maintenance YAMAHA TTR125 2007 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2007, Model line: TTR125, Model: YAMAHA TTR125 2007Pages: 616, PDF Size: 26.56 MB

Page 93 of 616

SPEC

2 - 20

MAINTENANCE SPECIFICATIONS

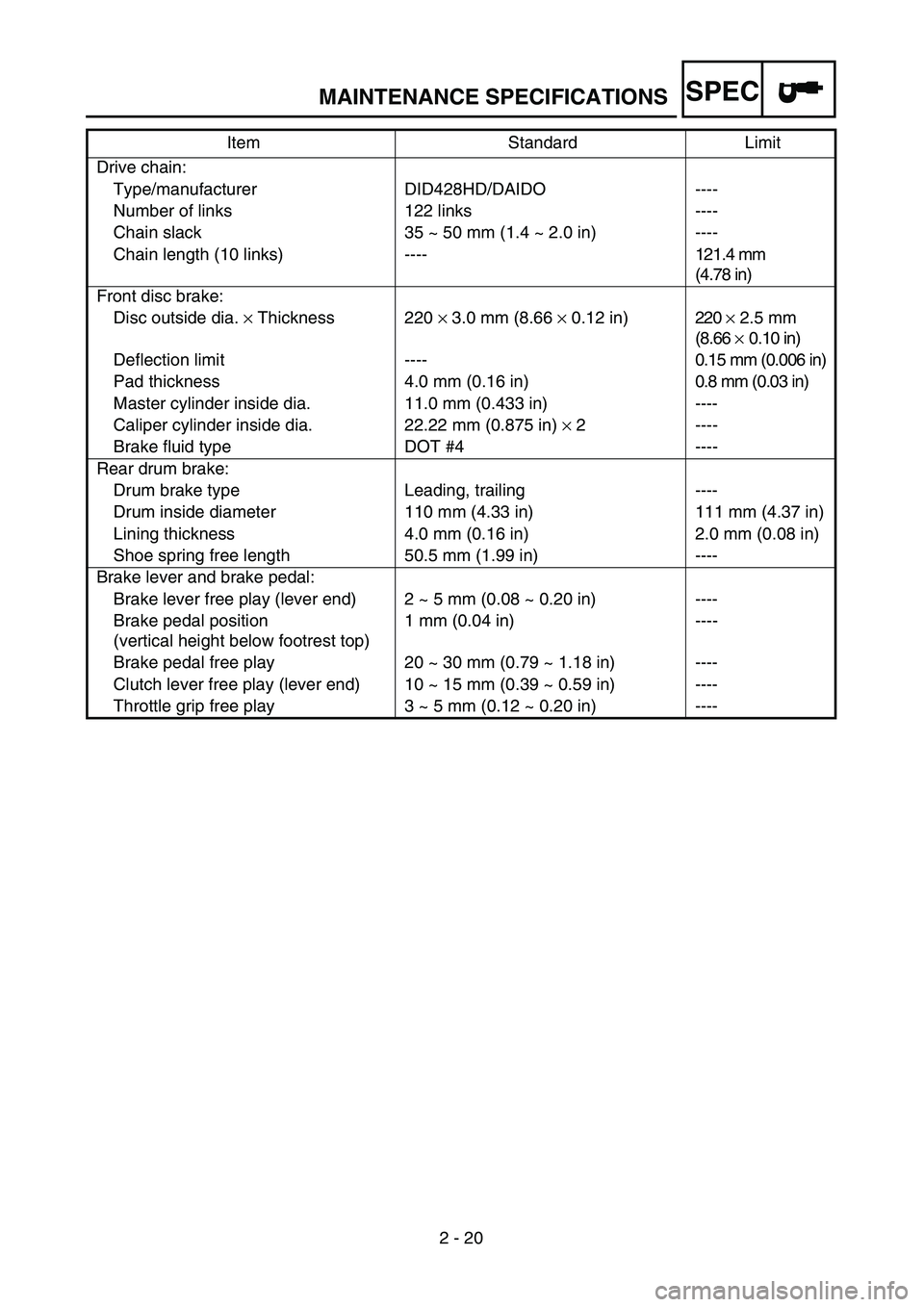

Drive chain:

Type/manufacturer DID428HD/DAIDO ----

Number of links 122 links ----

Chain slack 35 ~ 50 mm (1.4 ~ 2.0 in) ----

Chain length (10 links) ----121.4 mm

(4.78 in)

Front disc brake:

Disc outside dia. × Thickness 220 × 3.0 mm (8.66 × 0.12 in)220 × 2.5 mm

(8.66 × 0.10 in)

Deflection limit ----0.15 mm (0.006 in)

Pad thickness 4.0 mm (0.16 in)0.8 mm (0.03 in)

Master cylinder inside dia. 11.0 mm (0.433 in) ----

Caliper cylinder inside dia. 22.22 mm (0.875 in) × 2 ----

Brake fluid type DOT #4 ----

Rear drum brake:

Drum brake type Leading, trailing ----

Drum inside diameter 110 mm (4.33 in) 111 mm (4.37 in)

Lining thickness 4.0 mm (0.16 in) 2.0 mm (0.08 in)

Shoe spring free length 50.5 mm (1.99 in) ----

Brake lever and brake pedal:

Brake lever free play (lever end) 2 ~ 5 mm (0.08 ~ 0.20 in) ----

Brake pedal position

(vertical height below footrest top)1 mm (0.04 in) ----

Brake pedal free play 20 ~ 30 mm (0.79 ~ 1.18 in) ----

Clutch lever free play (lever end) 10 ~ 15 mm (0.39 ~ 0.59 in) ----

Throttle grip free play 3 ~ 5 mm (0.12 ~ 0.20 in) ----Item Standard Limit

Page 94 of 616

SPEC

2 - 21

MAINTENANCE SPECIFICATIONS

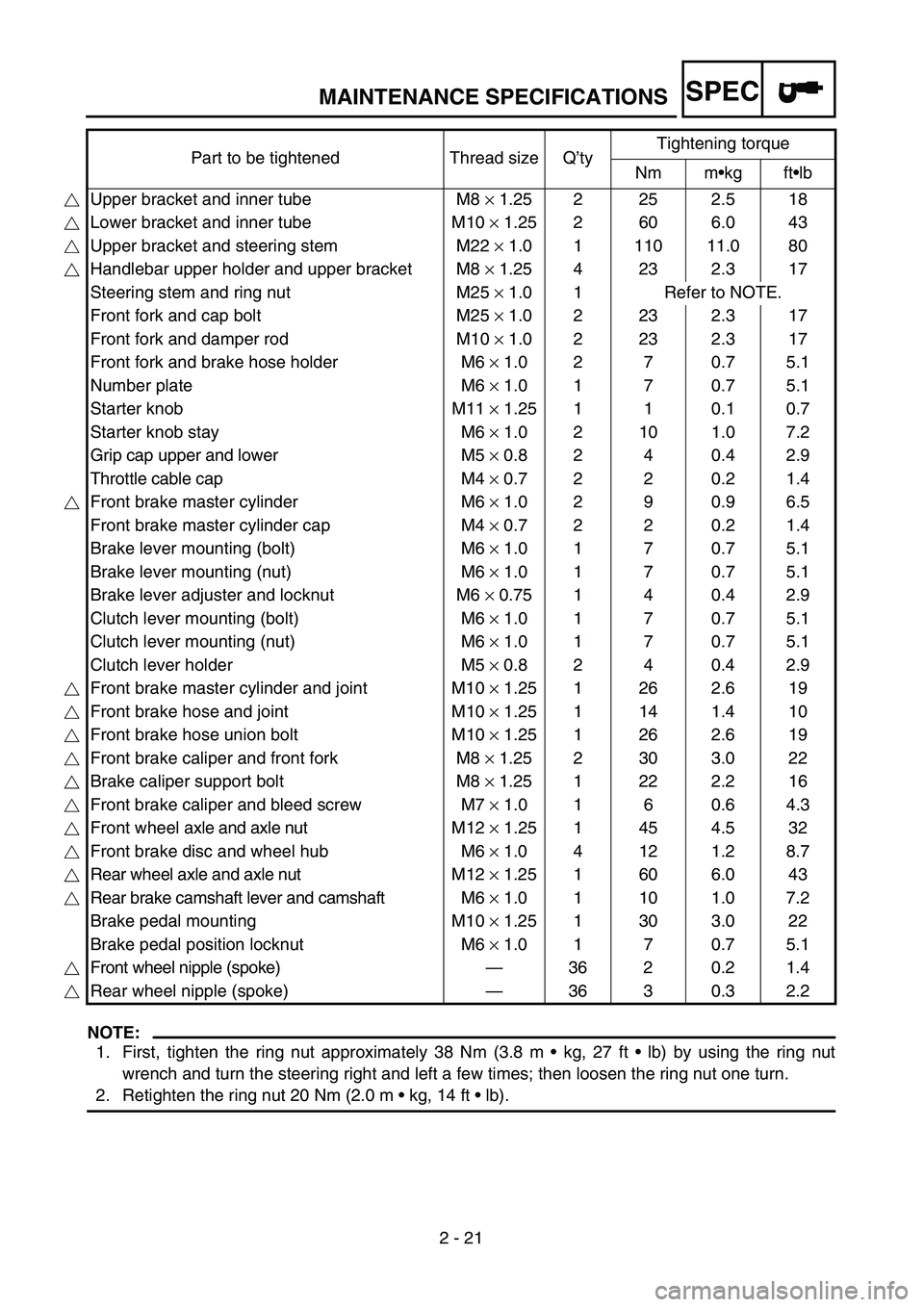

NOTE:

1. First, tighten the ring nut approximately 38 Nm (3.8 m • kg, 27 ft • lb) by using the ring nut

wrench and turn the steering right and left a few times; then loosen the ring nut one turn.

2. Retighten the ring nut 20 Nm (2.0 m • kg, 14 ft • lb). Part to be tightened Thread size Q’tyTightening torque

Nm m•kg ft•lb

Upper bracket and inner tube M8 × 1.25 2 25 2.5 18

Lower bracket and inner tube M10 × 1.25 2 60 6.0 43

Upper bracket and steering stem M22 × 1.0 1 110 11.0 80

Handlebar upper holder and upper bracket M8 × 1.25 4 23 2.3 17

Steering stem and ring nut M25 × 1.0 1 Refer to NOTE.

Front fork and cap bolt M25 × 1.0 2 23 2.3 17

Front fork and damper rod M10 × 1.0 2 23 2.3 17

Front fork and brake hose holder M6 × 1.0 2 7 0.7 5.1

Number plate M6 × 1.0 1 7 0.7 5.1

Starter knob M11 × 1.25 1 1 0.1 0.7

Starter knob stay M6 × 1.0 2 10 1.0 7.2

Grip cap upper and lower M5 × 0.8 2 4 0.4 2.9

Throttle cable cap M4 × 0.7 2 2 0.2 1.4

Front brake master cylinder M6 × 1.0 2 9 0.9 6.5

Front brake master cylinder cap M4 × 0.7 2 2 0.2 1.4

Brake lever mounting (bolt) M6 × 1.0 1 7 0.7 5.1

Brake lever mounting (nut) M6 × 1.0 1 7 0.7 5.1

Brake lever adjuster and locknut M6 × 0.75 1 4 0.4 2.9

Clutch lever mounting (bolt) M6 × 1.0 1 7 0.7 5.1

Clutch lever mounting (nut) M6 × 1.0 1 7 0.7 5.1

Clutch lever holder M5 × 0.8 2 4 0.4 2.9

Front brake master cylinder and joint M10 × 1.25 1 26 2.6 19

Front brake hose and joint M10 × 1.25 1 14 1.4 10

Front brake hose union bolt M10 × 1.25 1 26 2.6 19

Front brake caliper and front fork M8 × 1.25 2 30 3.0 22

Brake caliper support bolt M8 × 1.25 1 22 2.2 16

Front brake caliper and bleed screw M7 × 1.0 1 6 0.6 4.3

Front wheel axle and axle nut M12 × 1.25 1 45 4.5 32

Front brake disc and wheel hub M6 × 1.0 4 12 1.2 8.7

Rear wheel axle and axle nut M12 × 1.25 1 60 6.0 43

Rear brake camshaft lever and camshaft M6 × 1.0 1 10 1.0 7.2

Brake pedal mounting M10 × 1.25 1 30 3.0 22

Brake pedal position locknut M6 × 1.0 1 7 0.7 5.1

Front wheel nipple (spoke)—36 2 0.2 1.4

Rear wheel nipple (spoke)—36 3 0.3 2.2

Page 95 of 616

SPEC

2 - 22

MAINTENANCE SPECIFICATIONS

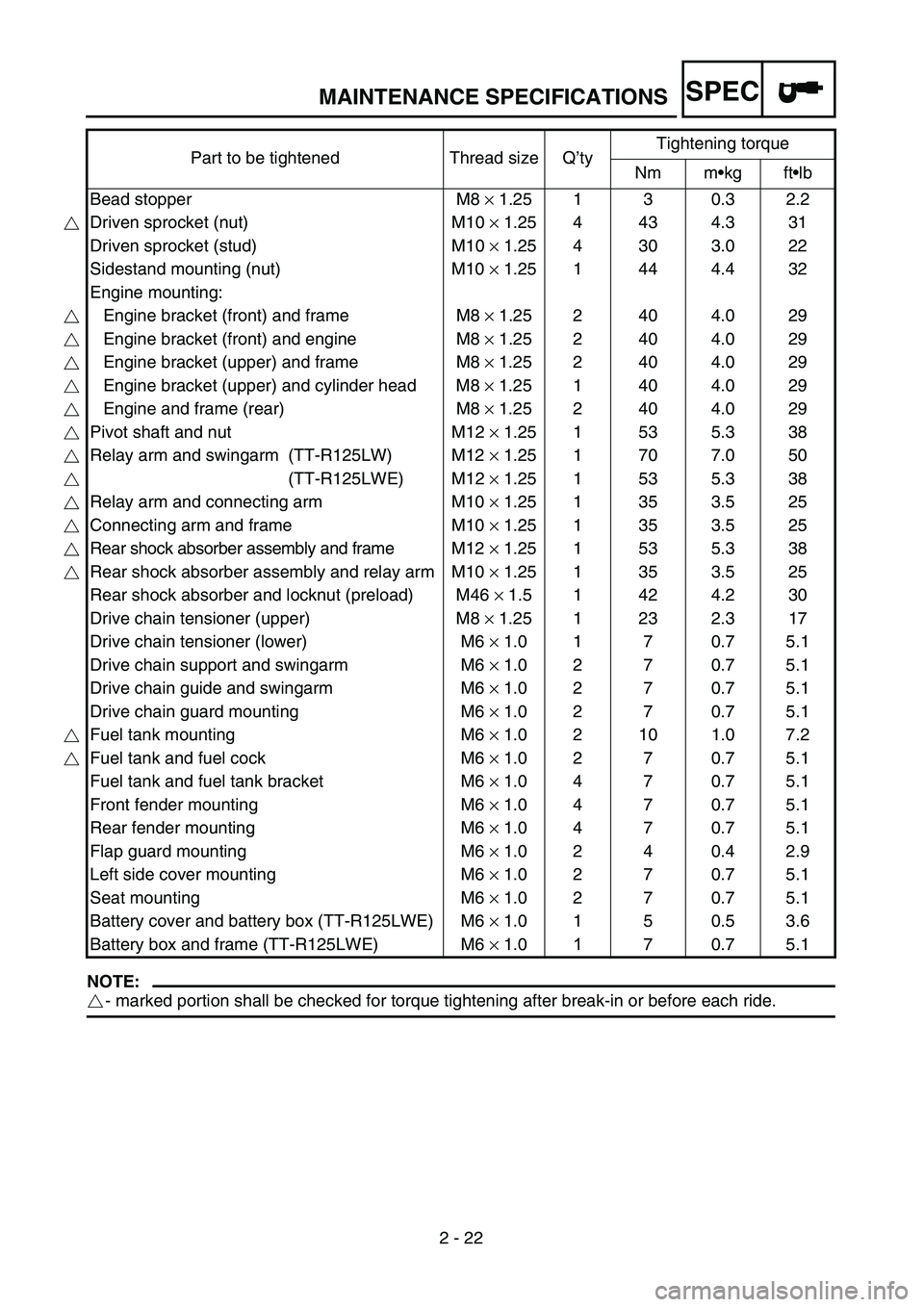

NOTE:

- marked portion shall be checked for torque tightening after break-in o\

r before each ride.Part to be tightened Thread size Q

’ty Tightening torque

Nm m •kg ft •lb

Bead stopper M8 × 1.25 1 3 0.3 2.2

Driven sprocket (nut) M10 × 1.25 4 43 4.3 31

Driven sprocket (stud) M10 × 1.25 4 30 3.0 22

Sidestand mounting (nut) M10 × 1.25 1 44 4.4 32

Engine mounting: Engine bracket (front) and frame M8 × 1.25 2 40 4.0 29

Engine bracket (front) and engine M8 × 1.25 2 40 4.0 29

Engine bracket (upper) and frame M8 × 1.25 2 40 4.0 29

Engine bracket (upper) and cylinder head M8 × 1.25 1 40 4.0 29

Engine and frame (rear) M8 × 1.25 2 40 4.0 29

Pivot shaft and nut M12 × 1.25 1 53 5.3 38

Relay arm and swingarm (TT-R125LW) M12 × 1.25 1 70 7.0 50

(TT-R125LWE) M12 × 1.25 1 53 5.3 38

Relay arm and connecting arm M10 × 1.25 1 35 3.5 25

Connecting arm and frame M10 × 1.25 1 35 3.5 25

Rear shock absorber assembly and frame M12 × 1.25 1 53 5.3 38

Rear shock absorber assembly and relay arm M10 × 1.25 1 35 3.5 25

Rear shock absorber and locknut (preload) M46 × 1.5 1 42 4.2 30

Drive chain tensioner (upper) M8 × 1.25 1 23 2.3 17

Drive chain tensioner (lower) M6 × 1.0 1 7 0.7 5.1

Drive chain support and swingarm M6 × 1.0 2 7 0.7 5.1

Drive chain guide and swingarm M6 × 1.0 2 7 0.7 5.1

Drive chain guard mounting M6 × 1.0 2 7 0.7 5.1

Fuel tank mounting M6 × 1.0 2 10 1.0 7.2

Fuel tank and fuel cock M6 × 1.0 2 7 0.7 5.1

Fuel tank and fuel tank bracket M6 × 1.0 4 7 0.7 5.1

Front fender mounting M6 × 1.0 4 7 0.7 5.1

Rear fender mounting M6 × 1.0 4 7 0.7 5.1

Flap guard mounting M6 × 1.0 2 4 0.4 2.9

Left side cover mounting M6 × 1.0 2 7 0.7 5.1

Seat mounting M6 × 1.0 2 7 0.7 5.1

Battery cover and battery box (TT-R125LWE) M6 × 1.0 1 5 0.5 3.6

Battery box and frame (TT-R125LWE) M6 × 1.0 1 7 0.7 5.1

Page 96 of 616

SPEC

2 - 23

MAINTENANCE SPECIFICATIONS

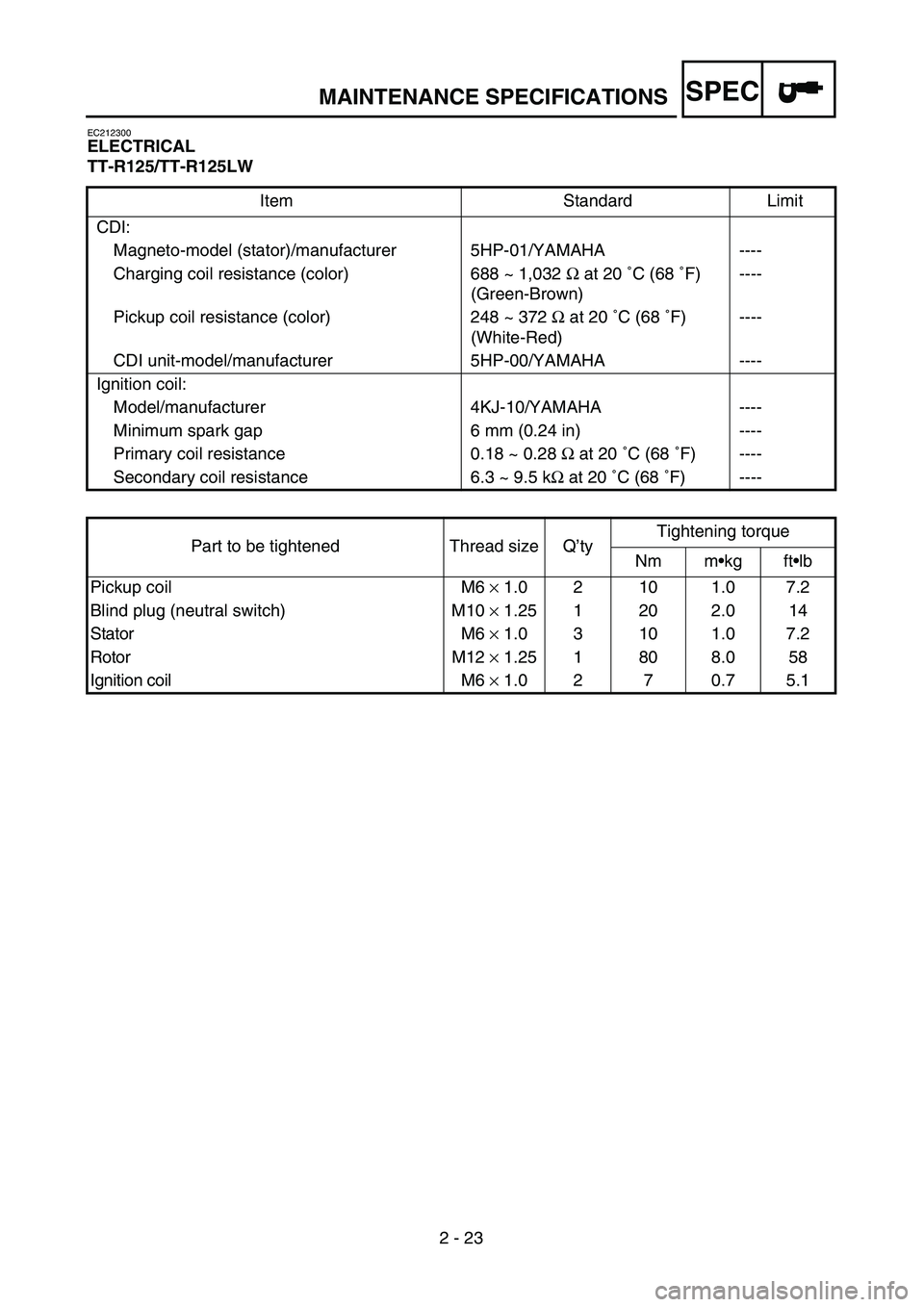

EC212300

ELECTRICAL

TT-R125/TT-R125LW

Item Standard Limit

CDI:

Magneto-model (stator)/manufacturer 5HP-01/YAMAHA ----

Charging coil resistance (color) 688 ~ 1,032 Ω at 20 ˚C (68 ˚F)

(Green-Brown)----

Pickup coil resistance (color) 248 ~ 372 Ω at 20 ˚C (68 ˚F)

(White-Red)----

CDI unit-model/manufacturer 5HP-00/YAMAHA ----

Ignition coil:

Model/manufacturer 4KJ-10/YAMAHA ----

Minimum spark gap 6 mm (0.24 in) ----

Primary coil resistance 0.18 ~ 0.28 Ω at 20 ˚C (68 ˚F) ----

Secondary coil resistance 6.3 ~ 9.5 kΩ at 20 ˚C (68 ˚F) ----

Part to be tightened Thread size Q’tyTightening torque

Nm m•kg ft•lb

Pickup coil M6 × 1.0 2 10 1.0 7.2

Blind plug (neutral switch) M10 × 1.25 1 20 2.0 14

Stator M6 × 1.0 3 10 1.0 7.2

Rotor M12 × 1.25 1 80 8.0 58

Ignition coil M6 × 1.0 2 7 0.7 5.1

Page 97 of 616

SPEC

2 - 24

MAINTENANCE SPECIFICATIONS

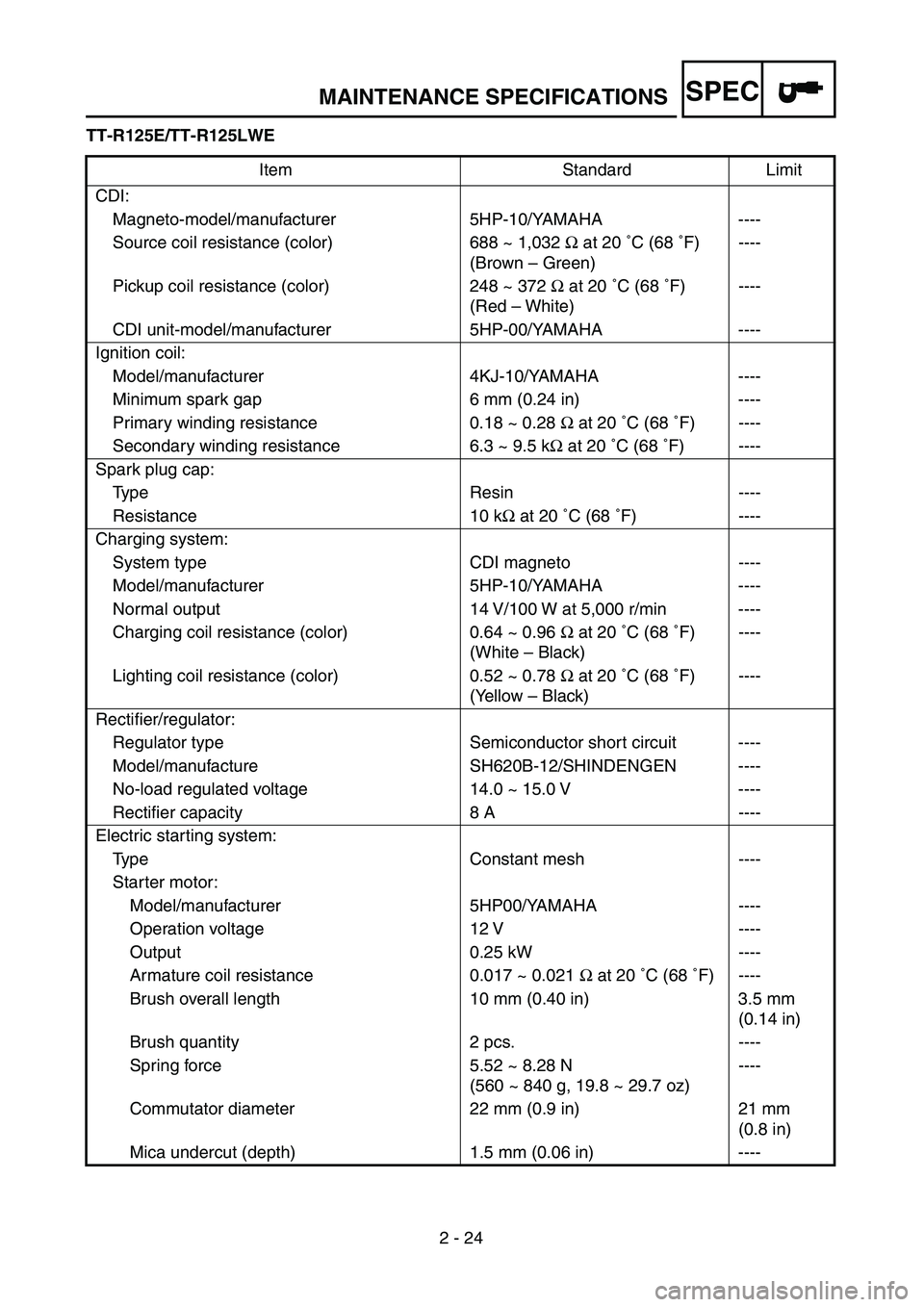

TT-R125E/TT-R125LWE

Item Standard Limit

CDI:

Magneto-model/manufacturer 5HP-10/YAMAHA ----

Source coil resistance (color) 688 ~ 1,032 Ω at 20 ˚C (68 ˚F)

(Brown – Green)----

Pickup coil resistance (color) 248 ~ 372 Ω at 20 ˚C (68 ˚F)

(Red – White)----

CDI unit-model/manufacturer 5HP-00/YAMAHA ----

Ignition coil:

Model/manufacturer 4KJ-10/YAMAHA ----

Minimum spark gap 6 mm (0.24 in) ----

Primary winding resistance 0.18 ~ 0.28 Ω at 20 ˚C (68 ˚F) ----

Secondary winding resistance 6.3 ~ 9.5 kΩ at 20 ˚C (68 ˚F) ----

Spark plug cap:

Type Resin ----

Resistance 10 kΩ at 20 ˚C (68 ˚F) ----

Charging system:

System type CDI magneto ----

Model/manufacturer 5HP-10/YAMAHA ----

Normal output 14 V/100 W at 5,000 r/min ----

Charging coil resistance (color) 0.64 ~ 0.96 Ω at 20 ˚C (68 ˚F)

(White – Black)----

Lighting coil resistance (color) 0.52 ~ 0.78 Ω at 20 ˚C (68 ˚F)

(Yellow – Black)----

Rectifier/regulator:

Regulator type Semiconductor short circuit ----

Model/manufacture SH620B-12/SHINDENGEN ----

No-load regulated voltage 14.0 ~ 15.0 V ----

Rectifier capacity 8 A ----

Electric starting system:

Type Constant mesh ----

Starter motor:

Model/manufacturer 5HP00/YAMAHA ----

Operation voltage 12 V ----

Output 0.25 kW ----

Armature coil resistance 0.017 ~ 0.021 Ω at 20 ˚C (68 ˚F) ----

Brush overall length 10 mm (0.40 in) 3.5 mm

(0.14 in)

Brush quantity 2 pcs. ----

Spring force 5.52 ~ 8.28 N

(560 ~ 840 g, 19.8 ~ 29.7 oz)----

Commutator diameter 22 mm (0.9 in) 21 mm

(0.8 in)

Mica undercut (depth) 1.5 mm (0.06 in) ----

Page 98 of 616

SPEC

2 - 25

MAINTENANCE SPECIFICATIONS

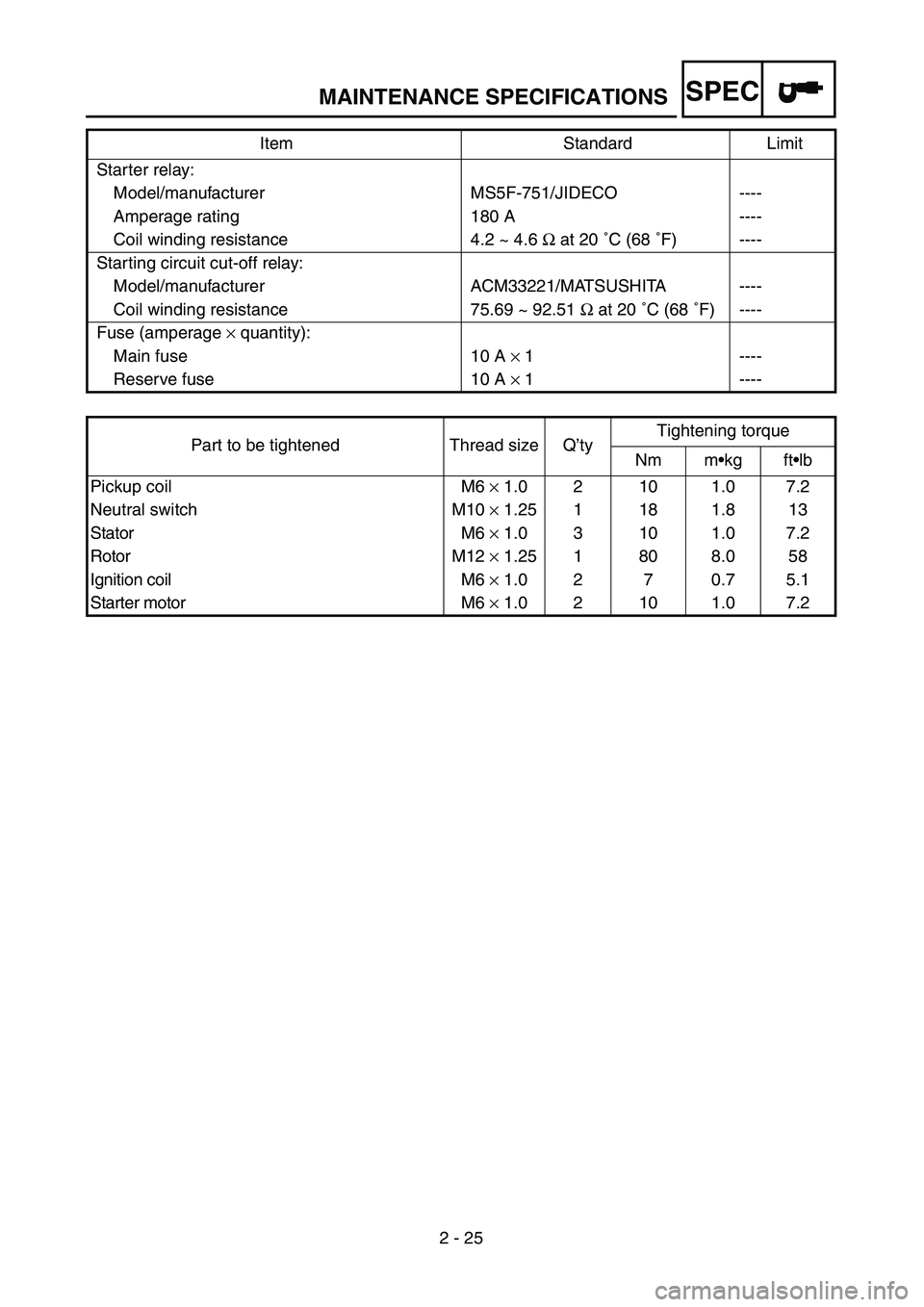

Starter relay:

Model/manufacturer MS5F-751/JIDECO ----

Amperage rating 180 A ----

Coil winding resistance 4.2 ~ 4.6 Ω at 20 ˚C (68 ˚F) ----

Starting circuit cut-off relay:

Model/manufacturer ACM33221/MATSUSHITA ----

Coil winding resistance 75.69 ~ 92.51 Ω at 20 ˚C (68 ˚F) ----

Fuse (amperage × quantity):

Main fuse 10 A × 1 ----

Reserve fuse 10 A × 1 ----

Part to be tightened Thread size Q’tyTightening torque

Nm m•kg ft•lb

Pickup coil M6 × 1.0 2 10 1.0 7.2

Neutral switch M10 × 1.25 1 18 1.8 13

Stator M6 × 1.0 3 10 1.0 7.2

Rotor M12 × 1.25 1 80 8.0 58

Ignition coil M6 × 1.0 2 7 0.7 5.1

Starter motor M6 × 1.0 2 10 1.0 7.2 Item Standard Limit

Page 170 of 616

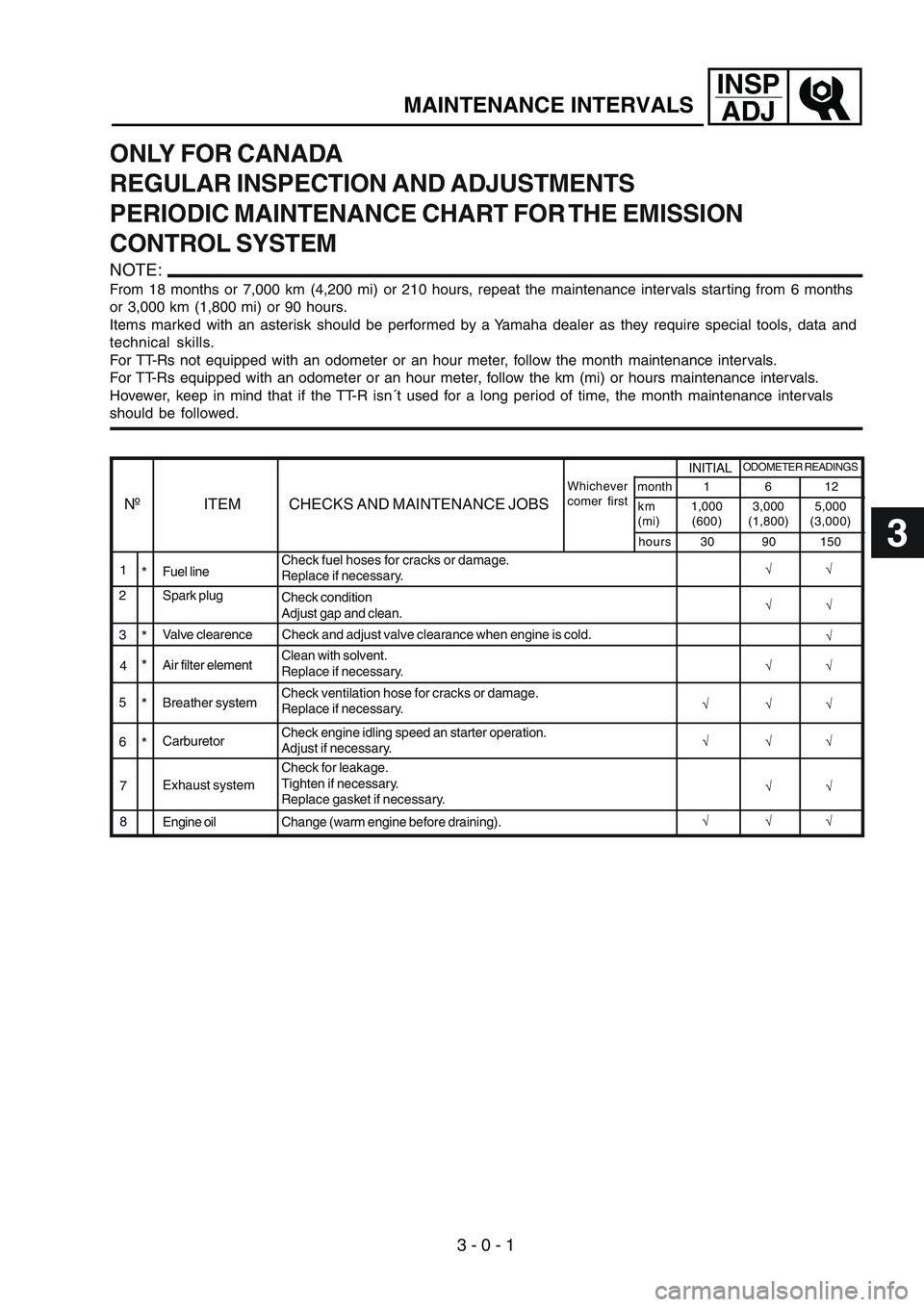

PERIODIC MAINTENANCE CHART FOR THE EMISSION

CONTROL SYSTEM

NOTE:

From 18 months or 7,000 km (4,200 mi) or 210 hours, repeat the maintenance intervals starting from 6 months

or 3,000 km (1,800 mi) or 90 hours.

Items marked with an asterisk should be performed by a Yamaha dealer as they require special tools, data and

technical skills.

For TT-Rs not equipped with an odometer or an hour meter, follow the month maintenance intervals.

For TT-Rs equipped with an odometer or an hour meter, follow the km (mi) or hours maintenance intervals.

Hovewer, keep in mind that if the TT-R isn´t used for a long period of time, the month maintenance intervals

should be followed.

Nº ITEM CHECKS AND MAINTENANCE JOBS

ODOMETER READINGSINITIAL

Fuel lineCheck fuel hoses for cracks or damage.

Replace if necessary. 1

*

Whichever

comer firstmonth

km

(mi)

hours1,000

(600)1612

3,000

(1,800)5,000

(3,000)

30 90 150

Spark plug

Check condition

Adjust gap and clean.

CarburetorCheck engine idling speed an starter operation.

Adjust if necessary.

Exhaust system

Engine oilChange (warm engine before draining).2

*3

*5

7

8

√√

√

√√√

√√

√√√√√

Valve clearenceCheck and adjust valve clearance when engine is cold.

Air filter elementClean with solvent.

Replace if necessary. 4

*

Breather systemCheck ventilation hose for cracks or damage.

Replace if necessary.

*6

Check for leakage.

Tighten if necessary.

Replace gasket if necessary.

√√

√√√

3

INSP

ADJ

MAINTENANCE INTERVALS

ONLY FOR CANADA

REGULAR INSPECTION AND ADJUSTMENTS

3 - 0 - 1

Page 171 of 616

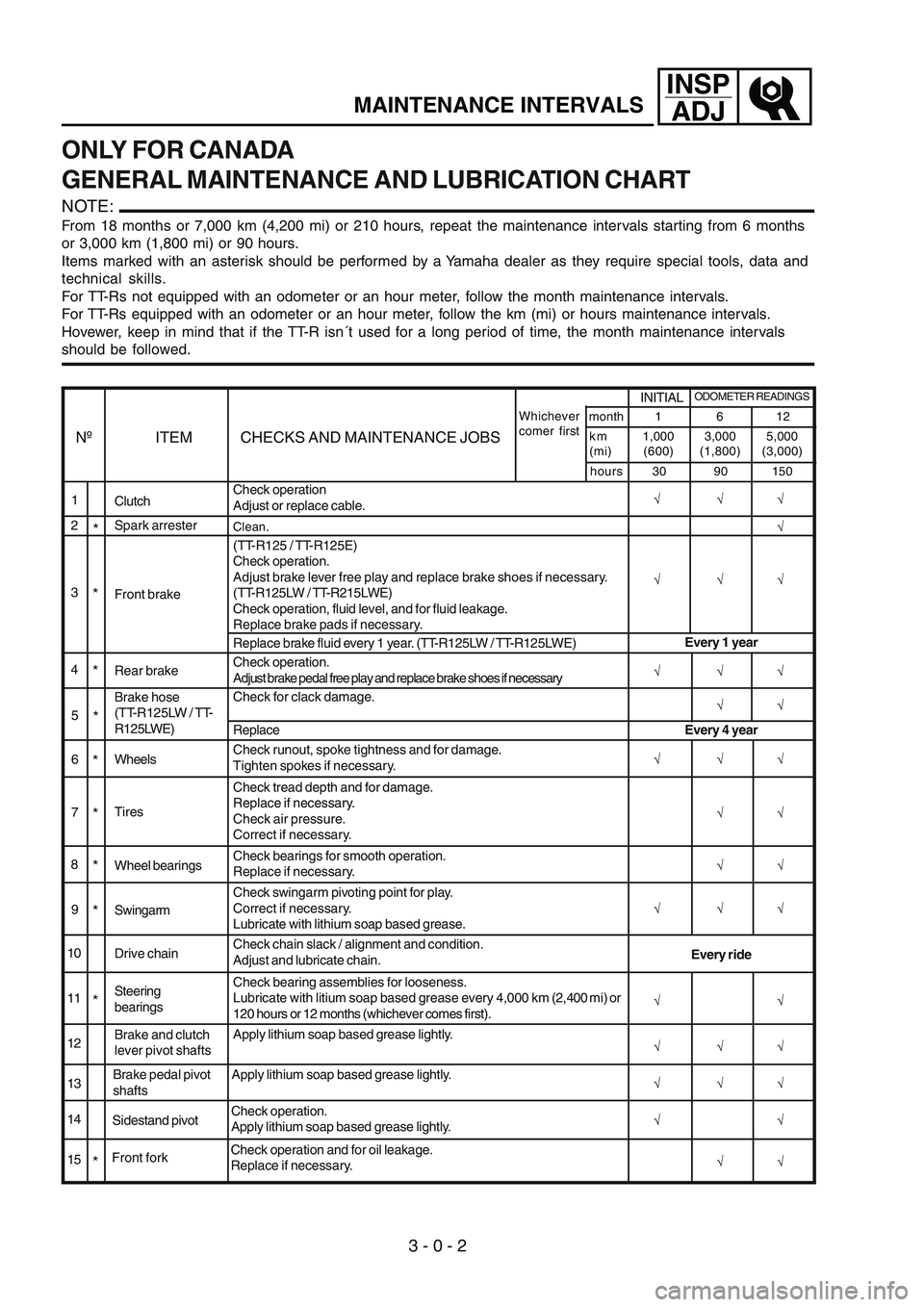

ONLY FOR CANADA

GENERAL MAINTENANCE AND LUBRICATION CHART

NOTE:

From 18 months or 7,000 km (4,200 mi) or 210 hours, repeat the maintenance intervals starting from 6 months

or 3,000 km (1,800 mi) or 90 hours.

Items marked with an asterisk should be performed by a Yamaha dealer as they require special tools, data and

technical skills.

For TT-Rs not equipped with an odometer or an hour meter, follow the month maintenance intervals.

For TT-Rs equipped with an odometer or an hour meter, follow the km (mi) or hours maintenance intervals.

Hovewer, keep in mind that if the TT-R isn´t used for a long period of time, the month maintenance intervals

should be followed.

INSP

ADJ

MAINTENANCE INTERVALS

3 - 0 - 2

Nº ITEM CHECKS AND MAINTENANCE JOBS

ODOMETER READINGSINITIAL

ClutchCheck operation

Adjust or replace cable. 1

*

Whichever

comer firstmonth

km

(mi)

hours1,000

(600)1612

3,000

(1,800)5,000

(3,000)

30 90 150

Spark arresterClean.

Front brake(TT-R125 / TT-R125E)

Check operation.

Adjust brake lever free play and replace brake shoes if necessary.

(TT-R125LW / TT-R215LWE)

Check operation, fluid level, and for fluid leakage.

Replace brake pads if necessary.

Replace brake fluid every 1 year. (TT-R125LW / TT-R125LWE)

Rear brakeCheck operation.

Adjust brake pedal free play and replace brake shoes if necessary

Brake hose

(TT-R125LW / TT-

R125LWE)Check for clack damage.

Replace

WheelsCheck runout, spoke tightness and for damage.

Tighten spokes if necessary.

TiresCheck tread depth and for damage.

Replace if necessary.

Check air pressure.

Correct if necessary.

Wheel bearingsCheck bearings for smooth operation.

Replace if necessary.

SwingarmCheck swingarm pivoting point for play.

Correct if necessary.

Lubricate with lithium soap based grease.

Drive chainCheck chain slack / alignment and condition.

Adjust and lubricate chain.

Steering

bearingsCheck bearing assemblies for looseness.

Lubricate with litium soap based grease every 4,000 km (2,400 mi) or

120 hours or 12 months (whichever comes first).

Brake and clutch

lever pivot shaftsApply lithium soap based grease lightly.

2

*3

*4

*5

*6

*7

*8

*9

10

11*

12

Brake pedal pivot

shaftsApply lithium soap based grease lightly.

Sidestand pivotCheck operation.

Apply lithium soap based grease lightly. 1314

Front forkCheck operation and for oil leakage.

Replace if necessary.

15*

Every 1 year

Every 4 year

Every ride

√√√

√

√√√

√√√

√√

√√√

√√

√√

√√√

√√

√√√

√√√

√√

√√

Page 172 of 616

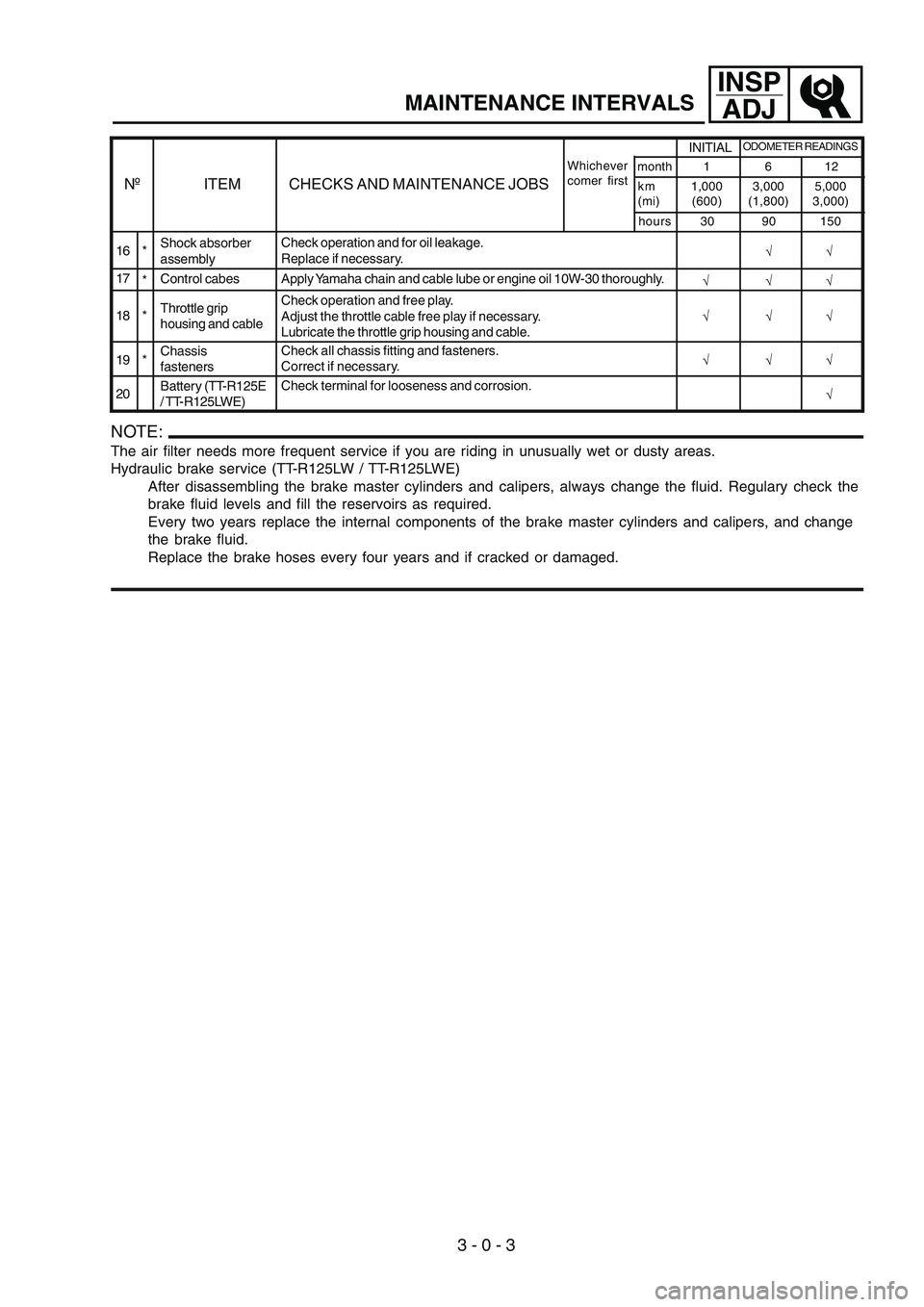

NOTE:

The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

Hydraulic brake service (TT-R125LW / TT-R125LWE)

After disassembling the brake master cylinders and calipers, always change the fluid. Regulary check the

brake fluid levels and fill the reservoirs as required.

Every two years replace the internal components of the brake master cylinders and calipers, and change

the brake fluid.

Replace the brake hoses every four years and if cracked or damaged.

Control cabesApply Yamaha chain and cable lube or engine oil 10W-30 thoroughly.

Throttle grip

housing and cableCheck operation and free play.

Adjust the throttle cable free play if necessary.

Lubricate the throttle grip housing and cable.

Chassis

fastenersCheck all chassis fitting and fasteners.

Correct if necessary.

Battery (TT-R125E

/ TT-R125LWE)Check terminal for looseness and corrosion.

Nº ITEM CHECKS AND MAINTENANCE JOBS

ODOMETER READINGSINITIAL

16

Whichever

comer firstmonth

km

(mi)

hours1,000

(600)1612

3,000

(1,800)5,000

3,000)

30 90 150

Shock absorber

assemblyCheck operation and for oil leakage.

Replace if necessary.*

17

*

18 *

19 *

20

√√

√√√

√√√

√√√

√

INSP

ADJ

MAINTENANCE INTERVALS

3 - 0 - 3

Page 176 of 616

3 - 1

INSP

ADJ

MAINTENANCE INTERVALS

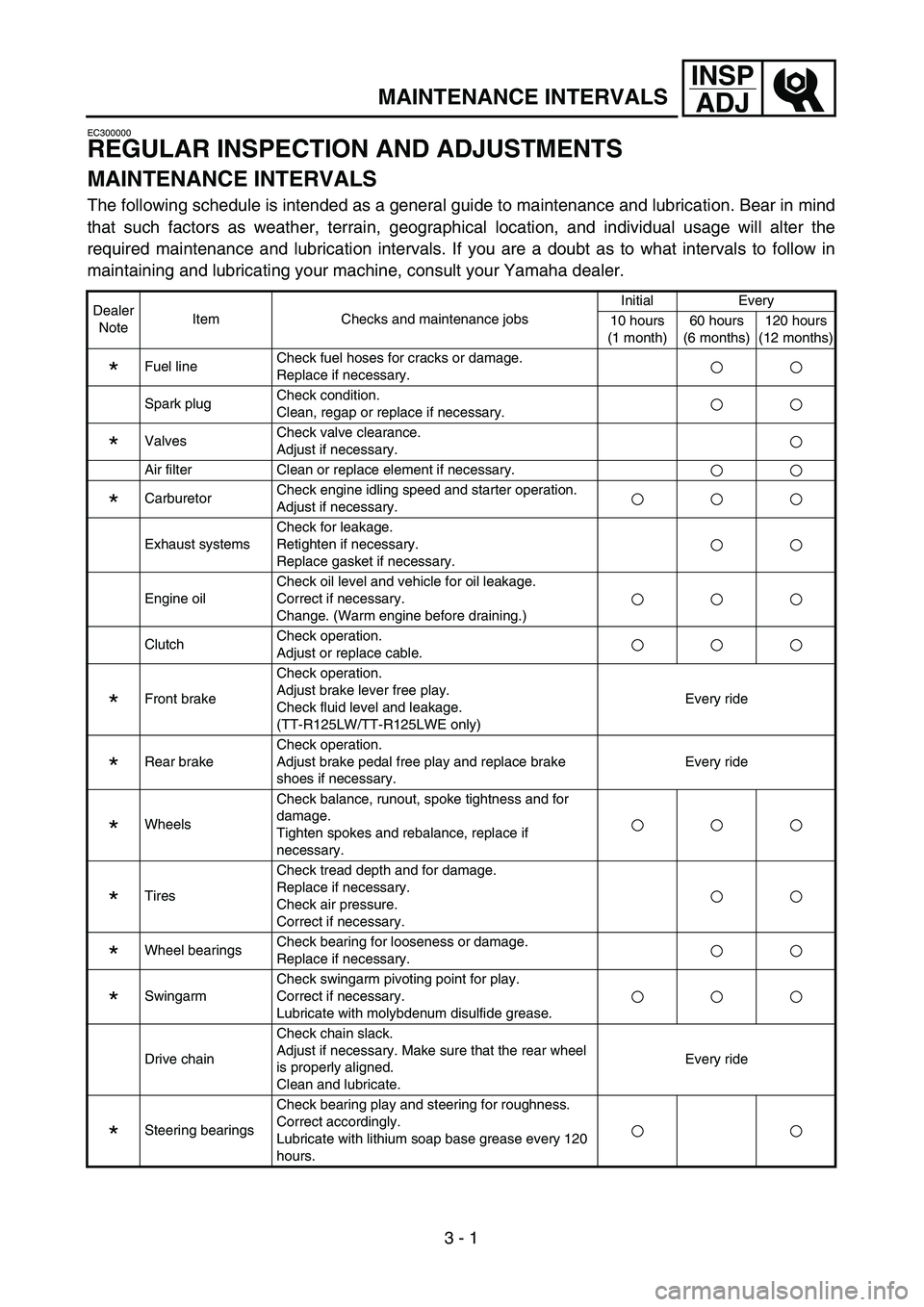

EC300000

REGULAR INSPECTION AND ADJUSTMENTS

MAINTENANCE INTERVALS

The following schedule is intended as a general guide to maintenance and lubrication. Bear in mind

that such factors as weather, terrain, geographical location, and individual usage will alter the

required maintenance and lubrication intervals. If you are a doubt as to what intervals to follow in

maintaining and lubricating your machine, consult your Yamaha dealer.

Dealer

NoteItem Checks and maintenance jobsInitial Every

10 hours

(1 month)60 hours

(6 months)120 hours

(12 months)

*Fuel lineCheck fuel hoses for cracks or damage.

Replace if necessary.

Spark plugCheck condition.

Clean, regap or replace if necessary.

*ValvesCheck valve clearance.

Adjust if necessary.

Air filter Clean or replace element if necessary.

*CarburetorCheck engine idling speed and starter operation.

Adjust if necessary.

Exhaust systemsCheck for leakage.

Retighten if necessary.

Replace gasket if necessary.

Engine oilCheck oil level and vehicle for oil leakage.

Correct if necessary.

Change. (Warm engine before draining.)

ClutchCheck operation.

Adjust or replace cable.

*Front brakeCheck operation.

Adjust brake lever free play.

Check fluid level and leakage.

(TT-R125LW/TT-R125LWE only)Every ride

*Rear brakeCheck operation.

Adjust brake pedal free play and replace brake

shoes if necessary.Every ride

*WheelsCheck balance, runout, spoke tightness and for

damage.

Tighten spokes and rebalance, replace if

necessary.

*TiresCheck tread depth and for damage.

Replace if necessary.

Check air pressure.

Correct if necessary.

*Wheel bearingsCheck bearing for looseness or damage.

Replace if necessary.

*SwingarmCheck swingarm pivoting point for play.

Correct if necessary.

Lubricate with molybdenum disulfide grease.

Drive chainCheck chain slack.

Adjust if necessary. Make sure that the rear wheel

is properly aligned.

Clean and lubricate.Every ride

*Steering bearingsCheck bearing play and steering for roughness.

Correct accordingly.

Lubricate with lithium soap base grease every 120

hours.