lock YAMAHA TRACER 900 2018 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2018, Model line: TRACER 900, Model: YAMAHA TRACER 900 2018Pages: 114, PDF Size: 7.51 MB

Page 46 of 114

Instrument and control functions

3-31

3 5. Align the projection on the bottom

of the rider seat with the “L” posi-

tion slot, and then push the rear of

the seat down to lock it in place as

shown.

6. Install the passenger seat.

TIPMake sure that the seats are properly

secured before riding.

EAU63060

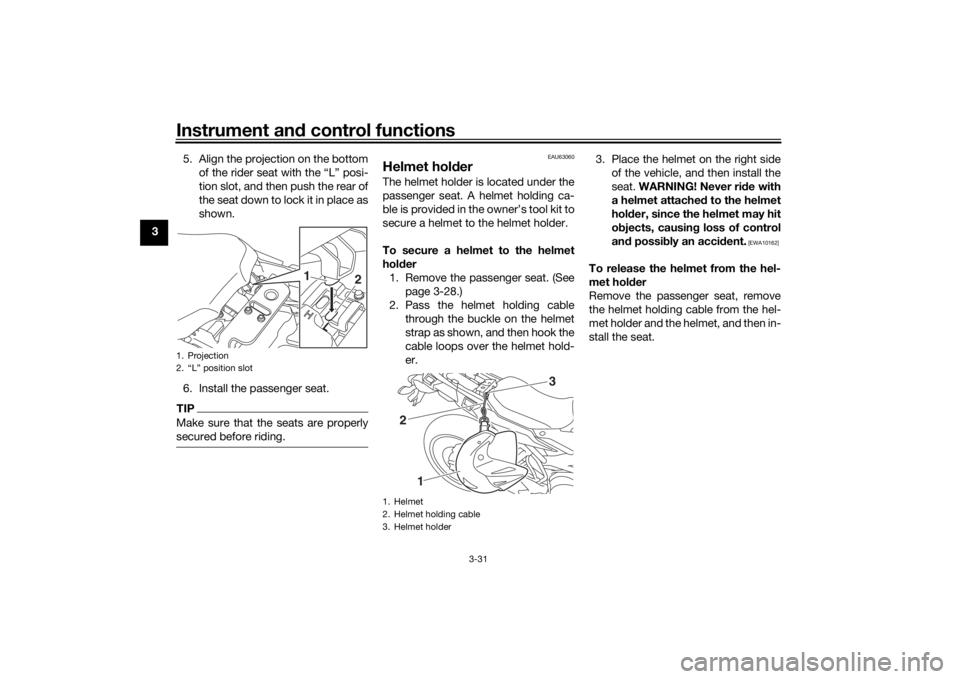

Helmet hold erThe helmet holder is located under the

passenger seat. A helmet holding ca-

ble is provided in the owner’s tool kit to

secure a helmet to the helmet holder.

To secure a helmet to the helmet

holder

1. Remove the passenger seat. (See page 3-28.)

2. Pass the helmet holding cable through the buckle on the helmet

strap as shown, and then hook the

cable loops over the helmet hold-

er. 3. Place the helmet on the right side

of the vehicle, and then install the

seat. WARNING! Never ri de with

a helmet attached to the helmet

hol der, since the helmet may hit

o bjects, causin g loss of control

an d possi bly an acci dent.

[EWA10162]

To release the helmet from the hel-

met hol der

Remove the passenger seat, remove

the helmet holding cable from the hel-

met holder and the helmet, and then in-

stall the seat.

1. Projection

2. “L” position slot

1

2

1. Helmet

2. Helmet holding cable

3. Helmet holder

3

2

1

UB5CE0E0.book Page 31 Wednesday, December 20, 2017 11:08 AM

Page 47 of 114

Instrument and control functions

3-32

3

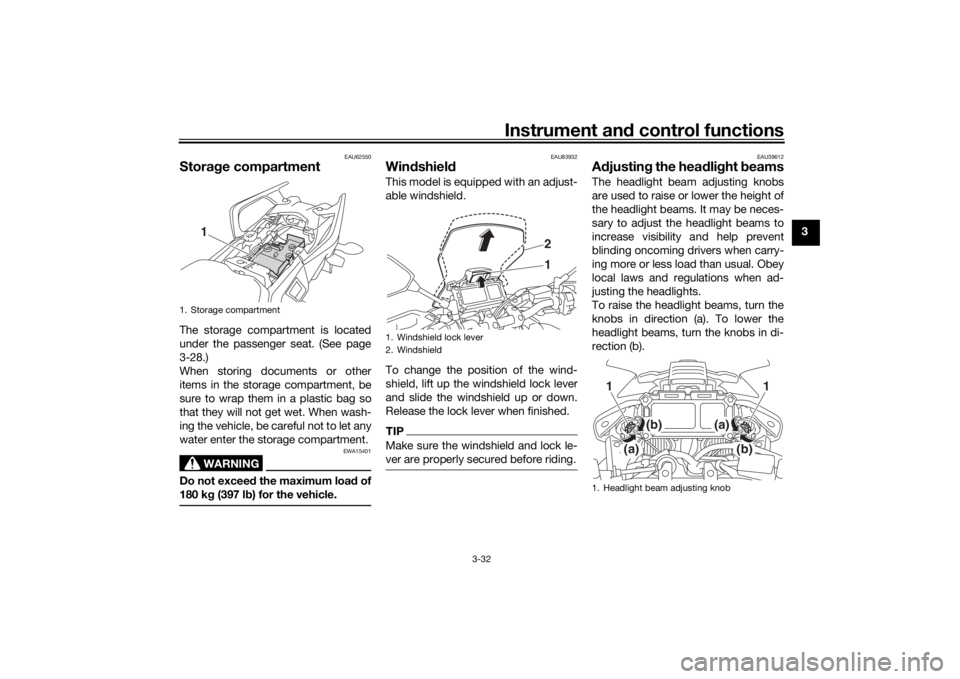

EAU62550

Stora ge compartmentThe storage compartment is located

under the passenger seat. (See page

3-28.)

When storing documents or other

items in the storage compartment, be

sure to wrap them in a plastic bag so

that they will not get wet. When wash-

ing the vehicle, be careful not to let any

water enter the storage compartment.

WARNING

EWA15401

Do not exceed the maximum loa d of

180 k g (397 l b) for the vehicle.

EAU83932

Win dshiel d This model is equipped with an adjust-

able windshield.

To change the position of the wind-

shield, lift up the windshield lock lever

and slide the windshield up or down.

Release the lock lever when finished.TIPMake sure the windshield and lock le-

ver are properly secured before riding.

EAU39612

A djustin g the hea dlig ht beamsThe headlight beam adjusting knobs

are used to raise or lower the height of

the headlight beams. It may be neces-

sary to adjust the headlight beams to

increase visibility and help prevent

blinding oncoming drivers when carry-

ing more or less load than usual. Obey

local laws and regulations when ad-

justing the headlights.

To raise the headlight beams, turn the

knobs in direction (a). To lower the

headlight beams, turn the knobs in di-

rection (b).

1. Storage compartment

1

1. Windshield lock lever

2. Windshield

12

1. Headlight beam adjusting knob

(a)

(b)

1

(b)

(a)

1

UB5CE0E0.book Page 32 Wednesday, December 20, 2017 11:08 AM

Page 72 of 114

Periodic maintenance an d a djustment

6-11

6

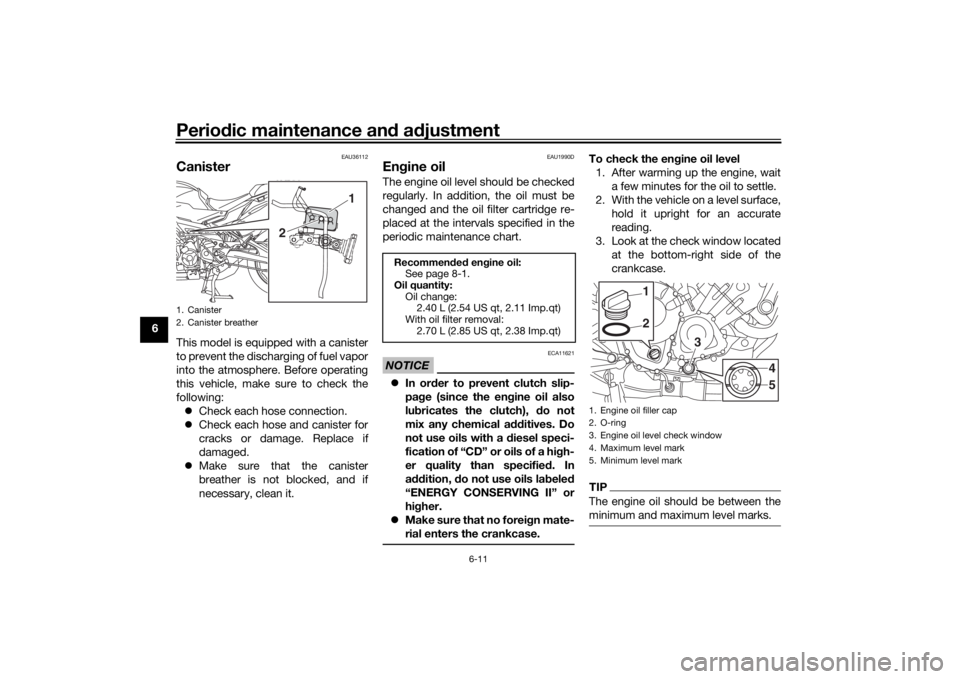

EAU36112

CanisterThis model is equipped with a canister

to prevent the discharging of fuel vapor

into the atmosphere. Before operating

this vehicle, make sure to check the

following:

Check each hose connection.

Check each hose and canister for

cracks or damage. Replace if

damaged.

Make sure that the canister

breather is not blocked, and if

necessary, clean it.

EAU1990D

Engine oilThe engine oil level should be checked

regularly. In addition, the oil must be

changed and the oil filter cartridge re-

placed at the intervals specified in the

periodic maintenance chart.NOTICE

ECA11621

In or der to prevent clutch slip-

pa ge (since the en gine oil also

lu bricates the clutch), do not

mix any chemical additives. Do

not use oils with a diesel speci-

fication of “CD” or oils of a hi gh-

er quality than specifie d. In

a ddition, do not use oils la beled

“ENERGY CONSERVING II” or

hi gher.

Make sure that no forei gn mate-

rial enters the crankcase.

To check the en gine oil level

1. After warming up the engine, wait a few minutes for the oil to settle.

2. With the vehicle on a level surface, hold it upright for an accurate

reading.

3. Look at the check window located at the bottom-right side of the

crankcase.TIPThe engine oil should be between the

minimum and maximum level marks.

1. Canister

2. Canister breather

1

2

Recommen ded en gine oil:

See page 8-1.

Oil quantity: Oil change:2.40 L (2.54 US qt, 2.11 Imp.qt)

With oil filter removal: 2.70 L (2.85 US qt, 2.38 Imp.qt)

1. Engine oil filler cap

2. O-ring

3. Engine oil level check window

4. Maximum level mark

5. Minimum level mark

21

3

45

UB5CE0E0.book Page 11 Wednesday, December 20, 2017 11:08 AM

Page 81 of 114

Periodic maintenance an d a djustment

6-20

6

b

rakin g performance, which may re-

sult in loss of control an d an acci-

d ent.

EAU36505

Brake li ght switchesThe brake light should come on just

before braking takes effect. The brake

light is activated by switches connect-

ed to the brake lever and brake pedal.

Since the brake light switches are

components of the anti-lock brake sys-

tem, they should only be serviced by a

Yamaha dealer.

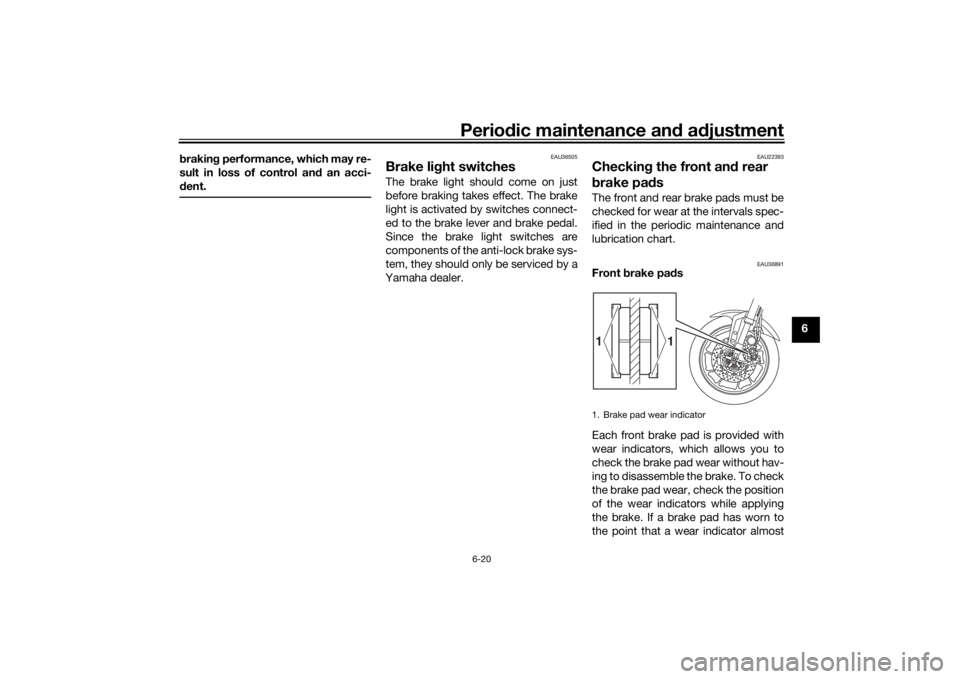

EAU22393

Checkin g the front an d rear

b rake pa dsThe front and rear brake pads must be

checked for wear at the intervals spec-

ified in the periodic maintenance and

lubrication chart.

EAU36891

Front brake pad s

Each front brake pad is provided with

wear indicators, which allows you to

check the brake pad wear without hav-

ing to disassemble the brake. To check

the brake pad wear, check the position

of the wear indicators while applying

the brake. If a brake pad has worn to

the point that a wear indicator almost1. Brake pad wear indicator

1

1

UB5CE0E0.book Page 20 Wednesday, December 20, 2017 11:08 AM

Page 83 of 114

Periodic maintenance an d a djustment

6-22

6

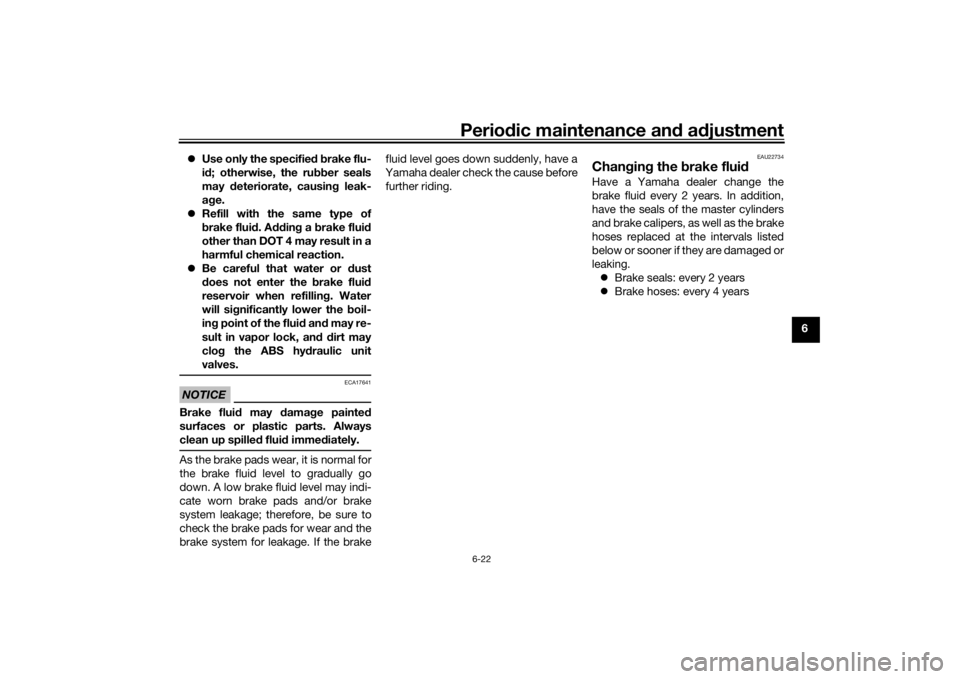

Use only the specifie d b rake flu-

i d ; otherwise, the ru bber seals

may deteriorate, causin g leak-

a g e.

Refill with the same type of

brake flui d. A ddin g a brake flui d

other than DOT 4 may result in a

harmful chemical reaction.

Be careful that water or dust

d oes not enter the brake flui d

reservoir when refillin g. Water

will si gnificantly lower the boil-

in g point of the flui d an d may re-

sult in vapor lock, an d d irt may

clo g the ABS hy draulic unit

valves.

NOTICE

ECA17641

Brake flui d may d amage painte d

surfaces or plastic parts. Always

clean up spille d flui d imme diately.As the brake pads wear, it is normal for

the brake fluid level to gradually go

down. A low brake fluid level may indi-

cate worn brake pads and/or brake

system leakage; therefore, be sure to

check the brake pads for wear and the

brake system for leakage. If the brake fluid level goes down suddenly, have a

Yamaha dealer check the cause before

further riding.

EAU22734

Chan

gin g the brake flui dHave a Yamaha dealer change the

brake fluid every 2 years. In addition,

have the seals of the master cylinders

and brake calipers, as well as the brake

hoses replaced at the intervals listed

below or sooner if they are damaged or

leaking.

Brake seals: every 2 years

Brake hoses: every 4 years

UB5CE0E0.book Page 22 Wednesday, December 20, 2017 11:08 AM

Page 84 of 114

Periodic maintenance an d a djustment

6-23

6

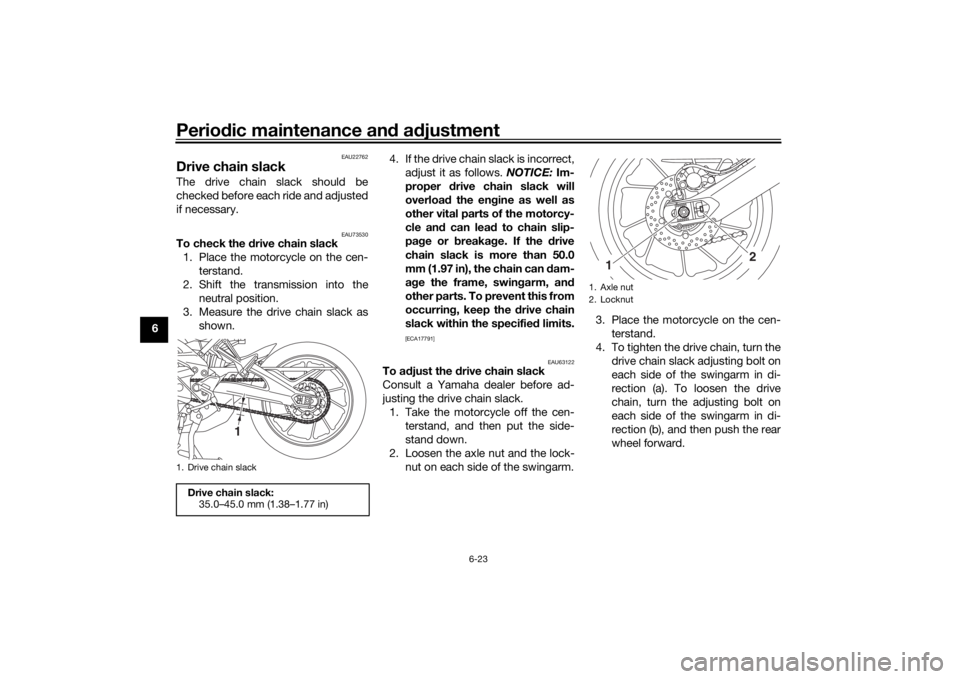

EAU22762

Drive chain slackThe drive chain slack should be

checked before each ride and adjusted

if necessary.

EAU73530

To check the drive chain slack

1. Place the motorcycle on the cen- terstand.

2. Shift the transmission into the neutral position.

3. Measure the drive chain slack as shown. 4. If the drive chain slack is incorrect,

adjust it as follows. NOTICE: Im-

proper drive chain slack will

overloa d the en gine as well as

other vital parts of the motorcy-

cle an d can lead to chain slip-

pa ge or breaka ge. If the d rive

chain slack is more than 50.0

mm (1.97 in), the chain can dam-

a g e the frame, swin garm, an d

other parts. To prevent this from

occurrin g, keep the d rive chain

slack within the specifie d limits.

[ECA17791]

EAU63122

To adjust the drive chain slack

Consult a Yamaha dealer before ad-

justing the drive chain slack. 1. Take the motorcycle off the cen- terstand, and then put the side-

stand down.

2. Loosen the axle nut and the lock- nut on each side of the swingarm. 3. Place the motorcycle on the cen-

terstand.

4. To tighten the drive chain, turn the drive chain slack adjusting bolt on

each side of the swingarm in di-

rection (a). To loosen the drive

chain, turn the adjusting bolt on

each side of the swingarm in di-

rection (b), and then push the rear

wheel forward.

1. Drive chain slackDrive chain slack:35.0–45.0 mm (1.38–1.77 in)

1

1. Axle nut

2. Locknut

2

1

UB5CE0E0.book Page 23 Wednesday, December 20, 2017 11:08 AM

Page 85 of 114

Periodic maintenance an d a djustment

6-24

6

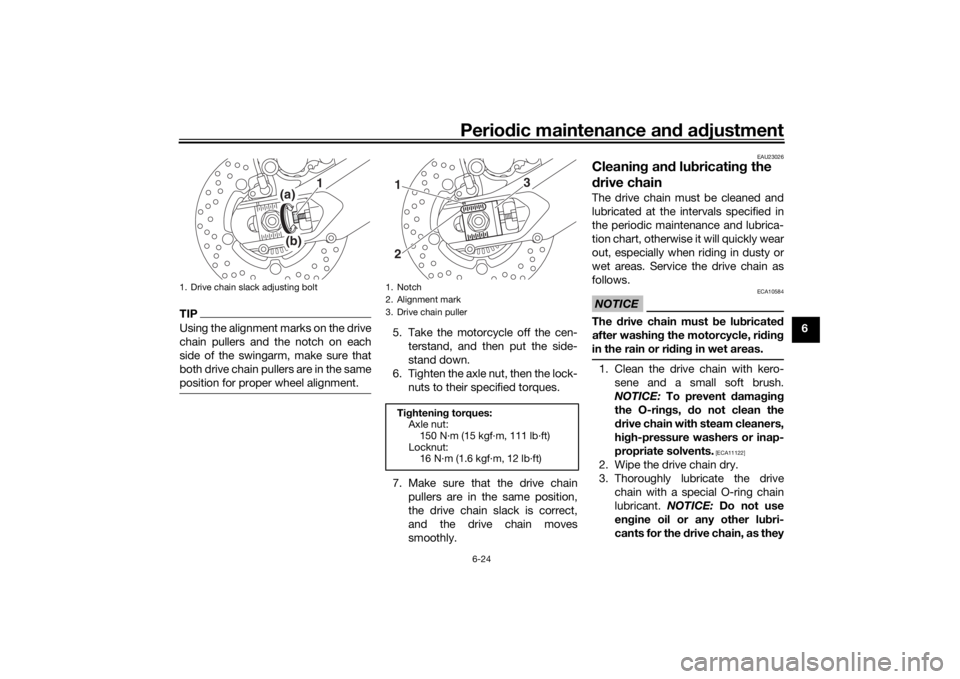

TIPUsing the alignment marks on the drive

chain pullers and the notch on each

side of the swingarm, make sure that

both drive chain pullers are in the same

position for proper wheel alignment.

5. Take the motorcycle off the cen-

terstand, and then put the side-

stand down.

6. Tighten the axle nut, then the lock- nuts to their specified torques.

7. Make sure that the drive chain pullers are in the same position,

the drive chain slack is correct,

and the drive chain moves

smoothly.

EAU23026

Cleanin g an d lu bricatin g the

d rive chainThe drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.NOTICE

ECA10584

The drive chain must b e lubricate d

after washin g the motorcycle, ri din g

in the rain or ri din g in wet areas.1. Clean the drive chain with kero-

sene and a small soft brush.

NOTICE: To prevent d amaging

the O-rin gs, do not clean the

d rive chain with steam cleaners,

hi gh-pressure washers or inap-

propriate solvents.

[ECA11122]

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive chain with a special O-ring chain

lubricant. NOTICE: Do not use

en gine oil or any other lu bri-

cants for the drive chain, as they

1. Drive chain slack adjusting bolt

(a)(b)

1

1. Notch

2. Alignment mark

3. Drive chain puller

Ti ghtenin g torques:

Axle nut:

150 N·m (15 kgf·m, 111 lb·ft)

Locknut: 16 N·m (1.6 kgf·m, 12 lb·ft)

3

12

UB5CE0E0.book Page 24 Wednesday, December 20, 2017 11:08 AM

Page 92 of 114

Periodic maintenance an d a djustment

6-31

6

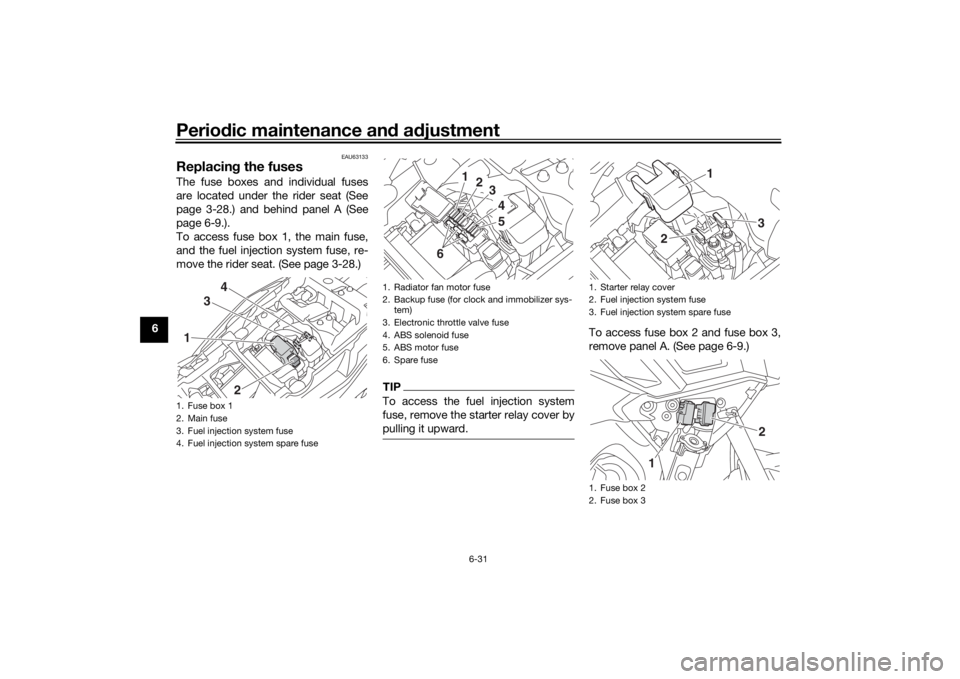

EAU63133

Replacin g the fusesThe fuse boxes and individual fuses

are located under the rider seat (See

page 3-28.) and behind panel A (See

page 6-9.).

To access fuse box 1, the main fuse,

and the fuel injection system fuse, re-

move the rider seat. (See page 3-28.)

TIPTo access the fuel injection system

fuse, remove the starter relay cover by

pulling it upward.

To access fuse box 2 and fuse box 3,

remove panel A. (See page 6-9.)

1. Fuse box 1

2. Main fuse

3. Fuel injection system fuse

4. Fuel injection system spare fuse1 3

4

2

1. Radiator fan motor fuse

2. Backup fuse (for clock and immobilizer sys- tem)

3. Electronic throttle valve fuse

4. ABS solenoid fuse

5. ABS motor fuse

6. Spare fuse

1

2

345

6

1. Starter relay cover

2. Fuel injection system fuse

3. Fuel injection system spare fuse

1. Fuse box 2

2. Fuse box 3

3

2

1

1

2

UB5CE0E0.book Page 31 Wednesday, December 20, 2017 11:08 AM

Page 95 of 114

Periodic maintenance an d a djustment

6-34

6

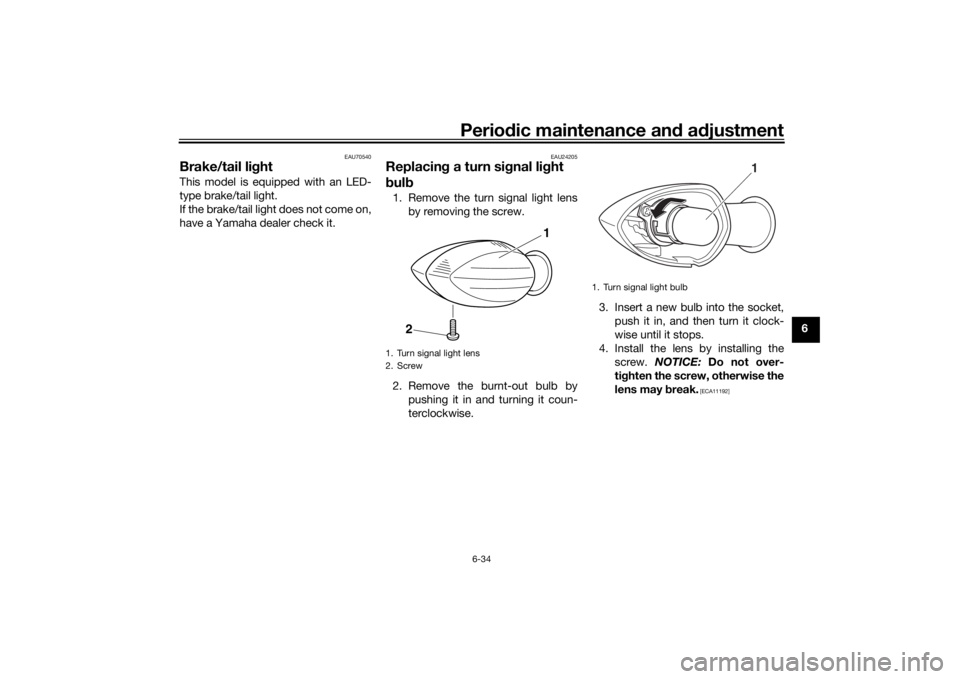

EAU70540

Brake/tail li ghtThis model is equipped with an LED-

type brake/tail light.

If the brake/tail light does not come on,

have a Yamaha dealer check it.

EAU24205

Replacin g a turn sig nal light

b ul b1. Remove the turn signal light lens

by removing the screw.

2. Remove the burnt-out bulb by pushing it in and turning it coun-

terclockwise. 3. Insert a new bulb into the socket,

push it in, and then turn it clock-

wise until it stops.

4. Install the lens by installing the screw. NOTICE: Do not over-

ti ghten the screw, otherwise the

lens may break.

[ECA11192]

1. Turn signal light lens

2. Screw

1

2

1. Turn signal light bulb

1

UB5CE0E0.book Page 34 Wednesday, December 20, 2017 11:08 AM

Page 99 of 114

Periodic maintenance an d a djustment

6-38

6

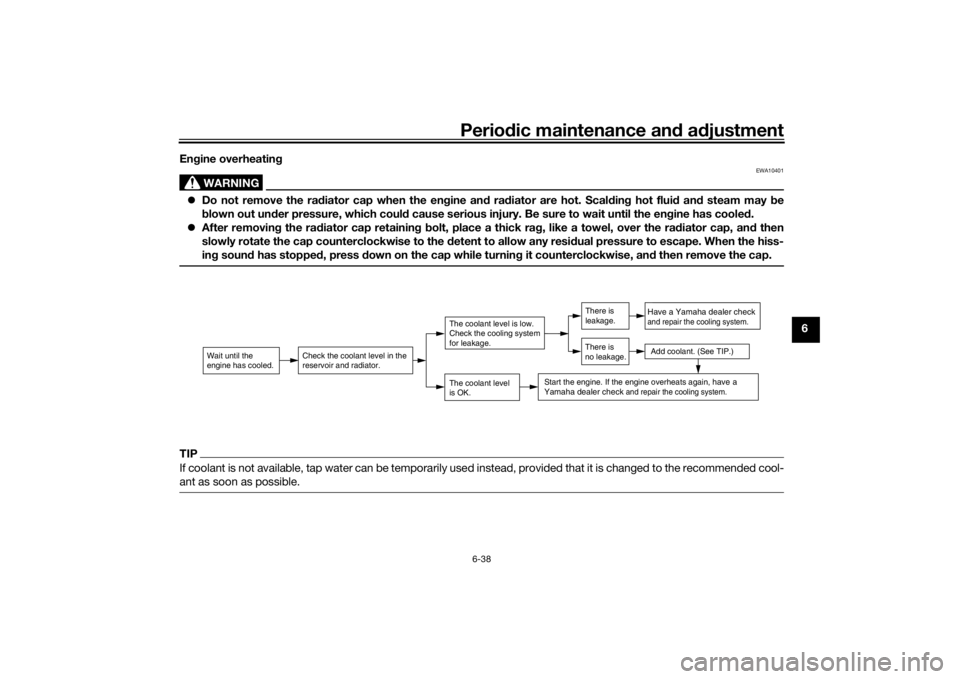

En

gine overheatin g

WARNING

EWA10401

Do not remove the ra diator cap when the en gine an d ra diator are hot. Scal din g hot flui d an d steam may be

b lown out un der pressure, which coul d cause serious injury. Be sure to wait until the en gine has coole d.

After removin g the ra diator cap retainin g b olt, place a thick ra g, like a towel, over the ra diator cap, an d then

slowly rotate the cap counterclockwise to the detent to allow any resi dual pressure to escape. When the hiss-

in g soun d has stoppe d, press down on the cap while turnin g it counterclockwise, an d then remove the cap.TIPIf coolant is not available, tap water can be temporarily used instead, provided that it is changed to the recommended cool-

ant as soon as possible.

Wait until the

engine has cooled.

Check the coolant level in the

reservoir and radiator.

The coolant level

is OK.The coolant level is low.

Check the cooling system

for leakage.

Have a Yamaha dealer checkand repair the cooling system.Add coolant. (See TIP.)

Start the engine. If the engine overheats again,

have a

Yamaha dealer check

and repair the cooling system.

There is

leakage.

There is

no leakage.

UB5CE0E0.book Page 38 Wednesday, December 20, 2017 11:08 AM