light YAMAHA TMAX 2014 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: TMAX, Model: YAMAHA TMAX 2014Pages: 100, PDF Size: 3.01 MB

Page 59 of 100

PERIODIC MAINTENANCE AND ADJUSTMENT

6-10

2

3

4

567

8

9

To install the panel

Place the panel in the original position,

and then install the screws.

EAU19643

Checking the spark plugsThe spark plugs are important engine

components, which should be checked

periodically, preferably by a Yamaha

dealer. Since heat and deposits will

cause any spark pl

ug to slowly erode,

they should be removed and checked

in accordance with the periodic mainte-

nance and lubrication chart. In addition,

the condition of the spark plugs can re-

veal the condition of the engine.

The porcelain insulator around the cen-

ter electrode of each spark plug should

be a medium-to-light tan (the ideal color

when the vehicle is ridden normally),

and all spark plugs installed in the en-

gine should have the same color. If any

spark plug shows a distinctly different

color, the engine could be operating im-

properly. Do not attempt to diagnose

such problems yourself. Instead, have

a Yamaha dealer check the vehicle.

If a spark plug shows signs of electrode

erosion and excessive carbon or other

deposits, it should be replaced. Before installing a spark plug, the spark

plug gap should be measured with a

wire thickness gauge and, if necessary,

adjusted to specification.

Clean the surface of the spark plug

gasket and its mating surface, and then

wipe off any grime from the spark plug

threads.

TIPIf a torque wrench is not available when

1. Screw

2. Panel D

1

2

1

Specified spark plug:

NGK/CR7E

1. Spark plug gapSpark plug gap:0.7–0.8 mm (0.028–0.031 in)

Tightening torque: Spark plug:13 Nm (1.3 m·kgf, 9.4 ft·lbf)

59C-9-E2.book 10 ページ 2013年6月18日 火曜日 午後1時33分

Page 60 of 100

PERIODIC MAINTENANCE AND ADJUSTMENT

6-11

1

2

3

4

56

7

8

9installing a spark plug, a good estimate

of the correct torque is 1/4–1/2 turn

past finger tight. However, the spark

plug should be tightened to the speci-

fied torque as soon as possible.

EAU1985D

Engine oil and oil filter

cartridgeThe engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter car-

tridge replaced at the intervals speci-

fied in the periodic maintenance and

lubrication chart.

To check the engine oil level

1. Place the vehicle on the center- stand. A slight tilt to the side can

result in a false reading.

2. Start the engine, warm it up for two minutes, and then turn it off.NOTICE

ECA11291

The engine must be cold before pro-

ceeding with the oil level check, oth-

erwise the check will result in a falsereading.

3. Wait two minutes until the oil set- tles, and then check the oil level

through the check window located

at the bottom-left side of the crank-

case.

TIPThe engine oil should be between theminimum and maximum level marks.

4. If the engine oil is below the mini- mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.

To change the engine oil (with or

without oil filter cartridge replace-

ment) 1. Place the vehicle on a level sur- face.

2. Start the engine, warm it up for several minutes, and then turn it1. Engine oil level check window

2. Maximum level mark

3. Minimum level mark

1

23

59C-9-E2.book 11 ページ 2013年6月18日 火曜日 午後1時33分

Page 63 of 100

PERIODIC MAINTENANCE AND ADJUSTMENT

6-14

2

3

4

567

8

9

been reached), the indicator must be

reset after the oil change for the next

periodic oil change to be indicated at

the correct time.

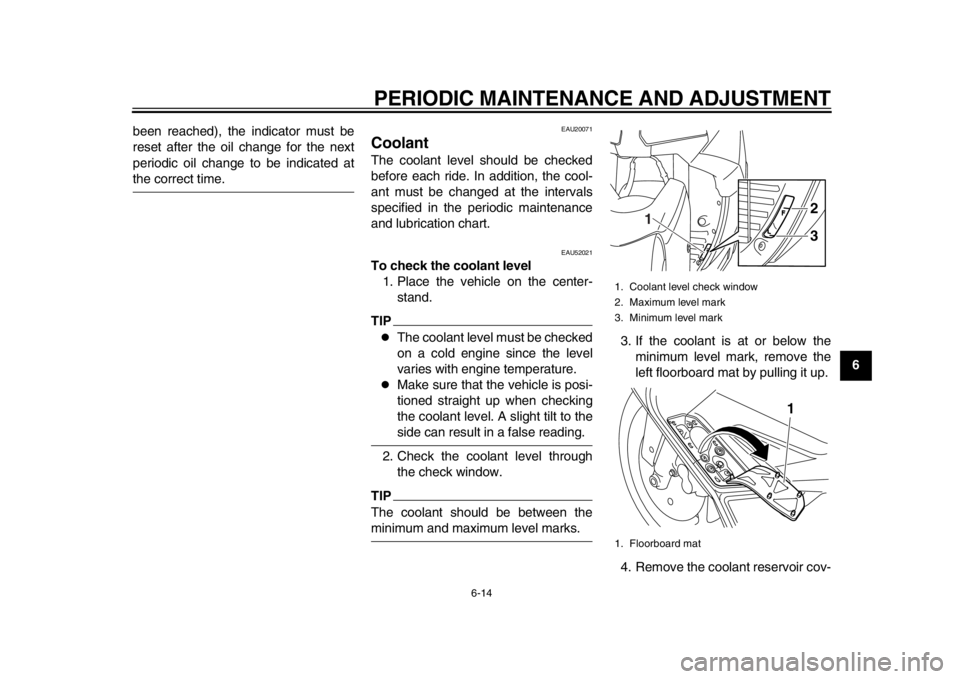

EAU20071

CoolantThe coolant level should be checked

before each ride. In addition, the cool-

ant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

EAU52021

To check the coolant level

1. Place the vehicle on the center- stand.TIP

The coolant level must be checked

on a cold engine since the level

varies with engine temperature.

Make sure that the vehicle is posi-

tioned straight up when checking

the coolant level. A slight tilt to theside can result in a false reading.

2. Check the coolant level through the check window.

TIPThe coolant should be between theminimum and maximum level marks. 3. If the coolant is at or below the

minimum level mark, remove the

left floorboard mat by pulling it up.

4. Remove the coolant reservoir cov-

1. Coolant level check window

2. Maximum level mark

3. Minimum level mark

1. Floorboard mat

2

3

1

1

59C-9-E2.book 14 ページ 2013年6月18日 火曜日 午後1時33分

Page 80 of 100

PERIODIC MAINTENANCE AND ADJUSTMENT

6-31

1

2

3

4

56

7

8

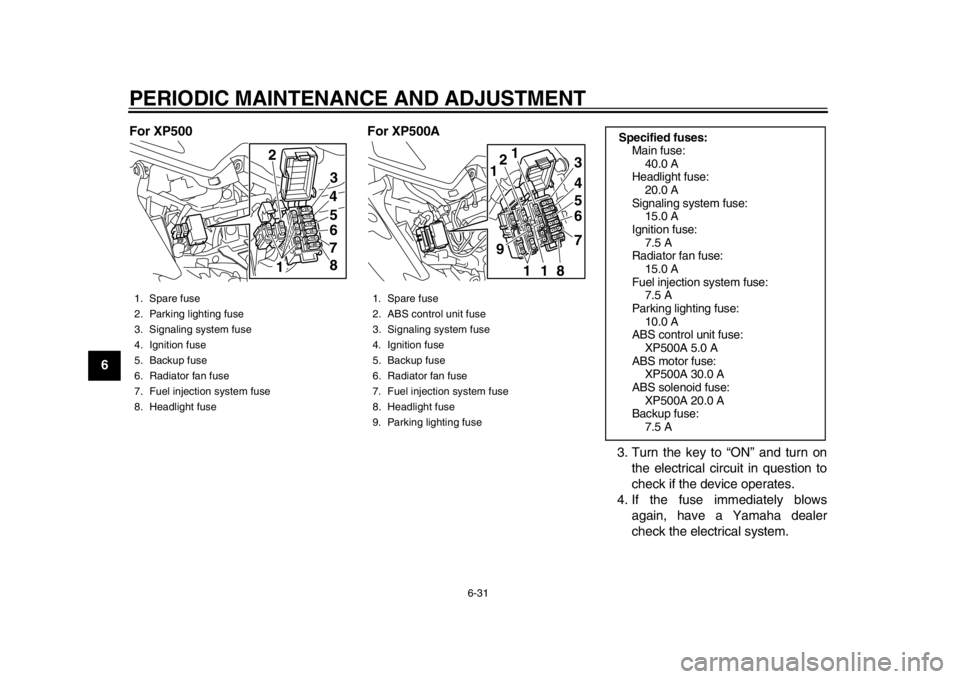

9For XP500 For XP500A

3. Turn the key to “ON” and turn onthe electrical circuit in question to

check if the device operates.

4. If the fuse immediately blows again, have a Yamaha dealer

check the electrical system.

1. Spare fuse

2. Parking lighting fuse

3. Signaling system fuse

4. Ignition fuse

5. Backup fuse

6. Radiator fan fuse

7. Fuel injection system fuse

8. Headlight fuse

3

4

56

7 8

2

1

1. Spare fuse

2. ABS control unit fuse

3. Signaling system fuse

4. Ignition fuse

5. Backup fuse

6. Radiator fan fuse

7. Fuel injection system fuse

8. Headlight fuse

9. Parking lighting fuse

1 2

1

3

5 4

6

7

1

9

18

Specified fuses:

Main fuse:40.0 A

Headlight fuse:

20.0 A

Signaling system fuse: 15.0 A

Ignition fuse: 7.5 A

Radiator fan fuse:

15.0 A

Fuel injection system fuse: 7.5 A

Parking lighting fuse: 10.0 A

ABS control unit fuse:

XP500A 5.0 A

ABS motor fuse: XP500A 30.0 A

ABS solenoid fuse: XP500A 20.0 A

Backup fuse:

7.5 A

59C-9-E2.book 31 ページ 2013年6月18日 火曜日 午後1時33分

Page 81 of 100

PERIODIC MAINTENANCE AND ADJUSTMENT

6-32

2

3

4

567

8

9

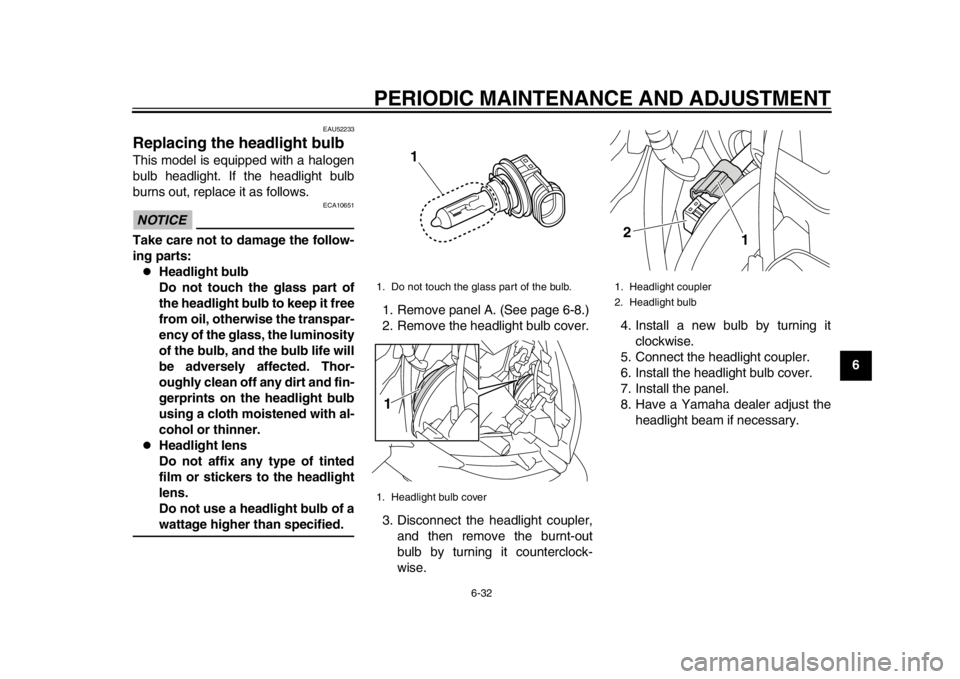

EAU52233

Replacing the headlight bulbThis model is equipped with a halogen

bulb headlight. If the headlight bulb

burns out, replace it as follows.NOTICE

ECA10651

Take care not to damage the follow-

ing parts:

Headlight bulb

Do not touch the glass part of

the headlight bulb to keep it free

from oil, otherwise the transpar-

ency of the glass, the luminosity

of the bulb, and the bulb life will

be adversely affected. Thor-

oughly clean off any dirt and fin-

gerprints on the headlight bulb

using a cloth moistened with al-

cohol or thinner.

Headlight lens

Do not affix any type of tinted

film or stickers to the headlight

lens.

Do not use a headlight bulb of awattage higher than specified. 1. Remove panel A. (See page 6-8.)

2. Remove the headlight bulb cover.

3. Disconnect the headlight coupler,

and then remove the burnt-out

bulb by turning it counterclock-

wise. 4. Install a new bulb by turning it

clockwise.

5. Connect the headlight coupler.

6. Install the headlight bulb cover.

7. Install the panel.

8. Have a Yamaha dealer adjust the headlight beam if necessary.

1. Do not touch the glass part of the bulb.

1. Headlight bulb cover

1

1

1. Headlight coupler

2. Headlight bulb

1

2

59C-9-E2.book 32 ページ 2013年6月18日 火曜日 午後1時33分

Page 82 of 100

PERIODIC MAINTENANCE AND ADJUSTMENT

6-33

1

2

3

4

56

7

8

9

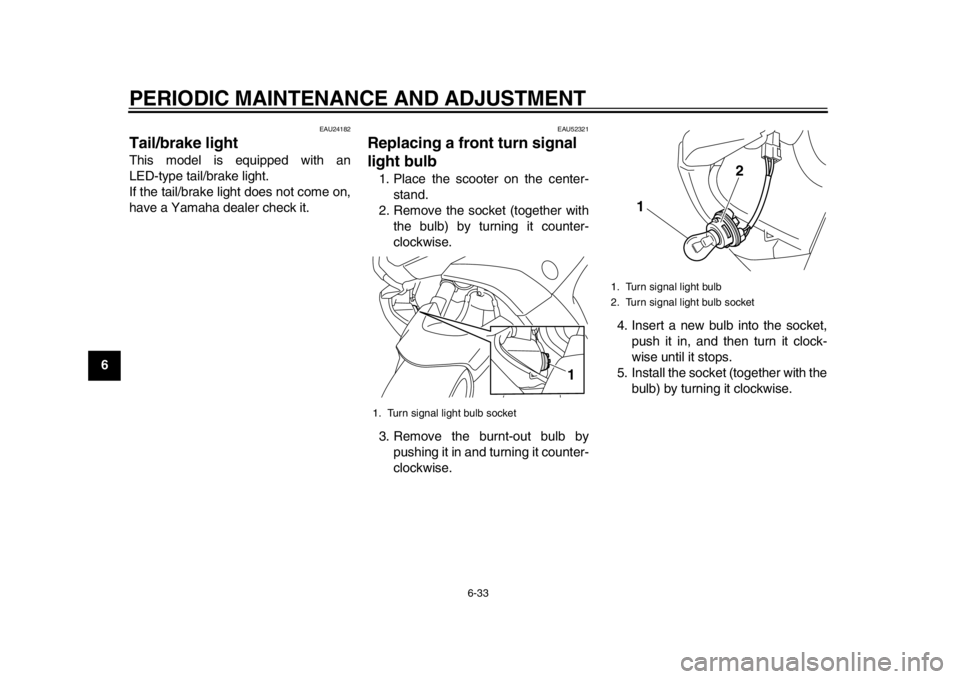

EAU24182

Tail/brake lightThis model is equipped with an

LED-type tail/brake light.

If the tail/brake light does not come on,

have a Yamaha dealer check it.

EAU52321

Replacing a front turn signal

light bulb1. Place the scooter on the center-stand.

2. Remove the socket (together with the bulb) by turning it counter-

clockwise.

3. Remove the burnt-out bulb by pushing it in and turning it counter-

clockwise. 4. Insert a new bulb into the socket,

push it in, and then turn it clock-

wise until it stops.

5. Install the socket (together with the bulb) by turning it clockwise.1. Turn signal light bulb socket

1

1. Turn signal light bulb

2. Turn signal light bulb socket

1 2

59C-9-E2.book 33 ページ 2013年6月18日 火曜日 午後1時33分

Page 83 of 100

PERIODIC MAINTENANCE AND ADJUSTMENT

6-34

2

3

4

567

8

9

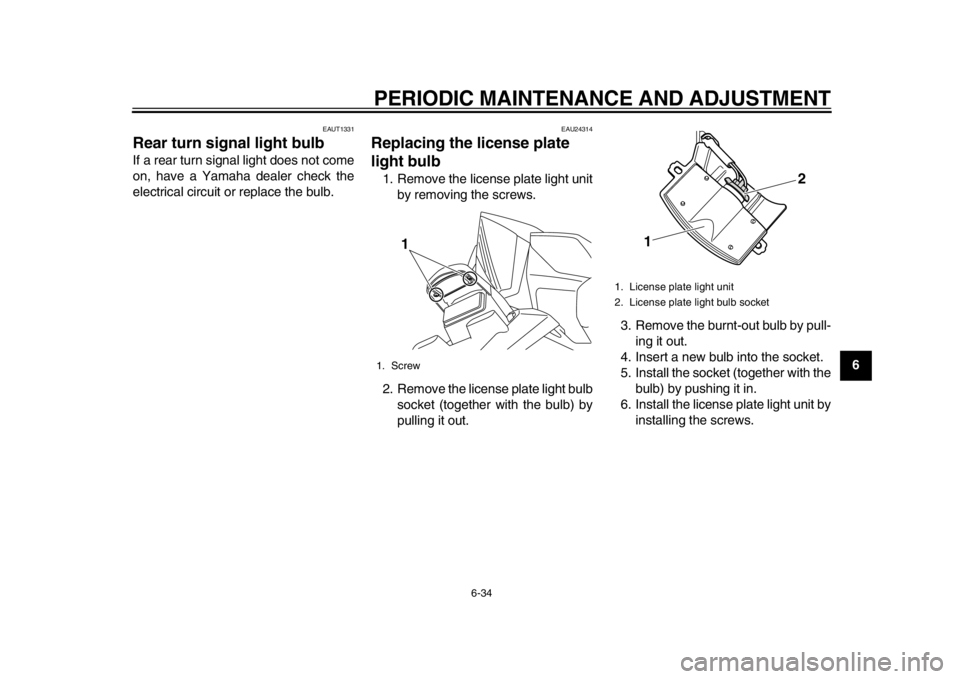

EAUT1331

Rear turn signal light bulbIf a rear turn signal light does not come

on, have a Yamaha dealer check the

electrical circuit or replace the bulb.

EAU24314

Replacing the license plate

light bulb1. Remove the license plate light unit

by removing the screws.

2. Remove the license plate light bulb socket (together with the bulb) by

pulling it out. 3. Remove the burnt-out bulb by pull-

ing it out.

4. Insert a new bulb into the socket.

5. Install the socket (together with the bulb) by pushing it in.

6. Install the license plate light unit by installing the screws.1. Screw

1

1. License plate light unit

2. License plate light bulb socket

1 2

59C-9-E2.book 34 ページ 2013年6月18日 火曜日 午後1時33分

Page 84 of 100

PERIODIC MAINTENANCE AND ADJUSTMENT

6-35

1

2

3

4

56

7

8

9

EAU52051

Replacing an auxiliary light

bulb1. Remove panel A. (See page 6-8.)

2. Remove the auxiliary light socket

(together with the bulb) by pulling it

out.

3. Remove the burnt-out bulb by pull- ing it out. 4. Insert a new bulb into the socket.

5. Install the auxiliary light socket (to-

gether with the bulb) by pushing it

in.

6. Install the panel.

EAU25882

TroubleshootingAlthough Yamaha scooters receive a

thorough inspection before shipment

from the factory, trouble may occur dur-

ing operation. Any problem in the fuel,

compression, or ignition systems, for

example, can cause poor starting and

loss of power.

The following troubleshooting charts

represent quick and easy procedures

for checking these vital systems your-

self. However, should your scooter re-

quire any repair, take it to a Yamaha

dealer, whose skilled technicians have

the necessary tools, experience, and

know-how to service the scooter prop-

erly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look like

Yamaha parts, but they are often inferi-

or, have a shorter service life and can

lead to expensive repair bills.

WARNING

EWA15142

When checking the fuel system, do

not smoke, and make sure there are

no open flames or sparks in the ar-

ea, including pilot lights from water

1. Auxiliary light bulb socket1

1. Auxiliary light bulb

2. Auxiliary light bulb socket

1 2

59C-9-E2.book 35 ページ 2013年6月18日 火曜日 午後1時33分

Page 88 of 100

7-1

1

2

3

4

5

67

8

9

SCOOTER CARE AND STORAGE

EAU37834

Matte color cautionNOTICE

ECA15193

Some models are equipped with

matte colored finished parts. Be

sure to consult a Yamaha dealer for

advice on what products to use be-

fore cleaning the vehicle. Using a

brush, harsh chemical products or

cleaning compounds when cleaning

these parts will scratch or damage

their surface. Wax also should not

be applied to any matte colored fin-ished parts.

EAU26105

CareWhile the open design of a scooter re-

veals the attractiveness of the technol-

ogy, it also makes it more vulnerable.

Rust and corrosion can develop even if

high-quality components are used. A

rusty exhaust pipe may go unnoticed

on a car, however, it detracts from the

overall appearance of a scooter. Fre-

quent and proper care does not only

comply with the terms of the warranty,

but it will also keep your scooter looking

good, extend its life and optimize its

performance.

Before cleaning1. Cover the muffler outlet with a plastic bag after the engine has

cooled down.

2. Make sure that all caps and covers as well as all electrical couplers

and connectors, including the

spark plug cap, are tightly in-

stalled.

3. Remove extremely stubborn dirt, like oil burnt onto the crankcase,

with a degreasing agent and a

brush, but never apply such prod- ucts onto seals, gaskets and wheel

axles. Always rinse the dirt and de-

greaser off with water.

Cleaning

NOTICE

ECA10784

Avoid using strong acidic wheel

cleaners, especially on spoked

wheels. If such products are

used on hard-to-remove dirt, do

not leave the cleaner on the af-

fected area any longer than in-

structed. Also, thoroughly rinse

the area off with water, immedi-

ately dry it, and then apply a cor-

rosion protection spray.

Improper cleaning can damage

plastic parts (such as cowlings,

panels, windshields, headlight

lenses, meter lenses, etc.) and

the mufflers. Use only a soft,

clean cloth or sponge with wa-

ter to clean plastic. However, if

the plastic parts cannot be thor-

oughly cleaned with water, di-

luted mild detergent with water

may be used. Be sure to rinse

off any detergent residue using

59C-9-E2.book 1 ページ 2013年6月18日 火曜日 午後1時33分

Page 89 of 100

SCOOTER CARE AND STORAGE

7-2

2

3

4

5

678

9

plenty of water, as it is harmful

to plastic parts.

Do not use any harsh chemical

products on plastic parts. Be

sure to avoid using cloths or

sponges which have been in

contact with strong or abrasive

cleaning products, solvent or

thinner, fuel (gasoline), rust re-

movers or inhibitors, brake flu-

id, antifreeze or electrolyte.

Do not use high-pressure wash-

ers or steam-jet cleaners since

they cause water seepage and

deterioration in the following ar-

eas: seals (of wheel and swing-

arm bearings, fork and brakes),

electric components (couplers,

connectors, instruments,

switches and lights), breather

hoses and vents.

For scooters equipped with a

windshield: Do not use strong

cleaners or hard sponges as

they will cause dulling or

scratching. Some cleaning com-

pounds for plastic may leave

scratches on the windshield.

Test the product on a small hid- den part of the windshield to

make sure that it does not leave

any marks. If the windshield is

scratched, use a quality plastic

polishing compound after

washing.

After normal use

Remove dirt with warm water, a mild

detergent, and a soft, clean sponge,

and then rinse thoroughly with clean

water. Use a toothbrush or bottlebrush

for hard-to-reach areas. Stubborn dirt

and insects will come off more easily if

the area is covered with a wet cloth for

a few minutes before cleaning.

After riding in the rain, near the sea oron salt-sprayed roadsSince sea salt or salt sprayed on roads

during winter are extremely corrosive in

combination with water, carry out the

following steps after each ride in the

rain, near the sea or on salt-sprayed

roads.TIPSalt sprayed on roads in the winter may

remain well into spring. 1. Clean the scooter with cold water and a mild detergent after the en-

gine has cooled down. NOTICE:

Do not use warm water since it

increases the corrosive action

of the salt.

[ECA10792]

2. Apply a corrosion protection spray on all metal, including chrome- and

nickel-plated, surfaces to prevent

corrosion.

After cleaning 1. Dry the scooter with a chamois or an absorbing cloth.

2. Use a chrome polish to shine chrome, aluminum and stain-

less-steel parts, including the ex-

haust system. (Even the thermally

induced discoloring of stain-

less-steel exhaust systems can be

removed through polishing.)

3. To prevent corrosion, it is recom- mended to apply a corrosion pro-

tection spray on all metal,

including chrome- and nickel-plat-

ed, surfaces.

4. Use spray oil as a universal clean-

59C-9-E2.book 2 ページ 2013年6月18日 火曜日 午後1時33分