand .........................................................................................3-18

Ignition circuit cut-off system ...........................................................3-19

3

5PS-28199-E1 8/29/02 9:16 AM Page 13

Page 30 of 110

3-16

INSTRUMENT AND CONTROL FUNCTIONS

3 3. To increase the damping force,

continue turning the adjusting

screw in direction a. The third

click after the minimum setting is

the maximum setting. If the

adjusting screw is turned further

in direction a, it will move half a

turn before returning to the mini-

mum setting.

NOTE:

Make sure that the adjusting screw is

turned to one of the four settings.

Setting

Minimum (soft) 1

Standard 2

Maximum (hard) 4

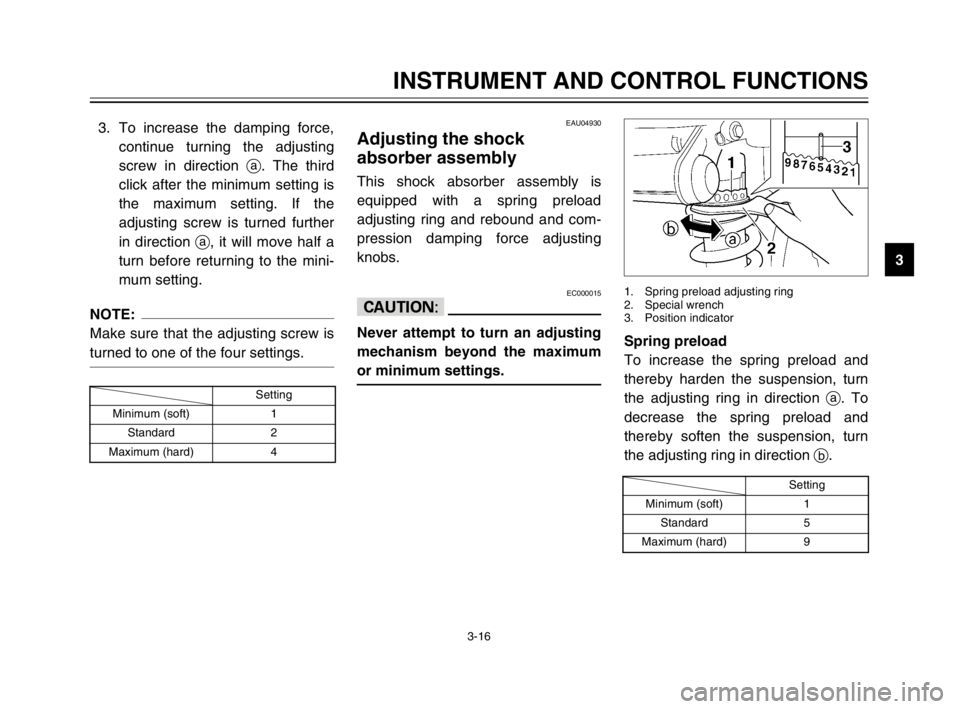

EAU04930

Adjusting the shock

absorber assembly

Shock absorber assembly, adjustingThis shock absorber assembly is

equipped with a spring preload

adjusting ring and rebound and com-

pression damping force adjusting

knobs.

EC000015

cC

Never attempt to turn an adjusting

mechanism beyond the maximum

or minimum settings.Spring preload

To increase the spring preload and

thereby harden the suspension, turn

the adjusting ring in direction a. To

decrease the spring preload and

thereby soften the suspension, turn

the adjusting ring in direction b.

1. Spring preload adjusting ring

2. Special wrench

3. Position indicator

Setting

Minimum (soft) 1

Standard 5

Maximum (hard) 9

5PS-28199-E1 8/29/02 9:16 AM Page 29

Page 32 of 110

3-18

INSTRUMENT AND CONTROL FUNCTIONS

3

EAU00315

w

This shock absorber contains

highly pressurized nitrogen gas.

For proper handling, read and

understand the following informa-

tion before handling the shock

absorber. The manufacturer can-

not be held responsible for proper-

ty damage or personal injury that

may result from improper han-

dling.

8Do not tamper with or attempt

to open the gas cylinder.

8Do not subject the shock

absorber to an open flame or

other high heat sources, other-

wise it may explode due to

excessive gas pressure.

8Do not deform or damage the

gas cylinder in any way, as

this will result in poor damp-

ing performance.

8Always have a Yamaha dealer

service the shock absorber.

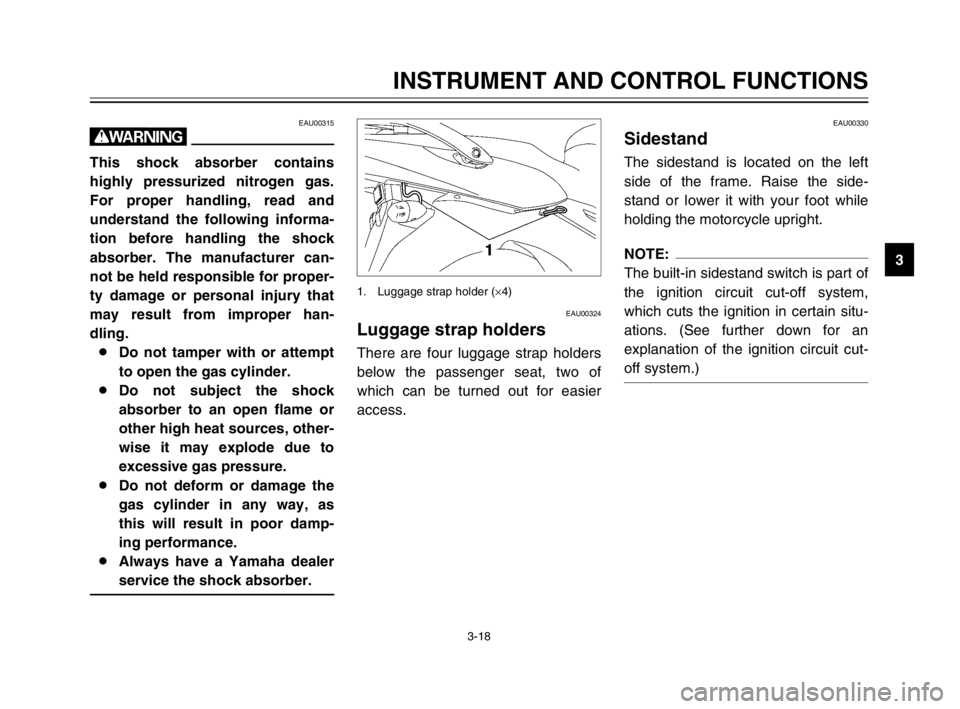

EAU00324

Luggage strap holdersLuggage strap holdersThere are four luggage strap holders

below the passenger seat, two of

which can be turned out for easier

access.

1. Luggage strap holder (×4)

EAU00330

SidestandSidestandThe sidestand is located on the left

side of the frame. Raise the side-

stand or lower it with your foot while

holding the motorcycle upright.

NOTE:

The built-in sidestand switch is part of

the ignition circuit cut-off system,

which cuts the ignition in certain situ-

ations. (See further down for an

explanation of the ignition circuit cut-

off system.)

5PS-28199-E1 8/29/02 9:16 AM Page 31

Page 49 of 110

6-3

PERIODIC MAINTENANCE AND MINOR REPAIR

6

10*Tires•Check tread depth and for damage.

•Replace if necessary.

•Check air pressure.

•Correct if necessary.√√√√ √

11

*Wheel bearings•Check bearing for looseness or damage.√√√√

12

*Swingarm•Check operation and for excessive play.√√√√

•Lubricate with lithium-soap-based grease. Every 50,000 km

13 Drive chain•Check chain slack.

•Make sure that the rear wheel is properly aligned.

•Clean and lubricate.Every 1,000 km and after washing

the motorcycle or riding in the rain

14

*Steering bearings•Check bearing play and steering for roughness.√√√√√

•Lubricate with lithium-soap-based grease.Every 20,000 km

15

*Chassis fasteners•Make sure that all nuts, bolts and screws are properly tightened.√√√√ √

16 Sidestand•Check operation.

•Lubricate.√√√√ √

17

*Sidestand switch•Check operation.√√√√√ √

18

*Front fork•Check operation and for oil leakage.√√√√

19

*Shock absorber

assembly•Check operation and shock absorber for oil leakage.√√√√

20

*

Rear suspension relay

arm and connecting arm

pivoting points•Check operation.√√√√

•Lubricate with lithium-soap-based grease.√√

21

*Electronic fuel injection•Adjust engine idling speed and synchronization.√√√√√ √ NO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING (× 1,000 km)

ANNUAL

CHECK

1 10203040

5PS-28199-E1 8/29/02 9:16 AM Page 48

Page 95 of 110

7

7-3

MOTORCYCLE CARE AND STORAGE

1. Clean the motorcycle with cold

water and a mild detergent, after

the engine has cooled down.

ECA00012

cC

Do not use warm water since it

increases the corrosive action of

the salt.

2. After drying the motorcycle,

apply a corrosion protection

spray on all metal, including

chrome- and nickel-plated, sur-

faces to prevent corrosion.After cleaning

1. Dry the motorcycle with a

chamois or an absorbing cloth.

2. Immediately dry the drive chain

and lubricate it to prevent it from

rusting.

3. Use a chrome polish to shine

chrome, aluminum and stainless-

steel parts, including the exhaust

system. (Even the thermally

induced discoloring of stainless-

steel exhaust systems can be

removed through polishing.)

4. To prevent corrosion, it is recom-

mended to apply a corrosion pro-

tection spray on all metal, includ-

ing chrome- and nickel-plated,

surfaces.

5. Use spray oil as a universal

cleaner to remove any remaining

dirt.

6. Touch up minor paint damage

caused by stones, etc.7. Wax all painted surfaces.

8. Let the motorcycle dry complete-

ly before storing or covering it.

EWA00001

w

8Make sure that there is no oil

or wax on the brakes or tires.

If necessary, clean the brake

discs and brake linings with a

regular brake disc cleaner or

acetone, and wash the tires

with warm water and a mild

detergent.

8Before operating the motorcy-

cle test its braking perfor-

mance and cornering behav-

ior.

5PS-28199-E1 8/29/02 9:17 AM Page 94

Page 101 of 110

8

8-3

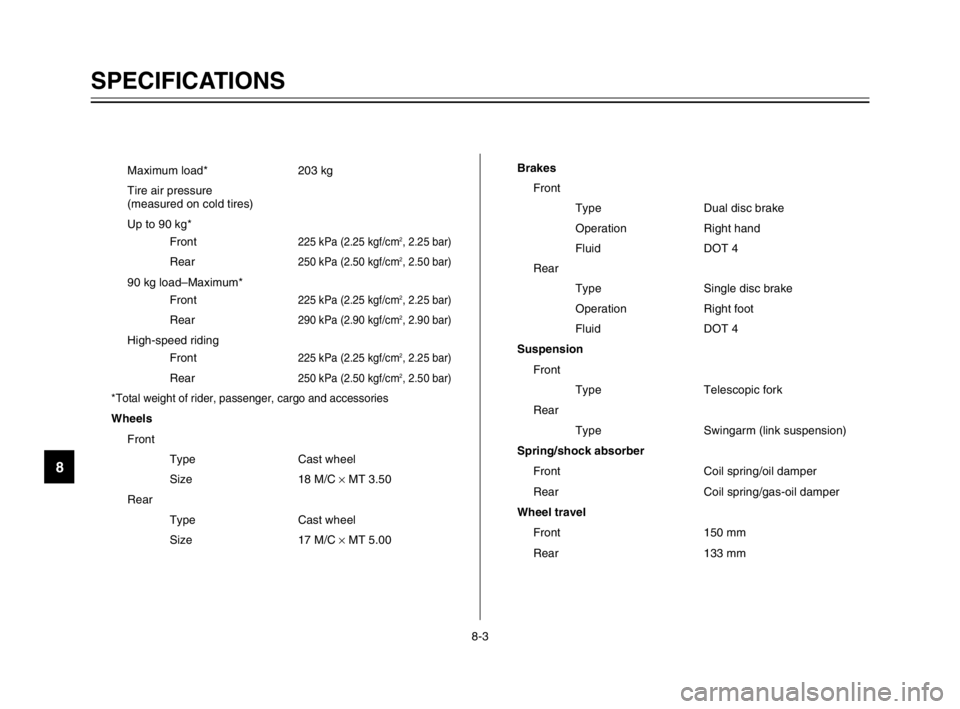

SPECIFICATIONS

Maximum load* 203 kg

Tire air pressure

(measured on cold tires)

Up to 90 kg*

Front

225 kPa (2.25 kgf/cm2, 2.25 bar)

Rear250 kPa (2.50 kgf/cm2, 2.50 bar)

90 kg load–Maximum*

Front

225 kPa (2.25 kgf/cm2, 2.25 bar)

Rear290 kPa (2.90 kgf/cm2, 2.90 bar)

High-speed riding

Front

225 kPa (2.25 kgf/cm2, 2.25 bar)

Rear250 kPa (2.50 kgf/cm2, 2.50 bar)

*Total weight of rider, passenger, cargo and accessories

Wheels

Front

Type Cast wheel

Size 18 M/C ×MT 3.50

Rear

Type Cast wheel

Size 17 M/C ×MT 5.00Brakes

Front

Type Dual disc brake

Operation Right hand

Fluid DOT 4

Rear

Type Single disc brake

Operation Right foot

Fluid DOT 4

Suspension

Front

Type Telescopic fork

Rear

Type Swingarm (link suspension)

Spring/shock absorber

Front Coil spring/oil damper

Rear Coil spring/gas-oil damper

Wheel travel

Front 150 mm

Rear 133 mm

5PS-28199-E1 8/29/02 9:17 AM Page 100

Page 108 of 110

Shift points (for Switzerland only) ...........5-3

Shifting ...................................................5-2

Shock absorber assembly, adjusting ....3-16

Sidestand .............................................3-18

Sidestand, checking and lubricating .....6-30

Spark plugs, checking ............................6-7

Specifications .........................................8-1

Speedometer unit ...................................3-4

Starting the engine .................................5-1

Steering, checking ................................6-32

Storage ...................................................7-4

Storage compartment ...........................3-14

Supporting the motorcycle ....................6-38

T

Tachometer unit .....................................3-5

Tail/brake light bulb, replacing ..............6-37

Throttle cable free play, adjusting ........6-18

Throttle grip and cable, checking

and lubricating ...................................6-29

Tires .....................................................6-18

Tool kit ....................................................6-1

Troubleshooting ....................................6-43

Troubleshooting charts .........................6-44

Turn signal light bulb, replacing ............6-37

V

Valve clearance, adjusting ...................6-18

Vehicle identification number .................9-1W

Wheel (front)..........................................6-39

Installing .............................................6-40

Removing ...........................................6-39

Wheel (rear) .........................................6-40

Installing .............................................6-42

Removing ...........................................6-40

Wheel bearings, checking ....................6-32

Wheels .................................................6-22

INDEX

5PS-28199-E1 8/29/02 9:17 AM Page 107