air filter YAMAHA TDM 900 2003 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2003, Model line: TDM 900, Model: YAMAHA TDM 900 2003Pages: 110, PDF Size: 7.38 MB

Page 11 of 110

2-1

EAU00026

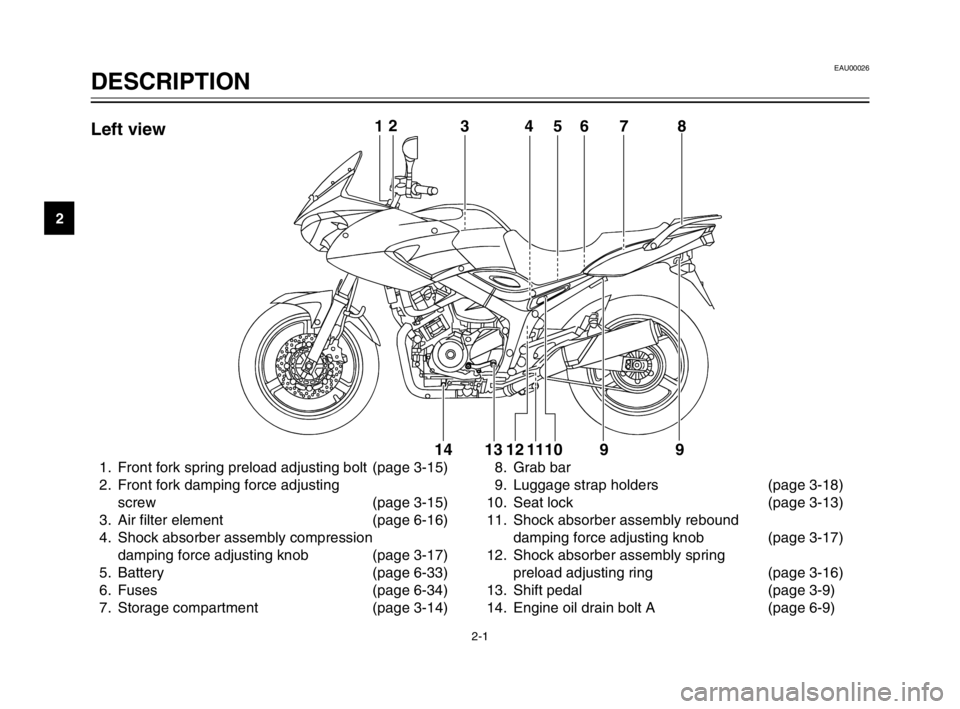

DESCRIPTIONPart locations

2

1. Front fork spring preload adjusting bolt (page 3-15)

2. Front fork damping force adjusting

screw (page 3-15)

3. Air filter element (page 6-16)

4. Shock absorber assembly compression

damping force adjusting knob (page 3-17)

5. Battery (page 6-33)

6. Fuses (page 6-34)

7. Storage compartment (page 3-14)8. Grab bar

9. Luggage strap holders (page 3-18)

10. Seat lock (page 3-13)

11. Shock absorber assembly rebound

damping force adjusting knob (page 3-17)

12. Shock absorber assembly spring

preload adjusting ring (page 3-16)

13. Shift pedal (page 3-9)

14. Engine oil drain bolt A (page 6-9)

12

345678

9 9 10 11 12 13 1412

345678

9 9 10 11 12 13 14Left view

5PS-28199-E1 8/29/02 9:16 AM Page 10

Page 46 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

Owner’s tool kit .....................................................6-1

Periodic maintenance and lubrication chart .........6-2

Removing and installing cowlings and panels ......6-5

Checking the spark plugs .....................................6-7

Engine oil and oil filter element ............................6-8

Coolant ...............................................................6-11

Replacing the air filter element ...........................6-16

Adjusting the engine idling speed .......................6-17

Adjusting the throttle cable free play ..................6-18

Adjusting the valve clearance .............................6-18

Tires ...................................................................6-18

Cast wheels ........................................................6-22

Adjusting the clutch lever free play .....................6-22

Adjusting the brake pedal position .....................6-23

Adjusting the rear brake light switch ...................6-24

Checking the front and rear brake pads .............6-24

Checking the brake fluid level ............................6-25

Changing the brake fluid ....................................6-26

Drive chain slack ................................................6-27

Lubricating the drive chain .................................6-28

Checking and lubricating the cables ...................6-29

Checking and lubricating the throttle grip

and cable .........................................................6-29Checking and lubricating the brake and

shift pedals ......................................................6-30

Checking and lubricating the brake and

clutch levers ....................................................6-30

Checking and lubricating the sidestand ..............6-30

Lubricating the rear suspension .........................6-31

Checking the front fork .......................................6-31

Checking the steering .........................................6-32

Checking the wheel bearings .............................6-32

Battery ................................................................6-33

Replacing the fuses ............................................6-34

Replacing a headlight bulb .................................6-35

Replacing a tail/brake light bulb .........................6-37

Replacing a turn signal light bulb .......................6-37

Supporting the motorcycle ..................................6-38

Front wheel .........................................................6-39

Rear wheel .........................................................6-40

Troubleshooting ..................................................6-43

Troubleshooting charts .......................................6-44

6

5PS-28199-E1 8/29/02 9:16 AM Page 45

Page 48 of 110

6-2

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EAU03685

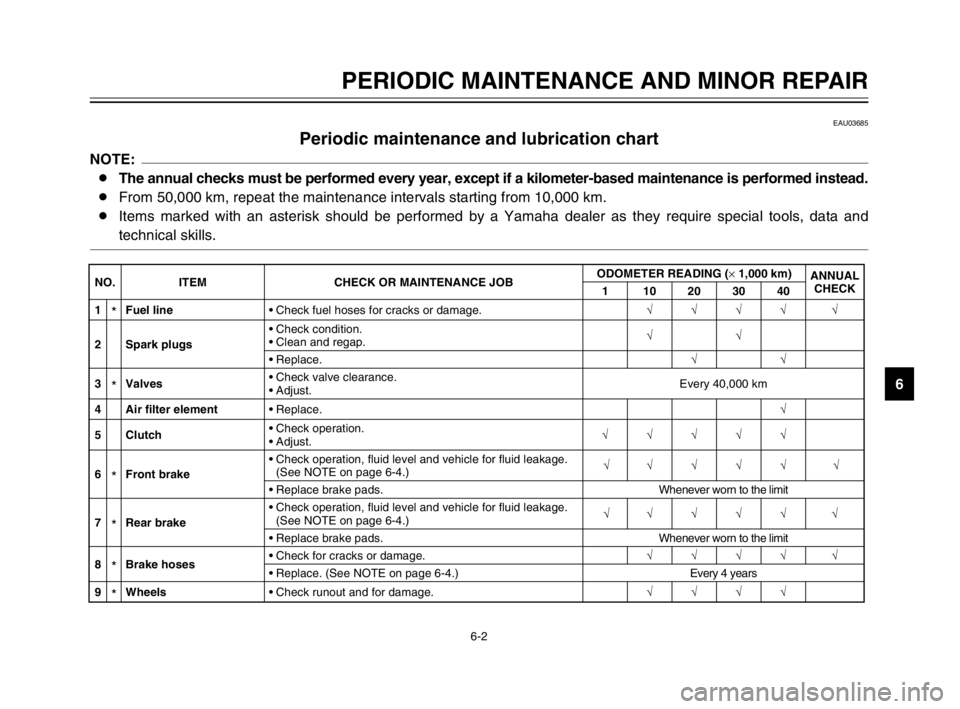

Periodic maintenance and lubrication chartPeriodic maintenance and lubrication chartNOTE:

8The annual checks must be performed every year, except if a kilometer-based maintenance is performed instead.

8From 50,000 km, repeat the maintenance intervals starting from 10,000 km.

8Items marked with an asterisk should be performed by a Yamaha dealer as they require special tools, data and

technical skills.

NO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING (× 1,000 km)

ANNUAL

CHECK

1 10203040

1

*Fuel line•Check fuel hoses for cracks or damage.√√√√ √

2 Spark plugs•Check condition.

•Clean and regap.√√

•Replace.√√

3

*Valves•Check valve clearance.

•Adjust.Every 40,000 km

4 Air filter element•Replace.√

5 Clutch•Check operation.

•Adjust.√√√√√

6

*Front brake•Check operation, fluid level and vehicle for fluid leakage.

(See NOTE on page 6-4.)√√√√√ √

•Replace brake pads.Whenever worn to the limit

7

*Rear brake•Check operation, fluid level and vehicle for fluid leakage.

(See NOTE on page 6-4.)√√√√√ √

•Replace brake pads.Whenever worn to the limit

8

*Brake hoses•Check for cracks or damage.√√√√ √

•Replace. (See NOTE on page 6-4.)Every 4 years

9

*Wheels•Check runout and for damage.√√√√

5PS-28199-E1 8/29/02 9:16 AM Page 47

Page 50 of 110

6-4

PERIODIC MAINTENANCE AND MINOR REPAIR

6

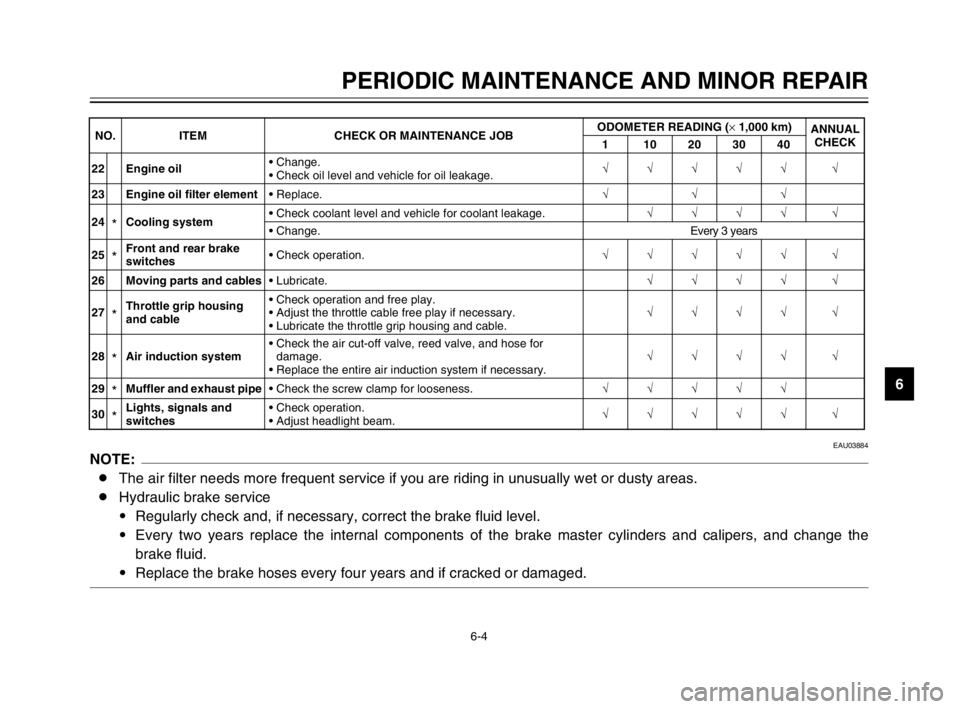

EAU03884

NOTE:

8The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

8Hydraulic brake service

9Regularly check and, if necessary, correct the brake fluid level.

9Every two years replace the internal components of the brake master cylinders and calipers, and change the

brake fluid.

9Replace the brake hoses every four years and if cracked or damaged.

22 Engine oil•Change.

•Check oil level and vehicle for oil leakage.√√√√√ √

23 Engine oil filter element•Replace.√√√

24

*Cooling system•Check coolant level and vehicle for coolant leakage.√√√√ √

•Change.Every 3 years

25

*Front and rear brake

switches•Check operation.√√√√√ √

26 Moving parts and cables•Lubricate.√√√√ √

27

*Throttle grip housing

and cable•Check operation and free play.

•Adjust the throttle cable free play if necessary.

•Lubricate the throttle grip housing and cable.√√√√ √

28

*Air induction system•Check the air cut-off valve, reed valve, and hose for

damage.

•Replace the entire air induction system if necessary.√√√√ √

29

*Muffler and exhaust pipe•Check the screw clamp for looseness.√√√√√

30

*Lights, signals and

switches•Check operation.

•Adjust headlight beam.√√√√√ √ NO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING (× 1,000 km)

ANNUAL

CHECK

1 10203040

5PS-28199-E1 8/29/02 9:16 AM Page 49

Page 54 of 110

6-8

PERIODIC MAINTENANCE AND MINOR REPAIR

6

NOTE:

If a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is

1/4–1/2 turn past finger tight.

However, the spark plug should be

tightened to the specified torque as

soon as possible.

3. Wait a few minutes until the oil

settles, remove the oil filler cap,

wipe the dipstick clean, insert it

back into the oil filler hole (with-

out screwing it in and with the

arrow mark pointing upward as

shown), and then remove it

again to check the oil level.

NOTE:

The engine oil should be between the

minimum and maximum level marks.

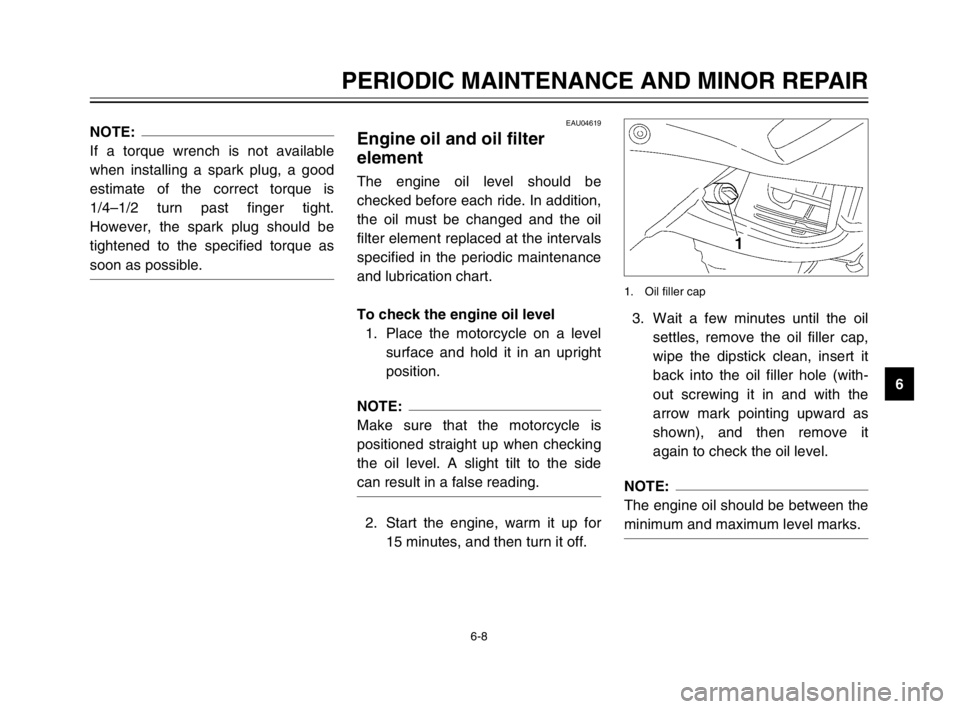

1. Oil filler cap

EAU04619

Engine oil and oil filter

element

Engine oil and oil filter elementThe engine oil level should be

checked before each ride. In addition,

the oil must be changed and the oil

filter element replaced at the intervals

specified in the periodic maintenance

and lubrication chart.

To check the engine oil level

1. Place the motorcycle on a level

surface and hold it in an upright

position.

NOTE:

Make sure that the motorcycle is

positioned straight up when checking

the oil level. A slight tilt to the side

can result in a false reading.

2. Start the engine, warm it up for

15 minutes, and then turn it off.

5PS-28199-E1 8/29/02 9:16 AM Page 53

Page 55 of 110

6-9

PERIODIC MAINTENANCE AND MINOR REPAIR

6

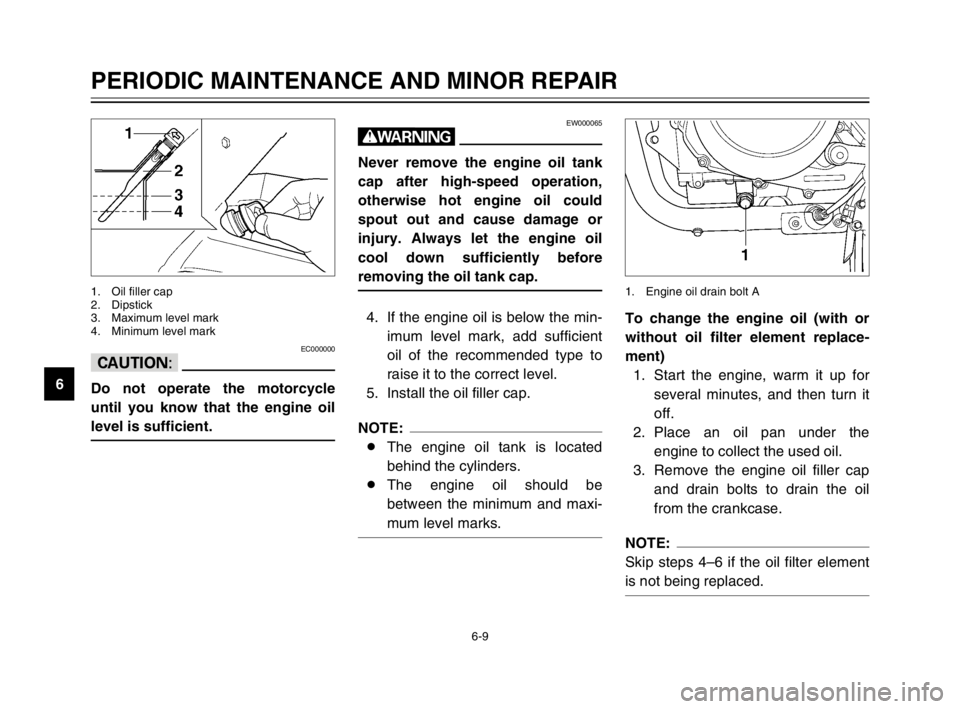

EC000000

cC

Do not operate the motorcycle

until you know that the engine oil

level is sufficient.

1. Oil filler cap

2. Dipstick

3. Maximum level mark

4. Minimum level mark

To change the engine oil (with or

without oil filter element replace-

ment)

1. Start the engine, warm it up for

several minutes, and then turn it

off.

2. Place an oil pan under the

engine to collect the used oil.

3. Remove the engine oil filler cap

and drain bolts to drain the oil

from the crankcase.

NOTE:

Skip steps 4–6 if the oil filter element

is not being replaced.

1. Engine oil drain bolt A

EW000065

w

Never remove the engine oil tank

cap after high-speed operation,

otherwise hot engine oil could

spout out and cause damage or

injury. Always let the engine oil

cool down sufficiently before

removing the oil tank cap.

4. If the engine oil is below the min-

imum level mark, add sufficient

oil of the recommended type to

raise it to the correct level.

5. Install the oil filler cap.

NOTE:

8The engine oil tank is located

behind the cylinders.

8The engine oil should be

between the minimum and maxi-

mum level marks.

5PS-28199-E1 8/29/02 9:16 AM Page 54

Page 56 of 110

6-10

PERIODIC MAINTENANCE AND MINOR REPAIR

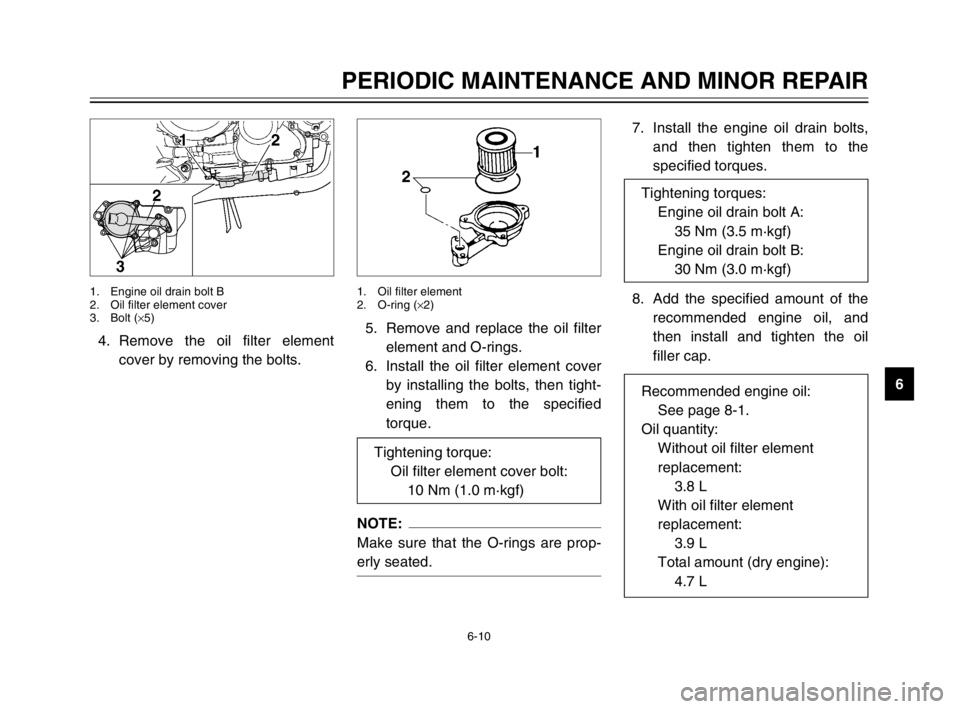

6 4. Remove the oil filter element

cover by removing the bolts.

1. Engine oil drain bolt B

2. Oil filter element cover

3. Bolt (×5)

7. Install the engine oil drain bolts,

and then tighten them to the

specified torques.

8. Add the specified amount of the

recommended engine oil, and

then install and tighten the oil

filler cap. 5. Remove and replace the oil filter

element and O-rings.

6. Install the oil filter element cover

by installing the bolts, then tight-

ening them to the specified

torque.

NOTE:

Make sure that the O-rings are prop-

erly seated.

1. Oil filter element

2. O-ring (×2)

Tightening torque:

Oil filter element cover bolt:

10 Nm (1.0 m·kgf)

Tightening torques:

Engine oil drain bolt A:

35 Nm (3.5 m·kgf)

Engine oil drain bolt B:

30 Nm (3.0 m·kgf)

Recommended engine oil:

See page 8-1.

Oil quantity:

Without oil filter element

replacement:

3.8 L

With oil filter element

replacement:

3.9 L

Total amount (dry engine):

4.7 L

5PS-28199-E1 8/29/02 9:16 AM Page 55

Page 62 of 110

6-16

PERIODIC MAINTENANCE AND MINOR REPAIR

6

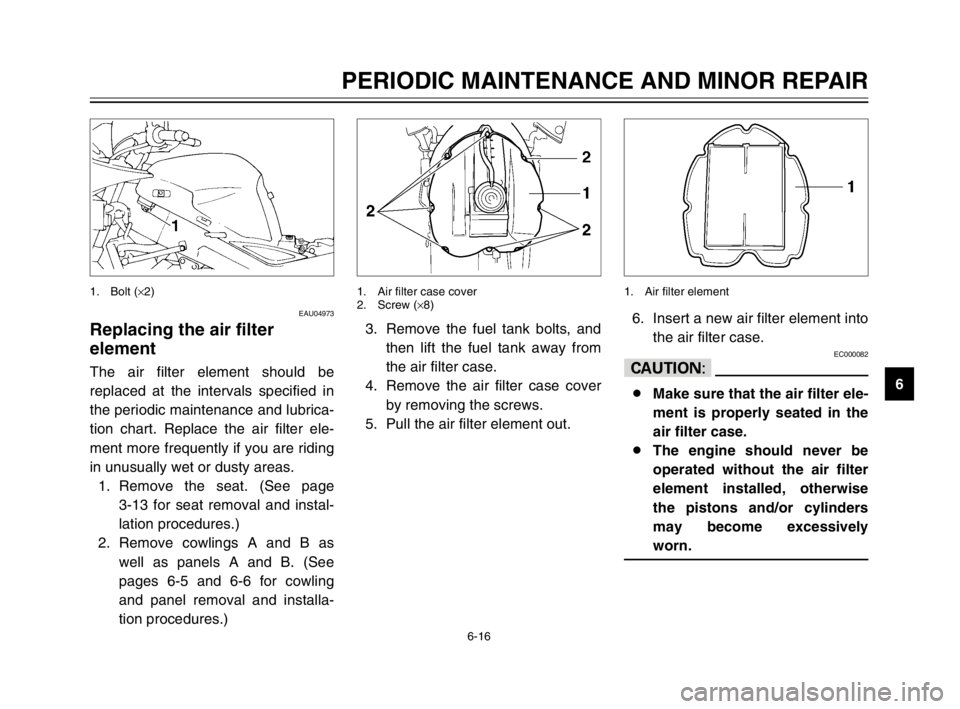

EAU04973

Replacing the air filter

element

Air filter element, replacingThe air filter element should be

replaced at the intervals specified in

the periodic maintenance and lubrica-

tion chart. Replace the air filter ele-

ment more frequently if you are riding

in unusually wet or dusty areas.

1. Remove the seat. (See page

3-13 for seat removal and instal-

lation procedures.)

2. Remove cowlings A and B as

well as panels A and B. (See

pages 6-5 and 6-6 for cowling

and panel removal and installa-

tion procedures.)

1. Bolt (×2)

6. Insert a new air filter element into

the air filter case.

EC000082

cC

8Make sure that the air filter ele-

ment is properly seated in the

air filter case.

8The engine should never be

operated without the air filter

element installed, otherwise

the pistons and/or cylinders

may become excessively

worn.

1. Air filter element

3. Remove the fuel tank bolts, and

then lift the fuel tank away from

the air filter case.

4. Remove the air filter case cover

by removing the screws.

5. Pull the air filter element out.

1. Air filter case cover

2. Screw (×8)

5PS-28199-E1 8/29/02 9:16 AM Page 61

Page 63 of 110

6-17

PERIODIC MAINTENANCE AND MINOR REPAIR

67. Install the air filter case cover by

installing the screws.

8. Place the fuel tank in the original

position and install the bolts.

EWA00067

w

8Before installing the fuel tank,

make sure that the fuel hoses

are not damaged. If any fuel

hose is damaged, do not start

the engine but have a Yamaha

dealer replace the hose, other-

wise fuel may leak.

8Make sure that the fuel hoses

are properly connected and

routed, and not pinched.

8Be sure to place the fuel tank

breather hose and the fuel

tank overflow hose in the orig-

inal position.

9. Install the panels and cowlings.

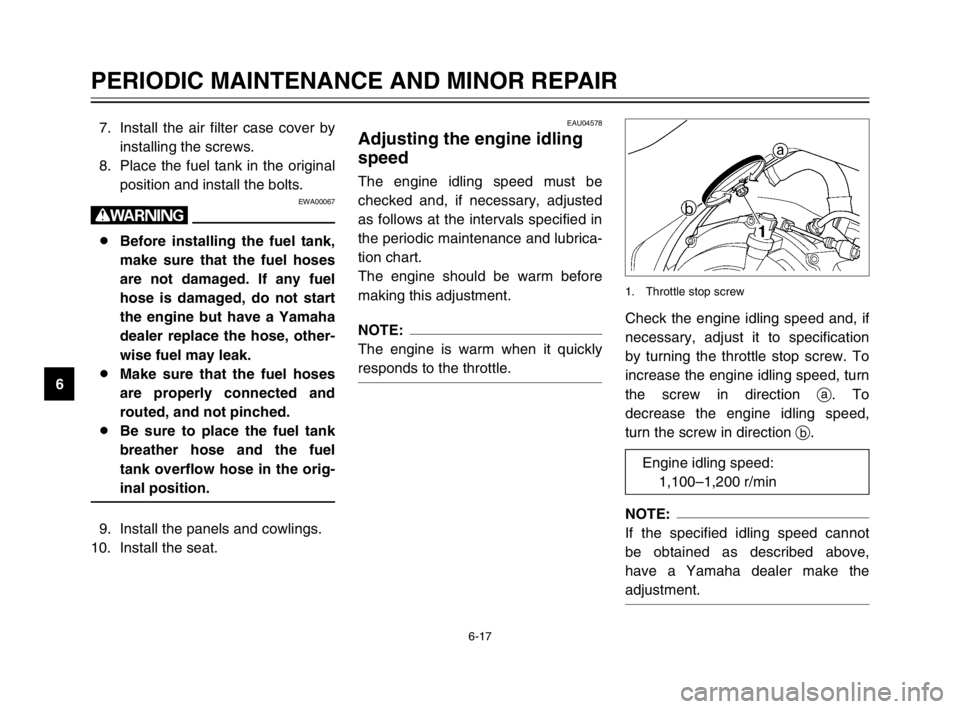

10. Install the seat.Check the engine idling speed and, if

necessary, adjust it to specification

by turning the throttle stop screw. To

increase the engine idling speed, turn

the screw in direction a. To

decrease the engine idling speed,

turn the screw in direction b.

NOTE:

If the specified idling speed cannot

be obtained as described above,

have a Yamaha dealer make the

adjustment.

1. Throttle stop screw

EAU04578

Adjusting the engine idling

speed

Engine idling speedThe engine idling speed must be

checked and, if necessary, adjusted

as follows at the intervals specified in

the periodic maintenance and lubrica-

tion chart.

The engine should be warm before

making this adjustment.

NOTE:

The engine is warm when it quickly

responds to the throttle.

Engine idling speed:

1,100–1,200 r/min

5PS-28199-E1 8/29/02 9:16 AM Page 62

Page 100 of 110

8

8-2

SPECIFICATIONS

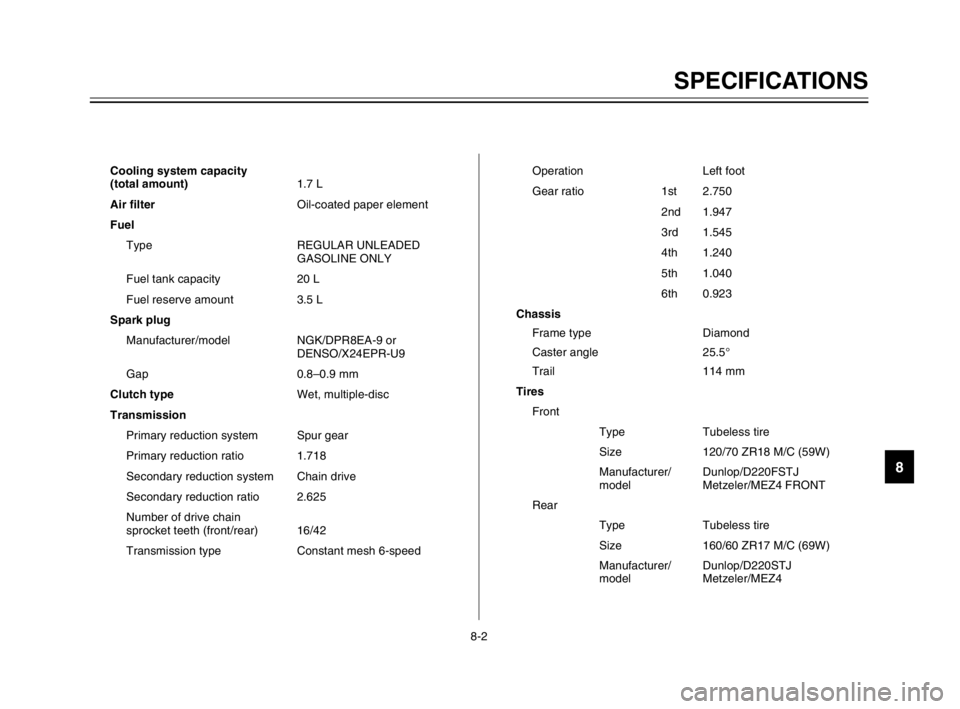

Cooling system capacity

(total amount)1.7 L

Air filterOil-coated paper element

Fuel

Type REGULAR UNLEADED

GASOLINE ONLY

Fuel tank capacity 20 L

Fuel reserve amount 3.5 L

Spark plug

Manufacturer/model NGK/DPR8EA-9 or

DENSO/X24EPR-U9

Gap 0.8–0.9 mm

Clutch typeWet, multiple-disc

Transmission

Primary reduction system Spur gear

Primary reduction ratio 1.718

Secondary reduction system Chain drive

Secondary reduction ratio 2.625

Number of drive chain

sprocket teeth (front/rear) 16/42

Transmission type Constant mesh 6-speedOperation Left foot

Gear ratio 1st 2.750

2nd 1.947

3rd 1.545

4th 1.240

5th 1.040

6th 0.923

Chassis

Frame type Diamond

Caster angle 25.5°

Trail 114 mm

Tires

Front

Type Tubeless tire

Size 120/70 ZR18 M/C (59W)

Manufacturer/ Dunlop/D220FSTJ

model Metzeler/MEZ4 FRONT

Rear

Type Tubeless tire

Size 160/60 ZR17 M/C (69W)

Manufacturer/ Dunlop/D220STJ

model Metzeler/MEZ4

5PS-28199-E1 8/29/02 9:17 AM Page 99