YAMAHA TDM 900 2009 Workshop Manual

Manufacturer: YAMAHA, Model Year: 2009, Model line: TDM 900, Model: YAMAHA TDM 900 2009Pages: 94, PDF Size: 3.75 MB

Page 51 of 94

PERIODIC MAINTENANCE AND ADJUSTMENT

6-6

2

3

4

5

67

8

9

EAU18712

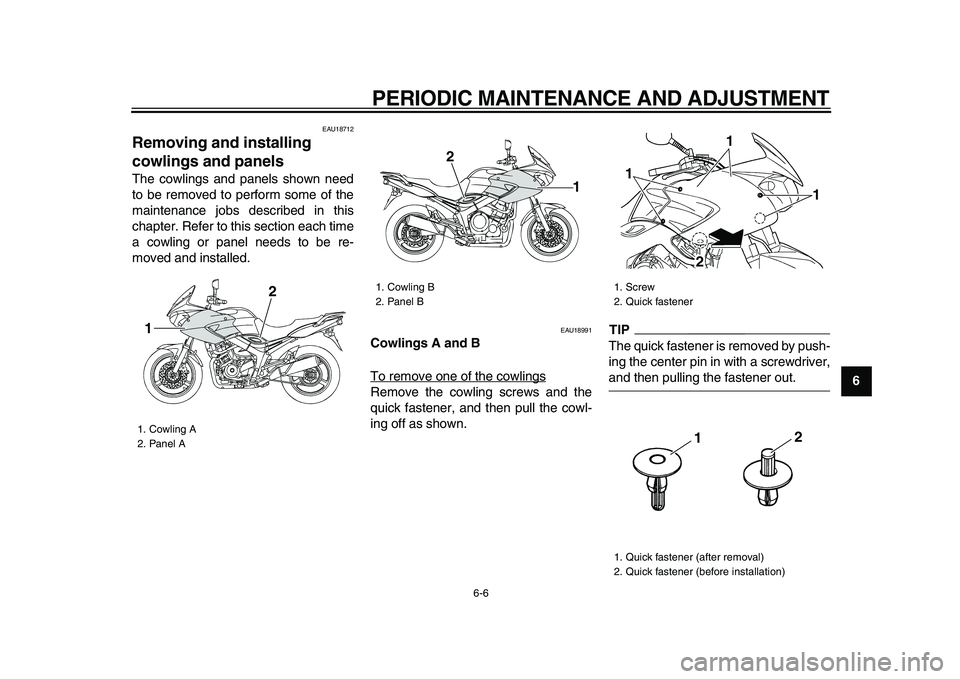

Removing and installing

cowlings and panels

The cowlings and panels shown need

to be removed to perform some of the

maintenance jobs described in this

chapter. Refer to this section each time

a cowling or panel needs to be re-

moved and installed.

EAU18991

Cowlings A and B

To remove one of the cowlings

Remove the cowling screws and the

quick fastener, and then pull the cowl-

ing off as shown.

TIP

The quick fastener is removed by push-

ing the center pin in with a screwdriver,

and then pulling the fastener out.

1. Cowling A

2. Panel A

2

1

1. Cowling B

2. Panel B2

1

1. Screw

2. Quick fastener

1. Quick fastener (after removal)

2. Quick fastener (before installation)

1

1

1

2

12

Page 52 of 94

PERIODIC MAINTENANCE AND ADJUSTMENT

6-7

1

2

3

4

5

6

7

8

9

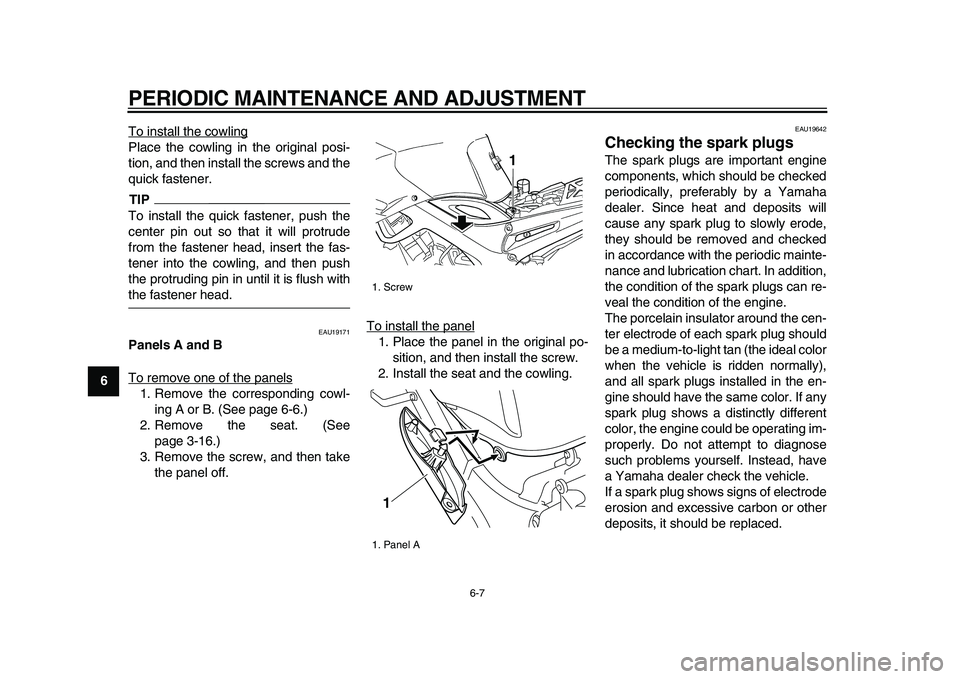

To install the cowling

Place the cowling in the original posi-

tion, and then install the screws and the

quick fastener.TIP

To install the quick fastener, push the

center pin out so that it will protrude

from the fastener head, insert the fas-

tener into the cowling, and then push

the protruding pin in until it is flush with

the fastener head.

EAU19171

Panels A and B

To remove one of the panels

1. Remove the corresponding cowl-

ing A or B. (See page 6-6.)

2. Remove the seat. (See

page 3-16.)

3. Remove the screw, and then take

the panel off.To install the panel

1. Place the panel in the original po-

sition, and then install the screw.

2. Install the seat and the cowling.

EAU19642

Checking the spark plugs

The spark plugs are important engine

components, which should be checked

periodically, preferably by a Yamaha

dealer. Since heat and deposits will

cause any spark plug to slowly erode,

they should be removed and checked

in accordance with the periodic mainte-

nance and lubrication chart. In addition,

the condition of the spark plugs can re-

veal the condition of the engine.

The porcelain insulator around the cen-

ter electrode of each spark plug should

be a medium-to-light tan (the ideal color

when the vehicle is ridden normally),

and all spark plugs installed in the en-

gine should have the same color. If any

spark plug shows a distinctly different

color, the engine could be operating im-

properly. Do not attempt to diagnose

such problems yourself. Instead, have

a Yamaha dealer check the vehicle.

If a spark plug shows signs of electrode

erosion and excessive carbon or other

deposits, it should be replaced.

1. Screw

1. Panel A

1

1

Page 53 of 94

PERIODIC MAINTENANCE AND ADJUSTMENT

6-8

2

3

4

5

67

8

9

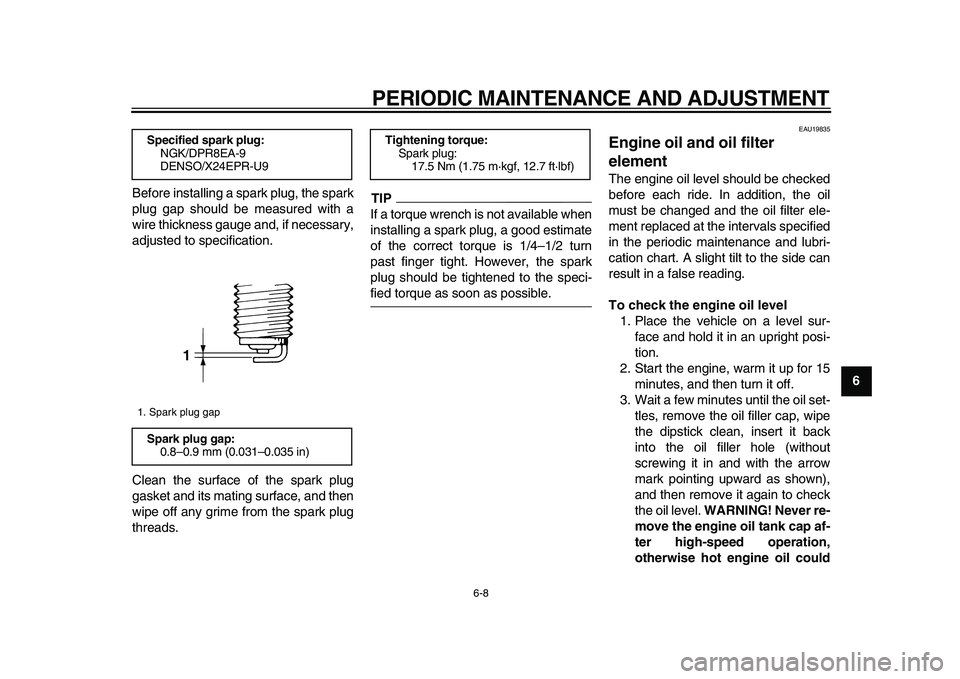

Before installing a spark plug, the spark

plug gap should be measured with a

wire thickness gauge and, if necessary,

adjusted to specification.

Clean the surface of the spark plug

gasket and its mating surface, and then

wipe off any grime from the spark plug

threads.

TIP

If a torque wrench is not available when

installing a spark plug, a good estimate

of the correct torque is 1/4–1/2 turn

past finger tight. However, the spark

plug should be tightened to the speci-

fied torque as soon as possible.

EAU19835

Engine oil and oil filter

element

The engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter ele-

ment replaced at the intervals specified

in the periodic maintenance and lubri-

cation chart. A slight tilt to the side can

result in a false reading.

To check the engine oil level

1. Place the vehicle on a level sur-

face and hold it in an upright posi-

tion.

2. Start the engine, warm it up for 15

minutes, and then turn it off.

3. Wait a few minutes until the oil set-

tles, remove the oil filler cap, wipe

the dipstick clean, insert it back

into the oil filler hole (without

screwing it in and with the arrow

mark pointing upward as shown),

and then remove it again to check

the oil level.

WARNING! Never re-

move the engine oil tank cap af-

ter high-speed operation,

otherwise hot engine oil could

Specified spark plug:

NGK/DPR8EA-9

DENSO/X24EPR-U9

1. Spark plug gap

Spark plug gap:

0.8–0.9 mm (0.031–0.035 in)

1

Tightening torque:

Spark plug:

17.5 Nm (1.75 m·kgf, 12.7 ft·lbf)

Page 54 of 94

![YAMAHA TDM 900 2009 Workshop Manual

PERIODIC MAINTENANCE AND ADJUSTMENT

6-9

1

2

3

4

5

6

7

8

9spout out and cause damage or

injury. Always let the engine oil

cool down sufficiently before re-

moving the oil tank cap.

[EWA10361]

NO YAMAHA TDM 900 2009 Workshop Manual

PERIODIC MAINTENANCE AND ADJUSTMENT

6-9

1

2

3

4

5

6

7

8

9spout out and cause damage or

injury. Always let the engine oil

cool down sufficiently before re-

moving the oil tank cap.

[EWA10361]

NO](/img/51/51368/w960_51368-53.png)

PERIODIC MAINTENANCE AND ADJUSTMENT

6-9

1

2

3

4

5

6

7

8

9spout out and cause damage or

injury. Always let the engine oil

cool down sufficiently before re-

moving the oil tank cap.

[EWA10361]

NOTICE:

Do not operate the ve-

hicle until you know that the en-

gine oil level is sufficient.

[ECA10011]

TIP

The engine oil should be between the

minimum and maximum level marks.

4. If the engine oil is below the mini-

mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.

5. Install the oil filler cap.

TIP

●

The engine oil tank is located be-

hind the cylinders.

●

The engine oil should be between

the minimum and maximum level

marks.

To change the engine oil (with or

without oil filter element replace-

ment)

1. Place the vehicle on a level sur-

face.

2. Start the engine, warm it up for

several minutes, and then turn it

off.

3. Place an oil pan under the engine

to collect the used oil.

4. Remove the engine oil filler cap

and drain bolts to drain the oil from

the crankcase.

TIP

Skip steps 5–7 if the oil filter element is

not being replaced.

1. Engine oil filler cap

1

1. Engine oil filler cap

2. Dipstick

3. Maximum level mark

4. Minimum level mark

1

2

3

4

1. Engine oil drain bolt A

1

Page 55 of 94

PERIODIC MAINTENANCE AND ADJUSTMENT

6-10

2

3

4

5

67

8

9

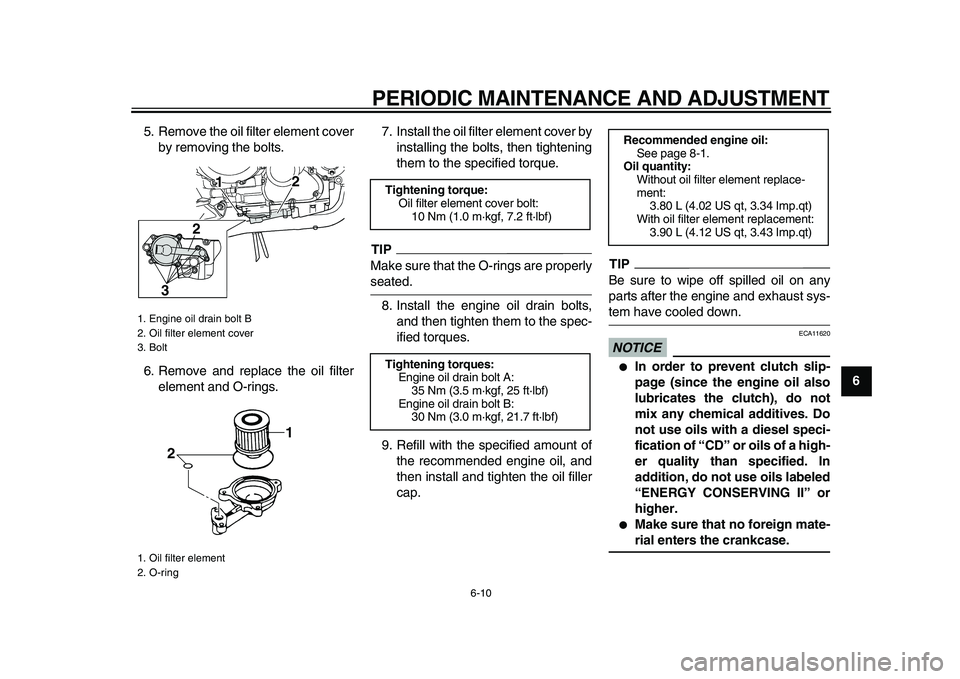

5. Remove the oil filter element cover

by removing the bolts.

6. Remove and replace the oil filter

element and O-rings.7. Install the oil filter element cover by

installing the bolts, then tightening

them to the specified torque.

TIP

Make sure that the O-rings are properly

seated.

8. Install the engine oil drain bolts,

and then tighten them to the spec-

ified torques.

9. Refill with the specified amount of

the recommended engine oil, and

then install and tighten the oil filler

cap.

TIP

Be sure to wipe off spilled oil on any

parts after the engine and exhaust sys-

tem have cooled down.

NOTICE

ECA11620

●

In order to prevent clutch slip-

page (since the engine oil also

lubricates the clutch), do not

mix any chemical additives. Do

not use oils with a diesel speci-

fication of “CD” or oils of a high-

er quality than specified. In

addition, do not use oils labeled

“ENERGY CONSERVING II” or

higher.

●

Make sure that no foreign mate-

rial enters the crankcase.

1. Engine oil drain bolt B

2. Oil filter element cover

3. Bolt

1. Oil filter element

2. O-ring

12

2

3

1

2

Tightening torque:

Oil filter element cover bolt:

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Tightening torques:

Engine oil drain bolt A:

35 Nm (3.5 m·kgf, 25 ft·lbf)

Engine oil drain bolt B:

30 Nm (3.0 m·kgf, 21.7 ft·lbf)

Recommended engine oil:

See page 8-1.

Oil quantity:

Without oil filter element replace-

ment:

3.80 L (4.02 US qt, 3.34 Imp.qt)

With oil filter element replacement:

3.90 L (4.12 US qt, 3.43 Imp.qt)

Page 56 of 94

PERIODIC MAINTENANCE AND ADJUSTMENT

6-11

1

2

3

4

5

6

7

8

9

10. Start the engine, and then let it idle

for several minutes while checking

it for oil leakage. If oil is leaking, im-

mediately turn the engine off and

check for the cause.

11. Turn the engine off, and then

check the oil level and correct it if

necessary.

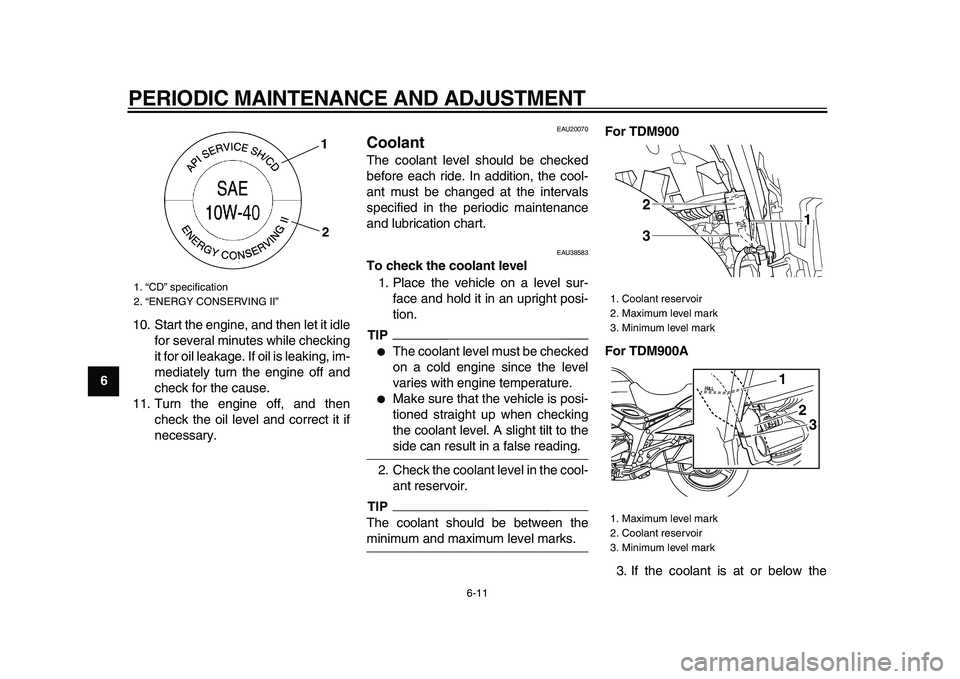

EAU20070

Coolant

The coolant level should be checked

before each ride. In addition, the cool-

ant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

EAU38583

To check the coolant level

1. Place the vehicle on a level sur-

face and hold it in an upright posi-

tion.

TIP

●

The coolant level must be checked

on a cold engine since the level

varies with engine temperature.

●

Make sure that the vehicle is posi-

tioned straight up when checking

the coolant level. A slight tilt to the

side can result in a false reading.

2. Check the coolant level in the cool-

ant reservoir.

TIP

The coolant should be between the

minimum and maximum level marks.

For TDM900

For TDM900A

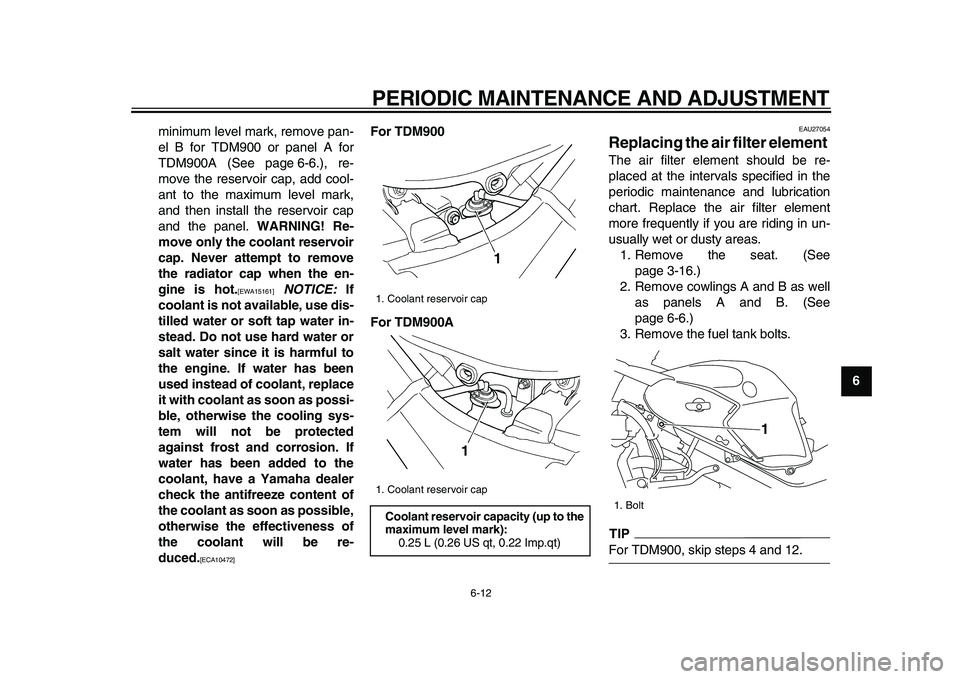

3. If the coolant is at or below the

1. “CD” specification

2. “ENERGY CONSERVING II”

1

2

1. Coolant reservoir

2. Maximum level mark

3. Minimum level mark

1. Maximum level mark

2. Coolant reservoir

3. Minimum level mark

1 2

33 1

2

Page 57 of 94

PERIODIC MAINTENANCE AND ADJUSTMENT

6-12

2

3

4

5

67

8

9

minimum level mark, remove pan-

el B for TDM900 or panel A for

TDM900A (See page 6-6.), re-

move the reservoir cap, add cool-

ant to the maximum level mark,

and then install the reservoir cap

and the panel.

WARNING! Re-

move only the coolant reservoir

cap. Never attempt to remove

the radiator cap when the en-

gine is hot.

[EWA15161]

NOTICE:

If

coolant is not available, use dis-

tilled water or soft tap water in-

stead. Do not use hard water or

salt water since it is harmful to

the engine. If water has been

used instead of coolant, replace

it with coolant as soon as possi-

ble, otherwise the cooling sys-

tem will not be protected

against frost and corrosion. If

water has been added to the

coolant, have a Yamaha dealer

check the antifreeze content of

the coolant as soon as possible,

otherwise the effectiveness of

the coolant will be re-

duced.

[ECA10472]

For TDM900

For TDM900A

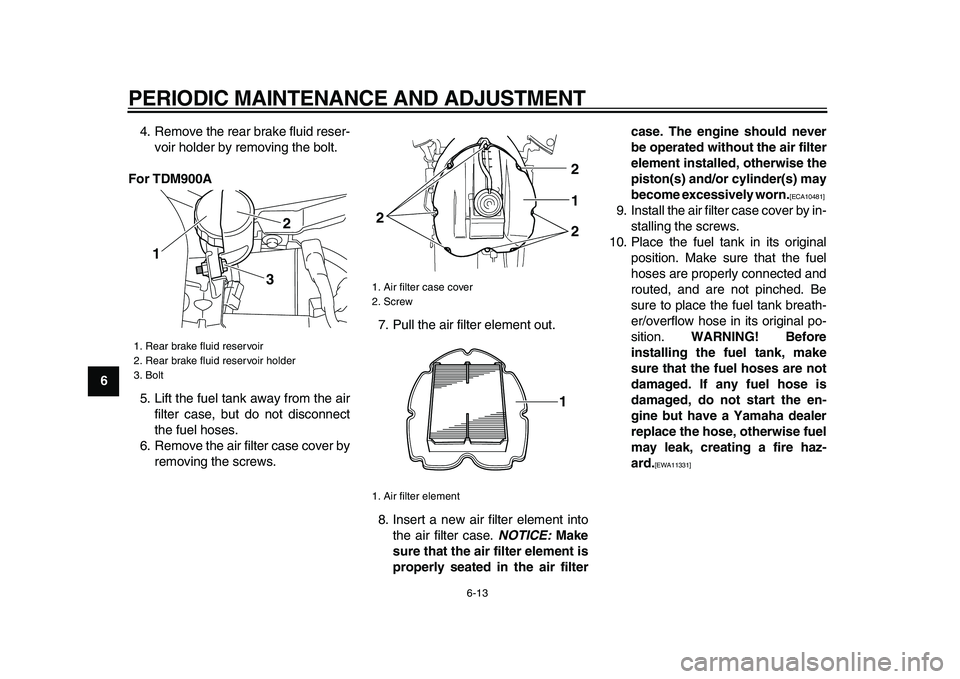

EAU27054

Replacing the air filter element

The air filter element should be re-

placed at the intervals specified in the

periodic maintenance and lubrication

chart. Replace the air filter element

more frequently if you are riding in un-

usually wet or dusty areas.

1. Remove the seat. (See

page 3-16.)

2. Remove cowlings A and B as well

as panels A and B. (See

page 6-6.)

3. Remove the fuel tank bolts.

TIP

For TDM900, skip steps 4 and 12.

1. Coolant reservoir cap

1. Coolant reservoir cap

Coolant reservoir capacity (up to the

maximum level mark):

0.25 L (0.26 US qt, 0.22 Imp.qt)

1

1

1. Bolt

1

Page 58 of 94

PERIODIC MAINTENANCE AND ADJUSTMENT

6-13

1

2

3

4

5

6

7

8

9

4. Remove the rear brake fluid reser-

voir holder by removing the bolt.

For TDM900A

5. Lift the fuel tank away from the air

filter case, but do not disconnect

the fuel hoses.

6. Remove the air filter case cover by

removing the screws.7. Pull the air filter element out.

8. Insert a new air filter element into

the air filter case.

NOTICE:

Make

sure that the air filter element is

properly seated in the air filtercase. The engine should never

be operated without the air filter

element installed, otherwise the

piston(s) and/or cylinder(s) may

become excessively worn.

[ECA10481]

9. Install the air filter case cover by in-

stalling the screws.

10. Place the fuel tank in its original

position. Make sure that the fuel

hoses are properly connected and

routed, and are not pinched. Be

sure to place the fuel tank breath-

er/overflow hose in its original po-

sition.

WARNING! Before

installing the fuel tank, make

sure that the fuel hoses are not

damaged. If any fuel hose is

damaged, do not start the en-

gine but have a Yamaha dealer

replace the hose, otherwise fuel

may leak, creating a fire haz-

ard.

[EWA11331]

1. Rear brake fluid reservoir

2. Rear brake fluid reservoir holder

3. Bolt

12

3

1. Air filter case cover

2. Screw

1. Air filter element

1 2

2 21

Page 59 of 94

PERIODIC MAINTENANCE AND ADJUSTMENT

6-14

2

3

4

5

67

8

9

11. Install the fuel tank bolts.

12. Install the rear brake fluid reservoir

holder by installing the bolt.

13. Install the panels and cowlings.

14. Install the seat.

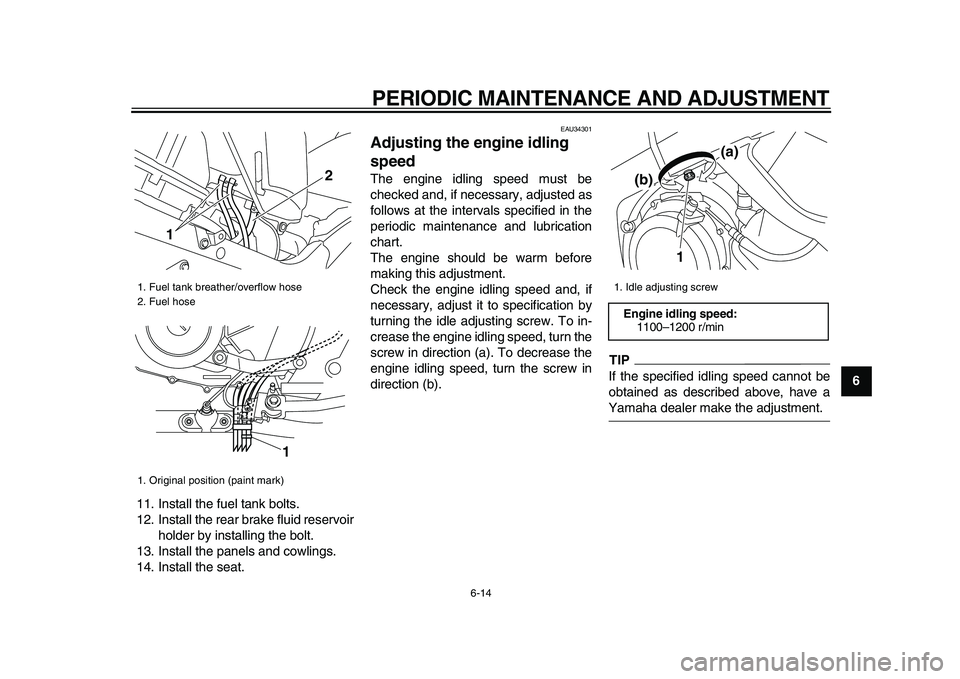

EAU34301

Adjusting the engine idling

speed

The engine idling speed must be

checked and, if necessary, adjusted as

follows at the intervals specified in the

periodic maintenance and lubrication

chart.

The engine should be warm before

making this adjustment.

Check the engine idling speed and, if

necessary, adjust it to specification by

turning the idle adjusting screw. To in-

crease the engine idling speed, turn the

screw in direction (a). To decrease the

engine idling speed, turn the screw in

direction (b).

TIP

If the specified idling speed cannot be

obtained as described above, have a

Yamaha dealer make the adjustment.

1. Fuel tank breather/overflow hose

2. Fuel hose

1. Original position (paint mark)

12

1

1. Idle adjusting screw

Engine idling speed:

1100–1200 r/min

1(a)

(b)

Page 60 of 94

PERIODIC MAINTENANCE AND ADJUSTMENT

6-15

1

2

3

4

5

6

7

8

9

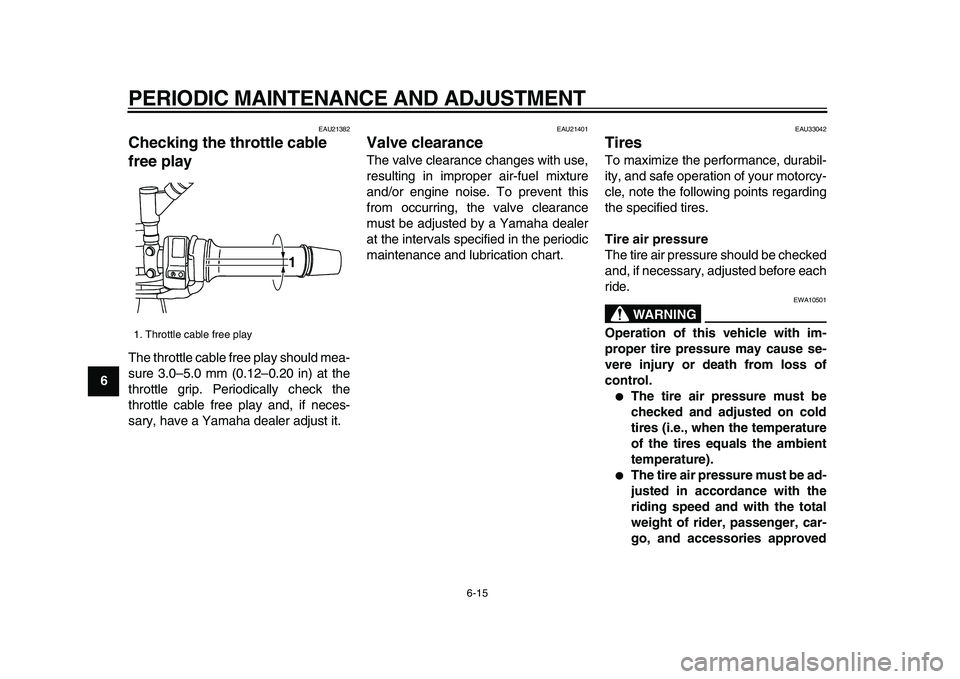

EAU21382

Checking the throttle cable

free play

The throttle cable free play should mea-

sure 3.0–5.0 mm (0.12–0.20 in) at the

throttle grip. Periodically check the

throttle cable free play and, if neces-

sary, have a Yamaha dealer adjust it.

EAU21401

Valve clearance

The valve clearance changes with use,

resulting in improper air-fuel mixture

and/or engine noise. To prevent this

from occurring, the valve clearance

must be adjusted by a Yamaha dealer

at the intervals specified in the periodic

maintenance and lubrication chart.

EAU33042

Tires

To maximize the performance, durabil-

ity, and safe operation of your motorcy-

cle, note the following points regarding

the specified tires.

Tire air pressure

The tire air pressure should be checked

and, if necessary, adjusted before each

ride.

WARNING

EWA10501

Operation of this vehicle with im-

proper tire pressure may cause se-

vere injury or death from loss of

control.

●

The tire air pressure must be

checked and adjusted on cold

tires (i.e., when the temperature

of the tires equals the ambient

temperature).

●

The tire air pressure must be ad-

justed in accordance with the

riding speed and with the total

weight of rider, passenger, car-

go, and accessories approved

1. Throttle cable free play

1