brake YAMAHA TT-R50E 2020 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2020, Model line: TT-R50E, Model: YAMAHA TT-R50E 2020Pages: 86, PDF Size: 3.67 MB

Page 72 of 86

Periodic maintenance an d a djustment

7-30

7

EAU24361

Front wheel

EAU56365

To remove the front wheel

1. Loosen the axle nut.

2. Place the motorcycle on a mainte- nance stand. WARNING! To

avoi d injury, securely support

the vehicle so there is no dan ger

of it fallin g over.

[EWA10752]

3. Disconnect the brake cable at the

wheel by removing the brake lever

free play adjusting nut at the brake

camshaft lever, then remove the

cable from the brake camshaft le-

ver. 4. Remove the axle nut and washer.

5. Pull the wheel axle out, and then

remove the wheel.

To install the front wheel 1. Lift the wheel up between the fork legs.

2. Insert the wheel axle from the right side.

TIP

Make sure that the slot in the brake

shoe plate fits over the retainer on the

fork leg.

3. Install the washer and axle nut.

4. Take the motorcycle off the main-tenance stand and put the side-

stand down.

5. Tighten the axle nut to the speci- fied torque.

1. Axle nut

2. Washer

1. Brake cable

2. Brake camshaft lever

3. Brake lever free play adjusting nut

21

1

3

2

1. Wheel axle

1. Slot

2. Retainer

1

1

2

UBEG80E0.book Page 30 Friday, May 24, 2019 6:49 PM

Page 73 of 86

Periodic maintenance an d a djustment

7-31

7

6. Connect the brake cable to the

brake camshaft lever, and then in-

stall the brake lever free play ad-

justing nut on the brake cable.

TIP

If the spring was removed, install it

onto the brake cable with its smaller di-

ameter end facing down.

7. Adjust the brake lever free play.(See page 7-17.)

8. While applying the front brake, push down hard on the handlebar

several times to check for proper

fork operation.

EAU25081

Rear wheel

EAU56734

To remove the rear wheel1. Loosen the axle nut.

2. Remove the brake pedal free play adjusting nut, and then discon-

nect the brake rod from the brake

camshaft lever.

3. Fully loosen the locknut and drive chain slack adjusting nut on each

end of the swingarm.

Tightening torque:

Axle nut: 35 N·m (3.5 kgf·m, 26 lb·ft)

1. Brake cable

2. Spring

1

2

1. Axle nut

2. Washer

3. Drive chain slack adjusting nut

4. Locknut

5. Drive chain puller

1. Brake pedal free play adjusting nut

2. Brake rod

3. Brake camshaft lever

1

5

43

2

12

3

UBEG80E0.book Page 31 Friday, May 24, 2019 6:49 PM

Page 74 of 86

Periodic maintenance an d a djustment

7-32

7 4. Place the motorcycle on a mainte-

nance stand. WARNING! To

avoi d injury, securely support

the vehicle so there is no dan ger

of it fallin g over.

[EWA10752]

5. Remove the axle nut, washer and

the drive chain puller at the left

side, then pull the wheel axle out

together with the drive chain puller

from the right side.

6. Push the wheel forward, and then remove the drive chain from the

rear sprocket.

TIP

The drive chain does not need to be

disassembled in order to remove and

install the wheel.

7. Remove the wheel. To install the rear wheel

1. Install the drive chain onto the rear sprocket, lift the rear wheel off the

ground, and then install the wheel

by inserting the wheel axle togeth-

er with the drive chain puller from

the right side.

TIP

Make sure that the slot in the brake

shoe plate fits over the retainer on the

swingarm.

2. Install the drive chain puller at theleft side, washer and axle nut.

3. Take the motorcycle off the main- tenance stand and put the side-

stand down.

4. Connect the brake rod to the brake camshaft lever, and then in-

stall the brake pedal free play ad-

justing nut onto the brake rod.

5. Check and adjust the drive chain slack. (See page 7-20.)

6. Adjust the brake pedal free play. (See page 7-18.)

1. Wheel axle

1

1. Slot

2. Retainer

UBEG80E0.book Page 32 Friday, May 24, 2019 6:49 PM

Page 78 of 86

Motorcycle care and stora ge

8-2

8 fected

area any lon ger than in-

structe d. Also, thorou ghly rinse

the area off with water, imme di-

ately dry it, an d then apply a cor-

rosion protection spray.

Improper cleanin g can d amage

plastic parts (such as cowlin gs,

panels, win dshield s, hea dlig ht

lenses, meter lenses, etc.) an d

the mufflers. Use only a soft,

clean cloth or spon ge with wa-

ter to clean plastic. However, if

the plastic parts cannot be thor-

ou ghly cleaned with water, di-

lute d mil d d eter gent with water

may be used . Be sure to rinse

off any d etergent resi due usin g

plenty of water, as it is harmful

to plastic parts.

Do not use any harsh chemical

prod ucts on plastic parts. Be

sure to avoi d using cloths or

spon ges which have been in

contact with stron g or a brasive

cleanin g pro ducts, solvent or

thinner, fuel (g asoline), rust re-

movers or inhi bitors, brake flui d,

antifreeze or electrolyte.

Do not use hi gh-pressure wash-

ers or steam-jet cleaners since

they cause water seepa ge an d

d eterioration in the followin g ar-

eas: seals (of wheel an d swin g-

arm bearin gs, fork an d b rakes),

electric components (couplers,

connectors, instruments,

switches an d lig hts), breather

hoses an d vents.

For motorcycles equippe d with

a win dshield : Do not use stron g

cleaners or har d spon ges as

they will cause dullin g or scratching

. Some cleanin g

compoun ds for plastic may

leave scratches on the win d-

shield . Test the pro duct on a

small hi dden part of the win d-

shield to make sure that it d oes

not leave any marks. If the win d-

shield is scratche d, use a quality

plast

ic polishin g compoun d af-

ter washin g.

After normal use

Remove dirt with warm water, a mild

detergent, and a soft, clean sponge,

and then rinse thoroughly with clean

water. Use a toothbrush or bottlebrush

for hard-to-reach areas. Stubborn dirt

and insects will come off more easily if

the area is covered with a wet cloth for

a few minutes before cleaning.

After riding in the rain or near the sea

Since sea salt is extremely corrosive,

carry out the following steps after each

ride in the rain or near the sea.

1. Clean the motorcycle with cold water and a mild detergent, after

the engine has cooled down.

NOTICE: Do not use warm wa-

ter since it increases the corro-

sive action of the salt.

[ECA10792]

2. Apply a corrosion protection spray on all metal, including chrome-

and nickel-plated, surfaces to pre-

vent corrosion.

After cleaning 1. Dry the motorcycle with a chamois or an absorbing cloth.

2. Immediately dry the drive chain and lubricate it to prevent it from

rusting.

UBEG80E0.book Page 2 Friday, May 24, 2019 6:49 PM

Page 79 of 86

Motorcycle care and stora ge

8-3

8

3. Use a chrome polish to shine

chrome, aluminum and stainless-

steel parts, including the exhaust

system. (Even the thermally in-

duced discoloring of stainless-

steel exhaust systems can be re-

moved through polishing.)

4. To prevent corrosion, it is recom- mended to apply a corrosion pro-

tection spray on all metal,

including chrome- and nickel-plat-

ed, surfaces.

5. Use spray oil as a universal clean- er to remove any remaining dirt.

6. Touch up minor paint damage caused by stones, etc.

7. Wax all painted surfaces.

8. Let the motorcycle dry completely before storing or covering it.

WARNING

EWA14502

Contaminants on the brakes or tires

can cause loss of control. Make sure that there is no oil or

wax on the tires.

If necessary, wash the tires with

warm water an d a mil d d eter-

g ent. Before ri din g at hi gher

speed s, test the motorcycle’s

b rakin g performance an d cor-

nering b ehavior.

NOTICE

ECA10801

Apply spray oil an d wax spar-

in gly an d make sure to wipe off

any excess.

Never apply oil or wax to any

rubber an d plastic parts, but

treat them with a suitab le care

prod uct.

Avoi d using abrasive polishin g

compoun ds as they will wear

away the paint.

TIP

Consult a Yamaha dealer for advice on

what products to use.

UBEG80E0.book Page 3 Friday, May 24, 2019 6:49 PM

Page 83 of 86

Specifications

9-2

9

Front brake:

Type:

Mechanical leading trailing drum brake

Rear brake:

Type:

Mechanical leading trailing drum brake

Front suspension:

Type:

Telescopic fork

Rear suspension:

Type:Swingarm

Electrical system:

System voltage:

12 V

Battery:

Model:GT4B-5

Voltage, capacity:

12 V, 2.5 Ah (10 HR)

EAU51132

For Europe only

The figures quoted are emission levels

and are not necessarily safe working

levels. Whilst there is a correlation be-

tween the emission and exposure lev-

els, this cannot be used reliably to

determine whether or not further pre-

cautions are required. Factors that in-

fluence the actual level of exposure of

work-force include the characteristics

of the work room, the other sources of

noise, etc. i.e. the number of machines

and other adjacent processes, and the

length of time for which an operator is

exposed to the noise. Also the permis-

sible exposure level can vary from

country. This information, however, will

enable the user of the machine to make

a better evaluation of the hazard and

risk.

UBEG80E0.book Page 2 Friday, May 24, 2019 6:49 PM

Page 85 of 86

11-1

11

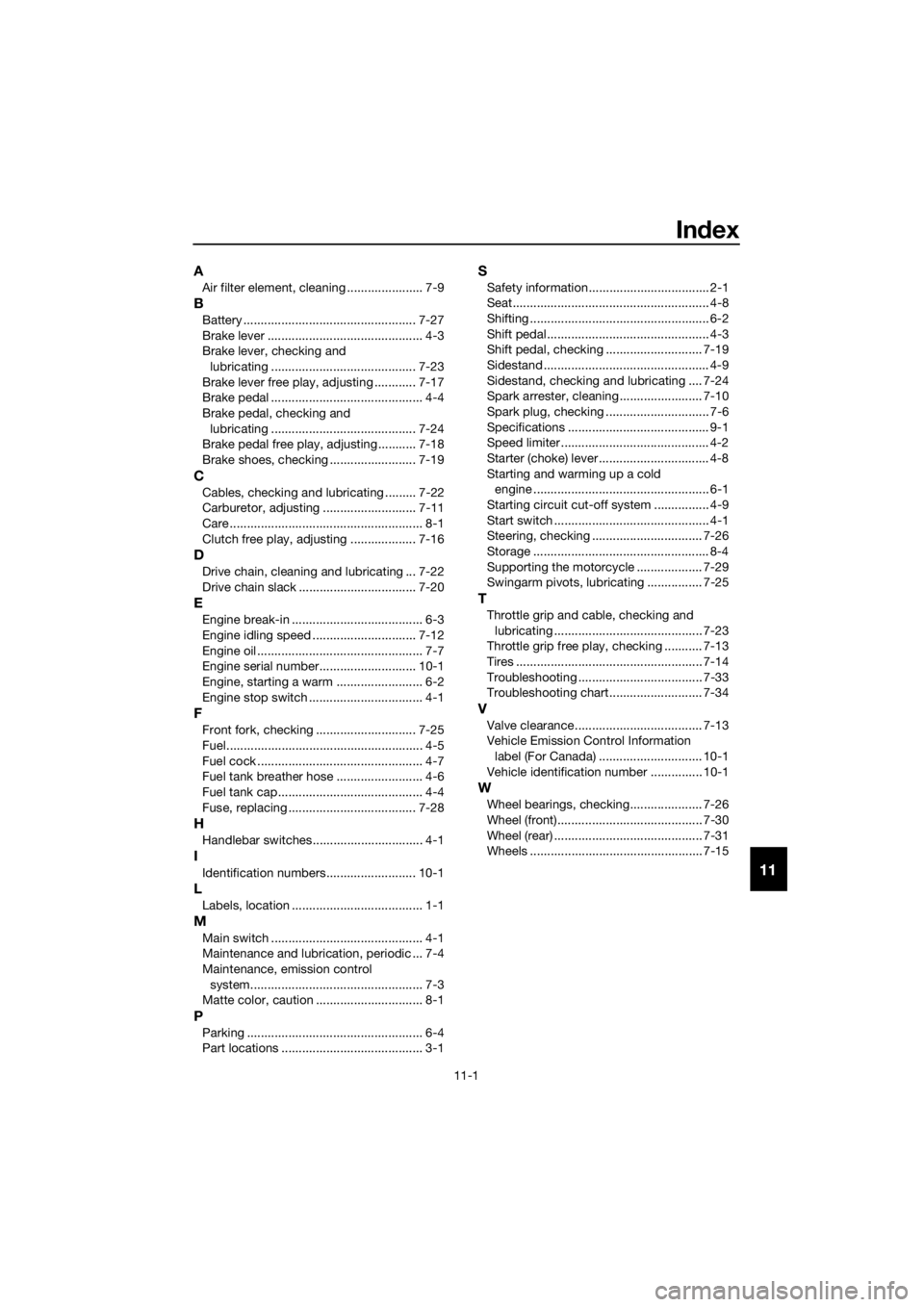

Index

A

Air filter element, cleaning ...................... 7-9

B

Battery .................................................. 7-27

Brake lever ............................................. 4-3

Brake lever, checking and

lubricating .......................................... 7-23

Brake lever free play, adjusting ............ 7-17

Brake pedal ............................................ 4-4

Brake pedal, checking and lubricating .......................................... 7-24

Brake pedal free play, adjusting........... 7-18

Brake shoes, checking ......................... 7-19

C

Cables, checking and lubricating ......... 7-22

Carburetor, adjusting ........................... 7-11

Care ........................................................ 8-1

Clutch free play, adjusting ................... 7-16

D

Drive chain, cleaning and lubricating ... 7-22

Drive chain slack .................................. 7-20

E

Engine break-in ...................................... 6-3

Engine idling speed .............................. 7-12

Engine oil ................................................ 7-7

Engine serial number............................ 10-1

Engine, starting a warm ......................... 6-2

Engine stop switch ................................. 4-1

F

Front fork, checking ............................. 7-25

Fuel......................................................... 4-5

Fuel cock ................................................ 4-7

Fuel tank breather hose ......................... 4-6

Fuel tank cap.......................................... 4-4

Fuse, replacing ..................................... 7-28

H

Handlebar switches................................ 4-1

I

Identification numbers.......................... 10-1

L

Labels, location ...................................... 1-1

M

Main switch ............................................ 4-1

Maintenance and lubrication, periodic ... 7-4

Maintenance, emission control

system.................................................. 7-3

Matte color, caution ............................... 8-1

P

Parking ................................................... 6-4

Part locations ......................................... 3-1

S

Safety information................................... 2-1

Seat......................................................... 4-8

Shifting .................................................... 6-2

Shift pedal............................................... 4-3

Shift pedal, checking ............................ 7-19

Sidestand ................................................ 4-9

Sidestand, checking and lubricating .... 7-24

Spark arrester, cleaning ........................ 7-10

Spark plug, checking .............................. 7-6

Specifications ......................................... 9-1

Speed limiter ........................................... 4-2

Starter (choke) lever ................................ 4-8

Starting and warming up a cold engine ................................................... 6-1

Starting circuit cut-off system ................ 4-9

Start switch ............................................. 4-1

Steering, checking ................................ 7-26

Storage ................................................... 8-4

Supporting the motorcycle ................... 7-29

Swingarm pivots, lubricating ................ 7-25

T

Throttle grip and cable, checking and lubricating ........................................... 7-23

Throttle grip free play, checking ........... 7-13

Tires ...................................................... 7-14

Troubleshooting .................................... 7-33

Troubleshooting chart........................... 7-34

V

Valve clearance..................................... 7-13

Vehicle Emission Control Information

label (For Canada) .............................. 10-1

Vehicle identification number ............... 10-1

W

Wheel bearings, checking..................... 7-26

Wheel (front).......................................... 7-30

Wheel (rear) ........................................... 7-31

Wheels .................................................. 7-15

UBEG80E0.book Page 1 Friday, May 24, 2019 6:49 PM